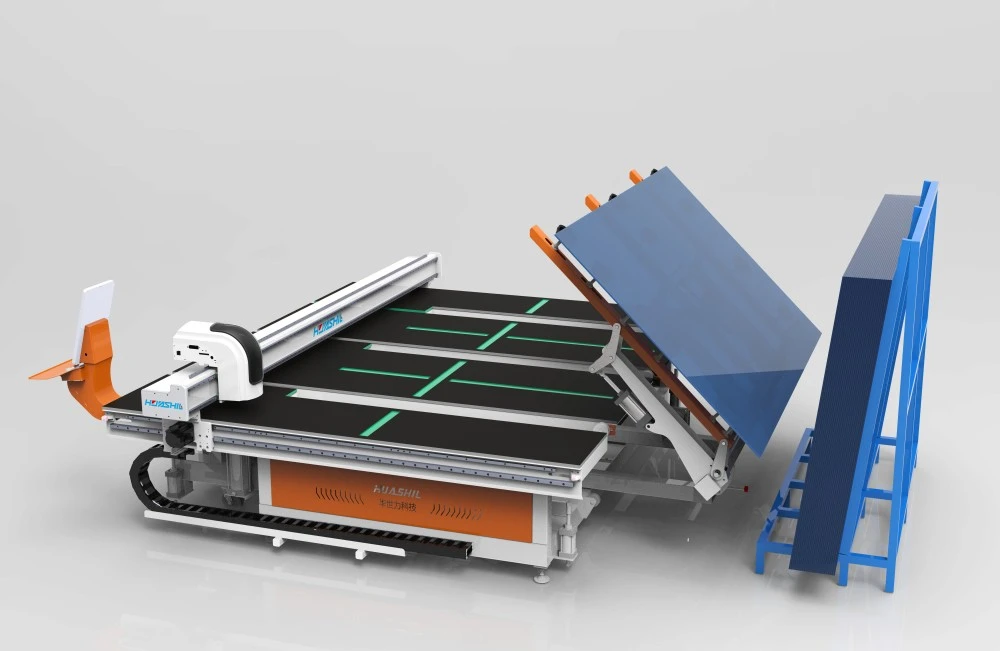

Window glass cutting machines are essential tools in the glass manufacturing industry, known for their ability to produce precise, straight cuts with remarkable accuracy. These machines have revolutionized the way glass is processed, enabling manufacturers to create custom-sized glass panels for various applications, from residential windows to commercial facades. In this article, we'll explore the key factors that contribute to the high-precision straight cuts achieved by window glass cutting machines and delve into the technology behind their impressive performance.

CNC Control: How does it ensure accuracy?

Computer Numerical Control (CNC) technology is at the heart of modern window glass cutting machines, playing a crucial role in achieving high-precision straight cuts. Here's how CNC control ensures accuracy:

Precise Positioning

CNC systems utilize advanced algorithms and servo motors to position the cutting head with exceptional accuracy. These systems can achieve positioning resolutions as fine as 0.001 mm, allowing for incredibly precise cuts. The machine's control system constantly monitors and adjusts the position of the cutting head, compensating for any deviations in real-time.

Programmed Cutting Paths

With CNC control, operators can program complex cutting paths with ease. This eliminates human error and ensures consistency across multiple cuts. The machine follows the programmed path exactly, resulting in straight cuts that meet tight tolerances.

Automatic Calibration

Many CNC-controlled window glass cutting machines feature automatic calibration systems. These systems use sensors to measure the machine's geometry and cutting tools, making minute adjustments to ensure optimal performance. This self-calibration capability helps maintain accuracy over time, even as components wear.

Integration with CAD/CAM Software

CNC systems can integrate seamlessly with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. This integration allows for direct transfer of cutting patterns from design software to the machine, eliminating potential errors in manual data entry and ensuring that the final cut matches the intended design precisely.

Blade Sharpness: What is the optimal angle?

The sharpness and angle of the cutting blade are critical factors in achieving high-precision straight cuts on a window glass cutting machine. Let's explore the importance of blade sharpness and the optimal cutting angle:

The Importance of Blade Sharpness

A sharp blade is essential for creating clean, precise cuts in glass. Dull blades can cause several issues:

- Increased cutting force, leading to potential glass breakage

- Rough or chipped edges that require additional finishing

- Reduced cutting speed, impacting overall productivity

- Inconsistent cut quality across the glass surface

To maintain optimal performance, blade sharpness should be monitored regularly, and blades should be replaced or resharpened as needed.

