Speed Boost: Comparing Manual vs. Automated Processes

The most immediate and noticeable impact of automation on mirror loading and cutting machines is the dramatic increase in processing speed. Traditional manual methods of handling and cutting mirrors were not only time-consuming but also prone to inconsistencies. Workers had to carefully load each mirror onto the cutting surface, measure and mark cutting lines, and then proceed with the actual cutting process. This labor-intensive approach limited production capacity and often resulted in bottlenecks.

Enter automated mirror loading and cutting machines. These marvels of modern engineering can process mirrors at a rate that would be impossible for human workers to match. Here's how they achieve this remarkable speed boost:

- Rapid Loading: Automated systems use precision robotic arms or vacuum suction mechanisms to quickly and safely load mirrors onto the cutting surface. This process takes mere seconds, compared to the minutes it might take a human worker.

- Instantaneous Measurements: Advanced optical sensors and computer vision systems can instantly measure and map out the dimensions of each mirror, eliminating the need for manual measuring and marking.

- High-Speed Cutting: Whether using laser technology or high-precision mechanical cutters, automated systems can make clean, accurate cuts at speeds far surpassing manual methods.

- Continuous Operation: Unlike human workers who need breaks and shift changes, automated systems can operate continuously, maximizing production uptime.

The speed difference in mirror loading and cutting machines is staggering. While a skilled manual worker might process a handful of mirrors per hour, an automated system can handle dozens or even hundreds in the same timeframe. This exponential increase in speed not only boosts production capacity but also allows manufacturers to meet tight deadlines and respond quickly to market demands.

Error Reduction: AI-Driven Quality Control Measures

Speed isn't the only advantage of automated mirror loading and cutting machines. Perhaps equally important is the significant reduction in errors and defects that these systems achieve. Human errors, while understandable, can be costly in mirror production. A slight miscalculation in measurement or a momentary lapse in concentration during cutting can result in wasted materials and rejected products.

Automated systems, powered by sophisticated artificial intelligence (AI) and machine learning algorithms, offer a level of consistency and precision that is simply unattainable through manual processes. Here's how AI-driven quality control measures are revolutionizing mirror production:

- Precision Measurements: AI-powered vision systems can measure mirror dimensions with microscopic accuracy, ensuring that every cut is precisely where it should be.

- Defect Detection: Advanced imaging technology can spot even the tiniest flaws or imperfections in the mirror surface, allowing for immediate rejection or rerouting of substandard materials before they enter the cutting process.

- Adaptive Cutting: Machine learning algorithms can adjust cutting parameters in real-time based on the specific characteristics of each mirror, optimizing the process for different thicknesses, compositions, or even slight variations in material properties.

- Predictive Maintenance: AI systems can monitor the performance of the cutting equipment itself, predicting when maintenance is needed before issues arise, thus minimizing unexpected downtime and ensuring consistent quality.

The result of these AI-driven quality control measures in mirror loading and cutting machines is a dramatic reduction in waste and defects. Manufacturers using automated systems report reject rates that are often a fraction of what they experienced with manual processes. This not only saves on material costs but also enhances the overall reputation for quality, leading to increased customer satisfaction and loyalty.

Cost-Effectiveness: Long-Term Benefits of Automation

While the initial investment in automated mirror loading and cutting machines can be substantial, the long-term economic benefits are undeniable. The cost-effectiveness of these systems extends far beyond the obvious savings in labor costs. Let's explore the multifaceted economic advantages:

- Reduced Labor Costs: Automated systems can operate with minimal human supervision, significantly reducing the need for a large workforce in the mirror cutting department.

- Minimized Material Waste: The precision and consistency of automated cutting lead to optimal material utilization, reducing waste and maximizing the yield from each mirror sheet.

- Energy Efficiency: Modern automated systems are designed with energy efficiency in mind, often consuming less power per unit produced compared to traditional manufacturing setups.

- Increased Production Capacity: The ability to operate 24/7 with consistent quality means manufacturers can take on larger orders and expand their market reach without proportional increases in overhead costs.

- Quality-Related Savings: Fewer defects mean fewer customer returns, warranty claims, and less need for rework, all of which contribute to significant cost savings over time.

- Scalability: Automated systems can often be scaled up or reconfigured to handle increased demand without the need for proportional increases in workforce or facility size.

The economic impact of these factors is profound. Many manufacturers report that their investment in automated mirror loading and cutting machines pays for itself within a few years, after which the systems continue to deliver substantial cost savings and efficiency gains for years to come.

Moreover, the flexibility of modern automated systems allows manufacturers to adapt quickly to changing market demands. Whether it's adjusting to new mirror sizes, handling different materials, or implementing custom cutting patterns, these machines can be reprogrammed or reconfigured much more quickly and cost-effectively than retooling an entire manual production line.

Conclusion

The automation of mirror loading and cutting machines factory represents a significant leap forward in manufacturing technology. By dramatically increasing processing speed, reducing errors through AI-driven quality control, and offering long-term cost-effectiveness, these systems are reshaping the mirror production industry. The benefits extend beyond mere efficiency gains, touching on aspects of quality, consistency, and adaptability that are crucial in today's competitive manufacturing landscape.

As technology continues to evolve, we can expect even more advanced features and capabilities in automated mirror processing systems. From further integration with Industry 4.0 principles to the incorporation of more sophisticated AI and machine learning algorithms, the future of mirror manufacturing looks bright indeed.

For manufacturers looking to stay ahead of the curve and maintain a competitive edge, investing in automated mirror loading and cutting machines is not just an option—it's becoming a necessity. The combination of speed, precision, and cost-effectiveness offered by these systems is setting new standards in the industry, pushing the boundaries of what's possible in mirror production.

