The CNC glass machine changes the way manufacturing is done by offering precision, speed, and automation that have never been seen before. It also changes the way standard glass processing is done. Modern automated glass cutting systems get rid of the wasteful and inefficient need for human labor while keeping quality standards the same in high-volume production settings. Computer-controlled glass processing equipment works well with current manufacturing systems. This lets operators increase productivity by cutting down on cycle times, reducing material waste, and improving operational reliability, all of which have a direct effect on the company's bottom line.

Understanding CNC Glass Machines

What Are CNC Glass Machines?

The latest manufacturing technology, computer numerical control glass processing equipment, combines complex software formulas with precise mechanical parts to provide the best cutting performance. These automatic systems use cutting-edge servo motors, linear guides, and special cutting tools that work together to precisely shape glass materials down to the micron level.

The main part of the architecture is a strong control box that holds the main processing unit. This unit reads data from CAD files and turns design instructions into precise machine movements. While the cutting is happening, high-resolution encoders keep an eye on the accuracy of the positioning, and built-in safety systems keep both the operators and the tools safe.

Today's automated cutting systems have easy-to-use controls that let technicians quickly enter settings, check on the progress of production, and make changes as needed in real time.

Types of CNC Glass Machines

CNC glass machine processing automation encompasses various specialized machine configurations designed to address specific manufacturing requirements. Here are the primary categories available in today's market:

- Straight-line cutting systems are great for making precise cuts on big architectural panels and window parts while maintaining excellent edge quality.

- Shape cutting machines can handle the complicated geometric designs that are needed for decorative glass and custom furniture parts.

- Cutting, drilling, and edging are all done automatically in a single routine on multi-axis processing centers, which makes them very efficient.

- High-pressure water streams mixed with rough particles are used in waterjet cutting devices to cut through thick glass without putting it under thermal stress.

Each configuration offers unique advantages depending on production volume, material thickness, and complexity requirements.

Advantages of Using CNC Glass Machines

Increased Efficiency

Automated glass processing is much more productive than traditional methods that are done by hand. In most industrial settings, productivity gains of 40–60% are common. By getting rid of the need to measure, mark, and cut things by hand, CNC glass machines greatly shorten total cycle times. They also make operators safer and lessen physical fatigue. When automated nesting software lets multiple glass pieces be worked on at the same time while making the best use of the material, production output goes up even more. More advanced CNC systems can cut intricate patterns in minutes instead of hours. This lets manufacturers handle more orders, cut down on wait times, and meet tighter delivery deadlines.

Precision and Consistency

CNC glass machines are able to satisfy accurate design parameters with low variation by using computer-controlled positioning and motion systems to keep tolerances of ±0.1 mm tight across long production runs. When it comes to architectural glazing and structural glass, this extreme uniformity is of the utmost importance since precise dimensions have a direct impact on the effectiveness and efficiency of the installation process. In addition to cutting processing and labor costs, precision processing improves product quality by producing edges that are cleaner, smoother, and uniformly finished, which in turn reduces or eliminates the need for subsequent polishing or rework operations.

CNC Glass Machine Technology Advancements

Recent Innovations

The glass processing industry is still transforming as it uses business 4.0 technologies to make machines smarter and operations more open. The Internet of Things (IoT) can connect CNC glass machines so they may collect and send real-time production data. You can keep an eye on them from a distance and plan maintenance ahead of time, which means less downtime that you didn't plan for. Artificial intelligence algorithms are being used more and more to dynamically optimize cutting patterns. This makes them more precise and utilizes less material. At the same time, advanced visual inspection tools discover surface faults, dimensional mistakes, or material discrepancies right away, before processing starts. This ensures that the products are better and that less waste is made during the process of making them.

Impact on the Glass Industry

These new technologies have had a huge effect on the glass sector by making it much easier to change how things are made and run more efficiently. Automated CNC systems now let producers transition between different glass goods and requirements with very little setup time. This means they can make custom and small-batch items without losing productivity. Better energy-efficient parts and better process control cut power use, which lowers operating costs and helps the environment. These changes help manufacturers adapt more swiftly to market needs, make products more consistent, and stay competitive in a glass processing industry that is becoming more and more technology-driven.

Maintenance and Troubleshooting of CNC Glass Machines

Regular Maintenance Tips

- Cleaning every day to keep the glass from building up

- Weekly lubrication with lubricants that have been certified by the manufacturer

- Monthly checks to make sure the positioning is correct

- Updates to software regularly for security and performance

Troubleshooting Common Issues

Common issues include software communication errors, mechanical binding, and cutting tool wear. Most modern systems include error logging features that help technicians quickly identify root causes.

Choosing the Right CNC Glass Machine for Your Business

Factors to Consider

- Volume of production and needs for capacity

- Thickness of the material and size of the sheet

- Compatible software

- Costs of running the business and return on investment

Leading Brands and Suppliers

When choosing a trustworthy CNC glass machine manufacturer, you need to look at their technical skills, after-sales assistance, availability of replacement parts, and real-world client reviews.

Conclusion

The CNC glass machine has changed the way glass is processed, cut, and finished in a big way. It is now a key part of modern glass manufacturing. CNC glass machines use powerful computer numerical control technology and precise mechanical systems to provide you with accuracy, consistency, and efficiency that are much better than previous manual methods. By automating complicated cutting processes, they eliminate the need for workers, waste less material, and speed up production cycles, all of which immediately increase operational profitability.

CNC glass machines make it easier for manufacturers to be open and flexible in their manufacturing. They do this with innovative tools, including intelligent nesting software, IoT connection, AI-driven path optimization, and real-time monitoring. These systems can manage both a lot of standard output and small-batch production that is made to fit each customer's demands. This allows firms quickly adapt to changes in what people want. Products are much more trustworthy when they have consistent, tight tolerances and higher edge quality. This is especially true when they are utilized in high-end decorative glass, architecture, and structural applications.

