Adjusting the settings on a float glass cutting machine is a critical process that directly impacts the quality, precision, and efficiency of glass cutting operations. Whether you're working with architectural glass, automotive glass, or specialty applications, proper machine configuration ensures clean cuts, minimizes waste, and extends the lifespan of your equipment. This guide explores the essential adjustments and optimization strategies for float glass cutting machines.

What are the basic parameters to adjust on a float glass cutting machine?

Cutting Pressure Calibration

The cutting pressure determines how much force the cutting wheel applies to the glass surface. For thin float glass (2-4mm), lower pressure settings between 1.5-2.5 bar are recommended, while thicker glass (6-19mm) requires higher pressure settings ranging from 2.5-4.5 bar. Modern float glass cutting machines feature digital pressure controls that allow for precise adjustments. When adjusting cutting pressure, perform test cuts and inspect the score line quality - an optimal score should be continuous, visible but not excessively deep, and should produce a clean break with minimal effort. Improper pressure settings can lead to incomplete scores, spontaneous breaking, or excessive edge chipping.

Cutting Speed Optimization

The cutting speed setting determines how quickly the cutting head moves across the glass. Most float glass cutting machines allow speed adjustments ranging from 50 to 180 meters per minute, but the ideal setting depends on glass thickness, composition, and cutting pattern complexity. For straight-line cutting of standard float glass, higher speeds are generally acceptable, while curved cuts require reduced speeds to maintain precision. When working with specialty glass types, cutting speed often needs to be reduced by 15-30% compared to standard float glass. Modern CNC float glass cutting machines can automatically adjust cutting speeds based on the geometry of the cut.

Cutting Oil Flow Rate

The cutting oil flow rate affects the quality of the score line and the longevity of the cutting wheel. Proper adjustment ensures sufficient lubricant reaches the cutting point without excessive waste. Typical flow rates range from 3-8 drops per minute for manual machines to continuous flow systems on automated float glass cutting machines that deliver 10-30ml per minute. When working with coated float glass, slightly higher oil flow rates are recommended to help penetrate the coating. Advanced machines feature automated oil delivery systems that adjust flow rates based on cutting speed, ensuring consistent lubrication throughout complex cutting patterns.

How can you troubleshoot common issues with float glass cutting machines?

Diagnosing Inconsistent Breaking Patterns

When a float glass cutting machine produces inconsistent breaking patterns, start by examining the cutting wheel for signs of wear or damage. Most premium float glass cutting machines use tungsten carbide wheels that should be rotated or replaced after cutting approximately 5,000-8,000 linear meters of glass. Verify that glass supports are properly aligned and providing uniform support across the entire sheet, as uneven support creates stress points. The breaking bars should also be inspected for proper alignment and pressure distribution. Modern float glass cutting machines incorporate pneumatic or hydraulic breaking systems with adjustable pressure settings that should be calibrated according to glass thickness. Also check environmental factors such as temperature fluctuations, which can create thermal stress in the glass.

Resolving Alignment and Calibration Problems

Precision alignment is critical for any float glass cutting machine. Begin troubleshooting by verifying the squareness of the machine's reference edges using a precision square. Check the alignment of the cutting bridge, ensuring it travels perpendicular to the reference edge. Modern CNC float glass cutting machines feature automated calibration programs that use optical sensors to detect and compensate for mechanical deviations. For machines with conveyors or air flotation systems, check that the glass transportation surface is perfectly level using a digital inclinometer. After any major maintenance or component replacement, a comprehensive re-calibration is essential to restore optimal performance.

Optimizing Cutting Wheel Selection and Maintenance

The cutting wheel is the heart of any float glass cutting machine. Different glass types and thicknesses require specific wheel angles, typically ranging from 118° to 165°, with sharper angles for thinner glass and obtuse angles for thicker materials. When troubleshooting cut quality issues, inspect the wheel under magnification for signs of uneven wear or contamination. The wheel rotation mechanism should turn smoothly, allowing the wheel to roll rather than drag across the glass surface. Most advanced float glass cutting machines include wheel pressure monitoring systems that can detect excessive wheel wear. Establish a regular wheel maintenance schedule, typically replacing wheels after 40-60 hours of active cutting time.

What advanced settings can improve the efficiency of a float glass cutting machine?

Optimization of Pattern Layout and Nesting

Advanced float glass cutting machines offer sophisticated software for pattern layout and nesting optimization, which can dramatically improve material utilization. These systems analyze cutting requirements and automatically arrange parts to maximize yield from each glass sheet. Modern machines can achieve material utilization rates exceeding 85% through intelligent nesting algorithms. The cutting sequence optimization determines the order in which parts are cut to maintain structural integrity throughout the process. Most advanced float glass cutting machines allow operators to define cutting rules that prioritize certain cut types. Proper optimization can reduce cutting cycle times by 15-25% while simultaneously improving yield rates.

