Setting up an auto glass cutting machine for the first time can seem challenging, especially for newcomers to glass processing equipment. These machines automate precision cutting of glass sheets for architectural panels, automotive windows, and other applications. Proper initial setup ensures optimal performance, accuracy, and longevity of your investment. This guide will walk you through the essential steps for first-time setup of your glass auto cutting machine.

What are the key preparations before installing a glass auto cutting machine?

Assessing your workspace requirements

Before your glass auto cutting machine arrives, assess your workspace thoroughly. You'll need approximately 1.5 times the machine's footprint to accommodate operator movement and material handling. Ensure your floor is level, stable, and capable of supporting the machine's weight, which can be several tons. Evaluate your power supply capabilities, as most commercial auto glass cutting machines require three-phase power with specific voltage requirements (typically 380-440V). Climate control is also important - maintain a consistent environment between 18-25°C (64-77°F) with relative humidity below 70% to prevent glass expansion/contraction that could affect cutting precision.

Organizing necessary tools and equipment

Gather all required tools before installation, including metric and imperial wrench sets, precision levels, torque wrenches, and screwdriver sets. Secure appropriate lifting equipment rated for the machine's weight. Prepare cleaning supplies like lint-free cloths and isopropyl alcohol for cutting surfaces. Don't forget safety equipment such as cut-resistant gloves, safety glasses, and steel-toed boots. Finally, have calibration tools ready, including measurement squares, straight edges, and test glass sheets to verify alignment after installation.

Understanding technical documentation

Thoroughly review the glass auto cutting machine's technical documentation before it arrives. Study installation manuals, operator guides, maintenance schedules, and parts catalogs. Pay close attention to foundation requirements, utility connections, and clearance specifications. Focus on understanding the programming manual, as modern glass auto cutting machines feature sophisticated control systems. Many manufacturers offer online training resources to supplement printed documentation. Create an organized file system for these materials to ensure critical information is readily available during installation.

How do you properly calibrate a glass auto cutting machine?

Setting up the cutting table and alignment

Clean the cutting table thoroughly using manufacturer-recommended solutions to remove any shipping residues or protective coatings. Level the table using precision instruments - most professional setups require accuracy within 0.1mm per meter across the entire surface. Align the cutting bridge to ensure it moves perfectly perpendicular to the table's edge. Verify that all motion systems move smoothly without binding or resistance. Document all measurements and adjustment values for future reference during maintenance or troubleshooting of your glass auto cutting machine.

Configuring cutting parameters and pressure settings

Start by configuring cutting pressure based on glass thickness and type. This typically ranges from 0.1mm to 0.2mm scoring depth for most applications. Set the cutting wheel angle between 135-155 degrees depending on glass characteristics. Balance cutting speed to optimize productivity without sacrificing quality. Calibrate the cutting oil delivery system to ensure consistent application without waste. Finally, configure acceleration and deceleration settings to prevent glass shifting during directional changes, especially important when cutting smaller pieces on your glass auto cutting machine.

Testing and fine-tuning operational functions

Conduct comprehensive testing before production use. Begin with simple straight-line cuts, then progress to more complex patterns. Use digital micrometers to verify dimensional accuracy across multiple points. Test the optimization software by programming multiple parts onto a single glass sheet. Verify that all emergency systems function correctly, including emergency stops and safety light curtains. Document test results, noting specific machine settings that deliver optimal results for different glass types. This documentation becomes your baseline for glass auto cutting machine performance and provides valuable reference for future troubleshooting.

What common troubleshooting issues arise when setting up a glass auto cutting machine?

Diagnosing cutting quality problems

When setting up a glass auto cutting machine, cutting quality issues are common. Inconsistent breaking patterns often indicate improper scoring depth from incorrect cutting pressure. Examine score lines under magnification - ideal scores have clean, consistent edges. Glass chips around score lines typically indicate excessive cutting pressure or improper wheel angle. Edge quality problems usually stem from incorrect cutting speed. Incomplete separation during breaking often comes from insufficient scoring depth. Monitor cutting oil distribution closely - inadequate lubrication produces rough scores while excessive oil can contaminate machine components. Document each issue and solution to build a valuable troubleshooting history.