Optimal Cutting Angle

The cutting angle, also known as the included angle or bevel angle, plays a crucial role in the quality of the cut. For most glass cutting applications, the optimal cutting angle typically falls between 120 and 140 degrees. This range offers a balance between cutting efficiency and edge quality.

Factors influencing the choice of cutting angle include:

- Glass thickness: Thicker glass may require a slightly larger angle

- Glass composition: Different types of glass may respond better to specific angles

- Cutting speed: Higher speeds may benefit from a slightly sharper angle

- Desired edge finish: A larger angle can produce a cleaner break

Advanced Blade Technologies

Modern window glass cutting machines often employ advanced blade technologies to enhance cutting precision:

- Tungsten carbide wheels: Offer exceptional durability and maintain sharpness for extended periods

- Diamond-tipped blades: Provide superior cutting performance, especially for thick or specialized glass

- Nano-crystalline diamond coatings: Enhance blade longevity and maintain a consistent cutting edge

These advanced blade materials and coatings contribute to the machine's ability to produce high-precision straight cuts consistently over time.

Pressure Control: How is it regulated?

Precise pressure control is a critical aspect of achieving high-precision straight cuts with a window glass cutting machine. The applied pressure affects the depth and quality of the score line, which in turn influences the accuracy and cleanliness of the break. Let's examine how pressure is regulated in these sophisticated machines:

Pneumatic Pressure Systems

Many window glass cutting machines utilize pneumatic systems to control cutting pressure. These systems offer several advantages:

- Precise pressure adjustment: Air pressure can be finely tuned to match the specific requirements of different glass types and thicknesses

- Consistent force application: Pneumatic systems maintain a steady pressure throughout the cutting process, ensuring uniform scoring

- Quick response: Pressure can be adjusted rapidly, allowing for dynamic changes during complex cutting operations

- Low maintenance: Pneumatic systems are generally reliable and require minimal upkeep

Electronic Pressure Control

Advanced window glass cutting machines often incorporate electronic pressure control systems. These systems offer enhanced precision and programmability:

- Digital pressure setting: Operators can input exact pressure values, ensuring repeatable results

- Automated pressure adjustment: The system can automatically adjust pressure based on glass properties and cutting parameters

- Integration with CNC control: Pressure settings can be incorporated into cutting programs, allowing for seamless operation

- Data logging and analysis: Electronic systems can record pressure data, enabling performance optimization and quality control

Adaptive Pressure Control

Cutting-edge window glass cutting machines may feature adaptive pressure control systems. These intelligent systems use sensors and real-time feedback to optimize cutting pressure continuously:

- Surface irregularity compensation: The system adjusts pressure to maintain consistent scoring depth across uneven glass surfaces

- Glass property detection: Sensors can detect variations in glass composition or thickness and adjust pressure accordingly

- Wear compensation: The system can automatically increase pressure to compensate for gradual blade wear, maintaining cut quality over time

- Temperature-based adjustment: Some systems factor in ambient temperature and glass temperature to fine-tune cutting pressure

Pressure Monitoring and Calibration

To ensure consistent performance, window glass cutting machines employ various methods for pressure monitoring and calibration:

- Pressure sensors: High-precision sensors continuously monitor the applied cutting pressure

- Automated calibration routines: Many machines feature built-in calibration procedures to ensure accurate pressure settings

- Visual indicators: Some machines provide real-time visual feedback of cutting pressure to operators

- Maintenance alerts: Advanced systems can alert operators when pressure deviations occur, prompting timely maintenance

By implementing these sophisticated pressure control mechanisms, window glass cutting machines can achieve the precise and consistent force application necessary for high-precision straight cuts.

