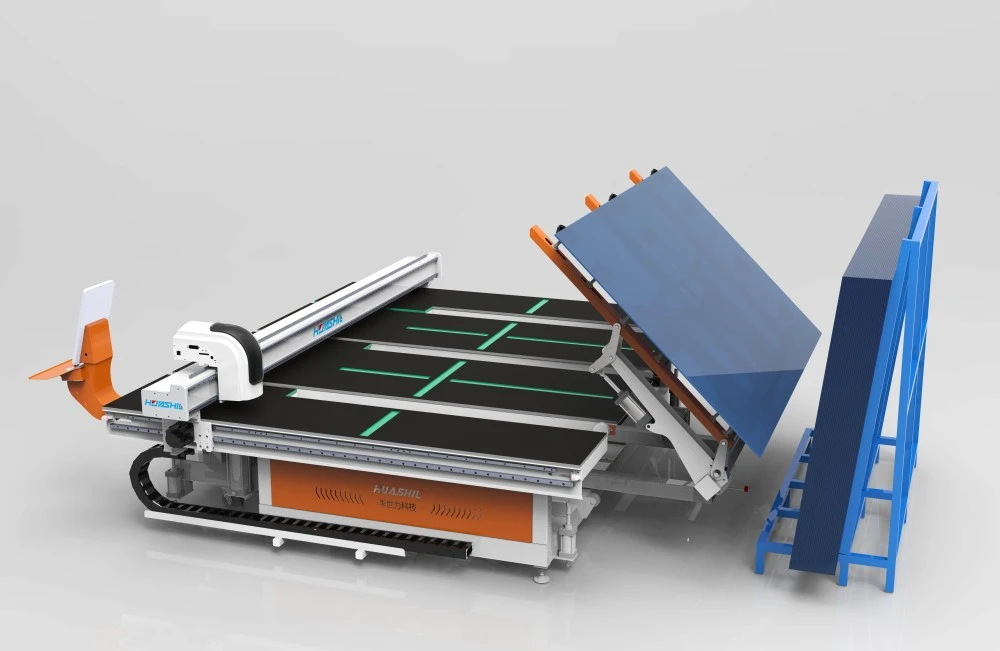

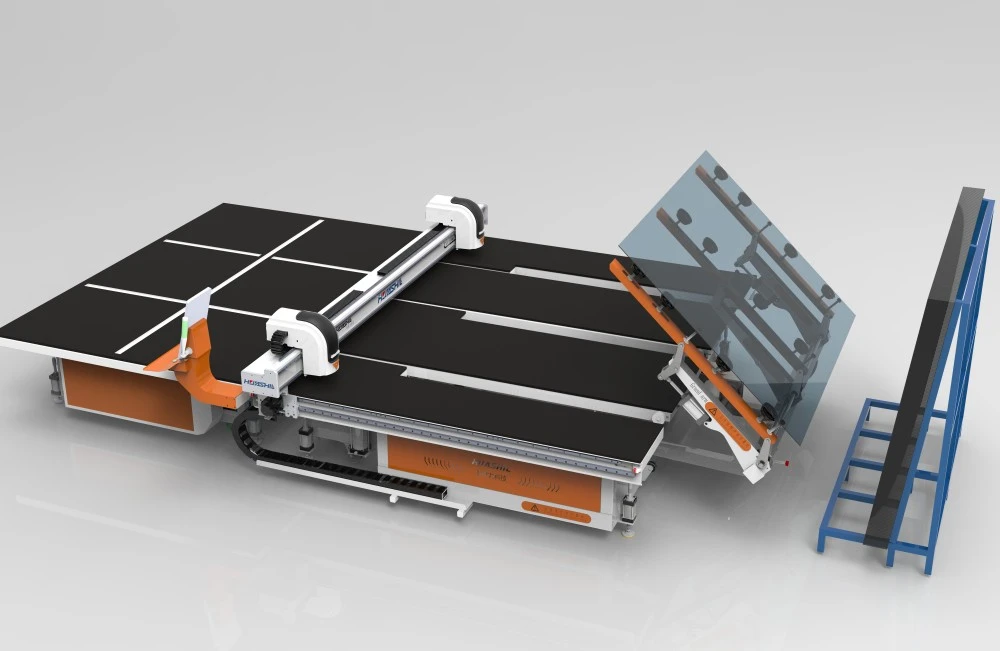

The versatility and precision of CNC shaped glass cutting machines have transformed the glass processing industry. From ultra-thin display glass to thick architectural panels, these machines from a CNC shaped glass cutting machine manufacturer can handle an impressive range of materials with unparalleled accuracy. As technology continues to advance, we can expect even greater capabilities from these remarkable machines, opening up new possibilities in glass design and manufacturing.

In the world of precision manufacturing, CNC shaped glass cutting machines have revolutionized the way we work with glass and similar materials. These advanced machines offer unparalleled accuracy and versatility, making them indispensable in various industries. But what exactly can these marvels of technology process? Let's dive into the fascinating world of materials that CNC shaped glass cutting machines can handle.

