Glass cutting is a precision-intensive process that lies at the heart of modern glass manufacturing and fabrication. A glass cutting table represents a sophisticated piece of technological engineering designed to transform raw glass sheets into precisely shaped components used across various industries. This blog post delves deep into the intricate world of glass cutting technology, exploring the mechanisms, techniques, and innovations that make these remarkable machines essential in glass processing.

What Are the Core Mechanical Components of a Glass Cutting Table?

How Do Cutting Heads Determine Precision?

Glass cutting tables rely on advanced cutting heads as their primary precision instruments. These sophisticated mechanisms incorporate diamond-wheel cutters that can create incredibly accurate cuts with minimal margin of error. The cutting head moves along carefully calibrated tracks, utilizing computer-controlled navigation systems that map out exact cutting trajectories. Each movement is calculated with microscopic precision, ensuring that glass sheets are divided into exact specifications without compromising structural integrity.

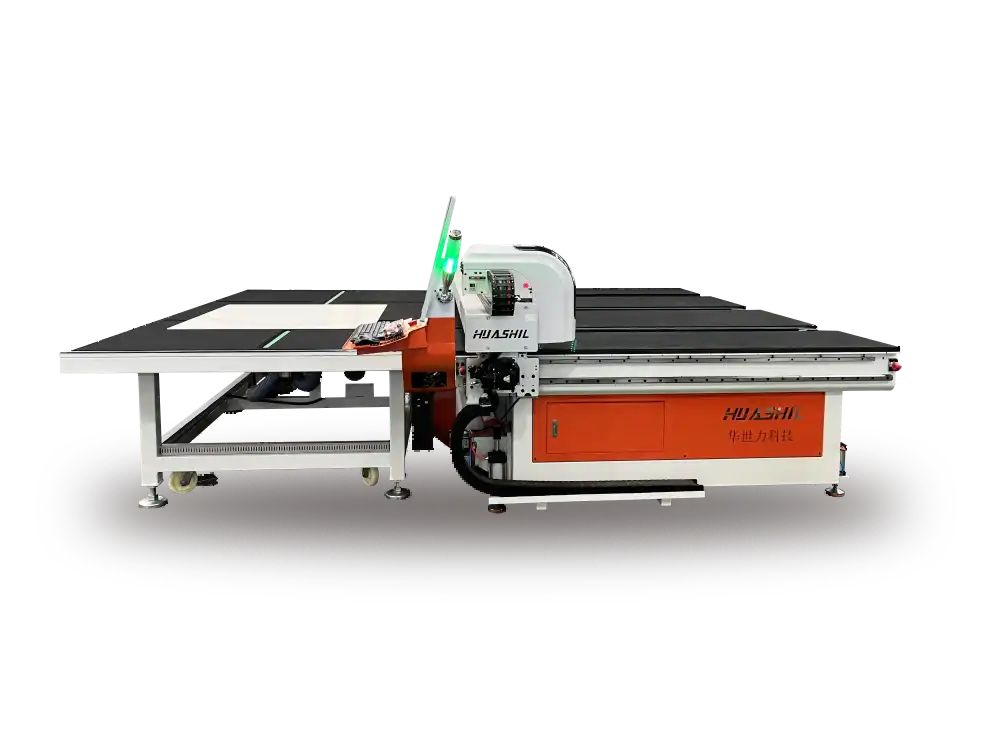

Advanced cutting heads typically feature multi-axis movement capabilities, allowing them to adjust angle, pressure, and cutting depth instantaneously. The diamond wheel itself is a marvel of engineering, designed to maintain sharp edges and consistent performance across thousands of cutting cycles. Manufacturers like Shandong Huashil Automation Technology Co., Ltd. invest significant research into developing cutting heads that can handle various glass thicknesses and types, from delicate architectural glass to robust industrial panels.

What Role Do Positioning Systems Play in Glass Cutting?

Positioning systems form the neural network of a glass cutting table, providing the fundamental infrastructure for accurate glass manipulation. These systems utilize advanced sensors, laser measurement tools, and precision linear guides to ensure that each glass sheet is positioned with nanometer-level accuracy. Vacuum-based holding mechanisms secure the glass firmly during the cutting process, preventing even the slightest movement that could compromise cutting precision.

Modern glass cutting tables incorporate multiple positioning sensors that continuously monitor the glass sheet's location, thickness, and surface characteristics. These real-time data points are processed through sophisticated software algorithms that adjust cutting parameters instantaneously. The result is a dynamic cutting environment where mechanical precision meets computational intelligence, enabling complex cutting patterns that were unimaginable just a decade ago.

How Do Control Systems Enhance Cutting Performance?

Control systems represent the brain of a glass cutting table, integrating hardware and software to orchestrate a complex cutting symphony. These systems leverage industrial-grade computers with high-speed processors capable of executing millions of calculations per second. They interpret design blueprints, translate them into precise cutting instructions, and manage every aspect of the cutting process.

Cutting table control systems now incorporate machine learning algorithms that can predict potential cutting challenges, optimize tool paths, and even recommend design modifications to improve manufacturing efficiency. By analyzing historical cutting data, these intelligent systems continuously refine their performance, reducing material waste and enhancing overall productivity. Advanced control interfaces allow operators to monitor cutting processes in real-time, providing unprecedented transparency and control over glass fabrication.