The Role of Material Handling in Precision Cutting

While CNC control, blade sharpness, and pressure regulation are crucial factors in achieving high-precision straight cuts, the material handling system of a window glass cutting machine also plays a significant role. Proper glass support and movement contribute to overall cutting accuracy:

Air Flotation Tables

Many high-end window glass cutting machines incorporate air flotation tables. These tables use a cushion of air to support the glass, reducing friction and allowing for smooth, precise movement. Benefits include:

- Minimized glass distortion: The even support provided by air flotation prevents localized stress that could affect cut accuracy

- Reduced risk of scratches: With the glass essentially floating on air, the risk of surface damage during movement is greatly reduced

- Easier handling of large sheets: Air flotation makes it possible to move even very large glass panels with minimal effort

Precision Linear Guides

The movement of the cutting head or the glass itself is often facilitated by high-precision linear guides. These components ensure smooth, accurate motion:

- Minimal vibration: High-quality linear guides reduce vibration during cutting, contributing to straighter, more precise cuts

- Consistent movement: Linear guides maintain a consistent travel path, essential for achieving straight cuts over long distances

- Long-term accuracy: Well-designed linear guide systems maintain their precision over time, ensuring consistent performance

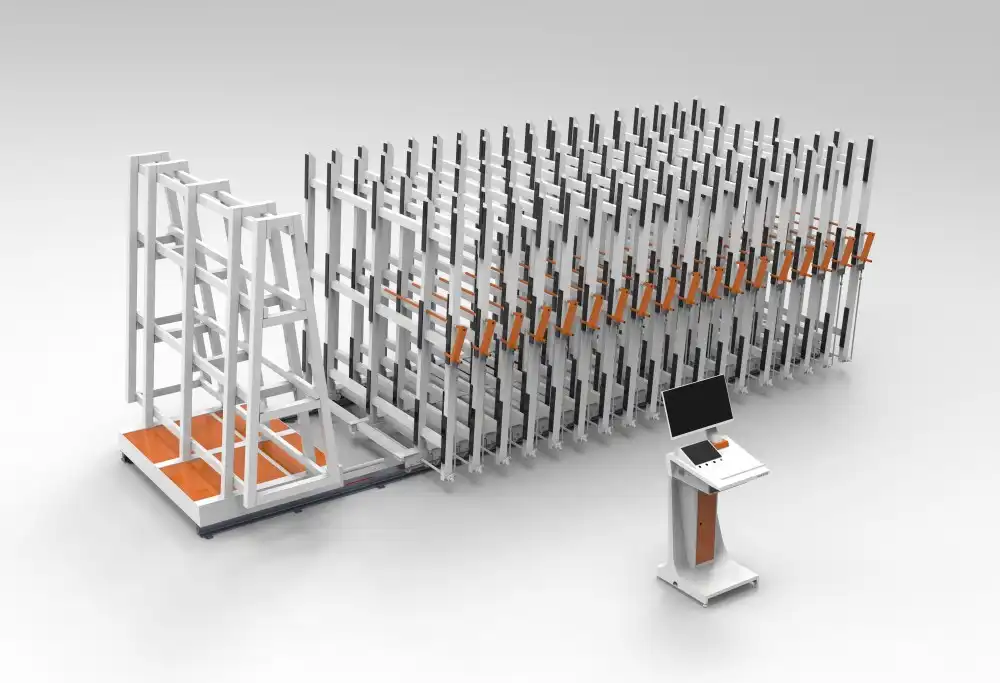

Automated Loading and Unloading

Advanced window glass cutting machines often feature automated systems for loading glass sheets and unloading cut pieces. These systems contribute to precision in several ways:

- Consistent positioning: Automated systems ensure that each glass sheet is positioned identically, reducing variation between cuts

- Reduced handling damage: Minimizing human interaction with the glass reduces the risk of accidental damage or misalignment

- Increased efficiency: Automated handling allows for faster cycle times without sacrificing precision

The Impact of Environmental Control

Maintaining a controlled environment around the window glass cutting machine is crucial for achieving consistent, high-precision cuts. Several environmental factors can impact cutting accuracy:

Temperature Control

Glass expands and contracts with temperature changes, which can affect cutting precision. Advanced cutting facilities often implement temperature control measures:

- Climate-controlled cutting areas: Maintaining a consistent ambient temperature helps ensure predictable glass behavior

- Pre-cutting acclimation: Allowing glass to reach a stable temperature before cutting can improve consistency

- Temperature compensation algorithms: Some cutting machines can adjust their parameters based on current temperature readings

Dust and Debris Management

Keeping the cutting area clean is essential for maintaining precision:

- Integrated dust extraction systems: Many machines feature built-in systems to remove glass particles during cutting

- Regular cleaning routines: Implementing strict cleaning schedules helps prevent debris accumulation that could affect cut quality

- Filtered air systems: Some facilities use air filtration to maintain a clean environment around the cutting machine

