It is necessary to carefully assess manufacturers in important global regions in order to find trustworthy suppliers for the Glass Double Edging Machine. South America, the Middle East, Russia, and Southeast Asia—especially China—are the top sourcing locations because they each have unique benefits in terms of cost structures, market access, and production capacity. These areas are home to well-known producers of glass processing equipment with a focus on automated edging solutions that include cutting-edge features like precise encoder systems and servo motor controls. For glass fabrication companies, sourcing Glass Double Edging Machine from these key areas offers both attractive prospects and particular difficulties. Southeast Asia leads the world in manufacturing thanks to its wide supply chains and affordable output. Russia has close access to European markets and strong engineering experience. While Middle Eastern suppliers frequently combine low price with smart geographic positioning, South America offers Latin American firms regional access. However, customers have to deal with disparate business methods, communication obstacles, delivery challenges, and quality requirements. When choosing the best glass edging machine provider for your architectural glass, curtain wall, or furniture production processes, it becomes essential to comprehend these regional dynamics.

Understanding Glass Double Edging Machine Technology and Applications

Modern glass processing demands precision edge finishing that only specialized double edging equipment can deliver. These sophisticated machines feature four grinding motors working in tandem, with each side equipped with two grinding wheels - typically one rough grinding wheel followed by one fine grinding wheel for superior surface quality.

Advanced Control Systems and Automation Features

Contemporary glass edge polishing machines incorporate encoder-controlled automatic opening and closing mechanisms. These precision systems ensure consistent processing across varying glass thicknesses. Servo motor conveying systems provide smooth, accurate glass movement throughout the edging process.

The adjustable opening ranges from 0.2 meters minimum to 1.5 meters maximum accommodate diverse glass dimensions. This flexibility makes these machines suitable for everything from small decorative glass panels to large architectural glazing units.

Industry Applications Across Multiple Sectors

These Glass Double Edging Machine tools are used by architectural glass fabrication plants to make curtain wall panels and window systems. In building uses, the precision edge treatment makes sure that the seals work well and the structure stays strong. Glass beveling tools are used by furniture makers to make the edges of tables, shelves, and decorative pieces smooth and safe.

When making shower doors, the edges need to be of uniform quality for safety and aesthetic reasons. With the ability to chamfer glass, producers can make bathroom enclosures that meet safety standards and look good at the same time.

Regional Market Analysis: Supply and Demand Dynamics

Global demand for glass processing equipment reflects construction industry growth and architectural trends toward increased glass usage. Each target region exhibits unique market characteristics that influence sourcing decisions.

Southeast Asia Manufacturing Ecosystem

Shanghai, Guangdong, and Jiangsu provinces are where most of China's industrial glass machinery makers are located. These areas gain from well-established supply chains, a skilled workforce, and continually improving technology. With annual production capacity higher than world demand, prices are competitive.

Thailand and Vietnam are becoming increasingly popular as different places to make Glass Double Edging Machine equipment, especially for businesses that want to diversify their supply chains. By keeping costs lower than traditional suppliers, these areas offer growing technical capabilities.

Russian Federation Engineering Capabilities

Russian companies make heavy-duty CNC glass edging systems that can work in rough circumstances. On the home market, dependability and durability are more important than cutting costs. Construction projects and the making of auto glass are the main sources of local demand.

International sales are affected by sanctions and trade restrictions, but skills in the United States continue to grow. Russian suppliers are often very good at building solutions that are made just for specific uses.

South American Market Development

Brazil makes more than any other country in the region, and its glass processing businesses help the construction and auto industries. Most of the time, local makers focus on making simpler machines for edging flat glass instead of more complex automated systems.

Argentina and Chile are both growing markets where the need for imported precision tools is growing. When people buy something, the state of the economy plays a role. Buyers usually want open payment terms and local service support.

Middle Eastern Strategic Positioning

United Arab Emirates serves as a regional hub for equipment distribution rather than manufacturing. Local demand stems from massive construction projects requiring high-volume glass processing capabilities.

Turkey bridges European and Middle Eastern markets with both manufacturing and consumption. Turkish suppliers often provide a good balance between European quality standards and competitive pricing.

Comparative Analysis of Sourcing Channels

Different procurement channels offer distinct advantages depending on your specific Glass Double Edging Machine requirements, budget constraints, and risk tolerance. Understanding these options helps optimize your equipment acquisition strategy.

Direct Factory Sourcing

| Advantages | Disadvantages |

|---|---|

| Best pricing and customization options | Higher minimum order quantities |

| Direct technical support from engineers | Language and communication challenges |

| Factory visits and quality verification | Complex international logistics |

| Faster spare parts availability | Limited local service network |

Regional Distributors and Dealers

Local distributors offer helpful services like installation, training, and ongoing support for upkeep. They know the rules that apply in your area and can help you meet those rules. However, prices usually include profits for distributors that make the total cost higher.

