Installing a float glass cutting machine requires precision, technical understanding, and adherence to manufacturer specifications. This guide will walk you through the essential steps to properly install your float glass cutting machine, ensuring optimal performance and longevity. Whether you're upgrading your glass fabrication facility or installing a new machine, following the correct procedures is crucial for safety, efficiency, and quality results.

What preparation is needed before installing a float glass cutting machine?

Site Assessment and Space Requirements

Before the float glass cutting machine arrives at your facility, thorough site preparation is essential. The installation area must provide adequate space for the machine, operational clearance, and maintenance access. A flat, level concrete foundation capable of supporting the machine's weight (3-15 tons depending on model) is required. The foundation should be reinforced to minimize vibration during operation, as excessive movement can compromise cutting precision. Ceiling height must accommodate the machine's vertical components, with most industrial float glass cutting machines requiring 3-4 meters of clearance. Environmental control is also important, as these machines perform best in temperatures between 18-25°C and humidity levels of 40-60%. Proper site preparation significantly impacts the machine's performance, accuracy, and longevity.

Electrical and Compressed Air Requirements

The float glass cutting machine requires specific electrical preparations for safe operation. Most industrial models operate on three-phase power with voltage requirements typically ranging from 380V to 480V. A qualified electrician should install appropriate circuit breakers, transformers if needed, and properly sized cables according to specifications. The electrical supply must be stable and protected against power fluctuations. Additionally, compressed air requirements are crucial - clean, dry compressed air at pressures between 6-8 bar (87-116 psi) is necessary for pneumatic components, including cutting head movements, glass hold-down systems, and breaking mechanisms. Installing air dryers, filters, and regulators prevents moisture and contaminants from affecting precision components. Ensuring these utilities are properly installed before delivery will prevent delays during installation.

Logistics and Transportation Planning

Transporting a float glass cutting machine requires careful planning due to its size and weight. Most machines are shipped partially disassembled, but specialized equipment is still necessary for safe handling. Arrange for appropriate lifting equipment such as forklifts with extended capacity or overhead cranes capable of handling the machine's weight (3,000-15,000 kg). Access routes must be evaluated for clearance, turning radius, and load-bearing capacity. Doorways, corridors, and elevators must be measured to ensure sufficient space. Additionally, timing the delivery to coincide with technical personnel availability is crucial. Many manufacturers recommend having their technicians present during unloading to prevent damage. A detailed logistics plan addressing transportation, unloading, and positioning will streamline the installation process and prevent potential damage.

How do you set up and calibrate a float glass cutting machine?

Assembly and Component Installation

The assembly process requires methodical precision and technical expertise. The main components—typically including the cutting table, bridge system, control cabinet, and cutting head—must be assembled according to manufacturer specifications. The cutting table must be perfectly leveled using precision instruments, with tolerances often less than 0.5mm across the entire surface, as even minor deviations can significantly impact cutting accuracy. The bridge system must be installed with precise alignment to ensure smooth movement. The cutting head assembly requires particular attention as it directly affects cutting quality. Throughout assembly, all mechanical connections, bearings, and drive systems must be properly lubricated and tensioned. Following the manufacturer's assembly sequence is essential, as improper order can create alignment issues that are difficult to correct later.

Electrical and Software Setup

After mechanical assembly, the float glass cutting machine requires electrical connections and software configuration. This begins with connecting power to the control cabinet, followed by establishing connections between the cabinet and various components, including motors, encoders, sensors, and safety systems. Cable routing must prevent interference between power and signal cables. After physical connections, the control software must be installed and configured according to the specific model and requirements. Modern float glass cutting machines utilize sophisticated CAD/CAM software that requires setup of parameters such as glass thickness ranges, cutting speeds, and breaking pressure. The software interface between the machine controller and production management systems also needs configuration for workflow integration. Technicians typically load and test basic cutting programs to verify proper communication between software commands and machine movements.

Precision Calibration and Initial Testing

Calibration is critical for achieving optimal performance. This process begins with geometric calibration, ensuring all axes move precisely according to programmed coordinates. Technicians verify squareness between X and Y axes, with deviations typically limited to less than 0.1mm per meter. Cutting pressure calibration adjusts the downforce applied by the scoring wheel according to different glass thicknesses. This pressure must be consistent across the entire cutting surface and precisely controlled to create proper scoring depth. Speed calibration ensures the machine moves smoothly during cutting operations. Following calibrations, test cuts are performed using various glass types and thicknesses to verify dimensional accuracy, edge quality, and breakout cleanliness. Throughout calibration, technicians make adjustments to both mechanical components and software parameters until the float glass cutting machine consistently produces cuts meeting quality specifications.

What maintenance is required to keep a float glass cutting machine operating efficiently?

Daily Maintenance Procedures

Consistent daily maintenance extends the operational life of your float glass cutting machine while maintaining cutting precision. Operators should perform visual inspections of the cutting table surface, removing any glass particles or debris that could interfere with glass positioning. The cutting wheel should be examined for signs of wear, with replacement recommended at the first indication of dulling. The air system requires daily attention, including draining moisture traps and verifying proper pressure settings (6-8 bar for most models). Lubricant levels should be checked and replenished as needed. All safety systems—including emergency stops, light curtains, and protective barriers—must be tested daily before operation. The cutting table's conveyor belts or air cushion systems need inspection for proper tension and alignment. These procedures typically require only 15-20 minutes but are crucial for preventing downtime and maintaining consistent cutting quality.

