The lifespan of a glass cutting assembly line is a critical consideration for manufacturers and businesses in the glass processing industry. Understanding the longevity of these sophisticated systems helps in planning investments, maintenance schedules, and future expansions. An automatic glass cutting line represents a significant capital investment, and knowing its expected service life allows companies to calculate return on investment and plan for eventual replacements or upgrades. Various factors influence how long these systems remain operational and efficient, from the quality of components to maintenance practices and technological advancements in the industry.

What factors affect the lifespan of an automatic glass cutting line?

Quality of Components and Manufacturing

The durability of an automatic glass cutting line heavily depends on the quality of its components and overall manufacturing standards. Premium systems built with high-grade materials and precision engineering typically outlast budget alternatives by several years. Key components such as cutting heads, motors, bearings, and control systems significantly influence the system's longevity. Top-tier automatic glass cutting lines often feature hardened steel guide rails, industrial-grade motors with higher duty cycles, and cutting tools made from specialized materials designed to withstand continuous operation. Additionally, systems from reputable manufacturers undergo rigorous quality control processes, ensuring that each component meets specific performance and durability standards before assembly.

Maintenance Practices and Schedules

Regular maintenance is perhaps the most critical factor determining how long an automatic glass cutting line will last. Well-maintained systems can remain operational for decades, while neglected equipment may fail prematurely. Effective maintenance goes beyond simply addressing issues as they arise; it involves proactive inspections, regular lubrication, calibration checks, and the timely replacement of wear parts. Many manufacturers recommend daily visual inspections, weekly lubrication schedules, monthly calibration checks, and comprehensive quarterly maintenance. Companies that implement computerized maintenance management systems to track and schedule these activities typically see extended lifespans for their automatic glass cutting lines. Proper training of maintenance personnel also ensures that complex procedures are performed correctly, preventing inadvertent damage during routine service.

Operating Conditions and Production Volume

The environment in which an automatic glass cutting line operates and its production volume significantly impact its service life. Factors such as ambient temperature, humidity levels, cleanliness, and protection from external elements all affect how quickly components deteriorate. Lines operating around the clock in high-volume production facilities will naturally experience more wear than those used intermittently. Similarly, systems processing thicker glass or specialized materials may experience accelerated tool wear. Temperature fluctuations can affect precision components and electronic systems, while dust and glass particles can infiltrate moving parts, causing abrasion over time. Installing climate control systems, air filtration, and proper enclosures can mitigate these environmental factors, extending the lifespan of an automatic glass cutting line considerably.

How often should automatic glass cutting lines be upgraded or replaced?

Technological Obsolescence vs. Mechanical Lifespan

While the mechanical components of an automatic glass cutting line might function properly for 15-20 years with proper maintenance, technological obsolescence often becomes a factor long before mechanical failure occurs. Control systems, software, and automation features evolve rapidly, making older systems less competitive even when still operational. Modern automatic glass cutting lines offer advantages in terms of speed, precision, energy efficiency, and integration capabilities that weren't available a decade ago. Many manufacturers find themselves upgrading their systems every 7-10 years to maintain competitive advantages, even though the mechanical components could continue functioning for much longer. The decision to upgrade often revolves around balancing the cost of replacement against the productivity and efficiency gains of newer technology.

Modular Upgrades and Retrofitting Options

Complete replacement isn't always necessary when considering how to extend the life of an automatic glass cutting line. Many manufacturers design their systems with modularity in mind, allowing for component-level upgrades that refresh the technology without requiring full replacement. Control system upgrades, for example, can bring older mechanical systems up to modern standards of connectivity and automation. Cutting head replacements can introduce newer cutting technologies while utilizing the existing frame and motion systems. Software updates can add features and improve efficiency without any hardware changes. These modular approaches effectively "reset the clock" on system obsolescence, extending the useful lifespan of the automatic glass cutting line while spreading investment costs over longer periods. Many equipment suppliers offer retrofitting packages specifically designed to modernize existing systems.

