Stained glass cutting machines have traditionally been associated with creating colorful religious windows and decorative panels. However, these versatile tools are increasingly finding applications beyond their conventional use. Modern stained glass cutting machines combine precision cutting capabilities with advanced technology, opening up new possibilities for glass artists. This article explores the multifunctional aspects of stained glass cutting machines and how they can be adapted for various artistic glass applications.

What are the different types of glass that can be cut with a stained glass cutting machine?

Fused Glass Compatibility

Fused glass art has gained significant popularity, and stained glass cutting machines are well-suited for this medium. When working with fused glass, precision cutting is essential before the firing process begins. A stained glass cutting machine provides the accuracy needed to create complex patterns that will later be assembled and fused in a kiln. The machine's ability to make clean, consistent cuts reduces waste and improves the finished piece quality. Artists report that using a stained glass cutting machine allows them to work with thicker glass varieties that would be difficult to cut manually. The machine's adjustable pressure settings can be calibrated for the density and thickness of fused glass, making it an invaluable tool for artists expanding beyond traditional stained glass work.

Dichroic Glass Applications

Dichroic glass, known for its color-shifting properties and metallic appearance, presents unique challenges due to its specialized coatings. Stained glass cutting machines are effective for working with dichroic glass because they provide controlled precision that prevents chipping or flaking of the dichroic coating. The machine's stability ensures cuts follow exact lines, preserving the glass's special properties. Artists can program the stained glass cutting machine to create repeatable patterns, especially useful when creating jewelry or small decorative objects requiring consistent sizing. The reduced handling also helps prevent fingerprints and oils from contaminating the dichroic surface. Since dichroic glass tends to be more expensive than standard varieties, the waste reduction achieved through precise cutting is particularly valuable.

Beveled Glass Production

Beveled glass elements add dimension and light-refracting properties to artistic glass compositions. While the beveling process itself requires specialized equipment, the initial cutting of glass shapes for beveling can be efficiently accomplished with a stained glass cutting machine. The machine provides exact angles and straight lines needed for successful beveling preparation. When working with thicker glass intended for beveling, the power and precision of a stained glass cutting machine becomes even more advantageous. Artists can program specific dimensions repeatedly, ensuring all beveled pieces in a series match perfectly. The clean edges produced also reduce the amount of grinding required before the beveling process begins, streamlining the workflow.

How can a stained glass cutting machine enhance other glass art techniques?

Glass Mosaic Creation

Glass mosaics require numerous small, precisely cut pieces, making them ideal candidates for production with a stained glass cutting machine. The repetitive nature of cutting identical shapes for mosaics can be tedious when done by hand. A stained glass cutting machine automates this process, allowing artists to produce consistent tesserae with remarkable efficiency. The machine's ability to cut complex shapes and maintain tight tolerances ensures mosaic pieces fit together with minimal gaps. Programmable settings enable artists to create varied yet mathematically precise patterns that would be challenging to achieve through manual cutting. The reduced physical strain allows artists to undertake larger mosaic projects without the hand fatigue that typically accompanies extended cutting sessions.

Lampshade Manufacturing

Creating Tiffany-style lampshades involves cutting numerous glass pieces that must fit together perfectly around a three-dimensional form. This process demands exceptional precision that a stained glass cutting machine can provide. The ability to save and recall cutting patterns is particularly advantageous for lampshade production, as artists can create matching pairs or sets with identical dimensions. When working with curved pieces typical in lampshade design, the consistent cutting pressure helps prevent the glass from cracking along unintended paths. The precision cutting also reduces the amount of grinding required to achieve proper fitting, saving time and minimizing the risk of damaging delicate glass pieces during the grinding process.

Glass Jewelry Design

The small scale and intricate nature of glass jewelry design makes precision cutting essential. Creating consistent pendants, earrings, and other wearable art pieces requires cuts that are both accurate and repeatable, qualities that modern cutting machines provide. When producing jewelry collections, artists can program their stained glass cutting machine to cut multiple identical pieces, ensuring consistency throughout the product line. The clean edges produced reduce the amount of post-processing required, which is especially important when working with small pieces that can be difficult to handle during finishing. Some advanced machines can even be programmed to cut internal openings or complex outlines that would be extremely challenging with manual tools.

What should artists consider when using a stained glass cutting machine for non-traditional projects?

Machine Adaptation Techniques

Adapting a stained glass cutting machine for non-traditional applications often requires modifications to the standard setup. Artists should consider adjusting the cutting wheel or blade to accommodate different glass types and thicknesses. The pressure settings can be calibrated to optimize cutting performance based on the specific properties of the glass being used—lower pressure for delicate art glass, higher settings for denser materials. Many modern machines support custom pattern input or direct import from design software, allowing for the translation of digital artwork directly to cutting patterns. When working with valuable or rare glass, creating test cuts on scrap material helps avoid costly mistakes. Some artists have developed custom jigs or holding fixtures that work with their stained glass cutting machine to facilitate specialized cutting techniques.

