In today's rapidly evolving manufacturing landscape, the glass industry faces mounting pressure to boost productivity while maintaining impeccable quality standards. Glass processing equipment plays a pivotal role in meeting these challenges, revolutionizing production lines and enhancing efficiency across various sectors. This article delves into the ways cutting-edge machinery transforms glass manufacturing, exploring key features, cost-reduction strategies, and technological innovations that are reshaping the industry.

What are the key features of efficient glass processing equipment?

Modern glass processing equipment boasts an array of features designed to optimize production and elevate product quality. These advanced machines incorporate sophisticated technologies that streamline operations, minimize waste, and ensure consistent results. Let's examine some of the paramount characteristics that define state-of-the-art glass processing machinery:

Precision and Accuracy

One of the hallmarks of efficient glass processing equipment is its unparalleled precision. Cutting-edge machines utilize advanced sensors and computer-controlled systems to achieve remarkably tight tolerances. This level of accuracy is indispensable for industries such as automotive and aerospace, where even minute deviations can compromise safety and performance.

High-precision equipment enables manufacturers to produce complex shapes and intricate designs with consistency and reliability. From precise edge grinding to flawless beveling, these machines execute tasks with a degree of accuracy that surpasses human capabilities, resulting in superior product quality and reduced rejection rates.

Automation and Integration

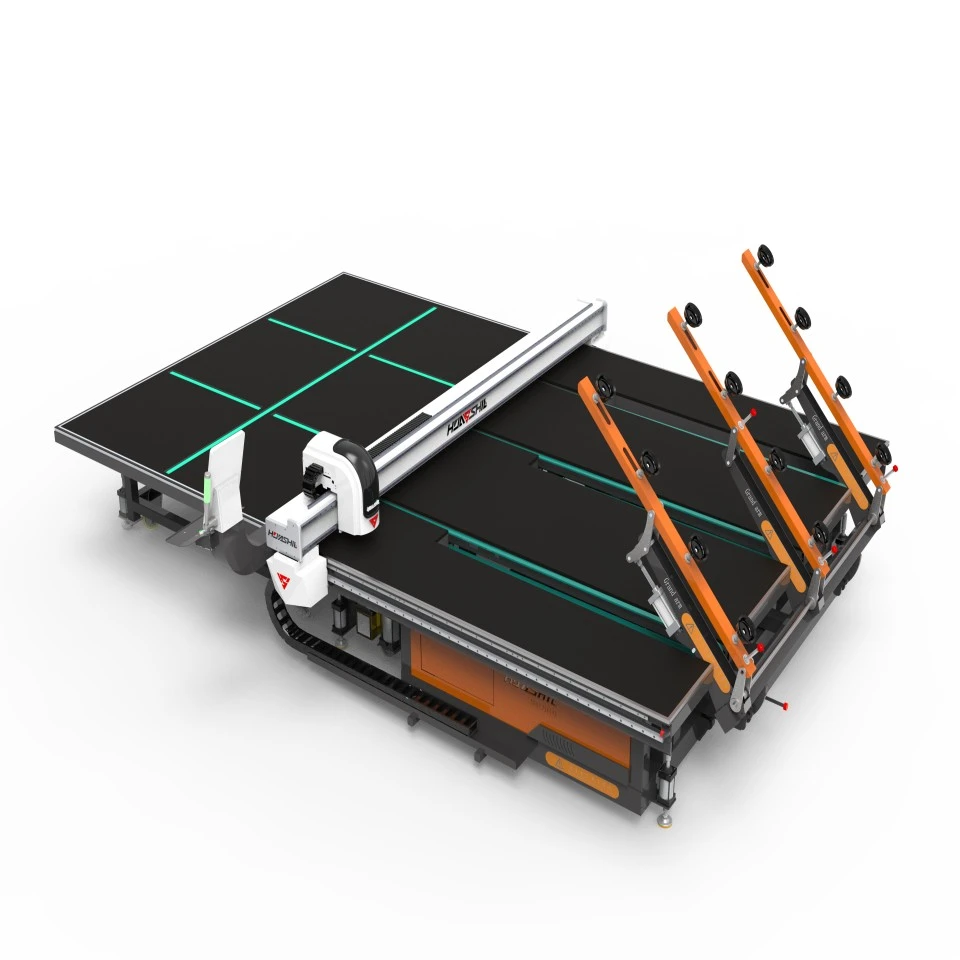

Automation is at the heart of modern glass processing efficiency. Advanced equipment incorporates robotics and artificial intelligence to perform repetitive tasks with speed and consistency. Automated systems can handle multiple operations simultaneously, from cutting and shaping to polishing and inspection, significantly reducing production time and labor costs.

Moreover, integrated systems allow for seamless communication between different machines in the production line. This interconnectedness enables real-time data sharing, facilitating smooth workflow and minimizing bottlenecks. The result is a highly efficient production process that maximizes output while maintaining stringent quality controls.

