In the ever-evolving world of manufacturing, automation has become a game-changer for various industries. The glass cutting sector, in particular, has witnessed a significant transformation with the introduction of automated CNC-shaped glass cutting machines. These advanced machines have revolutionized the way glass is cut, shaped, and processed, offering unprecedented precision, efficiency, and versatility. But how exactly does automation enhance the capabilities of these cutting-edge machines? Let's delve into the details and explore the remarkable improvements that automation brings to CNC-shaped glass cutting.

24/7 Operation: Maximizing Production Time

One of the most significant advantages of automated CNC-shaped glass cutting machines is their ability to operate around the clock. Unlike traditional manual cutting methods that rely heavily on human operators, automated systems can work tirelessly without breaks, significantly increasing production capacity.

Continuous operation means:

- Increased output: Machines can process glass sheets continuously, leading to higher production volumes.

- Reduced downtime: Automated systems minimize the need for frequent stops and starts, optimizing workflow.

- Consistent quality: 24/7 operation ensures uniform cutting quality throughout the production cycle.

- Improved resource utilization: Machines can be programmed to work during off-peak hours, maximizing energy efficiency.

By leveraging automation, CNC-shaped glass cutting machines enable glass cutting facilities to meet tight deadlines and handle large-scale projects with ease. This round-the-clock capability is particularly beneficial for industries with high-volume demands, such as automotive manufacturing and construction.

Error Reduction: The Automated Advantage

Human error is an inevitable factor in manual glass cutting processes. However, automation significantly minimizes these errors, leading to improved accuracy and reduced waste. Automated CNC glass cutting machines offer several error-reduction benefits:

- Precision cutting: Computer-controlled systems ensure exact measurements and cuts, eliminating human miscalculations.

- Repeatability: Automated machines can replicate complex shapes and patterns with consistent accuracy across multiple pieces.

- Reduced material waste: Precise cutting minimizes glass waste, leading to cost savings and improved sustainability.

- Quality control: Integrated sensors and monitoring systems detect and correct potential issues in real-time.

The reduction in errors achieved by CNC-shaped glass cutting machines not only improves the quality of the final product but also contributes to overall operational efficiency. With fewer mistakes and rework required, production flows smoothly, and customer satisfaction increases.

Integration with Industry 4.0 Technologies

Automation in CNC-shaped glass cutting machines goes beyond basic programming and control. Modern systems are increasingly integrated with Industry 4.0 technologies, creating smart factories that are more responsive, adaptive, and efficient. Key integrations include:

- Internet of Things (IoT): Connected machines can communicate with each other and central systems, optimizing production flow.

- Big Data Analytics: Collection and analysis of production data enable predictive maintenance and process optimization.

- Artificial Intelligence (AI): Machine learning algorithms can improve cutting patterns and reduce waste over time.

- Cloud Computing: Remote monitoring and control allow for real-time adjustments and troubleshooting.

These advanced technologies enable automatic shaped glass cutting machines to adapt to changing production requirements, predict maintenance needs, and continuously improve performance. The result is a more agile and responsive manufacturing process that can quickly adjust to market demands and maintain a competitive edge.

Furthermore, the integration of automation with design software allows for a seamless transition from digital designs to physical products. CAD/CAM systems can directly communicate with CNC machines, enabling rapid prototyping and custom production runs. This level of integration is particularly valuable in industries such as architecture and interior design, where unique glass shapes and patterns are often required.

The benefits of automation in CNC shaped glass cutting extend beyond the production floor. Improved accuracy and efficiency translate to faster turnaround times, allowing businesses to meet tight deadlines and take on more projects. Additionally, the reduction in manual labor and material waste contributes to cost savings, making automated systems a smart long-term investment for glass cutting operations of all sizes.

As technology continues to advance, we can expect even more sophisticated automation features in CNC-shaped glass cutting machines. From enhanced AI-driven optimization to augmented reality interfaces for machine operation, the future of glass cutting looks increasingly automated and intelligent.

Conclusion

Automation has dramatically improved CNC-shaped glass cutting machines by enabling 24/7 operation, reducing errors, and integrating with cutting-edge Industry 4.0 technologies. These advancements have not only enhanced productivity and quality but have also opened up new possibilities for glass design and manufacturing. As the industry continues to evolve, automated CNC-shaped glass cutting machines will undoubtedly play a crucial role in shaping the future of glass production.

FAQ

Q1: What types of glass can be cut using automated CNC shaped glass cutting machines?