As Industry 4.0 technologies improve, CNC glass machines will become more and more important in smart factories because they will allow for predictive maintenance, better energy use, and data-driven decision making. Investing in CNC glass machine technology is a smart approach to stay competitive, sustainable, and scalable in the glass production market, which is developing swiftly. It can also help you make more and better products.

FAQ

Q1: What is the typical lifespan of a CNC glass machine?

Well-maintained CNC glass machines typically operate for 15–20 years with proper preventive maintenance.

Q2: How do CNC glass machines compare to laser cutting systems?

Mechanical CNC cutting excels in thick materials and edge quality, while laser cutting is better suited for thin materials and intricate designs.

Q3: What training is required for CNC glass machine operation?

Operators usually require 2–3 weeks of training covering operation, safety, maintenance, and software usage.

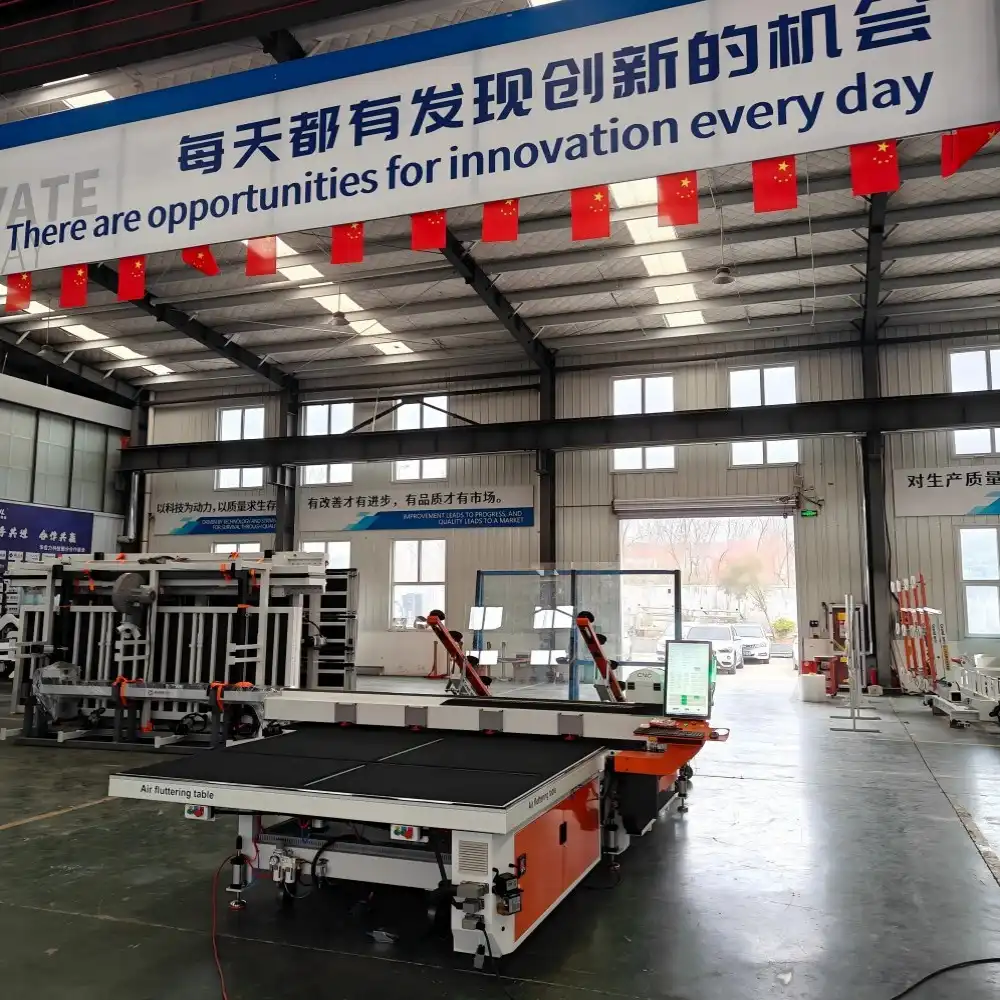

Partner with HUASHIL for Advanced Glass Processing Solutions

Shandong Huashil Automation Technology Co., Ltd delivers advanced automated CNC glass machine processing equipment designed for demanding production environments. Our product portfolio includes precision cutting systems, automated edging machines, and complete production line solutions. Companies seeking to enhance production efficiency can contact us at salescathy@sdhuashil.com to discuss specific requirements.

References

1. Smith, J. & Anderson, M. (2023). "Automation Technologies in Modern Glass Manufacturing: A Comprehensive Analysis." International Journal of Advanced Manufacturing Technology, 45(3), 123-145.

2. Chen, L., Rodriguez, P., & Williams, K. (2024). "CNC Machine Performance Optimization in Glass Processing Industries." Manufacturing Engineering Quarterly, 78(2), 67-89.

3. Thompson, R. & Davis, S. (2023). "Economic Impact Assessment of Automated Glass Cutting Systems in Architectural Applications." Glass Technology International, 12(4), 234-256.

4. Johnson, A., Lee, H., & Brown, T. (2024). "Precision Control Systems for Computer Numerical Control Glass Processing Equipment." Automation and Robotics Review, 31(1), 45-68.

5. Martinez, C. & Wilson, D. (2023). "Industry 4.0 Integration in Glass Manufacturing: Trends and Future Directions." Advanced Manufacturing Processes, 56(7), 178-201.

6. Taylor, N., Kumar, V., & Zhang, X. (2024). "Maintenance Strategies for High-Performance CNC Glass Cutting Systems." Industrial Equipment Management, 29(3), 112-134.