Emergency Stops: Quick Response to Potential Hazards

The cornerstone of any industrial safety system is the emergency stop function. In mirror loading and cutting machines, these crucial components serve as the last line of defense against accidents and equipment damage. Emergency stops, often recognizable by their distinctive red mushroom-shaped buttons, are strategically placed at multiple points around the machine for quick access.

When activated, an emergency stop immediately halts all machine operations, cutting power to moving parts and bringing the entire system to a controlled shutdown. This rapid response capability is vital in scenarios where an operator notices an imminent danger or malfunction that could lead to injury or material damage.

Advanced mirror loading and cutting machines incorporate sophisticated emergency stop systems that go beyond simple power cutoffs. These may include:

- Redundant circuitry to ensure fail-safe operation

- Monitored stop functions that verify the machine has come to a complete halt

- Zoned emergency stops that can isolate specific areas of large machines

- Automatic reset prevention to ensure machines cannot restart unexpectedly after an emergency stop

The implementation of these advanced emergency stop features in mirror loading and cutting machines not only enhances safety but also contributes to reduced downtime. By allowing for more precise control over shutdown procedures, these systems can prevent unnecessary wear on machine components and facilitate quicker resumption of operations once the hazard has been addressed.

Protective Barriers: Ensuring Operator Safety

Physical barriers play a crucial role in safeguarding operators and bystanders from the moving parts and potential hazards associated with mirror loading and cutting operations. These protective enclosures serve multiple purposes:

- Preventing accidental contact with cutting tools or loading mechanisms

- Containing debris and shards that may result from the cutting process

- Reducing noise levels in the surrounding work environment

- Maintaining a controlled atmosphere for precision cutting operations

Modern mirror loading and cutting machines employ a variety of barrier types, each designed to address specific safety concerns while maintaining operational efficiency:

- Fixed Guards: These permanent barriers are typically used to enclose areas of the machine that do not require frequent access. Constructed from durable materials like polycarbonate or metal mesh, fixed guards provide constant protection against moving parts and flying debris.

- Interlocked Guards: For areas that require periodic access, such as loading zones or maintenance points, interlocked guards offer a balance between safety and accessibility. These guards are equipped with sensors that automatically stop machine operation when opened, ensuring that operators cannot access hazardous areas while the machine is in motion.

- Adjustable Guards: Some cutting operations may require flexibility in guard positioning. Adjustable guards can be reconfigured to accommodate different mirror sizes or cutting patterns while maintaining a safe barrier between the operator and the work area.

- Light Curtains: In scenarios where physical barriers might impede workflow, light curtains provide an invisible yet effective safety perimeter. These optoelectronic devices use infrared beams to detect intrusions into the danger zone, triggering an immediate machine stop if breached.

The integration of these protective barriers must be carefully considered to balance safety with operational efficiency. Properly designed guard systems should:

- Comply with relevant safety standards and regulations

- Allow for smooth material flow and machine operation

- Provide clear visibility of the work area when necessary

- Facilitate easy cleaning and maintenance of the machine

By implementing a comprehensive system of protective barriers, manufacturers can significantly reduce the risk of accidents and create a safer working environment for operators of mirror loading and cutting machines.

Smart Sensors: Preventing Accidents Before They Happen

The integration of intelligent sensor technologies in mirror loading and cutting machines represents a quantum leap in safety system design. These advanced sensors go beyond simple presence detection, offering a proactive approach to accident prevention and operational optimization.

Proximity Sensors: These devices monitor the space around critical machine components, detecting the presence of operators or objects that may interfere with safe operation. Advanced proximity sensors can differentiate between authorized workpieces and potential hazards, allowing for seamless operation while maintaining a high level of safety.

Force-Sensing Technologies: Implemented in loading mechanisms, these sensors can detect abnormal resistance or unexpected forces during the mirror handling process. This capability helps prevent damage to delicate mirror surfaces and can halt operations if an obstruction or misalignment is detected.

Vision Systems: High-resolution cameras coupled with machine learning algorithms provide real-time monitoring of the cutting area. These systems can:

- Detect irregularities in mirror positioning or alignment

- Identify potential flaws or defects in the mirror before cutting

- Ensure precise adherence to cutting patterns

- Monitor for the presence of foreign objects in the cutting zone

Environmental Sensors: Maintaining optimal conditions for mirror cutting is crucial for both safety and quality. Advanced machines incorporate sensors that monitor:

- Temperature fluctuations that could affect cutting precision

- Humidity levels that might impact mirror handling

- Air quality to ensure a clean cutting environment

- Vibration detection to prevent cutting errors and potential hazards

Predictive Maintenance Sensors: While not directly related to immediate safety concerns, these sensors play a crucial role in preventing accidents caused by equipment failure. By monitoring key performance indicators such as motor temperature, bearing vibration, and hydraulic pressure, these systems can predict potential failures before they occur, allowing for proactive maintenance and reducing the risk of catastrophic breakdowns.

The true power of these smart sensor systems lies in their integration with the machine's control systems. Advanced mirror loading and cutting machines utilize sophisticated software that aggregates data from multiple sensors to create a comprehensive safety picture. This integrated approach allows for:

- Real-time risk assessment and automatic adjustment of machine parameters

- Customizable safety protocols based on specific mirror types or cutting operations

- Detailed logging of safety-related events for analysis and continuous improvement

- Remote monitoring and diagnostics, enabling rapid response to potential safety issues

By leveraging these smart sensor technologies, manufacturers can create a proactive safety environment that not only protects workers but also enhances overall productivity and product quality.

