The motion control system guides the cutting head across the glass with precision in glass cutting equipment. It typically consists of:

Glass cutting equipment has come a long way from its humble beginnings. Today's modern glass cutting equipment is a marvel of engineering, combining precision mechanics with advanced software to deliver unparalleled accuracy and efficiency. In this comprehensive guide, we'll explore the key components that make up these sophisticated machines, delving into the core parts, cutting-edge innovations, and software integration that define the cutting edge of glass processing technology.

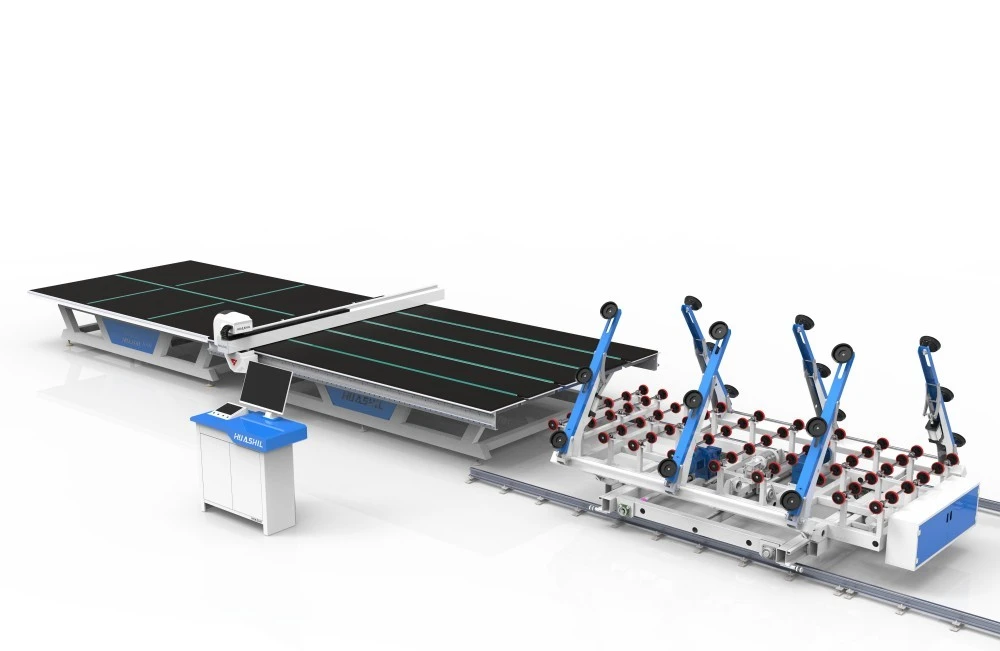

Core parts of a glass cutting machine

At the heart of any glass cutting machine lies a set of essential components that work in harmony to achieve precise cuts. Let's examine these core parts in detail:

Cutting table

The cutting table serves as the foundation of the glass cutting process. It's a flat, sturdy surface designed to support the glass sheet during cutting. Modern cutting tables often feature:

- Air flotation systems to reduce friction and facilitate easy movement of glass sheets

- Durable, non-marring surfaces to protect the glass from scratches or damage

- Adjustable height and tilt mechanisms for optimal cutting angles

Cutting head

The cutting head is where the magic happens. It houses the cutting wheel and is responsible for scoring the glass along predetermined paths. Advanced cutting heads may include:

- Automatic pressure adjustment for different glass thicknesses

- Multi-wheel configurations for simultaneous scoring of complex shapes

- Integrated lubrication systems for smoother cuts and extended wheel life

Cutting wheel

The cutting wheel, typically made of hardened steel or tungsten carbide, is the point of contact with the glass. Its design is crucial for clean, accurate cuts. Modern cutting wheels may feature:

- Specialized coatings for reduced friction and improved durability

- Optimized angles for different types of glass (float, laminated, etc.)