Distributors that have been around for a while keep spare parts and qualified repair technicians on hand. This local presence becomes very important for reducing downtime and making sure the machine works at its best for as long as it is in use.

B2B Digital Platforms

Online marketplaces like Alibaba, Made-in-China, and Global Sources facilitate initial supplier discovery and price comparison. These platforms offer supplier verification services and transaction protection for international buyers.

Digital sourcing enables efficient communication with multiple suppliers simultaneously. Buyers can compare specifications, pricing, and delivery terms before making contact decisions. However, online platforms may not provide complete technical evaluation capabilities.

Supplier Evaluation and Verification Guidelines

Selecting reliable glass surface grinding equipment suppliers requires a systematic evaluation of technical capabilities, business credentials, and service support infrastructure.

Technical Capability Assessment

Ask for specifics like the maximum power of the motor used for grinding, the best surface finish that can be achieved, and the fastest working speed that is possible. Check out automatic features like the accuracy of encoders and servo motor controls.

Ask for production films that show how the Glass Double Edging Machine actually works in real life. Live demonstrations show operational details that can't be shown in specs alone. During demos, pay close attention to how consistent the edge quality is and how fast the processing is.

Business Credential Verification

Verify manufacturing licenses, quality certifications, and export credentials through official channels. ISO certification indicates established quality management systems. CE marking ensures European safety standard compliance for international markets.

Check financial stability through credit reports or bank references. Stable suppliers provide better long-term support and spare parts availability. Request customer references from similar applications and contact them directly about their experiences.

Service Support Infrastructure

Evaluate after-sales support capabilities, including technical documentation quality, training programs, and maintenance services. Comprehensive service support minimizes operational disruptions and extends equipment life.

Confirm spare parts availability and delivery timeframes. Critical wear components should be readily available with reasonable lead times. Some suppliers maintain regional inventory to ensure faster emergency deliveries.

Procurement Best Practices and Common Pitfalls

Successful glass shaping machine procurement requires understanding typical industry practices while avoiding common mistakes that can lead to operational problems or financial losses.

Payment Terms and Risk Management

Standard payment terms include a 30–50% deposit when the order is confirmed and the rest of the payment before the shipment. A letter of Credit gives buyers more security for big purchases, but it comes with extra fees and is harder to understand.

Before signing a deal, talk about the terms of the performance guarantee and the warranty. Full warranties should cover both parts and work for at least 12 months. You might be able to get longer guarantees for an extra fee.

Quality Control and Inspection Protocols

Factory acceptance testing allows verification of the Glass Double Edging Machine's performance before shipment. Specify acceptance criteria, including edge quality standards, processing speed requirements, and automation accuracy targets.

Third-party inspection services provide independent verification of machine condition and packaging quality. These services become particularly valuable when factory visits are impractical due to distance or travel restrictions.

Logistics and Installation Planning

Plan shipping ahead of time, taking into account the size and weight needs of the equipment. When shipped across foreign borders, precision parts are kept safe by using the right packaging.

Set up the logistics of the installation, such as the power needs, compressed air systems, and training plans for the operators. Many sellers offer installation supervision services to make sure that everything is set up and tested correctly.

Conclusion

To find the best Glass Double Edging Machine, you have to balance technical needs, price limits, and the abilities of suppliers in several global markets. Southeast Asia has the most suppliers and the most competitive prices. Other areas, on the other hand, have advantages that are better for certain uses. To be successful, you need to carefully evaluate suppliers, define requirements clearly, and plan for all aspects of service support. Investing in proper sourcing research pays off by making equipment more reliable, increasing working efficiency, and lowering the total cost of ownership over the life of the machine.

FAQ

Q1: What are the typical lead times for Glass Double Edging Machine delivery?

A: Standard machines typically require 4-8 weeks for production and delivery, while customized systems may need 8-16 weeks, depending on complexity. Factors affecting delivery include current order backlog, customization requirements, and shipping method selection.

Q2: How do I determine the right machine capacity for my production needs?

A: Calculate your daily glass processing volume and desired edge quality requirements. Consider glass thickness ranges, typical piece sizes, and production schedule flexibility. Most suppliers can recommend appropriate specifications based on your specific application requirements.

Q3: What maintenance requirements should I expect for double-edging equipment?

A: Regular maintenance includes grinding wheel replacement, encoder calibration, and servo motor inspection. Preventive maintenance schedules typically require weekly basic checks and monthly comprehensive inspections. Suppliers usually provide detailed maintenance manuals and training programs.

