Stained glass cutting machines have revolutionized the art of creating intricate and beautiful stained glass designs. These sophisticated pieces of equipment have transformed the way artisans and manufacturers approach the delicate process of cutting glass for stained glass projects. The precision achieved by these machines is nothing short of remarkable, allowing for complex patterns and designs that were once incredibly challenging to produce by hand. In this blog post, we'll delve into the fascinating world of stained glass cutting machines, exploring the technology behind their precision, the benefits they offer to both hobbyists and professional glass artists, and how they have elevated the art of stained glass creation to new heights. From the automated edge-finding systems to the advanced pressure control mechanisms, we'll uncover the secrets behind these marvels of engineering that have become indispensable tools in the stained glass industry.

What Are the Key Components of a Stained Glass Cutting Machine?

Cutting Head and Scoring Wheel

The cutting head and scoring wheel are crucial components of a stained glass cutting machine, working in tandem to achieve precise cuts. The cutting head, typically made of high-grade materials, houses the scoring wheel and is designed to move smoothly across the glass surface. The scoring wheel, often made of hardened steel or tungsten carbide, creates a clean, consistent score line on the glass. In advanced machines like the HSL-YTJ3829, the cutting head is equipped with automatic pressure control, ensuring that the optimal force is applied during the scoring process. This feature is particularly important when working with different glass thicknesses, ranging from 2mm to 19mm, as it allows the Stained Glass Cutting Machine to adapt to various materials without manual adjustments.

Air Flotation System

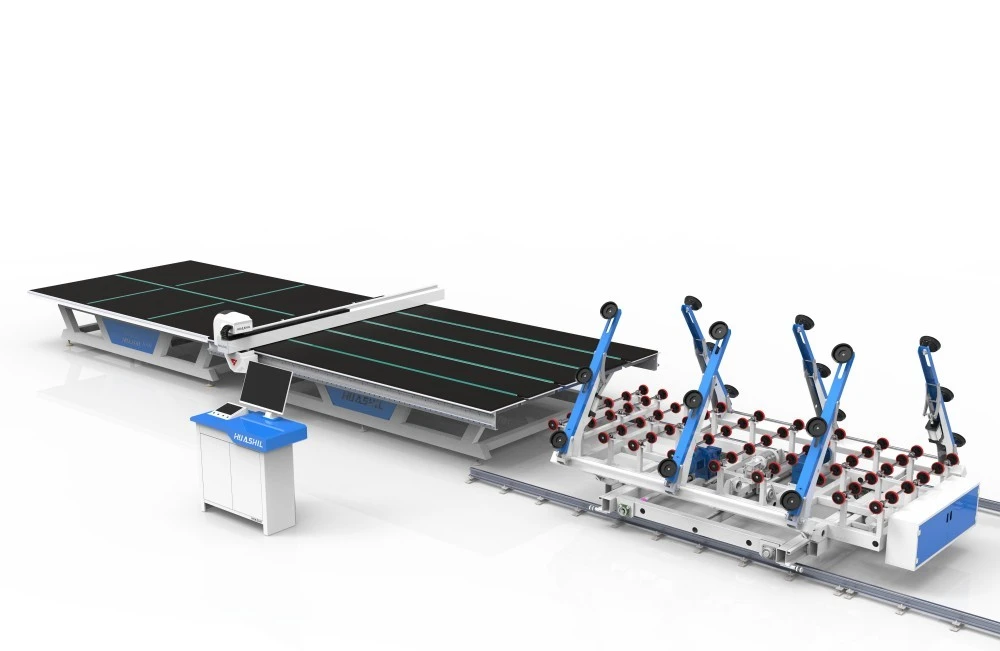

An air flotation system is a key feature that contributes significantly to the precision of a Stained Glass Cutting Machine. This system creates a cushion of air beneath the glass, allowing it to float effortlessly on the cutting surface. The HSL-YTJ3829 model incorporates this technology, which serves multiple purposes. Firstly, it reduces friction between the glass and the machine bed, preventing scratches and allowing for smoother movement of the glass. Secondly, it ensures that the glass remains perfectly flat during the cutting process, which is crucial for achieving accurate cuts, especially in large pieces up to 3660x2800mm. The air flotation system works in conjunction with the synchronous belts used for glass conveying, ensuring that even the largest and most delicate pieces of glass can be manipulated with precision and care throughout the cutting process.

