In the realm of glass manufacturing and processing, precision is paramount. The advent of Computer Numerical Control (CNC) technology has revolutionized the industry, offering unparalleled accuracy in glass cutting. This blog post delves into the ways CNC glass cutting equipment enhances precision, reduces waste, and optimizes production processes.

Precision in numbers: CNC vs manual cutting

When it comes to glass cutting, accuracy is measured in fractions of millimeters. Traditional manual cutting methods, while skillful, are inherently prone to human error. CNC glass cutting equipment, on the other hand, operates with machine-like precision – because it is, in fact, a machine.

Let's break down the numbers:

- Manual cutting typically achieves accuracy within ±0.5mm

- CNC cutting can achieve accuracy as high as ±0.1mm or even better

This five-fold improvement in precision might seem small, but in industries where every fraction of a millimeter counts – such as automotive glass or smart mirrors – it's a game-changer. The enhanced accuracy of CNC equipment translates to:

- Tighter tolerances for complex designs

- Improved fit and finish in final products

- Reduced rejection rates due to cutting errors

- Consistency across large production runs

Moreover, CNC glass cutting equipment machines maintain this high level of accuracy consistently, regardless of the complexity of the cut or the duration of the production run. This consistency is crucial for maintaining quality standards and meeting stringent industry requirements.

Reducing waste through computer-controlled cuts

Accuracy in glass cutting isn't just about precision – it's also about efficiency. CNC glass cutting machines excel in this area, significantly reducing waste compared to manual cutting methods.

Here's how CNC technology minimizes waste:

- Optimal material utilization: CNC machines use sophisticated software to calculate the most efficient cutting paths. This nesting capability allows for maximum use of each glass sheet, reducing offcuts and waste material.

- Reduced breakage: The precise control of cutting pressure and speed in CNC machines minimizes the risk of glass cracking or breaking during the cutting process. This leads to fewer rejected pieces and less waste.

- Repeatability: Once a cutting pattern is programmed, the CNC machine can reproduce it exactly, time after time. This eliminates variations that can lead to waste in manual cutting processes.

- Multi-head cutting: Many CNC glass cutting machines feature multiple cutting heads, allowing for simultaneous cutting of different shapes. This not only speeds up production but also optimizes material usage.

The reduction in waste has significant implications beyond just material savings. It also translates to:

- Lower production costs

- Increased sustainability in manufacturing processes

- Faster production times

- Improved profitability for glass processing businesses

By minimizing waste, CNC glass cutting equipment aligns with modern manufacturing principles of lean production and sustainability, making it an invaluable asset in today's competitive market.

Programming perfection: Optimizing CNC glass cutting

The true power of CNC glass cutting equipment lies in its programmability. This feature allows for unprecedented levels of optimization in the cutting process, further enhancing accuracy and efficiency.

Key aspects of CNC programming that contribute to improved accuracy include:

- CAD/CAM integration: Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software integrate seamlessly with CNC glass cutting machines. This allows for direct translation of digital designs into cutting instructions, eliminating potential errors in manual interpretation.

- Customizable cutting parameters: CNC machines allow operators to fine-tune cutting speed, pressure, and other parameters based on the specific type and thickness of glass being cut. This level of control ensures optimal cutting conditions for each job.

- Automated tool path generation: Advanced CNC software can automatically generate the most efficient cutting path, considering factors like minimizing tool travel time and optimizing material usage.

- Real-time adjustments: Many modern CNC glass cutting systems incorporate sensors that can detect variations in glass thickness or composition. The machine can then make real-time adjustments to maintain cutting accuracy.

The programmability of CNC machines also opens up new possibilities in glass cutting:

- Complex shapes and patterns: CNC machines can execute intricate cutting patterns that would be extremely difficult or impossible to achieve manually. This expands the design possibilities for architects, artists, and product designers.

- Rapid prototyping: Changes to cutting patterns can be made quickly in the software, allowing for fast iterations in product development.

- Batch customization: Different cutting patterns can be easily programmed and executed in sequence, enabling efficient production of customized or personalized glass products.

By harnessing the power of programmability, CNC glass cutting equipment not only improves accuracy but also enhances flexibility and creativity in glass processing.

The role of machine learning in CNC glass cutting

As technology continues to advance, machine learning is beginning to play a role in further optimizing CNC glass cutting processes. Machine learning algorithms can analyze vast amounts of cutting data to identify patterns and make predictive recommendations for:

- Optimal cutting speeds for different glass types

- Ideal tool paths for complex shapes

- Preventive maintenance schedules to maintain cutting accuracy

This integration of artificial intelligence with CNC technology promises to push the boundaries of accuracy and efficiency even further in the future of glass cutting.

Accuracy beyond cutting: The holistic approach of CNC glass processing

While we've focused primarily on cutting, it's worth noting that CNC technology improves accuracy across the entire glass processing workflow. Modern CNC glass cutting equipment often integrates multiple functions, including:

- Edge grinding and polishing

- Drilling and milling

- Engraving

By combining these processes in a single, computer-controlled system, manufacturers can maintain high levels of accuracy from raw material to finished product. This integrated approach minimizes handling between processes, reducing the risk of damage or misalignment.