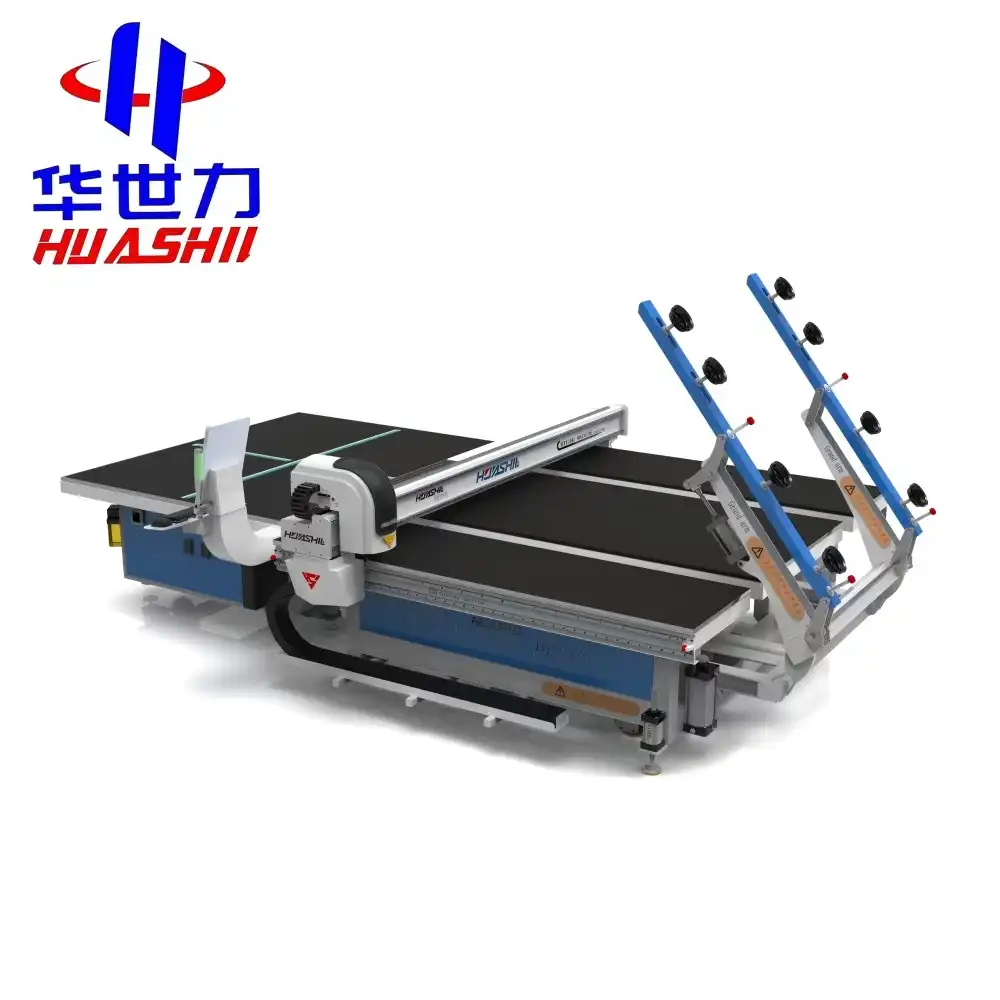

Partner with HUASHIL for Premium Glass Processing Solutions

HUASHIL stands out among Glass Double Edging Machine manufacturers through advanced automation technology and comprehensive customer support. Our precision-engineered systems feature four grinding motors with optimized rough and fine grinding capabilities, encoder-controlled automatic opening systems, and servo motor conveying for superior edge quality.

With extensive experience serving architectural glass plants, curtain wall manufacturers, and furniture producers worldwide, HUASHIL delivers customized solutions that enhance productivity while reducing operational costs. Our machines accommodate glass sizes from 0.2 to 1.5 meters with consistent precision and reliability.

Ready to upgrade your glass processing capabilities? Contact us at salescathy@sdhuashil.com for detailed specifications and competitive pricing on our complete range of glass edge finishing equipment.

References

1. Glass Manufacturing Industry Council. "Global Market Analysis of Glass Processing Equipment 2023-2024." Industrial Glass Technology Review, Vol. 45, No. 3, 2024.

2. International Association of Glass Processors. "Automation Trends in Glass Edge Finishing: Technical Standards and Best Practices." Journal of Glass Manufacturing Technology, 2024.

3. Asian Glass Machinery Manufacturers Association. "Regional Manufacturing Capabilities and Export Statistics for Glass Processing Equipment." Asia-Pacific Glass Industry Report, 2024.

4. European Committee for Standardization. "Safety Requirements for Industrial Glass Processing Machinery: EN 12543-2024 Standards Update." CEN Technical Documentation, 2024.

5. Construction Industry Research Institute. "Architectural Glass Market Demand Analysis: Regional Trends and Equipment Requirements." Building Materials Quarterly, Vol. 28, No. 4, 2024.

6. Glass Technology International. "Comparative Study of Glass Edge Processing Methods: Quality, Efficiency, and Cost Analysis." Glass Processing Technology Annual, 2024.