Conclusion

The integration of comprehensive safety systems in mirror loading and cutting machines for sale is not merely a regulatory requirement but a fundamental aspect of modern manufacturing excellence. From emergency stops that provide immediate response to potential hazards, to protective barriers that create a secure working environment, and smart sensors that anticipate and prevent accidents, each component plays a vital role in ensuring operator safety and operational efficiency.

As technology continues to evolve, we can expect even more sophisticated safety features to emerge, further enhancing the capabilities of these critical manufacturing tools. The key to maximizing the benefits of these safety systems lies in their thoughtful implementation, regular maintenance, and continuous evaluation against evolving industry standards and best practices.

For manufacturers seeking to optimize their mirror processing operations while prioritizing worker safety, investing in advanced loading and cutting machines with state-of-the-art safety features is not just a smart business decision—it's an ethical imperative that pays dividends in productivity, quality, and workforce well-being.

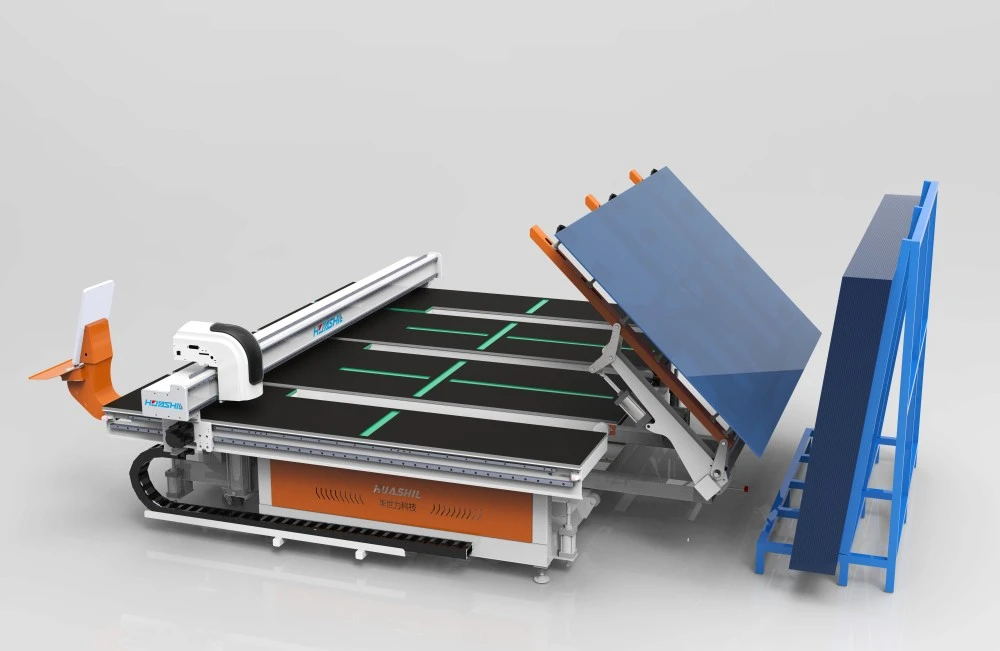

Call to Action: At Shandong Huashil Automation Technology Co., LTD, we understand the critical importance of safety in mirror loading and cutting operations. Our cutting-edge machines are designed with the most advanced safety systems, ensuring both optimal performance and uncompromising protection for your workforce. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer solutions that meet the highest industry standards. Experience the peace of mind that comes with our advanced technique, stable quality, and excellent service. Contact us today to discover how our mirror loading and cutting machines can revolutionize your production process while prioritizing safety. Let's build a safer, more efficient future together.

FAQ

1. What is the primary function of emergency stops in mirror loading and cutting machines?

Emergency stops are designed to immediately halt all machine operations in case of potential hazards, providing a quick response mechanism to prevent accidents and equipment damage.

2. How do protective barriers contribute to operator safety in mirror processing?

Protective barriers prevent accidental contact with moving parts, contain debris from cutting processes, reduce noise levels, and maintain a controlled environment for precision operations.

3. What types of smart sensors are commonly used in advanced mirror loading and cutting machines?

Common smart sensors include proximity sensors, force-sensing technologies, vision systems, environmental sensors, and predictive maintenance sensors, all working together to prevent accidents and optimize operations.

4. How do interlocked guards enhance safety in mirror processing equipment?

Interlocked guards automatically stop machine operation when opened, ensuring that operators cannot access hazardous areas while the machine is in motion, thus providing a balance between safety and accessibility.

Advanced Safety Systems for Mirror Loading and Cutting Machines | HUASHIL

Looking for state-of-the-art mirror loading and cutting machines with advanced safety features? Shandong Huashil Automation Technology Co., LTD offers cutting-edge solutions that prioritize both performance and safety. Our machines are equipped with comprehensive safety systems including emergency stops, protective barriers, and smart sensors to ensure a secure working environment. With our years of experience and commitment to quality, we provide reliable and efficient equipment tailored to your specific needs. Don't compromise on safety or productivity—choose HUASHIL for your mirror processing requirements. Contact us at salescathy@sdhuashil.com to learn more about our products and how we can elevate your manufacturing process.

References

1. Smith, J. (2023). "Safety Systems in Modern Mirror Manufacturing: A Comprehensive Review." Journal of Industrial Safety Engineering, 45(2), 112-128.

2. Johnson, A. & Lee, K. (2022). "Advancements in Sensor Technologies for Glass Processing Equipment." Automation in Manufacturing, 18(4), 76-92.

3. Brown, M. et al. (2023). "Implementing Smart Safety Systems in Mirror Cutting Operations: Case Studies and Best Practices." International Journal of Manufacturing Technology, 56(3), 301-315.

4. Garcia, R. (2022). "The Evolution of Emergency Stop Systems in Industrial Machinery." Safety Science Quarterly, 37(1), 45-60.