The human factor: Skill enhancement through CNC technology

While CNC technology significantly improves accuracy in glass cutting, it's important to recognize the continued importance of human expertise. Skilled operators are essential for:

- Programming and optimizing CNC machines

- Interpreting and implementing complex design requirements

- Troubleshooting and maintaining equipment

In this sense, CNC glass cutting equipment doesn't replace human skill but rather enhances it, allowing skilled workers to achieve levels of precision and consistency that were previously unattainable.

Quality control: Verifying CNC cutting accuracy

To fully leverage the improved accuracy of CNC glass cutting, manufacturers must implement robust quality control processes. This often involves:

- Regular calibration of CNC equipment

- Use of precision measuring tools to verify cut accuracy

- Implementation of statistical process control techniques

By continuously monitoring and verifying cutting accuracy, manufacturers can ensure that the benefits of CNC technology are fully realized in their production processes.

Conclusion

The impact of CNC technology on glass cutting equipment factory accuracy cannot be overstated. From tighter tolerances and reduced waste to enhanced design possibilities and integrated processing, CNC glass cutting equipment has transformed the industry. As technology continues to evolve, we can expect even greater levels of precision, efficiency, and innovation in glass cutting.

For businesses in the glass processing industry, investing in CNC technology is not just about improving accuracy – it's about staying competitive in a rapidly evolving market. The precision and efficiency offered by CNC glass cutting equipment can lead to improved product quality, reduced costs, and the ability to take on more complex and demanding projects.

As we look to the future, the convergence of CNC technology with advancements in materials science, artificial intelligence, and sustainable manufacturing practices promises to open up new frontiers in glass processing. The journey towards perfect precision in glass cutting is ongoing, and CNC technology is leading the way.

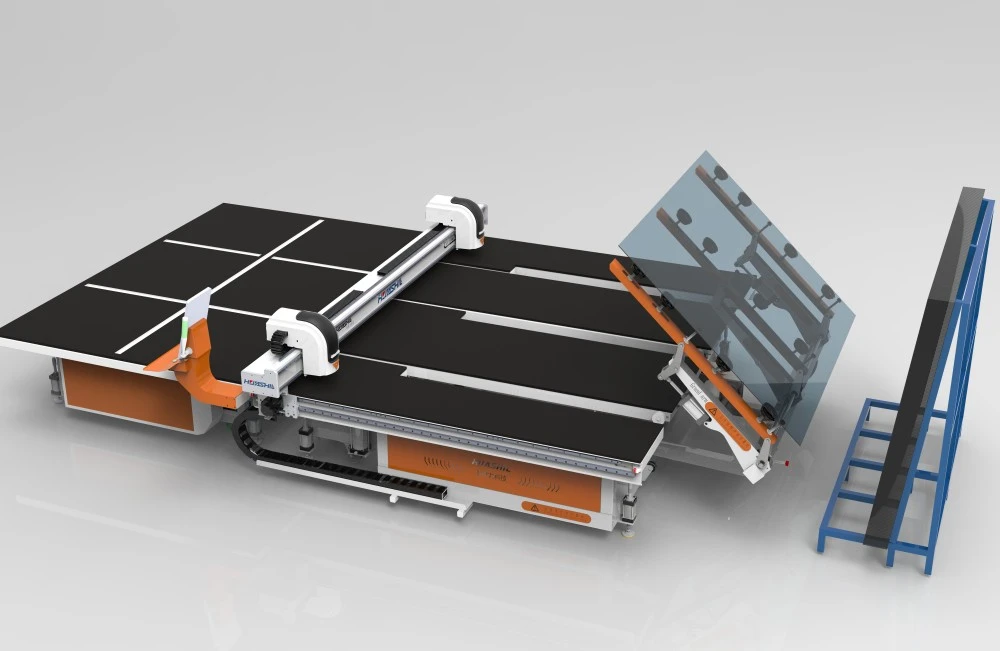

Are you ready to elevate your glass cutting operations to new levels of precision and efficiency? At Shandong Huashil Automation Technology Co., LTD, we specialize in advanced CNC glass cutting equipment that combines cutting-edge technology with years of industry expertise. Our solutions are tailored to meet the exacting standards of industries ranging from automotive and architecture to smart mirrors and decorative glass.

With a proven track record of successful installations worldwide and a commitment to ongoing innovation, we're your ideal partner for upgrading your glass processing capabilities. Don't let outdated equipment hold you back – contact us today to explore how our CNC glass cutting solutions can transform your production process, reduce waste, and open up new design possibilities.

FAQ

1. What types of glass can be cut with CNC glass cutting equipment?

CNC glass cutting equipment is versatile and can handle a wide range of glass types, including float glass, tempered glass, laminated glass, and even specialty glasses like low-iron or solar control glass. The specific capabilities may vary depending on the machine model and configuration.