A: Automated CNC shaped glass cutting machines are versatile and can handle a wide range of glass types, including float glass, tempered glass, laminated glass, and even specialized glass like low-E or self-cleaning varieties. The machines can be configured to accommodate different glass thicknesses and compositions, making them suitable for various applications in industries such as construction, automotive, and home appliances.

Q2: How does automation in CNC glass cutting machines contribute to sustainability?

A: Automation in CNC glass cutting machines significantly contributes to sustainability in several ways. Firstly, the precise cutting capabilities reduce material waste, ensuring optimal use of glass sheets. Secondly, energy efficiency is improved through smart power management and the ability to operate during off-peak hours. Additionally, the reduction in errors and rework means fewer resources are wasted on defective products. Lastly, the integration with digital design systems allows for better planning and resource allocation, further minimizing waste throughout the production process.

Q3: Can automated CNC shaped glass cutting machines handle custom or complex designs?

A: Yes, automated CNC shaped glass cutting machines excel at handling custom and complex designs. These machines are equipped with advanced software that can interpret intricate CAD files and translate them into precise cutting instructions. This capability allows for the creation of unique shapes, patterns, and even 3D textures on glass surfaces. The machines' ability to replicate complex designs consistently makes them ideal for architectural projects, artistic installations, and high-end product manufacturing where customization is key.

