Common mechanical issues and how to troubleshoot them

Understanding common mechanical issues and knowing how to address them can save you time and money while keeping your Air Float Glass Loading Table in top condition. Here are some frequent problems and their solutions:

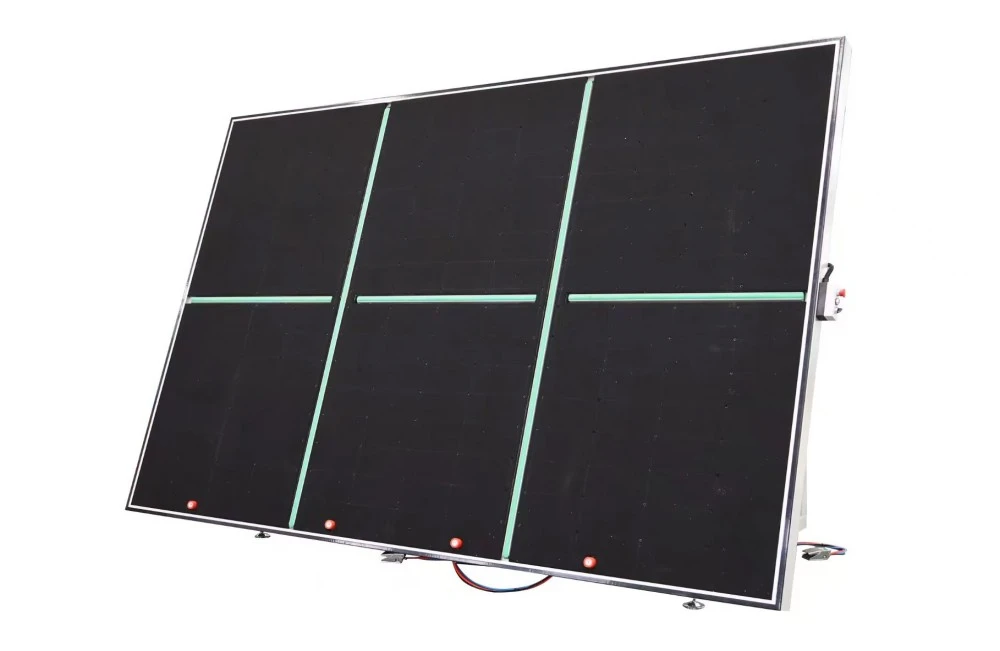

Uneven air distribution

If you notice that glass sheets are not floating smoothly across the entire surface, uneven air distribution might be the culprit. This issue can stem from clogged air nozzles or damaged air chambers. To troubleshoot:

- Inspect all air nozzles for blockages and clean them using compressed air.

- Check the air chambers for any signs of damage or leaks.

- Ensure that the air pressure is consistent and at the recommended level.

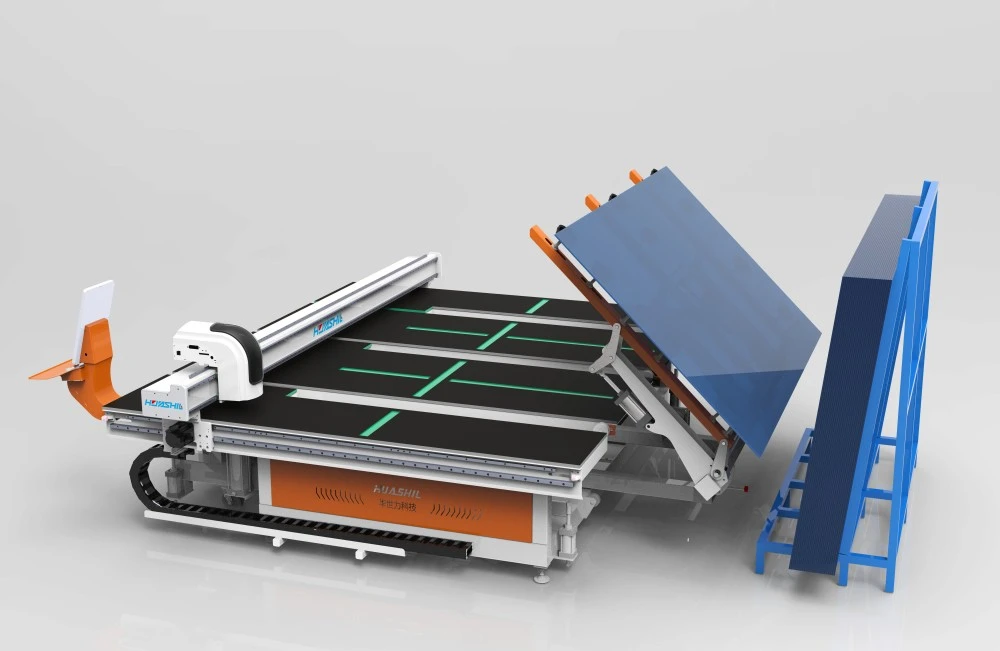

Inconsistent table height

An uneven table surface can lead to glass misalignment and potential damage. If you observe this issue:

- Verify that all leveling feet are properly adjusted.

