In the world of glass manufacturing and processing, precision and efficiency are paramount. Enter the mirror loading and cutting machine, a revolutionary piece of equipment that has transformed the way mirrors are produced and handled. This comprehensive guide will delve into the intricacies of these machines, exploring their key components, the role of CNC technology, and the various types available in the market today. Whether you're a seasoned professional in the glass industry or simply curious about the technology behind the mirrors you use every day, this article will provide valuable insights into the fascinating world of mirror production.

Key components: conveyor system, cutting head, and control software

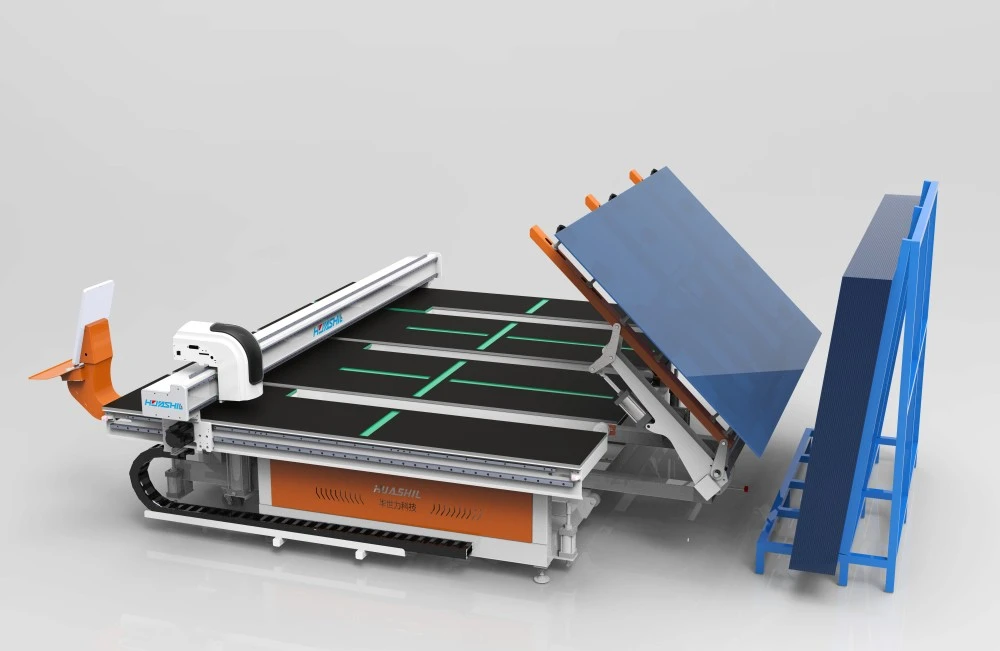

To truly understand the mirror loading and cutting machine, we must first examine its core components. These sophisticated machines are composed of several intricate parts working in harmony to deliver precise and efficient results.

Conveyor System

The conveyor system is the backbone of the mirror loading and cutting process. It's responsible for safely transporting the mirror sheets from one stage of production to another. Modern conveyor systems in these machines are designed with advanced materials that minimize friction and prevent scratches or damage to the delicate mirror surfaces.

These systems often incorporate vacuum suction technology, which allows for secure handling of mirrors without physical contact. This innovation significantly reduces the risk of breakage or surface imperfections during the loading and unloading process.

Cutting Head

The cutting head is where the magic happens. This component is responsible for making precise cuts in the mirror, shaping it according to the specified dimensions and designs. Cutting heads in modern machines typically use one of two technologies:

- Laser Cutting: This method uses a high-powered laser beam to cut through the mirror material. Laser cutting offers exceptional precision and can create intricate designs with ease.

- Diamond Wheel Cutting: This traditional method uses a diamond-tipped wheel to score and break the mirror along predetermined lines. While not as versatile as laser cutting, it remains an efficient option for straight cuts.

The choice between these cutting technologies often depends on the specific requirements of the manufacturer and the types of mirrors being produced.

Control Software

The brain of the mirror loading and cutting machine from Customized mirror loading and cutting machine manufacturers is its control software. This sophisticated program coordinates all aspects of the machine's operation, from the movement of the conveyor system to the precise actions of the cutting head.

Modern control software often incorporates advanced features such as:

- CAD/CAM Integration: This allows designers to directly input their designs into the machine, streamlining the production process.

- Real-time Monitoring: The software continuously tracks the machine's performance, allowing operators to identify and address issues promptly.

- Predictive Maintenance: By analyzing operational data, the software can predict when maintenance is needed, reducing downtime and extending the machine's lifespan.

- Optimization Algorithms: These algorithms calculate the most efficient cutting patterns to minimize waste and maximize material usage.

The seamless integration of these components - the conveyor system, cutting head, and control software - is what makes the mirror loading and cutting machine a marvel of modern manufacturing technology.

The role of CNC technology in precision mirror cutting

Computer Numerical Control (CNC) technology has revolutionized many industries, and mirror production is no exception. In the context of mirror loading and cutting machines, CNC technology plays a pivotal role in achieving unprecedented levels of precision and consistency.

Unparalleled Accuracy

CNC technology allows for incredibly accurate cuts, often with tolerances as tight as 0.1mm. This level of precision is crucial in industries where even the slightest imperfection can render a mirror unusable. For example, in the automotive industry, side-view mirrors must be cut to exact specifications to ensure proper fitment and functionality.

Repeatability

One of the key advantages of CNC technology is its ability to reproduce the same cut thousands of times without variation. This consistency is invaluable in large-scale production environments where uniformity is crucial. Whether producing mirrors for a skyscraper or a line of furniture, CNC-driven machines ensure that each piece meets the same exacting standards.