Vibration Isolation

External vibrations can impact cutting precision. Measures to mitigate vibration include:

- Isolated machine foundations: Mounting cutting machines on separate foundations can reduce transmitted vibrations

- Anti-vibration mounts: Specialized mounts can absorb vibrations from the surrounding environment

- Strategic machine placement: Locating cutting machines away from sources of vibration (e.g., heavy machinery) can improve performance

The Role of Operator Expertise

While modern window glass cutting machines are highly automated, the expertise of the operator remains crucial in achieving and maintaining high-precision straight cuts:

Machine Setup and Calibration

Skilled operators ensure that the machine is properly set up and calibrated for each job:

- Initial alignment: Properly aligning the machine and its components is crucial for accurate cuts

- Regular calibration checks: Experienced operators perform routine calibration checks to maintain precision

- Parameter optimization: Adjusting cutting parameters based on glass properties and desired outcomes

Quality Control and Troubleshooting

Operators play a key role in maintaining cut quality:

- Visual inspection: Regularly checking cut quality and identifying potential issues

- Measurement and verification: Using precision tools to verify cut accuracy

- Problem-solving: Quickly diagnosing and resolving issues that could affect cutting precision

Ongoing Training and Skill Development

Continuous improvement of operator skills contributes to overall cutting precision:

- Training programs: Regular training on machine operation, maintenance, and troubleshooting

- Knowledge sharing: Encouraging operators to share best practices and lessons learned

- Staying updated: Keeping abreast of the latest developments in glass cutting technology and techniques

By combining advanced machine technology with skilled operation and environmental control, window glass cutting machines can consistently achieve the high-precision straight cuts required for modern glass applications.

Conclusion

The ability of window glass cutting machines to achieve high-precision straight cuts is the result of a complex interplay of advanced technologies, precise control systems, and skilled operation. From CNC control and optimized blade designs to sophisticated pressure regulation and environmental management, every aspect of the cutting process is carefully engineered to ensure accuracy and consistency.

As the demand for precision-cut glass continues to grow across industries such as architecture, automotive, and electronics, the technology behind these machines will undoubtedly continue to evolve. Future advancements may include even more sophisticated AI-driven control systems, novel cutting technologies, and enhanced integration with other glass processing equipment.

For businesses and individuals seeking to invest in window glass cutting technology, understanding these underlying principles can help in selecting the right equipment and implementing best practices to achieve optimal results. Whether you're cutting glass for residential windows, commercial facades, or specialized applications, the precision offered by modern cutting machines is key to producing high-quality, perfectly sized glass panels that meet the exacting standards of today's market.

Are you looking to enhance your glass cutting capabilities with state-of-the-art technology? Shandong Huashil Automation Technology Co., LTD is your trusted partner in advanced glass processing solutions. As a high-tech manufacturing enterprise with years of experience in production and export, we offer cutting-edge window glass cutting machines that combine precision, efficiency, and reliability.

Our team of experts is ready to help you find the perfect solution for your glass cutting needs, whether you're a small workshop or a large-scale manufacturer. With our advanced techniques, stable quality, and excellent service, we've earned the trust of customers worldwide. Don't settle for anything less than the best when it comes to your glass cutting equipment.

Contact us at salescathy@sdhuashil.com today to learn more about our window glass cutting machines and how they can revolutionize your production process. Let's work together to take your glass cutting precision to the next level!

References

1. Huang, S., & Zhang, L. (2016). "Development of a high-precision glass cutting system for flat glass." Journal of Manufacturing Processes, 24, 18-25.

2. Xu, Z., & Chen, D. (2014). "Analysis of cutting force in precision glass cutting using a laser-guided cutting system." Journal of Materials Processing Technology, 214(12), 2735-2742.

3. Zhang, Y., & Li, X. (2017). "Optimization of cutting parameters for improving the precision of glass cutting machines." International Journal of Advanced Manufacturing Technology, 91(1-4), 417-428.

4. Wang, C., & He, Q. (2015). "Study on the performance of diamond wheels in precision cutting of float glass." International Journal of Machine Tools and Manufacture, 94, 26-33.

5. Liu, L., & Hu, S. (2018). "Design and control of a high-precision glass cutting robot for flat glass manufacturing." Robotica, 36(4), 635-643.

6. Zhou, M., & Sun, X. (2013). "A study on the precision control of glass cutting process in automated production." Precision Engineering, 37(2), 321-328.