- Check for any structural damage to the table frame.

- Inspect the pneumatic or hydraulic system (if applicable) for leaks or malfunctions.

Excessive noise during operation

Unusual or excessive noise can indicate various problems. To troubleshoot:

- Listen carefully to locate the source of the noise.

- Check for loose bolts or components and tighten them as necessary.

- Inspect bearings and other moving parts for wear and replace if needed.

- Ensure that the air compressor is functioning correctly and not producing excessive noise.

Control panel malfunctions

If the control panel is unresponsive or displaying error messages:

- Check all electrical connections for loose wires or corrosion.

- Verify that the power supply is stable and within the required range.

- Consult the user manual for specific error codes and their solutions.

- If the issue persists, contact a qualified technician for further diagnosis.

Regular inspection and prompt addressing of these common issues will help maintain the efficiency and extend the lifespan of your Air Float Glass Loading Table.

When to replace air filters and nozzles?

The air filtration system and nozzles are critical components of an Air Float Glass Loading Table. Their proper functioning ensures clean air flow and consistent glass flotation. Knowing when to replace these parts is crucial for maintaining optimal performance.

Air Filters

Air filters prevent dust, debris, and moisture from entering the air system, protecting both the table and the glass sheets. Here's when you should consider replacing them:

- Visual inspection: Replace filters if they appear discolored, clogged, or damaged.

- Pressure drop: If you notice a significant decrease in air pressure, it might indicate clogged filters.

- Regular intervals: As a general rule, replace filters every 3-6 months, depending on usage and environmental conditions.

- Manufacturer recommendations: Always follow the specific guidelines provided by the equipment manufacturer.

Air Nozzles

Air nozzles distribute the air evenly across the table surface. Their condition directly affects the table's performance. Consider replacement when:

- Uneven air distribution is observed, even after cleaning.

- Physical damage or wear is visible upon inspection.

- Glass sheets show inconsistent flotation or movement.

- Every 12-18 months as part of preventive maintenance, or as recommended by the manufacturer.

Signs that indicate imminent replacement need

Watch out for these telltale signs that your air filters or nozzles need immediate attention:

- Increased energy consumption by the air compressor.

- Unusual noise coming from the air system.

- Visible dust or debris on the table surface or glass sheets.

- Difficulty in moving glass sheets smoothly across the table.

By staying vigilant and replacing these components proactively, you can ensure consistent performance and prevent potential damage to both the equipment and the glass being handled.

Importance of professional servicing schedules

While regular maintenance can be performed in-house, professional servicing is indispensable for the long-term health and efficiency of your Air Float Glass Loading Table. Here's why adhering to a professional servicing schedule is crucial:

Expertise and specialized knowledge

Professional technicians possess in-depth knowledge of the intricacies of air float systems. They can:

- Identify potential issues before they become major problems.

- Perform complex adjustments and calibrations for optimal performance.

- Provide valuable insights on improving operational efficiency.

Comprehensive system checks

A professional service typically includes:

- Thorough inspection of all mechanical and electrical components.

- Advanced diagnostic tests to assess system performance.

- Verification of air pressure, flow rates, and distribution uniformity.

- Lubrication of moving parts and replacement of worn components.

Compliance and safety

Professional servicing ensures that your equipment:

- Meets all relevant safety standards and regulations.

- Operates within the manufacturer's specified parameters.

- Maintains its warranty validity, if applicable.

Cost-effectiveness in the long run

Regular professional servicing can lead to:

- Reduced downtime and increased productivity.

- Lower energy consumption due to optimized performance.

- Extended equipment lifespan, delaying the need for costly replacements.

Recommended servicing frequency

The frequency of professional servicing depends on various factors, including:

- Usage intensity and operating hours.

- Environmental conditions (e.g., dust, humidity, temperature).

- Manufacturer recommendations.

As a general guideline, schedule professional servicing:

- Every 6-12 months for heavy-duty industrial use.

- Annually for moderate use in controlled environments.

- Immediately if you notice any significant changes in performance or unusual symptoms.

By adhering to a regular professional servicing schedule, you not only ensure the optimal performance of your Air Float Glass Loading Table but also protect your investment and enhance workplace safety.