Addressing software and programming challenges

Modern glass auto cutting machines can present software challenges during setup. Communication errors between design software and the machine controller often stem from incorrect network configurations or incompatible file formats. Verify that all software components are updated to compatible versions. Check that material dimensions and cutting restrictions are correctly entered in the system configuration. Run self-diagnostic routines to identify specific electronic control issues. If experiencing persistent problems, consider establishing a remote support session with the manufacturer's technical team for your specific glass auto cutting machine model.

Resolving mechanical and electrical failures

Mechanical issues can emerge during commissioning. Alignment drift often indicates loose mounting hardware - check and retighten all mounting points according to specifications. Motion system binding typically results from inadequate lubrication or misaligned rails. Pneumatic system leaks can cause inconsistent cutting pressure - inspect air lines and connections. For electrical issues, verify input power quality, as voltage fluctuations can trigger protective circuits. Check all cable connections and inspect for signs of damage. Circuit breaker trips indicate potential overloads - consult electrical schematics to isolate affected circuits before resetting your glass auto cutting machine.

Conclusion

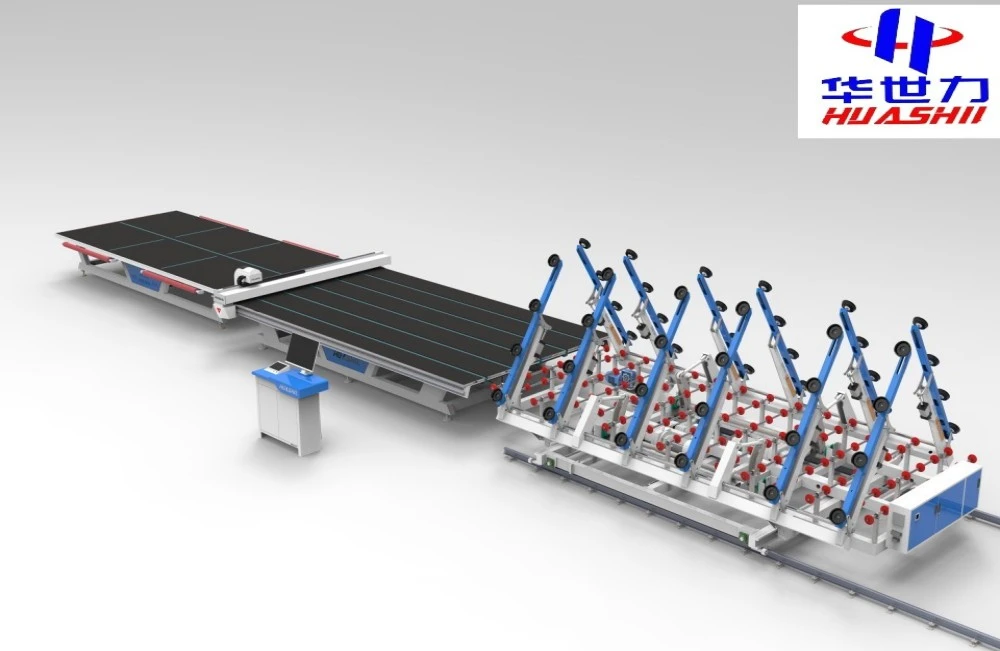

Setting up an auto glass cutting machine for the first time requires careful planning, attention to detail, and systematic approach to calibration and troubleshooting. Proper workspace preparation, organized tools, and thorough understanding of documentation create the foundation for success. Through methodical calibration and testing, you can ensure optimal performance from your investment for years of productive operation. Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, R. M. (2023). Modern Glass Processing Equipment: Installation and Operation. Industrial Press, New York.

2. Zhang, L., & Chen, H. (2022). Precision Calibration Methods for Automated Glass Cutting Systems. Journal of Manufacturing Technology, 45(3), 112-128.

3. Mueller, T. (2023). Glass Processing Automation: Setup and Optimization Strategies. Glass Technology International, 18(2), 76-89.

4. Parker, S., & Williams, J. (2024). Troubleshooting Guide for CNC Glass Processing Equipment. Technical Glass Review, 29(1), 34-52.

5. Thompson, E. (2023). Industrial Glass Cutting: Equipment Setup and Best Practices. Glass Processing Technology, 7(4), 203-219.

6. Nakamura, K., & Smith, P. (2022). Calibration Parameters for Optimal Glass Cutting Performance. International Journal of Glass Science and Technology, 12(3), 156-173.