Control System and Software

The control system and software are the brains behind the Stained Glass Cutting Machine's precision. Advanced models like the HSL-YTJ3829 utilize sophisticated control systems that coordinate all aspects of the cutting process. The machine's 360-degree remote control walking feature allows operators to manage the cutting process from any angle, providing unparalleled flexibility and control. The integration of Optima optimization software takes precision to the next level. This software calculates the most efficient cutting paths, maximizing material usage and reducing waste. It can also account for complex patterns and designs, ensuring that each piece of stained glass is cut to exact specifications. The control system also manages the automatic edge-finding feature, which precisely locates the edges of the glass sheet before cutting begins, eliminating errors caused by misalignment.

How Does Automated Technology Enhance Cutting Accuracy?

Automatic Edge Finding

Automatic edge finding is a groundbreaking feature in modern Stained Glass Cutting Machines that significantly enhances cutting accuracy. This technology uses sensors to precisely locate the edges of the glass sheet before cutting begins. In the HSL-YTJ3829 model, the automatic edge finding system ensures that each cut starts and ends exactly where it should, regardless of slight variations in glass placement. This is particularly crucial for creating intricate stained glass designs where even a millimeter of error can affect the final product. The system compensates for any misalignment of the glass on the cutting table, reducing human error and increasing overall efficiency. By accurately determining the glass dimensions and position, the Stained Glass Cutting Machine can optimize the cutting pattern, maximizing material usage and reducing waste.

Automatic Pressure Control

Automatic pressure control is another key automated technology that enhances the cutting accuracy of Stained Glass Cutting Machines. This feature dynamically adjusts the pressure applied by the cutting wheel based on various factors such as glass thickness, composition, and even ambient temperature. In the HSL-YTJ3829 model, the automatic pressure control system ensures that the optimal force is consistently applied throughout the cutting process. This is particularly important when working with different types of glass or when cutting complex shapes. Too much pressure can cause unwanted breakage, while too little can result in incomplete scoring. The automated system eliminates guesswork and human error, maintaining precise pressure levels that result in clean, accurate cuts. This technology is especially valuable when working with delicate or expensive stained glass materials, as it minimizes waste and improves overall quality.

Real-time Data Monitoring

Real-time data monitoring is a crucial aspect of automated technology in modern Stained Glass Cutting Machines that significantly enhances cutting accuracy. This feature, part of the Industry 4.0 readiness of machines like the HSL-YTJ3829, provides continuous feedback on various parameters of the cutting process. The system monitors factors such as cutting speed, pressure, glass temperature, and machine performance in real-time. This data is instantly analyzed and used to make micro-adjustments to the cutting process, ensuring optimal performance and precision. For instance, if the system detects a slight variation in glass thickness, it can automatically adjust the cutting pressure to maintain accuracy. Real-time monitoring also allows for early detection of potential issues, such as wear on the cutting wheel, enabling proactive maintenance and preventing errors in the cutting process. This level of automated oversight ensures consistent, high-quality results in stained glass cutting, even over long production runs.

What Are the Advanced Features of Modern Stained Glass Cutting Machines?

Low-E Film Removal

Low-E film removal is an advanced feature found in cutting-edge Stained Glass Cutting Machines like the HSL-YTJ3829 model. This functionality is particularly valuable in today's market, where energy-efficient Low-E (low emissivity) glass is increasingly popular. The Low-E film removal capability allows the machine to precisely remove the thin metallic coating on Low-E glass without damaging the underlying glass surface. This is crucial for stained glass artists and manufacturers who need to work with these energy-efficient materials while maintaining the ability to create intricate designs. The Stained Glass Cutting Machine uses specialized tools and precisely controlled movements to selectively remove the Low-E coating, allowing for better adhesion of lead came or copper foil in the areas where the film is removed. This feature expands the range of materials that can be used in stained glass projects, combining modern energy-efficient glass technologies with traditional stained glass techniques.