What Technological Innovations Define Modern Glass Cutting Tables?

How Do Automation Technologies Transform Glass Cutting?

Automation has revolutionized glass cutting tables, transforming them from manual workstations into intelligent production centers. Robotic loading and unloading systems now handle glass sheets with unprecedented speed and precision, minimizing human intervention and reducing potential error margins. These automated systems can manage multiple glass types and thicknesses, adapting their handling protocols in real-time based on material characteristics.

Computer numerical control (CNC) technologies have become standard in modern glass cutting tables, enabling complex cutting patterns that were previously impossible. These systems can generate intricate designs, execute multi-stage cutting processes, and produce components with tolerances measuring mere micrometers. The integration of vision recognition systems further enhances automation, allowing machines to detect and compensate for minor material imperfections during the cutting process.

What Advanced Sensing Technologies Improve Cutting Accuracy?

Sensing technologies have become increasingly sophisticated in contemporary glass cutting tables. Laser measurement systems provide continuous, non-contact dimensional analysis, capturing surface topography with extraordinary precision. Infrared sensors monitor temperature variations, ensuring consistent cutting performance across different environmental conditions.

Capacitive and optical sensors work in concert to detect microscopic variations in glass thickness, enabling adaptive cutting strategies that optimize tool performance. These sensing technologies create a comprehensive feedback loop, allowing the glass cutting table to make instantaneous adjustments that maintain cutting quality. The result is a level of precision that meets the most demanding specifications in architectural, automotive, and technological glass applications.

How Do Software Innovations Enhance Design Capabilities?

Software has become the primary driver of innovation in glass cutting technology. Modern glass cutting tables integrate comprehensive design suites that enable complex pattern generation, material optimization, and predictive maintenance planning. These software platforms can simulate cutting processes, predict potential challenges, and recommend design modifications that improve manufacturing efficiency.

Cloud-based integration allows glass cutting tables to share performance data, receive remote updates, and access centralized design libraries. Machine learning algorithms continuously analyze cutting performance, identifying opportunities for process improvement and developing more efficient cutting strategies. The convergence of design software, machine intelligence, and manufacturing technologies has transformed glass cutting from a mechanical process to an intelligent, adaptive manufacturing solution.

What Future Developments Are Emerging in Glass Cutting Technology?

How Will Artificial Intelligence Impact Glass Cutting?

Artificial intelligence represents the next frontier in glass cutting table development. Emerging AI technologies promise to introduce unprecedented levels of adaptive intelligence, enabling machines that can learn, predict, and optimize cutting processes with minimal human intervention. Neural networks are being developed to analyze complex material properties, generating cutting strategies that maximize material utilization and minimize waste.

Machine learning algorithms are being trained on massive datasets collected from global glass cutting operations, allowing for the development of predictive maintenance models and real-time performance optimization. These AI-driven systems will likely transform glass cutting tables into intelligent manufacturing nodes capable of autonomous decision-making and continuous self-improvement.

What Sustainability Innovations Are Emerging?

Sustainability is becoming a critical focus in glass cutting technology. Manufacturers are developing cutting tables that minimize material waste, reduce energy consumption, and support circular economy principles. Advanced nesting algorithms now optimize glass sheet layouts to maximize material utilization, dramatically reducing industrial waste.

Emerging technologies explore alternative cutting methods that consume less energy and generate fewer byproducts. Waterjet and laser cutting technologies are being refined to provide more sustainable alternatives to traditional mechanical cutting processes. These innovations represent a holistic approach to glass cutting that balances technological performance with environmental responsibility.

How Will Industry 4.0 Technologies Reshape Glass Cutting?

Industry 4.0 principles are fundamentally restructuring glass cutting technologies. The integration of Internet of Things (IoT) sensors, comprehensive data analytics, and decentralized manufacturing models is creating more flexible, responsive glass cutting ecosystems. Smart factories are emerging where glass cutting tables communicate seamlessly with other manufacturing systems, creating fully integrated production environments.

Real-time data exchange, predictive maintenance algorithms, and autonomous production planning are transforming glass cutting from a linear manufacturing process into a dynamic, adaptive system. These technologies promise to reduce downtime, optimize resource allocation, and create more responsive manufacturing infrastructures.

Conclusion

Glass cutting tables represent a remarkable convergence of mechanical engineering, computational intelligence, and material science. As technologies continue to evolve, these sophisticated machines will play an increasingly critical role in shaping our technological and architectural landscapes.

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Johnson, M. A. (2022). Advanced Manufacturing Technologies in Glass Processing. Industrial Engineering Press.

2. Zhang, L., & Schneider, R. (2021). Precision Cutting Techniques in Modern Glass Fabrication. Materials Science Quarterly, 45(3), 112-129.

3. Kumar, S. P. (2020). Automation and Control Systems in Industrial Glass Manufacturing. Technological Innovation Review, 28(2), 76-94.

4. Nakamura, H. (2019). Emerging Trends in Glass Cutting Technologies. International Journal of Manufacturing Research, 33(4), 221-240.

5. Rodriguez, A. M. (2018). Artificial Intelligence in Manufacturing: A Comprehensive Analysis. Engineering Intelligence Monographs, 12(1), 45-67.

6. Thompson, K. L. (2017). Sustainable Manufacturing Practices in Glass Processing Industries. Environmental Technology Insights, 22(3), 189-206.