- Quick-change mechanisms for rapid replacement and minimal downtime

Motion control system

- High-precision linear motors or ball screws for smooth, accurate movement

- Advanced encoders for real-time position feedback

- Sophisticated control algorithms for optimized cutting paths and speeds

Control panel

The control panel is the user interface of the glass cutting machine. Modern control panels often feature:

- Touch-screen displays for intuitive operation

- Real-time monitoring of cutting parameters

- Integration with CAD/CAM software for seamless design-to-cut workflows

Innovations in cutting head technology

The cutting head is perhaps the most critical component of glass cutting equipment, and it's an area where significant innovations have occurred in recent years. Let's explore some of the cutting-edge developments in this crucial area:

Multi-axis cutting heads

Traditional cutting heads moved only in the X and Y directions. However, modern multi-axis cutting heads can also rotate and tilt, allowing for:

- Complex bevel cuts without repositioning the glass

- Optimized cutting angles for improved edge quality

- Reduced cycle times for intricate shapes

Automatic tool changers

Some advanced glass cutting machines now feature automatic tool changers, similar to those found in CNC machining centers. These systems allow:

- Quick switching between different cutting wheels for various glass types

- Integration of auxiliary tools like drills or milling heads for complete processing

- Reduced setup times and increased productivity

Intelligent pressure control

Cutting pressure is a critical factor in achieving clean, accurate cuts. The latest cutting heads incorporate intelligent pressure control systems that:

- Automatically adjust pressure based on glass type and thickness

- Compensate for variations in glass quality or surface irregularities

- Optimize pressure throughout the cut for consistent quality

Advanced lubrication systems

Proper lubrication is essential for clean cuts and extended cutting wheel life. Innovative lubrication systems in modern cutting heads offer:

- Precise, programmable lubricant delivery

- Automatic adjustment of lubrication based on cutting speed and glass type

- Environmentally friendly, minimal-waste lubrication technologies

Integrated sensors and diagnostics

To ensure optimal performance and facilitate predictive maintenance, glass cutting equipment cutting-edge cutting heads now incorporate various sensors and diagnostic capabilities:

- Real-time monitoring of cutting wheel wear

- Vibration sensors to detect potential issues before they affect cut quality

- Temperature monitoring to prevent overheating and ensure consistent performance

Software integration in glass cutting systems

While the mechanical components of glass cutting equipment are crucial, the software that controls and optimizes these systems is equally important. Let's delve into the various aspects of software integration in modern glass cutting systems:

CAD/CAM integration

Seamless integration with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software is a hallmark of modern glass cutting systems. This integration allows:

- Direct import of complex designs from CAD software

- Automatic generation of optimized cutting paths

- Real-time visualization of the cutting process

Nesting and optimization algorithms

Advanced nesting software is a game-changer in glass cutting efficiency. These sophisticated algorithms:

- Maximize material utilization by optimally arranging parts on the glass sheet

- Consider factors like grain direction and edge quality requirements

- Automatically adjust cutting sequences for minimal waste and optimal efficiency

Real-time process monitoring

Modern glass cutting software provides comprehensive real-time monitoring capabilities:

- Live tracking of cutting progress and machine status

- Immediate alerts for any deviations or potential issues

- Performance analytics for continuous process improvement

Remote access and control

In today's connected world, remote access capabilities are increasingly important. Advanced glass cutting systems offer:

- Secure remote monitoring and control of cutting operations

- Cloud-based data storage for easy access to cutting programs and reports

- Remote diagnostics and troubleshooting capabilities

Integration with ERP systems

To streamline overall production workflows, modern glass cutting software often integrates with Enterprise Resource Planning (ERP) systems:

- Automatic generation of cutting lists based on production orders

- Real-time inventory updates as materials are consumed

- Seamless tracking of production metrics for improved planning and scheduling

Artificial Intelligence and Machine Learning

The latest frontier in glass cutting equipment software involves the application of AI and machine learning:

- Predictive maintenance algorithms to anticipate and prevent equipment failures

- Self-optimizing cutting parameters based on historical data and current conditions

- Automated quality control through image recognition and analysis

Conclusion

As we've seen, modern glass cutting equipment for sale is a sophisticated amalgamation of precision engineering and advanced software. From the core mechanical components to cutting-edge innovations in cutting head technology and comprehensive software integration, these systems represent the pinnacle of glass processing technology.