Automation and Integration Settings

Modern float glass cutting machines often feature extensive automation capabilities that require proper configuration. Integration with upstream and downstream processes requires careful synchronization of handover points and communication protocols. Machine vision systems can be incorporated to automatically detect glass dimensions, orientation, and potential defects before cutting begins. For facilities running multiple float glass cutting machines, production management software can distribute cutting tasks based on machine capabilities and current workload. Energy management settings are also increasingly important, with modern machines offering standby modes that can reduce energy consumption by 20-30% during partial production periods.

Quality Control Parameter Configuration

Quality control settings on advanced float glass cutting machines allow operators to define acceptance criteria that ensure consistent output quality. Edge quality parameters determine acceptable microchip depths, with typical tolerances ranging from 0.1mm to 0.5mm depending on the application. Dimensional accuracy settings specify allowable deviations from nominal dimensions, typically ranging from ±0.2mm for precision applications to ±1.0mm for standard architectural glass. Modern float glass cutting machines incorporate in-process measurement systems that verify critical dimensions during cutting and can automatically compensate for detected deviations in real-time. The most advanced machines feature adaptive quality control systems that automatically adjust cutting parameters based on measured results.

Conclusion

Properly adjusting the settings on a float glass cutting machine is crucial for achieving optimal cutting quality, maximizing productivity, and extending equipment lifespan. From basic parameters like cutting pressure and speed to advanced configurations for automation and quality control, each setting plays a vital role in the cutting process. By understanding these adjustments and implementing regular maintenance routines, operators can ensure their float glass cutting machines deliver consistent, high-quality results.

