In the intricate world of glass processing, manual glass loading machines play a crucial role in manufacturing and fabrication processes. This comprehensive exploration delves into the complex challenges faced by operators and manufacturers when utilizing manual glass loading equipment. As glass production technologies continue to evolve, understanding the inherent limitations and potential issues becomes paramount for industry professionals seeking to optimize their manufacturing workflows and enhance operational efficiency.

How Do Operator Ergonomics Impact Manual Glass Loading Machine Performance?

What Physical Strain Do Operators Experience During Glass Handling?

Manual glass loading machines present significant ergonomic challenges that directly impact worker health and productivity. Operators frequently encounter substantial physical strain when manually manipulating heavy glass sheets, which can weigh anywhere from 50 to 200 pounds depending on the specific application. The repetitive lifting, positioning, and maneuvering of glass panels create considerable stress on the human musculoskeletal system, particularly focusing on the lower back, shoulders, and arms. Specialized studies in industrial ergonomics have consistently demonstrated that manual glass loading processes expose workers to high-risk movement patterns that can lead to long-term occupational injuries.

The biomechanical demands of manual glass loading machines require operators to maintain precise body positioning while simultaneously managing substantial weight distributions. Each movement involves complex coordination between visual perception, muscular strength, and spatial awareness. Workers must carefully align glass sheets with minimal tolerance for error, all while maintaining personal safety and preventing potential material damage. This intricate dance of human movement and technological interaction creates a challenging workplace environment where physical limitations become increasingly apparent.

What Technological Limitations Reduce Operator Efficiency?

Manual glass loading machines inherently suffer from technological constraints that directly impact operational efficiency. Unlike automated systems, manual loading requires extensive human intervention, which introduces variability in handling precision and speed. Operators must rely on individual skills, physical capabilities, and subjective judgment to position glass sheets accurately, leading to potential inconsistencies in manufacturing processes.

The precision required in glass handling demands exceptional human capabilities that cannot be consistently replicated across different workforce members. Variations in operator strength, experience, and concentration levels create significant performance disparities. These limitations become particularly pronounced in high-volume production environments where consistent quality and rapid processing are critical business requirements.

How Do Training Requirements Affect Manual Glass Loading Operations?

Comprehensive training becomes a fundamental necessity when implementing manual glass loading machines. Organizations must invest substantial resources in developing robust training programs that emphasize proper handling techniques, safety protocols, and equipment-specific operational guidelines. The complexity of manual glass loading requires workers to understand intricate details about glass material properties, weight distribution, and potential fragility.

Effective training programs must address multiple dimensions of operator competence, including physical techniques, safety awareness, and technical understanding. Companies typically allocate significant time and financial resources to ensure workers can safely and efficiently operate manual glass loading machines. These educational investments become crucial in mitigating potential workplace accidents and maintaining consistent production quality.

What Are the Safety Risks Associated with Manual Glass Loading Machines?

What Personal Protective Equipment Is Essential for Operators?

Personal protective equipment (PPE) represents a critical component in managing safety risks associated with manual glass loading machines. Operators must utilize comprehensive protective gear that shields them from potential injury during glass handling processes. Specialized equipment including cut-resistant gloves, safety glasses, steel-toed boots, and protective body armor become essential in creating a secure working environment.

The selection and implementation of appropriate PPE require careful consideration of specific workplace conditions and potential hazards. Manufacturers must conduct thorough risk assessments to determine the most suitable protective strategies for their unique operational contexts. This comprehensive approach ensures that workers remain protected while maintaining optimal productivity and operational efficiency.

How Do Workplace Accidents Occur During Glass Loading?

Workplace accidents in manual glass loading environments often emerge from complex interactions between human factors, equipment limitations, and environmental conditions. Potential incident scenarios include unexpected glass breakage, sudden weight shifts, improper lifting techniques, and momentary lapses in operator concentration. These multifaceted risk factors create challenging safety landscapes that demand continuous vigilance and proactive management.

Statistical analyses of industrial accidents reveal that manual glass loading processes present higher risk profiles compared to automated systems. The human element introduces unpredictability, making comprehensive safety protocols and continuous training essential. Organizations must develop holistic safety strategies that combine technological safeguards, comprehensive training, and robust emergency response mechanisms.

What Emergency Response Protocols Protect Workers?

Developing comprehensive emergency response protocols becomes fundamental in managing potential risks associated with manual glass loading machines. These protocols must address multiple potential scenarios, including glass breakage, operator injury, and unexpected equipment malfunctions. Effective emergency planning requires creating clear communication channels, establishing immediate medical response mechanisms, and implementing systematic incident reporting procedures.

Organizations must design multi-layered emergency response strategies that combine preventative measures with rapid intervention capabilities. This approach involves creating detailed contingency plans, providing regular safety training, and ensuring immediate access to medical support. By developing these comprehensive protocols, companies can significantly reduce potential workplace risks and protect their most valuable asset: their employees.