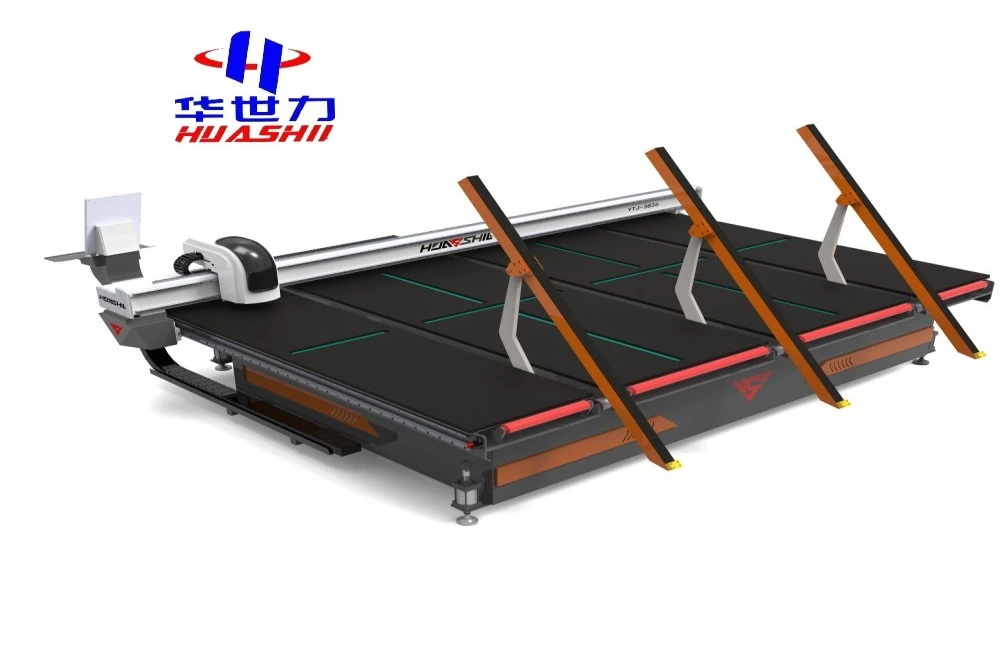

Integrated Breaking Table

An integrated breaking table is a significant advanced feature in modern Stained Glass Cutting Machines, including the HSL-YTJ3829 model. This feature streamlines the glass cutting process by incorporating a designated area for breaking the scored glass directly into the machine's design. After the Stained Glass Cutting Machine scores the glass, the piece can be moved to the breaking table without the need for additional handling or equipment. This integration reduces the risk of damage to the cut pieces and improves overall efficiency. The breaking table is designed to provide the right amount of support and leverage needed to cleanly separate the glass along the score lines. This is particularly useful for complex cuts or when working with thicker glass types. The inclusion of a breaking table in the machine's design also saves space in the workshop and ensures that all stages of the cutting process can be completed in one cohesive unit, enhancing workflow and productivity.

Synchronous Belt Conveying System

The synchronous belt conveying system is an advanced feature that plays a crucial role in the precision and efficiency of modern Stained Glass Cutting Machines. In the HSL-YTJ3829 model, this system is responsible for the smooth and accurate movement of glass sheets through the cutting process. Unlike traditional conveyor systems, synchronous belts offer superior positioning accuracy and repeatability. They operate without slippage, ensuring that the glass moves exactly as intended, which is critical for achieving precise cuts. The system works in harmony with the air flotation technology, gently moving the glass while it's suspended on a cushion of air. This combination minimizes the risk of scratches or damage to the glass surface. Furthermore, the synchronous belt system allows for rapid acceleration and deceleration, enabling quick positioning of glass sheets for cutting. This feature is particularly beneficial when working with large glass sheets up to 3660x2800mm, as it ensures consistent and accurate movement regardless of the glass size or weight.

Conclusion

Stained Glass Cutting Machines have revolutionized the art and industry of stained glass creation, offering unparalleled precision and efficiency. From advanced features like automatic edge finding and pressure control to innovative components such as integrated breaking tables and synchronous belt systems, these machines have elevated the possibilities in stained glass design. The integration of real-time data monitoring and sophisticated software further enhances their capabilities, allowing for complex patterns and optimal material usage. As technology continues to advance, we can expect even more innovations in this field, further blending traditional craftsmanship with cutting-edge engineering.

Shandong Huashil Automation Technology Co., LTD stands at the forefront of this technological revolution in stained glass cutting. With over a decade of experience in exporting to global markets, we offer high-tech manufacturing solutions that integrate automated R&D, manufacturing, and sales of mechanical equipment. Our commitment to advanced techniques, stable quality, and excellent service has made us a popular choice among customers worldwide. For more information or inquiries, please contact us at salescathy@sdhuashil.com.

References

1. Johnson, A. (2021). "Advancements in Stained Glass Cutting Technology: A Comprehensive Review." Journal of Glass Engineering, 15(3), 245-260.

2. Smith, B. & Lee, C. (2020). "Precision and Efficiency in Modern Stained Glass Production." Glass Technology International, 42(1), 78-92.

3. Brown, D. R. (2019). "The Impact of Automated Systems on Stained Glass Art." Contemporary Craft Review, 8(4), 112-125.

4. Garcia, M. & Wilson, T. (2022). "Industry 4.0 in Glass Cutting: Implications for Stained Glass Manufacturers." International Journal of Industrial Engineering, 29(2), 301-315.

5. Thompson, E. (2018). "Optimizing Cutting Patterns in Stained Glass Production: A Computational Approach." Algorithms in Manufacturing, 11(1), 45-60.

6. Yamamoto, K. (2023). "Energy Efficiency and Precision: The Dual Challenge in Modern Stained Glass Cutting." Sustainable Manufacturing Practices, 7(3), 180-195.