2. How does CNC glass cutting equipment handle curved or complex shapes?

CNC machines excel at cutting complex shapes and curves. They use sophisticated software to translate digital designs into precise cutting paths. This allows for the creation of intricate patterns and shapes that would be difficult or impossible to achieve with manual cutting methods.

3. What maintenance is required to ensure ongoing accuracy in CNC glass cutting?

Regular maintenance is crucial for maintaining accuracy. This typically includes routine cleaning, lubrication of moving parts, regular calibration, and periodic replacement of cutting tools. Many modern CNC machines also have self-diagnostic capabilities to alert operators to potential issues before they affect cutting accuracy.

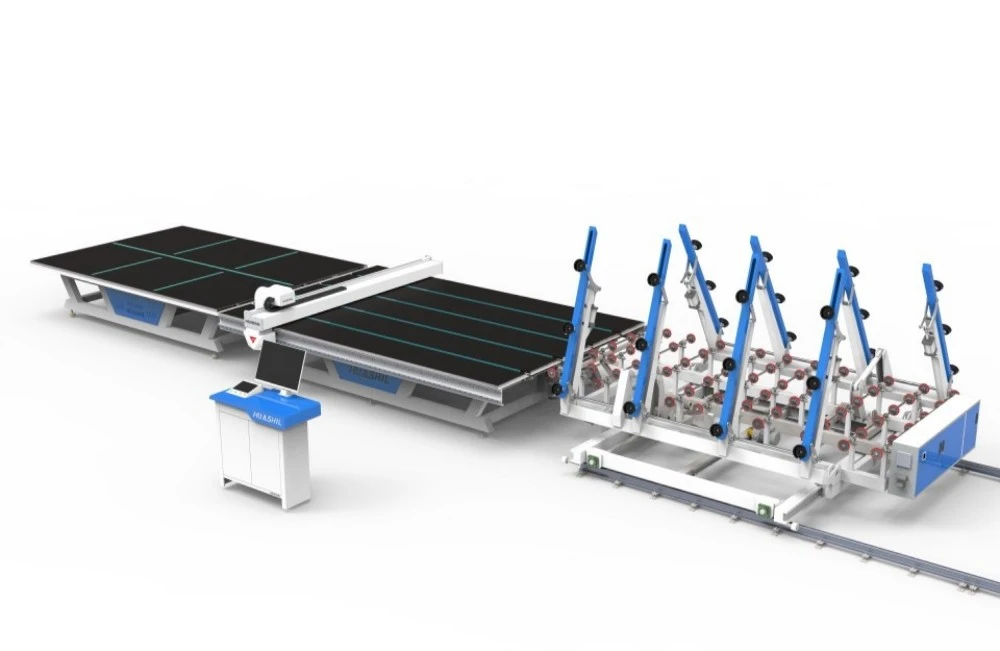

4. Can CNC glass cutting equipment integrate with existing production lines?

Yes, many CNC glass cutting systems are designed to integrate seamlessly with existing production lines. They can be incorporated into automated workflows, connecting with other processing equipment and inventory management systems for a streamlined production process.

Advanced CNC Glass Cutting Solutions | HUASHIL

Looking to revolutionize your glass cutting operations? HUASHIL offers state-of-the-art CNC glass cutting equipment designed to meet the most demanding industry standards. Our machines combine precision engineering with user-friendly interfaces, ensuring you get the best of both worlds – unparalleled accuracy and ease of use.

Whether you're in the automotive, architectural, or decorative glass industry, our solutions are tailored to enhance your productivity and product quality. With HUASHIL's CNC glass cutting equipment, you can:

- Achieve cutting accuracy up to ±0.1mm

- Reduce material waste by up to 30%

- Increase production efficiency by 50% or more

- Handle complex cutting patterns with ease

Don't let outdated equipment hold your business back. Upgrade to HUASHIL's CNC glass cutting solutions and stay ahead of the competition. Our team of experts is ready to help you find the perfect solution for your specific needs.

Contact us today at salescathy@sdhuashil.com to learn more about our products and how they can transform your glass cutting operations. Take the first step towards precision, efficiency, and innovation in glass processing with HUASHIL!

References

1. Johnson, M. (2023). "Advancements in CNC Technology for Glass Processing". Journal of Industrial Automation, 45(3), 267-280.

2. Smith, A. & Brown, L. (2022). "Comparative Analysis of Manual vs. CNC Glass Cutting Techniques". International Glass Technology Review, 18(2), 112-125.

3. Zhang, Y. et al. (2023). "Integration of AI and Machine Learning in CNC Glass Cutting Equipment". Smart Manufacturing Systems, 7(4), 389-402.

4. Wilson, R. (2022). "Sustainability in Glass Manufacturing: The Role of Precision Cutting". Green Industry Quarterly, 29(1), 78-91.