Economic Considerations for Replacement Timing

The decision to replace an automatic glass cutting line involves complex economic calculations beyond simply considering whether the equipment still functions. As systems age, maintenance costs typically increase, downtime becomes more frequent, and parts availability may become an issue. Modern systems generally offer energy efficiency improvements, reduced material waste, faster processing times, and reduced labor requirements. Manufacturers must calculate the total cost of ownership, factoring in these operational improvements against capital expenditure. The "right" time to replace varies widely, but many glass processors find that the 10-12 year mark often represents an economic tipping point where the benefits of new technology outweigh the costs of continued operation of older systems. Financing options, tax incentives for capital equipment, and market demand for higher quality or specialized products also influence replacement timing decisions.

What maintenance practices maximize the lifespan of an automatic glass cutting line?

Preventive Maintenance Strategies

Implementing robust preventive maintenance strategies is essential for maximizing the lifespan of an automatic glass cutting line. This approach focuses on addressing potential issues before they develop into critical failures that could damage the system or cause extended downtime. Effective preventive maintenance begins with following the manufacturer's recommended maintenance schedule meticulously. This typically includes regular inspection of cutting tools, verification of alignment and calibration, checking fluid levels and quality, inspecting cables and connections, and monitoring wear on moving parts. Creating detailed maintenance logs helps track component performance over time and identify patterns that might indicate emerging issues. Many glass processors use condition monitoring techniques, such as vibration analysis and thermal imaging, to detect early signs of component failure in automatic glass cutting lines. These proactive approaches can significantly extend operational life while minimizing unexpected disruptions to production.

Operator Training and Standard Operating Procedures

The human element plays a crucial role in determining how long an automatic glass cutting line will last. Properly trained operators who understand the system's capabilities and limitations can prevent damage caused by improper use. Comprehensive training programs should cover not only basic operation but also troubleshooting, daily maintenance checks, and recognition of abnormal operating conditions. Developing and enforcing standard operating procedures ensures consistency across shifts and personnel changes. These procedures should include proper startup and shutdown sequences, material handling protocols, and cleaning routines specific to the automatic glass cutting line. Regular refresher training and skills assessment help maintain operator proficiency and adapt to any system modifications or upgrades. Some manufacturers even implement certification programs for operators to ensure competency and accountability in equipment operation.

Spare Parts Management and Vendor Relationships

Strategic management of spare parts inventory and nurturing strong relationships with equipment vendors can significantly impact the longevity of an automatic glass cutting line. Maintaining an appropriate inventory of critical spare parts prevents extended downtime when failures occur. Components with known wear patterns, such as cutting wheels, belts, and filters, should be stocked according to their replacement frequency and criticality to operations. Establishing strong relationships with the original equipment manufacturer or authorized service providers ensures access to genuine parts and technical support. Many suppliers offer service contracts that include regular maintenance visits, priority support, and discounted parts. These partnerships provide access to the latest technical bulletins, software updates, and product improvements that can extend the useful life of the equipment. Some vendors also offer remote monitoring services that can detect potential issues before they cause failure in automatic glass cutting lines.

Conclusion

The lifespan of a glass cutting assembly line typically ranges from 10-20 years, depending on quality, maintenance practices, and technological advancements. With proper care and strategic upgrades, automatic glass cutting lines can remain productive and efficient for extended periods. The key to maximizing service life lies in implementing comprehensive maintenance programs, investing in operator training, and making timely upgrades to critical components when necessary, rather than waiting for catastrophic failure.

