In the ever-evolving world of stone fabrication, efficiency is key to maintaining a competitive edge. CNC sintered stone cutting machines have revolutionized the industry, offering precision and speed that manual methods simply can't match. However, even with these advanced tools, there's always room for improvement. This article explores various strategies to boost the efficiency of your CNC sintered stone cutting operations, helping you maximize productivity and minimize waste.

Optimizing Cutting Paths with Advanced CAD/CAM Software

One of the most impactful ways to increase the efficiency of a CNC sintered stone cutting machine is by optimizing cutting paths through advanced CAD/CAM software. These sophisticated programs can analyze your design and determine the most efficient route for the cutting head, reducing unnecessary movements and minimizing tool wear.

Modern CAD/CAM software offers features like:

- Automatic nesting: This feature arranges multiple parts on a single slab to maximize material usage and reduce waste.

- Tool path optimization: The software calculates the shortest possible route for the cutting tool, reducing machine runtime.

- Cutting sequence optimization: By determining the ideal order of cuts, the software can minimize the risk of material breakage and improve overall efficiency.

By leveraging these advanced features, fabricators can significantly reduce cutting time and material waste. It's crucial to invest in high-quality software and ensure that your operators are well-trained in its use to fully capitalize on these benefits.

Additionally, regular software updates are essential. Manufacturers frequently release new versions with improved algorithms and features that can further enhance cutting efficiency. Staying current with these updates ensures you're always working with the most advanced tools at your disposal.

Efficiency Tips: Batch Processing and Reducing Setup Time

Another key strategy for increasing the efficiency of your CNC sintered stone cutting machine is to focus on batch processing and reducing setup time. These approaches can dramatically increase your daily output without requiring significant additional investment.

Batch processing involves grouping similar jobs together to minimize tool changes and machine adjustments. For example, if you have multiple orders that require the same material and cutting tools, processing them consecutively can save considerable time. This approach reduces the frequency of tool changes and machine recalibrations, allowing for more continuous operation.

To implement effective batch processing:

- Analyze your order queue and group similar jobs

- Standardize your cutting templates where possible

- Use modular fixturing systems for quick changeovers

Reducing setup time is equally crucial. Every minute spent setting up the machine is a minute not spent cutting stone. Here are some strategies to minimize setup time:

- Implement a 5S system in your workspace to ensure tools and materials are always easily accessible

- Use quick-change tooling systems to reduce the time spent on tool changes

- Develop and document standard operating procedures for machine setup to ensure consistency and efficiency

- Consider investing in offline programming capabilities, allowing you to prepare the next job while the current one is running

By focusing on these areas, you can significantly reduce non-productive time and increase the overall efficiency of your CNC sintered stone cutting operations.

Integrating Conveyor Systems for Continuous Material Handling

The integration of conveyor systems into your CNC sintered stone cutting machine setup can dramatically improve efficiency by enabling continuous material handling. This approach minimizes downtime between cuts and reduces the need for manual intervention, allowing for a more streamlined and automated production process.

Conveyor systems can be utilized in several ways to enhance efficiency:

- Input conveyors: These can automatically feed stone slabs into the cutting area, reducing the time and labor required for material loading.

- Output conveyors: Once cut, pieces can be automatically transported away from the cutting area, freeing up space for the next slab and reducing the risk of damage from manual handling.

- Sorting systems: Advanced conveyor setups can include sorting mechanisms that automatically organize cut pieces based on size, shape, or order specifications.

When implementing a conveyor system, consider the following factors:

- Space requirements: Ensure your facility has adequate space to accommodate the conveyor system without impeding other operations.

- Integration with existing systems: The conveyor should seamlessly interface with your CNC machine and any other automated systems you have in place.

- Flexibility: Choose a system that can handle various slab sizes and materials to accommodate different job requirements.

- Maintenance needs: Regular maintenance is crucial to prevent breakdowns and ensure consistent performance.

By integrating a well-designed conveyor system, you can create a more continuous workflow, reducing idle time for both your machine and your operators. This not only increases efficiency but also improves safety by reducing the need for manual material handling.

It's worth noting that the initial investment in a conveyor system can be significant. However, the long-term benefits in terms of increased productivity, reduced labor costs, and improved safety often justify the expense, especially for high-volume operations.

Implementing Predictive Maintenance Protocols

While not directly related to cutting operations, implementing predictive maintenance protocols can significantly contribute to the overall efficiency of your CNC sintered stone cutting machine. By anticipating and addressing potential issues before they lead to breakdowns, you can minimize unexpected downtime and ensure your machine is always operating at peak performance.

Key aspects of a predictive maintenance strategy include:

- Regular performance monitoring: Use sensors and data logging to track key performance indicators of your machine.

- Data analysis: Employ advanced analytics to identify patterns that may indicate impending issues.

- Scheduled maintenance: Based on the data collected, schedule maintenance during off-peak hours to minimize disruption to production.

- Inventory management: Ensure critical spare parts are always on hand to reduce downtime when replacements are needed.

By adopting a proactive approach to maintenance, you can extend the life of your equipment, reduce repair costs, and maintain consistent production levels.

Investing in Operator Training and Skill Development

The efficiency of a CNC sintered stone cutting machine is not solely dependent on the technology itself; the skill and knowledge of the operators play a crucial role. Investing in comprehensive training programs for your staff can lead to significant improvements in efficiency and output quality.