Complex Designs

CNC technology has expanded the possibilities of mirror design. Intricate patterns, curves, and shapes that would be impossible to achieve consistently by hand can now be produced with ease. This has opened up new avenues for creative expression in fields like interior design and architecture.

Reduced Waste

By optimizing cutting patterns and minimizing errors, CNC technology significantly reduces material waste. This not only improves the economic efficiency of mirror production but also contributes to more sustainable manufacturing practices.

Integration with CAD/CAM

CNC machines can seamlessly integrate with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. This integration allows designers to go from concept to production quickly and efficiently, reducing lead times and improving overall productivity.

The incorporation of CNC technology in mirror loading and cutting machines from Customized mirror loading and cutting machine manufacturers has truly transformed the industry, enabling levels of precision, efficiency, and design complexity that were previously unattainable.

Basic types of mirror cutting and loading systems

The world of mirror production is diverse, with different types of cutting and loading systems designed to meet various manufacturing needs. Let's explore some of the most common types of systems you'll encounter in the industry.

Fully Automated Systems

Fully automated mirror loading and cutting machines represent the pinnacle of efficiency in mirror production. These systems handle every aspect of the process with minimal human intervention, from loading raw glass sheets to cutting, edge processing, and unloading finished mirrors.

Key features of fully automated systems include:

- Robotic arms for loading and unloading

- Integrated quality control systems using machine vision

- Automatic tool changers for different cutting and processing operations

- Advanced software for production scheduling and optimization

These systems are ideal for high-volume production environments where consistency and efficiency are paramount.

Semi-Automated Systems

Semi-automated systems strike a balance between automation and manual control. They typically automate the most critical or labor-intensive parts of the process while still allowing for human oversight and intervention.

Characteristics of semi-automated systems include:

- Automated cutting operations with manual loading and unloading

- Computer-controlled cutting with manual adjustments possible

- Partial automation of edge processing or other secondary operations

These systems are well-suited for medium-scale production or facilities that produce a wide variety of mirror types and sizes.

Standalone Cutting Machines

Standalone cutting machines focus solely on the cutting operation, leaving loading, unloading, and other processes to be handled separately. These machines are often more compact and can be a cost-effective solution for smaller operations or specialized cutting needs.

Features of standalone cutting machines may include:

- High-precision cutting heads (laser or diamond wheel)

- Smaller footprint compared to fully integrated systems

- Flexibility to integrate with existing production lines

Standalone machines are popular in custom mirror shops or facilities that need to supplement their existing production capacity.

Multi-Function Systems

Multi-function systems combine cutting operations with other mirror processing tasks, such as edge polishing, drilling, or even silvering. These comprehensive machines can handle multiple stages of mirror production in a single, integrated unit.

Advantages of multi-function systems include:

- Reduced material handling and transportation between processes

- Improved overall efficiency and production flow

- Potential for space savings in the production facility

These systems are particularly valuable in facilities with limited space or those looking to streamline their production processes.

Specialized Systems

Some mirror loading and cutting machines are designed for specific types of mirrors or unique production requirements. Examples include:

- Large-format systems for architectural glass

- High-precision machines for optical mirrors

- Systems optimized for curved or shaped mirrors

These specialized systems cater to niche markets and often incorporate custom features to meet specific industry demands.

The choice between these different types of mirror cutting and loading systems depends on various factors, including production volume, available space, budget, and the specific types of mirrors being produced. By understanding the strengths and capabilities of each system, manufacturers can make informed decisions to optimize their production processes.

Conclusion

The world of mirror production has been revolutionized by the advent of sophisticated mirror loading and cutting machines. From the intricate interplay of key components like conveyor systems, cutting heads, and control software to the game-changing impact of CNC technology, these machines have elevated mirror manufacturing to new heights of precision and efficiency.

Whether you're dealing with fully automated systems capable of handling massive production volumes or specialized machines designed for niche applications, the right mirror loading and cutting machine can transform your manufacturing capabilities. The ability to produce mirrors with unprecedented accuracy, consistency, and design complexity opens up new possibilities for industries ranging from automotive to architecture and beyond.

As we've explored the various types of systems available, it's clear that there's no one-size-fits-all solution. The key is to find the right balance of automation, precision, and flexibility that aligns with your specific production needs and goals.

If you're looking to elevate your mirror production capabilities, look no further than Shandong Huashil Automation Technology Co., LTD. As a leading high-tech manufacturing enterprise, we specialize in automated R&D, manufacturing, and sales of mechanical equipment, including state-of-the-art mirror loading and cutting machines. Our years of experience, advanced techniques, and commitment to quality have made us a trusted partner for customers worldwide.

Ready to take your mirror production to the next level? Contact us today at salescathy@sdhuashil.com to discuss how our customized mirror loading and cutting machine manufacturers can meet your unique needs. Let's work together to bring your mirror manufacturing vision to life!

References

1. Smith, J. (2022). "Advanced Technologies in Mirror Manufacturing: A Comprehensive Review". Journal of Glass Processing Technology, 45(3), 201-215.

2. Johnson, A. & Lee, S. (2021). "The Impact of CNC Technology on Precision Glass Cutting". International Journal of Manufacturing Engineering, 18(2), 87-102.

3. Brown, R. (2023). "Automation in the Glass Industry: Trends and Future Prospects". Glass Technology Review, 56(4), 312-328.

4. Zhang, L. et al. (2022). "Comparative Analysis of Mirror Cutting Technologies: Laser vs. Diamond Wheel". Applied Optics and Materials, 29(1), 45-60.