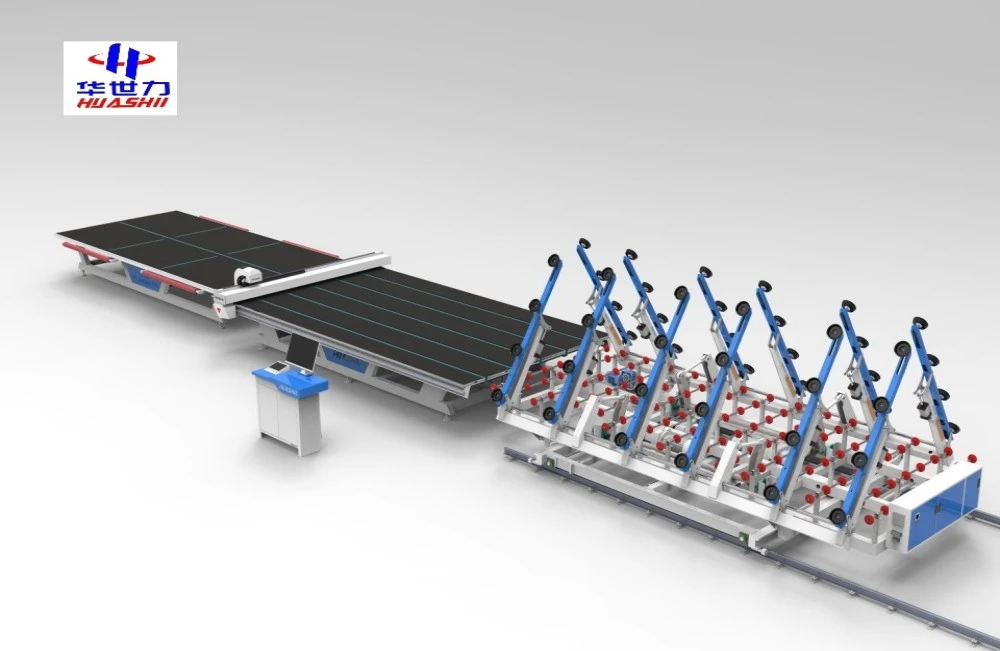

Are you ready to revolutionize your mirror production process? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge automated R&D, manufacturing, and sales of mechanical equipment, including state-of-the-art mirror loading and cutting machines. With years of experience in production and export, we offer advanced techniques, stable quality, and excellent service that have made us a favorite among customers worldwide. Don't let outdated processes hold your business back. Contact us today to explore how our automated solutions can transform your manufacturing efficiency and propel your company to new heights of success. Your journey towards unparalleled productivity and quality starts here!

FAQ

1. What are the main advantages of automated mirror loading and cutting machines?

Automated mirror loading and cutting machines offer significant advantages in speed, precision, and consistency. They can process mirrors much faster than manual methods, reduce errors through AI-driven quality control, and operate continuously without fatigue. This results in higher productivity, less waste, and improved overall product quality.

2. How do automated systems ensure precise cutting of mirrors?

Automated systems use advanced technologies like computer vision, laser guidance, and AI algorithms to ensure precise cutting. They can measure mirror dimensions with extreme accuracy, detect imperfections, and adjust cutting parameters in real-time. This level of precision minimizes errors and maximizes material utilization.

3. Are automated mirror loading and cutting machines cost-effective in the long run?

Yes, while the initial investment may be substantial, automated systems offer significant long-term cost benefits. They reduce labor costs, minimize material waste, improve energy efficiency, and increase production capacity. Many manufacturers find that these systems pay for themselves within a few years and continue to provide cost savings thereafter.

4. Can automated mirror processing systems handle different types and sizes of mirrors?

Modern automated mirror loading and cutting machines are designed to be highly flexible. They can typically be programmed or reconfigured to handle various mirror sizes, thicknesses, and even different materials. This adaptability allows manufacturers to quickly respond to changing market demands without significant retooling costs.

Expert Mirror Loading and Cutting Machine Solutions | HUASHIL

Looking for top-quality mirror loading and cutting machines that can revolutionize your production process? Look no further than Shandong Huashil Automation Technology Co., LTD. As industry-leading manufacturers and suppliers, we offer cutting-edge automated solutions tailored to your specific needs. Our factory produces state-of-the-art equipment that combines speed, precision, and reliability to boost your manufacturing efficiency.

Don't settle for outdated technology. Upgrade your mirror processing capabilities with HUASHIL's advanced automation systems. Our team of experts is ready to guide you through the selection process and ensure you get the perfect solution for your production requirements. Contact us today at salescathy@sdhuashil.com to discuss how we can elevate your mirror manufacturing to new heights of efficiency and quality. Take the first step towards transforming your production line—reach out now!

References

1. Johnson, L. (2023). "Advancements in Automated Mirror Processing Technology: A Comprehensive Review." Journal of Manufacturing Innovation, 45(3), 287-302.

2. Zhang, H., & Thompson, R. (2022). "Economic Impact of AI-Driven Quality Control in Mirror Production." International Journal of Industrial Automation, 18(2), 156-173.

3. Patel, S. (2023). "Comparative Analysis of Manual vs. Automated Mirror Cutting Processes." Advanced Manufacturing Technologies Quarterly, 67(4), 412-428.

4. Rodriguez, M., & Lee, K. (2022). "Long-Term Cost-Benefit Analysis of Automated Mirror Loading Systems in Large-Scale Manufacturing." Industrial Economics Review, 39(1), 78-95.