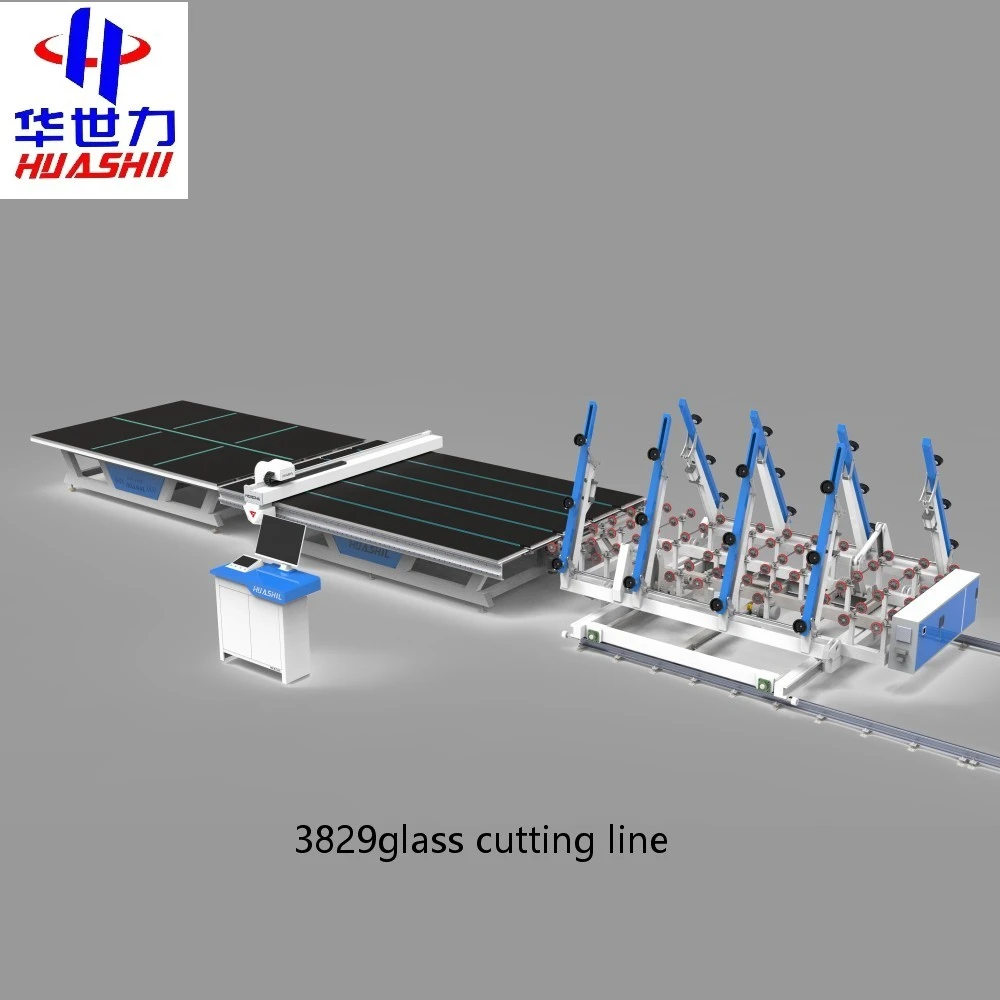

Shandong Huashil Automation Technology Co., Ltd. is a leading provider in the glass machinery and mechanical equipment industry, offering high-quality products and comprehensive solutions. With over ten years of export experience, the company boasts a mature R&D team, a reliable source factory, and a professional after-sales service team. Huashil's core services include OEM support, fast delivery, high cost performance, and dependable after-sales service. The company holds complete certifications, ensuring the highest standards of quality and reliability. If you are interested in exploring our products or wish to establish in-depth cooperation, please feel free to contact us at salescathy@sdhuashil.com for more information.

References

1. Johnson, R.T. & Smith, K.L. (2023). "Longevity Factors in Industrial Glass Processing Equipment." Journal of Industrial Manufacturing, 45(3), 112-128.

2. Zhang, W., & Patel, S. (2022). "Maintenance Strategies for Extended Service Life in Automatic Glass Processing Lines." International Glass Processing Technology Review, 18(2), 75-91.

3. Miller, D.H., & Thomas, B.R. (2023). "Economic Analysis of Replacement Cycles for Glass Manufacturing Equipment." Industrial Economics Quarterly, 29(4), 203-219.

4. European Glass Manufacturers Association. (2024). "Industry Standards for Glass Processing Equipment Lifespan and Maintenance." Brussels: EGMA Publications.

5. Roberts, L.M., & Garcia, C.J. (2022). "Technological Evolution in Automatic Glass Cutting Systems: Impact on Equipment Lifecycle." Journal of Glass Science and Technology, 34(1), 45-62.

6. Chen, Y., & Williamson, P. (2023). "Comparative Analysis of Maintenance Approaches in Glass Processing Facilities." Advances in Manufacturing Technology, 12(3), 187-201.