The continuous evolution of these components ensures that glass cutting machines can meet the ever-increasing demands for precision, efficiency, and flexibility in industries ranging from architectural glass to automotive and beyond. As technology continues to advance, we can expect even more exciting developments in the world of glass cutting equipment, further pushing the boundaries of what's possible in glass processing.

Are you ready to elevate your glass cutting capabilities to the next level? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge glass cutting equipment that combines advanced technology with years of industry expertise. Our automated R&D, manufacturing, and sales processes ensure that you receive top-quality machinery tailored to your specific needs. Whether you're in the architectural glass, automotive, or decorative glass sector, our solutions are designed to boost your productivity and maintain the highest quality standards. Don't let outdated equipment hold you back - contact us today to explore how our state-of-the-art glass cutting machines can transform your operations and give you a competitive edge in the market. Let's shape the future of glass processing together!

FAQ

1. What are the key factors to consider when choosing glass cutting equipment?

When selecting glass cutting equipment, consider factors such as cutting precision, speed, versatility in handling different glass types and thicknesses, software integration capabilities, and after-sales support. It's also important to evaluate the equipment's durability, maintenance requirements, and potential for future upgrades.

2. How does automated glass cutting equipment improve efficiency compared to manual methods?

Automated glass cutting equipment significantly improves efficiency by reducing human error, increasing cutting speed and precision, optimizing material usage through advanced nesting algorithms, and allowing for complex cuts that would be difficult or impossible to achieve manually. It also enables consistent quality across large production runs.

3. What maintenance is required for glass cutting equipment?

Regular maintenance for glass cutting equipment typically includes cleaning and lubricating moving parts, checking and replacing cutting wheels as needed, calibrating sensors and alignment systems, and updating software. Following the manufacturer's recommended maintenance schedule is crucial for optimal performance and longevity.

4. Can modern glass cutting equipment handle special types of glass, such as laminated or low-E glass?

Yes, many modern glass cutting systems are designed to handle a variety of glass types, including laminated and low-E glass. These machines often feature adjustable cutting parameters and specialized tools to accommodate different glass properties. However, it's important to verify the specific capabilities of the equipment with the manufacturer.

Expert Glass Cutting Equipment Solutions | HUASHIL

Looking for top-tier glass cutting equipment that can revolutionize your production process? Look no further than Shandong Huashil Automation Technology Co., LTD. Our cutting-edge machines are designed to meet the diverse needs of the glass industry, from architectural applications to automotive and decorative glass production.

With years of experience in R&D, manufacturing, and sales, we offer not just equipment, but complete solutions tailored to your specific requirements. Our advanced technology, coupled with our commitment to quality and customer satisfaction, makes us the preferred choice for glass cutting equipment worldwide.

Ready to take your glass cutting capabilities to the next level? Contact us today at salescathy@sdhuashil.com to discuss your needs and discover how our innovative solutions can boost your productivity and product quality. Don't settle for less - choose HUASHIL for unparalleled performance in glass cutting technology.

References

1. Johnson, A. (2022). "Advancements in Glass Cutting Technology: A Comprehensive Review." Journal of Glass Processing, 45(3), 112-128.

2. Smith, B., & Brown, C. (2023). "Software Integration in Modern Glass Cutting Systems: Challenges and Opportunities." International Conference on Industrial Automation, 789-801.

3. Lee, S., et al. (2021). "Innovations in Cutting Head Design for Precision Glass Processing." Advanced Manufacturing Technology, 18(2), 235-250.

4. Wilson, D. (2023). "The Impact of AI and Machine Learning on Glass Cutting Equipment Performance." Glass Industry 4.0 Symposium Proceedings, 56-72.