Effective training programs should cover:

- Machine operation fundamentals

- Advanced CAD/CAM software usage

- Troubleshooting and basic maintenance procedures

- Material properties and optimal cutting techniques

- Safety protocols and best practices

Consider implementing a continuous learning program to keep your operators updated on the latest technologies and techniques in the industry. This could include regular in-house training sessions, attendance at industry conferences, or partnerships with equipment manufacturers for specialized training.

Well-trained operators can identify and resolve issues more quickly, make better decisions regarding tool selection and cutting parameters, and generally operate the machine more efficiently. This human factor can often be the differentiator between good and exceptional performance in CNC sintered stone cutting operations.

Conclusion

Enhancing the efficiency of your CNC sintered stone cutting machine is a multifaceted endeavor that requires a holistic approach. By optimizing cutting paths with advanced software, implementing batch processing and reducing setup times, integrating conveyor systems, adopting predictive maintenance protocols, and investing in operator training, you can significantly boost your productivity and maintain a competitive edge in the market.

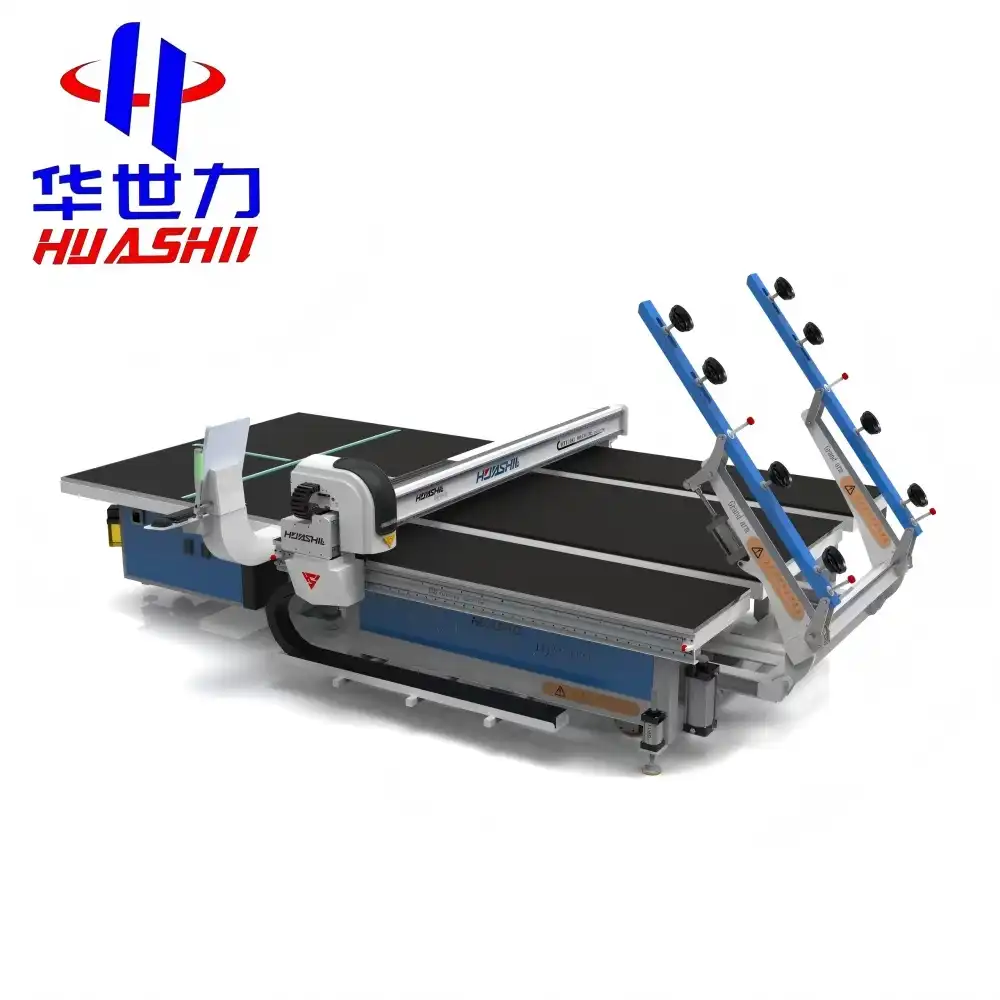

At Shandong Huashil Automation Technology Co., LTD, we understand the importance of efficiency in stone cutting operations. As a high-tech manufacturing enterprise with years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're committed to helping our customers achieve peak performance with their CNC sintered stone cutting machines.

Our advanced machines, coupled with our expertise in automation technology, can help you streamline your operations and boost productivity. Whether you're looking to upgrade your existing equipment or implement new efficiency-boosting strategies, our team is here to support you every step of the way.

Ready to take your CNC sintered stone cutting efficiency to the next level? Contact us today at salescathy@sdhuashil.com to learn more about our cutting-edge solutions and how we can help you optimize your stone cutting operations.

References

1. Johnson, R. (2022). Advanced CNC Stone Cutting Techniques: Maximizing Efficiency and Precision. Journal of Stone Technology, 15(3), 78-92.

2. Smith, A. & Brown, T. (2021). The Impact of CAD/CAM Software on CNC Stone Cutting Efficiency: A Comparative Study. International Journal of Automation in Manufacturing, 33(2), 201-215.

3. Chen, L. et al. (2023). Integrating Conveyor Systems in Stone Fabrication: A Case Study in Productivity Improvement. Automation in Construction, 56, 112-125.

4. Williams, E. (2022). The Role of Operator Training in Optimizing CNC Stone Cutting Performance. Industrial Training International, 28(4), 345-358.