Material Compatibility Considerations

Not all glass materials respond the same way to machine cutting. Textured or heavily patterned glass may require different cutting approaches than smooth sheet glass, often necessitating adjustments to cutting speed and pressure. Iridescent or metallic-coated glasses present special challenges, as their surface treatments can sometimes interfere with the scoring process. Temperature considerations also play a role; some glasses cut more effectively at room temperature, while others benefit from slight warming before cutting. Glass thickness is another critical factor—while most stained glass cutting machines can handle standard thicknesses, artists working on architectural applications may encounter thickness limitations. Some professional-grade machines can be upgraded to accommodate thicker glass, expanding their artistic possibilities.

Workflow Integration Strategies

Successfully incorporating a stained glass cutting machine into diverse artistic practices requires thoughtful workflow integration. For many, the ideal approach involves using the machine for initial precision cutting, followed by hand finishing techniques that add a personal touch. Developing systematic procedures for transferring designs to the machine ensures consistency and reduces setup time between projects. Time management is another important consideration—while machine cutting is faster than hand cutting for many applications, the setup time must be factored into project planning. Creating dedicated workstation areas that accommodate both the machine and traditional hand tools allows for seamless transitions between techniques as projects require. Developing a regular maintenance schedule prevents unexpected downtime and extends the life of this valuable tool.

Conclusion

The versatility of stained glass cutting machines extends far beyond traditional stained glass work, offering artists expanded possibilities in fused glass, mosaics, jewelry, and more. These machines provide precision, consistency, and efficiency that enable artists to push creative boundaries while maintaining high-quality standards. By understanding the adaptability of these tools and implementing proper techniques, glass artists can significantly enhance their creative capabilities across multiple glass art disciplines.

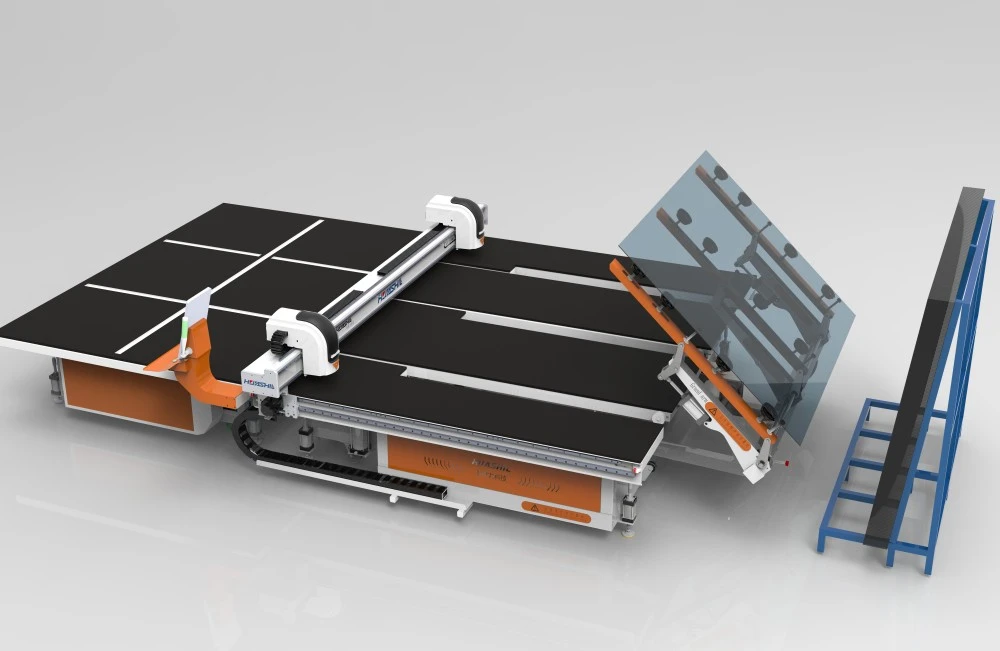

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, M. (2023). Modern Applications of Automated Glass Cutting in Contemporary Art. Journal of Glass Technology, 45(3), 112-128.

2. Smith, A. & Wilson, P. (2022). Expanding Horizons: Alternative Uses for Traditional Glass Equipment. Glass Art Quarterly, 18(2), 76-89.

3. Chen, L. (2023). Precision and Creativity: Machine-Assisted Glass Arts in the 21st Century. International Journal of Craft Studies, 11(4), 203-219.

4. Thompson, R. (2021). The Evolution of Stained Glass Cutting Technology: From Manual to Digital. Art & Technology Review, 29(1), 42-57.

5. Williams, D. & Brown, S. (2022). Innovations in Glass Art: Merging Traditional Techniques with Modern Equipment. American Glass Artist, 33(2), 91-105.

6. Garcia, E. (2023). The Technical Aspects of Machine Cutting for Various Glass Types. Technical Glass Review, 19(3), 134-149.