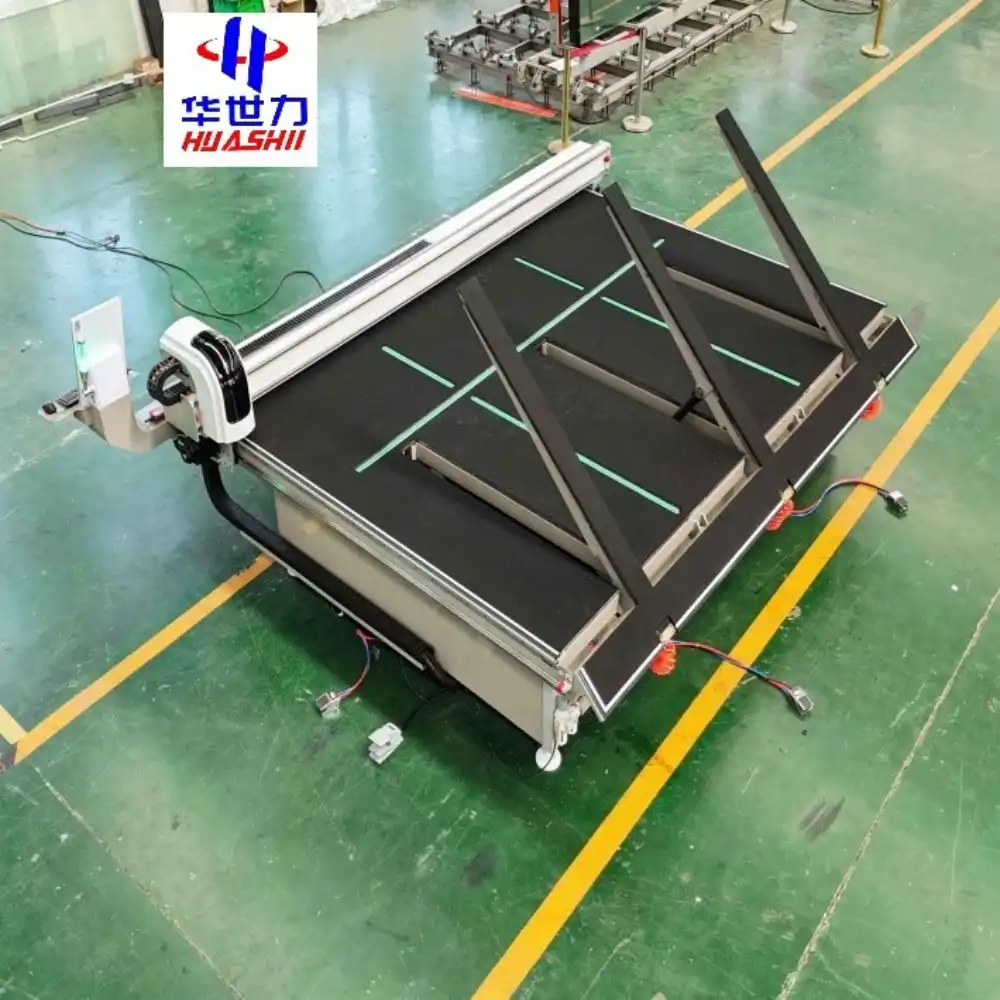

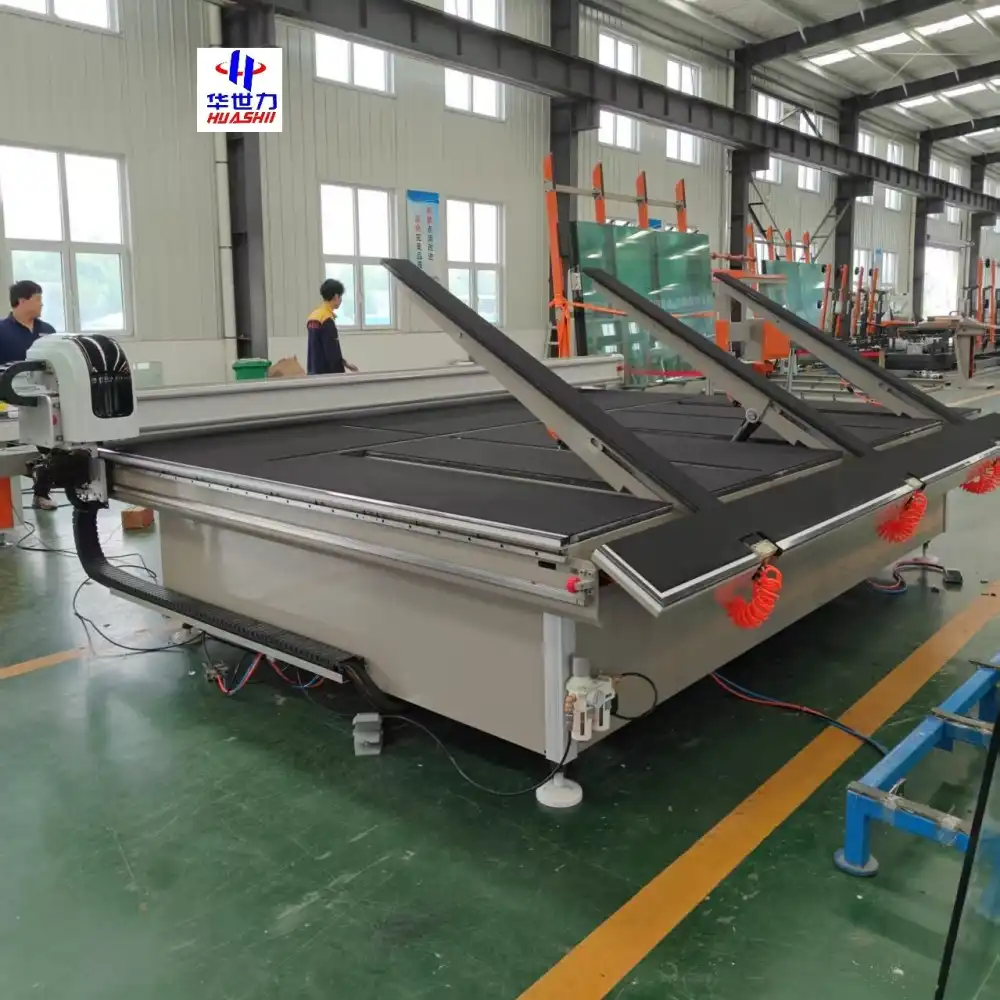

Shandong Huashil Automation Technology Co., Ltd. is a leading provider in the glass machinery and mechanical equipment industry, offering high-quality products and comprehensive solutions. With over ten years of export experience, the company boasts a mature R&D team, a reliable source factory, and a professional after-sales service team. Huashil's core services include OEM support, fast delivery, high cost performance, and dependable after-sales service. The company holds complete certifications, ensuring the highest standards of quality and reliability. If you are interested in exploring our products or wish to establish in-depth cooperation, please feel free to contact us at salescathy@sdhuashil.com for more information.

References

1. Wilson, J.T. (2023). Advanced Techniques in Float Glass Processing and Cutting. Journal of Glass Technology, 47(3), 128-142.

2. Tanaka, H. & Roberts, P. (2024). Optimization Methods for CNC Glass Cutting Operations. International Glass Processing Review, 19(2), 78-95.

3. Martinez, S.L. & Chen, K. (2023). Troubleshooting Guide for Industrial Glass Cutting Equipment. Glass Manufacturing Technology Quarterly, 36(4), 215-228.

4. Brown, A.J. & Patel, V. (2022). Automation in Modern Glass Fabrication: Equipment Settings and Calibration. Industrial Glass Processing Handbook, 3rd Edition, 156-183.

5. Zhang, Y., Anderson, R., & Liang, Q. (2024). Quality Control Parameters in Precision Glass Cutting Applications. Journal of Materials Processing Technology, 292, 117-134.

6. Nakamura, T. & Williams, S. (2023). Energy Efficiency and Performance Optimization in Glass Processing Equipment. Sustainable Manufacturing Review, 18(1), 42-58.