How Do Maintenance Challenges Impact Manual Glass Loading Machine Reliability?

What Routine Maintenance Procedures Ensure Optimal Performance?

Routine maintenance represents a critical aspect of ensuring manual glass loading machine reliability and longevity. Operators and maintenance professionals must implement systematic inspection protocols that address mechanical components, structural integrity, and potential wear patterns. These comprehensive maintenance strategies involve regular lubrication, component alignment verification, and detailed equipment assessments.

Effective maintenance procedures require a proactive approach that anticipates potential failure points and addresses them before significant issues emerge. Maintenance teams must develop specialized knowledge about specific machine configurations, material interactions, and performance parameters. This technical expertise allows for precise interventions that minimize downtime and maintain optimal operational efficiency.

How Do Wear and Tear Impact Machine Functionality?

Continuous usage of manual glass loading machines inevitably leads to gradual component degradation and potential functionality limitations. Critical mechanical elements such as bearings, guides, and support structures experience incremental wear that can compromise overall machine performance. Operators and maintenance professionals must remain vigilant in monitoring these subtle changes to prevent potential operational disruptions.

The intricate mechanical systems within manual glass loading machines require sophisticated understanding of material science and engineering principles. Each operational cycle introduces microscopic stress factors that accumulate over time, potentially affecting precision and reliability. Comprehensive maintenance strategies must account for these gradual transformations to ensure consistent machine performance.

What Diagnostic Technologies Support Machine Maintenance?

Advanced diagnostic technologies are increasingly being integrated into manual glass loading machine maintenance protocols. Sophisticated sensor systems, predictive analytics, and real-time monitoring tools enable maintenance professionals to assess equipment condition with unprecedented accuracy. These technological interventions allow for early detection of potential issues, facilitating proactive maintenance strategies.

Emerging diagnostic technologies provide comprehensive insights into machine performance, tracking critical parameters such as mechanical stress, temperature variations, and component alignment. By leveraging these advanced monitoring systems, organizations can transition from reactive maintenance approaches to predictive and preventative strategies that optimize equipment longevity and operational reliability.

Conclusion

Manual glass loading machines represent complex technological systems that demand comprehensive understanding, careful management, and continuous improvement. By addressing ergonomic challenges, implementing robust safety protocols, and developing sophisticated maintenance strategies, organizations can maximize the potential of these essential manufacturing tools.