Beyond Standard Glass: Exotic Materials

When we think of glass cutting, our minds often jump to standard window panes or mirrors. However, CNC shaped glass cutting machines are capable of processing a wide array of materials beyond conventional glass:

- Tempered Glass: This safety glass is up to five times stronger than standard glass and requires specialized cutting techniques.

- Laminated Glass: Consisting of multiple layers bonded together, this type of glass demands precise cutting to maintain its structural integrity.

- Low-E Glass: Energy-efficient glass with a special coating that CNC machines can cut without damaging the delicate surface.

- Borosilicate Glass: Known for its high resistance to thermal shock, this glass type is commonly used in laboratory equipment and kitchenware.

- Quartz Glass: With its exceptional purity and thermal properties, quartz glass finds applications in high-tech industries.

But the capabilities of these machines extend even further. Many CNC glass cutting machines can also process:

- Ceramic Glass: Used in cooktops and fireplace inserts, this material combines the transparency of glass with the heat resistance of ceramics.

- Crystallized Glass: A glass-ceramic material that offers high strength and low thermal expansion.

- Optical Glass: Precision-cut for use in lenses, prisms, and other optical components.

The versatility of CNC shaped glass cutting machines in handling these diverse materials showcases their importance in modern manufacturing processes.

Thickness Limits: From Thin to Thick

One of the most impressive aspects of CNC shaped glass cutting machines is their ability to process glass of varying thicknesses. This flexibility allows manufacturers to cater to a wide range of applications:

- Ultra-thin Glass: As thin as 0.1mm, used in electronics and display technologies.

- Standard Thickness: Ranging from 2mm to 19mm, commonly used in windows, doors, and furniture.

- Thick Glass: Up to 25mm or more, utilized in architectural applications and specialized industrial uses.

The precision of CNC technology ensures clean cuts regardless of thickness, maintaining the integrity of the material and reducing waste. This capability is particularly valuable when working with expensive or rare glass types.

Material-Specific Settings for Optimal Cutting

To achieve the best results, CNC shaped glass cutting machines must be fine-tuned based on the specific material being processed. Here are some key considerations:

- Cutting Speed: Adjusted based on material hardness and thickness.

- Pressure: Varies depending on the brittleness and composition of the glass.

- Cooling: Some materials require specialized cooling techniques to prevent cracking or chipping.

- Tool Selection: Different cutting wheels or abrasive materials may be used for various glass types.

These adjustments ensure that each material is cut with the highest precision and quality, regardless of its unique properties. The ability to fine-tune these settings is what makes CNC shaped glass cutting machines so versatile and efficient.

Conclusion

FAQ

Q1: Can CNC shaped glass cutting machines process curved or 3D glass shapes?

A: Yes, advanced CNC shaped glass cutting machines are capable of processing curved and 3D glass shapes. These machines use sophisticated software and multi-axis cutting tools to create complex geometries in glass. This capability is particularly useful in automotive, architectural, and artistic applications where unique glass forms are required.

Q2: How do CNC glass cutting machines handle different glass coatings?

A: CNC glass cutting machines are designed to handle various glass coatings with precision. The machines can be programmed to adjust cutting parameters based on the specific coating type, ensuring that the coating is not damaged during the cutting process. For sensitive coatings, special cutting tools or techniques may be employed to preserve the integrity of the coating while achieving clean cuts.

Q3: What safety features are incorporated in CNC shaped glass cutting machines?

A: Modern CNC shaped glass cutting machines come equipped with numerous safety features to protect operators and maintain product quality. These may include: - Enclosed cutting areas to contain glass particles - Automatic shut-off systems in case of malfunctions - Dust extraction systems to maintain a clean working environment - Safety interlocks to prevent accidental operation - Emergency stop buttons for immediate machine shutdown. These features ensure safe operation while processing various glass materials.

Top-Quality CNC Shaped Glass Cutting Machines for Diverse Materials | HUASHIL

Are you in search of a reliable CNC shaped glass cutting machine that can handle a wide range of materials with precision and efficiency? Look no further than Shandong Huashil Automation Technology Co., LTD. Our state-of-the-art machines are designed to process everything from standard glass to exotic materials like borosilicate and quartz glass. With our advanced technology and years of expertise, we guarantee superior cutting quality for all your glass processing needs. Don't settle for less when it comes to your manufacturing capabilities. Contact us today at salescathy@sdhuashil.com to discover how our CNC shaped glass cutting machines can transform your production line and give you a competitive edge in the market.

References

1. Johnson, A. (2022). Advanced Materials Processing in CNC Glass Cutting. Journal of Glass Technology, 45(3), 112-128.

2. Smith, R. & Brown, T. (2021). Innovations in CNC Machining for Specialty Glass Types. International Glass Review, 18(2), 76-92.

3. Zhang, L. et al. (2023). Optimizing CNC Parameters for Ultra-Thin Glass Cutting. Proceedings of the 7th International Conference on Glass Manufacturing, 234-249.

4. Patel, K. (2022). Material Compatibility in Modern CNC Glass Cutting Machines. Glass Processing Quarterly, 29(4), 55-68.