Weekly and Monthly Maintenance Tasks

A structured program of weekly and monthly maintenance is essential for preserving precision and reliability. Weekly maintenance should include cleaning of optical sensors, position encoders, and reflectors. The control cabinet's cooling systems and filters require regular inspection to prevent overheating. All cable connections should be checked for secure fastening. Monthly maintenance includes testing and calibration of measuring systems using reference standards to verify dimensional accuracy. The machine's geometric alignment should be verified using diagonal cutting tests to ensure the X and Y axes remain perpendicular. All belts, chains, and drive systems should be inspected for proper tension and wear. Lubrication systems require monthly verification, including checking oil quality and replacing filters. These periodic maintenance procedures help identify potential issues before they affect production quality.

Preventive Maintenance and Component Replacement

A strategic preventive maintenance program maximizes the lifespan and performance of your float glass cutting machine. This approach focuses on scheduled replacement of wear components before they fail. Cutting wheels typically require replacement after processing between 3,000 and 5,000 linear meters of glass. Establishing a tracking system for cutting distance allows for timely replacement before quality deteriorates. Drive belts, bearings, and linear guides usually require replacement every 6-12 months depending on production volume. The compressed air system components should be replaced according to recommended intervals, typically every 3-6 months for filters. Electronic components such as sensors also benefit from scheduled evaluation. Most float glass cutting machine manufacturers provide detailed maintenance schedules in their service manuals. Keeping comprehensive maintenance records helps identify patterns of wear or recurring issues. By implementing disciplined preventive maintenance, glass fabricators can achieve higher equipment availability rates and more consistent product quality.

Conclusion

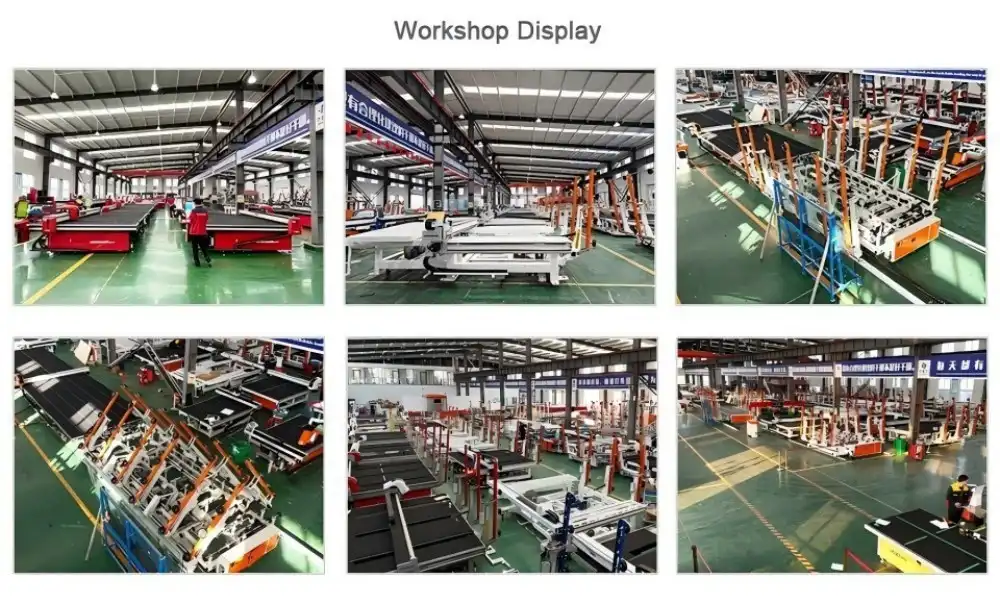

Installing a float glass cutting machine is a comprehensive process requiring careful planning, precise execution, and ongoing maintenance. By following the guidelines outlined in this article, you can ensure optimal performance, extended equipment life, and high-quality cutting results. Remember that proper installation sets the foundation for years of efficient operation. Proper maintenance routines will maximize your investment's return and minimize production disruptions. Shandong Huashil Automation Technology Co., Ltd. is a leading provider in the glass machinery and mechanical equipment industry, offering high-quality products and comprehensive solutions. With over ten years of export experience, the company boasts a mature R&D team, a reliable source factory, and a professional after-sales service team. Huashil's core services include OEM support, fast delivery, high cost performance, and dependable after-sales service. The company holds complete certifications, ensuring the highest standards of quality and reliability. If you are interested in exploring our products or wish to establish in-depth cooperation, please feel free to contact us at salescathy@sdhuashil.com for more information.

References

1. Wilson, R.T. (2023). Modern Glass Cutting Technologies: Installation and Operation. Journal of Glass Processing Technology, 45(3), 112-128.

2. Chen, H. & Thompson, K.L. (2022). Industrial Glass Cutting Machinery: Setup and Maintenance Guide. Glass Industry Technical Publications, London.

3. Petrova, M.V. (2023). Precision Requirements for Float Glass Processing Equipment. International Journal of Manufacturing Engineering, 18(2), 203-215.

4. Williams, J.D. & Garcia, S.P. (2024). Calibration Techniques for CNC Glass Cutting Systems. Advanced Materials Processing, 29(4), 78-92.

5. Anderson, T.R. (2022). Float Glass Manufacturing: Equipment Installation Standards. Glass Technology Association Technical Manual, 5th Edition.

6. Nakamura, H. & Singh, R. (2023). Energy Efficiency in Modern Glass Cutting Equipment: Installation Best Practices. Sustainable Manufacturing Journal, 12(1), 45-61.