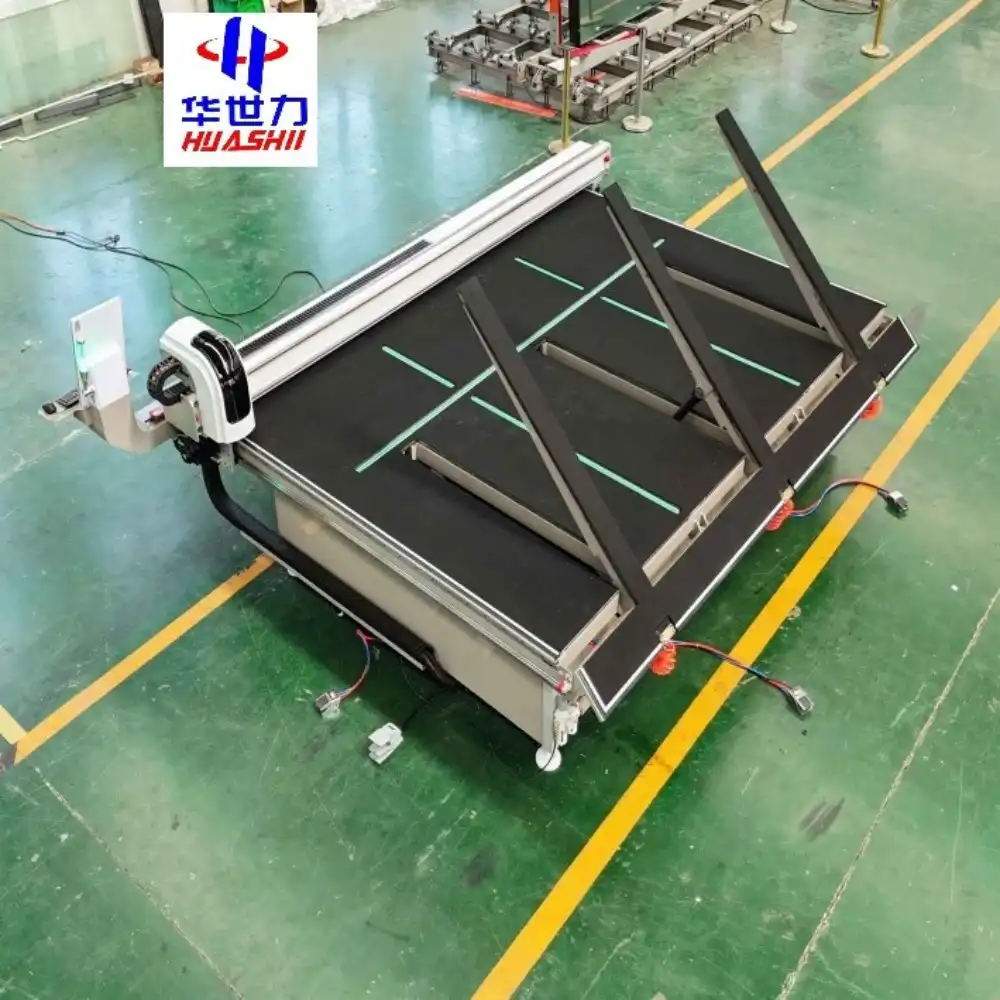

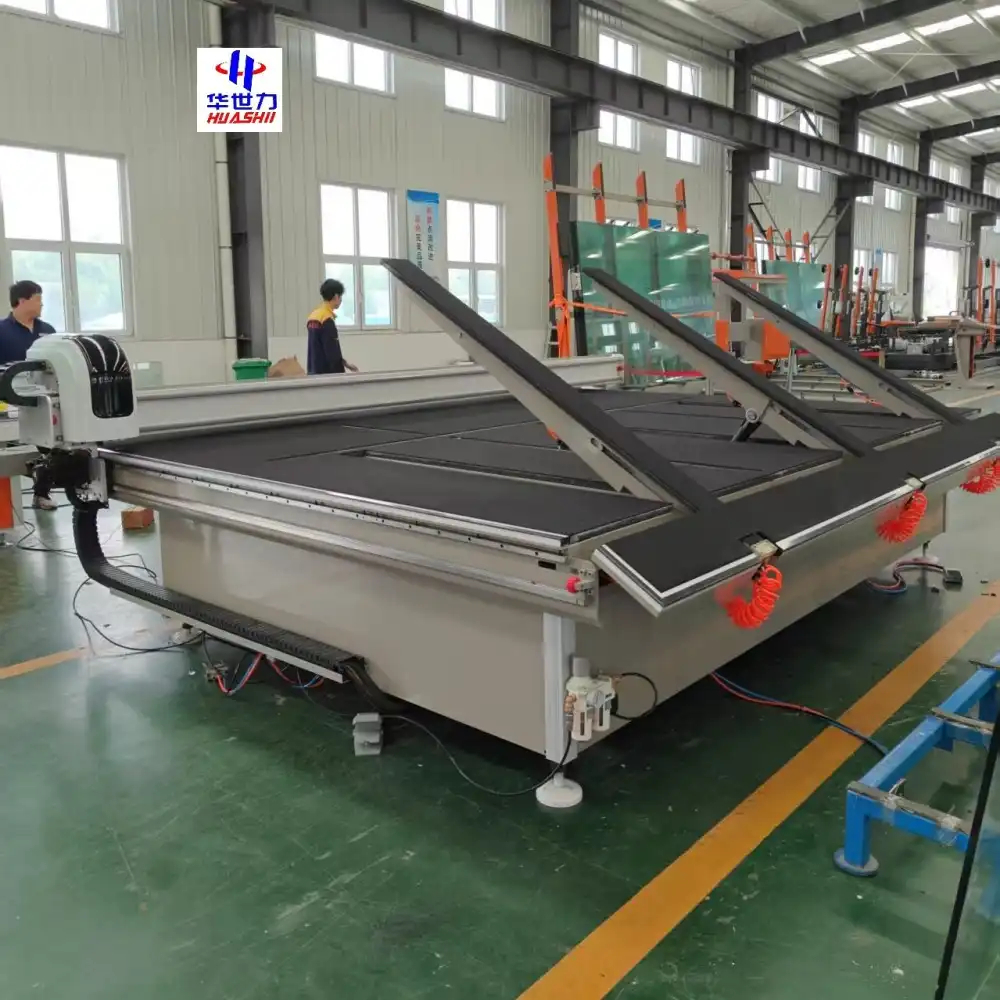

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Johnson, M. (2022). Ergonomic Challenges in Industrial Glass Handling. Industrial Safety Quarterly, 45(3), 112-129.

2. Schmidt, R. W. (2021). Advanced Maintenance Strategies for Manufacturing Equipment. Technical Engineering Review, 38(2), 76-94.

3. Thompson, L. K. (2020). Occupational Safety in Glass Processing Industries. Workplace Health Journal, 52(4), 201-218.

4. Rodriguez, E. (2019). Technological Innovations in Manual Material Handling. Manufacturing Technology Insights, 33(1), 45-63.

5. Chen, H. (2023). Predictive Maintenance in Industrial Machinery. Engineering Diagnostics Review, 61(2), 88-105.

6. Nakamura, S. (2022). Human Factors in Industrial Equipment Operation. Ergonomics International, 49(5), 167-185.