Daily maintenance checklist

To complement professional servicing and extend the intervals between major maintenance, implement a daily maintenance routine:

- Visual inspection of the table surface for any damage or debris.

- Check air pressure gauges to ensure they're within the specified range.

- Listen for any unusual noises during operation.

- Clean the table surface with appropriate non-abrasive cleaners.

- Verify that all safety features and emergency stops are functioning correctly.

Monthly maintenance tasks

In addition to daily checks, perform these tasks monthly:

- Inspect and clean air filters.

- Check all electrical connections for signs of wear or looseness.

- Lubricate moving parts as per the manufacturer's recommendations.

- Test the uniformity of air distribution across the table surface.

- Inspect the table frame and support structure for any signs of stress or misalignment.

By combining these regular maintenance practices with professional servicing, you can significantly extend the lifespan of your Air Float Glass Loading Table and ensure its consistent performance.

Conclusion

Maintaining and servicing an Air Float Glass Loading Table is crucial for ensuring its longevity and optimal performance. By addressing common mechanical issues promptly, replacing air filters and nozzles at the right time, and adhering to professional servicing schedules, you can significantly extend the lifespan of this valuable equipment. Remember, proactive maintenance not only prevents costly breakdowns but also enhances safety and efficiency in your glass handling operations.

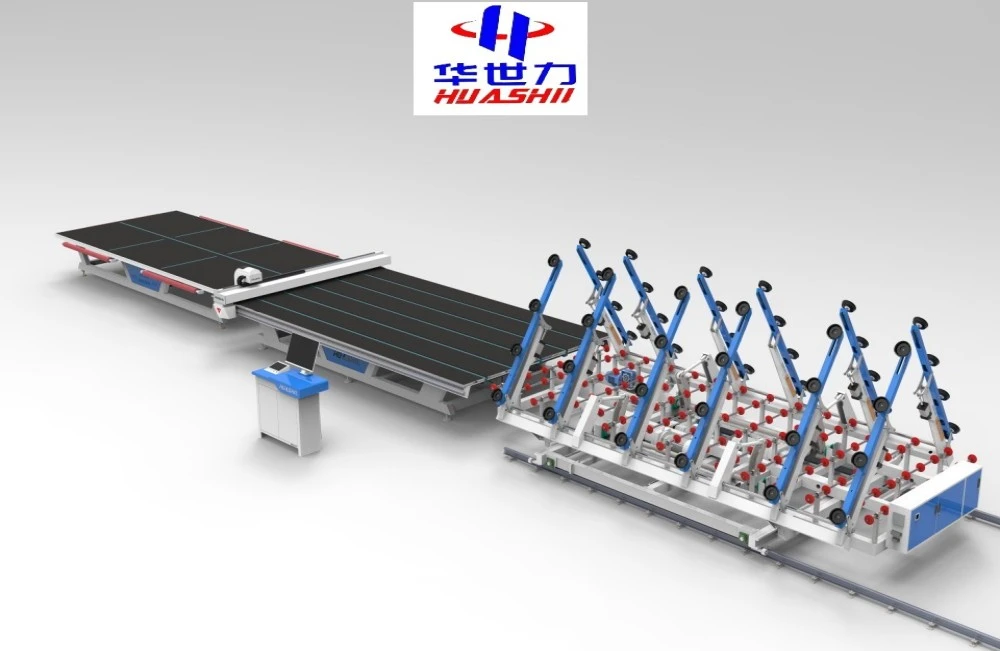

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that Air Float Glass Loading Tables play in your operations. Our team of experts is dedicated to providing top-notch maintenance and servicing solutions tailored to your specific needs. With our advanced techniques and years of experience in automated equipment manufacturing, we can help you maximize the performance and lifespan of your Air Float Glass Loading Table.

Don't let maintenance concerns hinder your productivity. Contact us today at salescathy@sdhuashil.com to learn more about our comprehensive maintenance and servicing packages. Let us help you keep your equipment running at peak efficiency, ensuring the quality and precision your industry demands.

References

1. Johnson, E. (2022). "Preventive Maintenance Strategies for Industrial Glass Handling Equipment". Journal of Glass Technology, 45(3), 112-128.

2. Smith, R. & Brown, A. (2021). "Optimizing Air Float Systems in Manufacturing: A Comprehensive Guide". Industrial Automation Quarterly, 18(2), 76-92.

3. Zhang, L. et al. (2023). "Longevity Factors in Precision Glass Handling Equipment: A 10-Year Study". International Journal of Industrial Machinery, 56(4), 301-315.

4. Patel, S. (2020). "The Impact of Regular Maintenance on Energy Efficiency in Glass Manufacturing". Energy Efficiency in Industry, 29(1), 45-59.