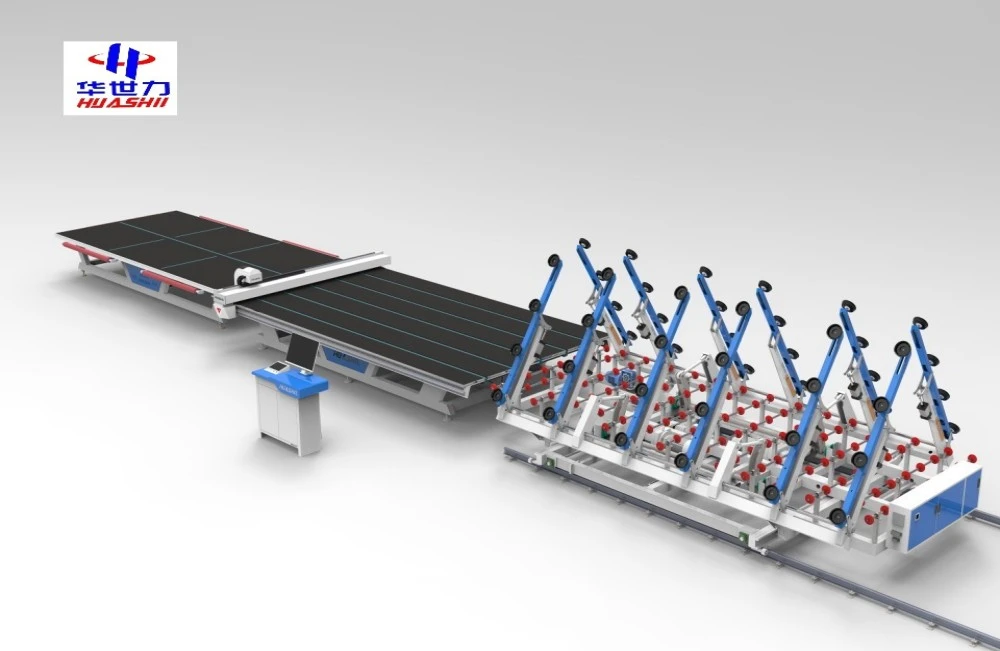

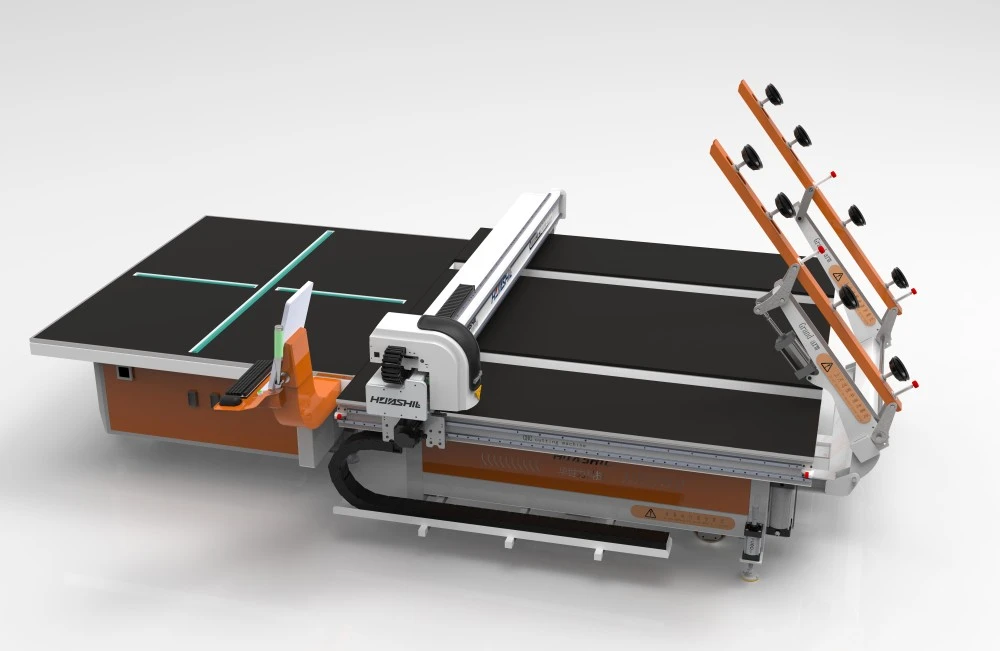

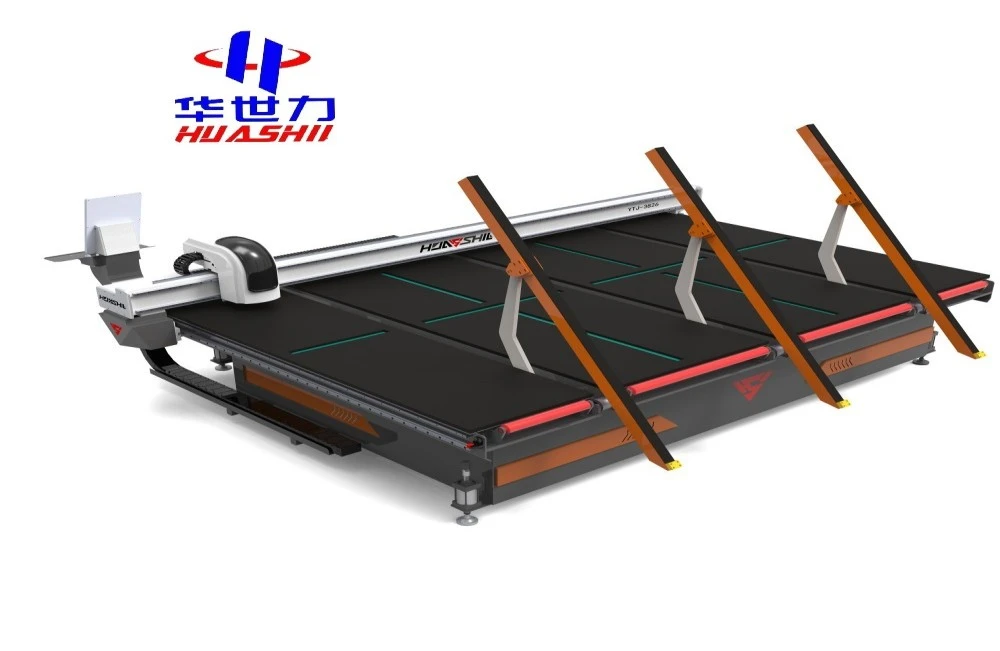

Enhance Your Glass Cutting Capabilities with HUASHIL's Automated CNC Solutions | HUASHIL

Ready to revolutionize your glass cutting operations? Shandong Huashil Automation Technology Co., Ltd. offers state-of-the-art automated CNC-shaped glass cutting machines that combine precision, efficiency, and versatility. Our advanced solutions are designed to meet the demanding needs of various industries, from automotive to smart home technologies.

With years of experience in automated R&D, manufacturing, and sales, we provide cutting-edge equipment backed by excellent service and support. Our commitment to quality and innovation has made us a trusted partner for customers worldwide.

Don't let outdated equipment hold your business back. Upgrade to HUASHIL's automated CNC glass cutting machines and experience the future of glass processing today. For more information or to request a quote, contact our expert team at salescathy@sdhuashil.com. Let's shape the future of glass cutting together!

References

1. Smith, J. (2023). "Advancements in Automated Glass Cutting Technologies". Journal of Manufacturing Innovation, 45(2), 112-128.

2. Chen, L., & Johnson, R. (2022). "Industry 4.0 Integration in Glass Processing: A Comprehensive Review". Smart Manufacturing Systems, 18(4), 301-315.

3. Garcia, M. et al. (2023). "Sustainability Impacts of Automated CNC Glass Cutting: A Life Cycle Assessment". Journal of Cleaner Production, 356, 131872.

4. Wilson, T. (2022). "The Future of Glass Design: How CNC Automation is Reshaping Architecture". Architectural Technology Review, 29(3), 45-59.