Flexibility and Adaptability

In an era of customization and rapidly changing market demands, flexibility is a crucial attribute of efficient glass processing equipment. Modern machinery is designed to handle a wide range of glass types, thicknesses, and sizes, allowing manufacturers to switch between different products quickly and effortlessly.

This adaptability extends to the ability to perform multiple operations on a single machine, reducing the need for separate equipment for each process. For instance, a single piece of equipment might be capable of cutting, drilling, and polishing, streamlining the production flow and optimizing floor space utilization.

Energy Efficiency and Sustainability

As environmental concerns take center stage, energy-efficient glass processing equipment has become increasingly important. Modern machines are engineered to minimize energy consumption without compromising performance. Features such as regenerative braking systems, heat recovery units, and smart power management contribute to reduced energy costs and a smaller carbon footprint.

Additionally, advanced equipment often incorporates recycling systems that capture and reuse water and abrasive materials, further enhancing sustainability and reducing operational costs. These eco-friendly features not only benefit the environment but also align with the growing demand for sustainable manufacturing practices.

How does advanced glass processing equipment reduce manufacturing costs?

The implementation of cutting-edge glass processing machinery offers numerous avenues for cost reduction in manufacturing operations. By leveraging these advanced technologies, companies can significantly improve their bottom line while maintaining or even enhancing product quality. Here's an in-depth look at how modern equipment contributes to cost savings:

Increased Production Speed

One of the most immediate and tangible benefits of advanced glass processing equipment is the substantial increase in production speed. High-performance machines can process glass at rates that were previously unattainable, dramatically boosting output volumes. This acceleration in production translates directly into reduced labor costs per unit and improved overall efficiency.

For instance, automated cutting systems can precisely slice large sheets of glass into multiple pieces in a fraction of the time it would take using traditional methods. Similarly, high-speed polishing machines can achieve a perfect finish on multiple glass panels simultaneously, significantly reducing processing time.

Minimized Material Waste

Advanced glass processing equipment utilizes sophisticated optimization algorithms to maximize material usage and minimize waste. These systems analyze the dimensions of the raw glass sheets and calculate the most efficient cutting patterns to yield the highest number of usable pieces. By reducing scrap and optimizing material utilization, manufacturers can substantially lower their raw material costs.

Moreover, precision cutting and shaping equipment reduces the likelihood of errors that result in wasted materials. The high accuracy of these machines ensures that each cut is executed perfectly, minimizing the need for rework or rejection of imperfect pieces.

Reduced Labor Costs

Automation plays a crucial role in reducing labor costs associated with glass processing. By employing advanced machinery, manufacturers can significantly decrease their reliance on manual labor for repetitive and physically demanding tasks. This not only reduces direct labor costs but also minimizes the risks associated with workplace injuries and fatigue-related errors.

Furthermore, modern equipment often requires fewer operators to manage multiple processes, allowing companies to optimize their workforce allocation. Skilled technicians can be redeployed to focus on more complex tasks that require human expertise, such as quality control and process optimization.

Enhanced Quality Control

The integration of advanced quality control systems within glass processing equipment leads to a significant reduction in defects and rejections. Automated inspection technologies, such as high-resolution cameras and laser sensors, can detect even the slightest imperfections that might be missed by human inspectors.

By identifying and addressing quality issues early in the production process, manufacturers can prevent costly rework and minimize the risk of defective products reaching customers. This proactive approach to quality control not only reduces direct costs associated with waste and rework but also helps maintain customer satisfaction and brand reputation.

Predictive Maintenance

Modern glass processing machinery often incorporates predictive maintenance capabilities, leveraging sensors and data analytics to anticipate potential equipment failures before they occur. This proactive approach to maintenance helps prevent unexpected downtime, which can be extremely costly in terms of lost production and potential damage to in-process materials.

By scheduling maintenance activities during planned downtimes and addressing potential issues before they escalate, manufacturers can extend the lifespan of their equipment and optimize its performance. This results in reduced maintenance costs, improved equipment reliability, and increased overall production efficiency.

What technological innovations are driving glass processing equipment performance?

The glass processing industry is witnessing a technological revolution, with continuous advancements enhancing equipment performance and capabilities. These innovations are not only improving existing processes but also opening up new possibilities for glass manufacturing and applications. Let's explore some of the key technological breakthroughs driving the evolution of glass processing equipment:

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing glass processing by introducing unprecedented levels of automation and optimization. These technologies enable equipment to learn from past operations, continuously improving performance and adapting to changing conditions without human intervention.

AI-powered systems can analyze vast amounts of data in real-time, making split-second decisions to optimize cutting patterns, adjust processing parameters, and predict maintenance needs. This level of intelligent automation not only enhances efficiency but also ensures consistent quality across production runs.

Advanced Laser Technologies

Laser technology has made significant strides in glass processing, offering unparalleled precision and versatility. Advanced laser cutting and engraving systems can create intricate designs and patterns on glass surfaces with microscopic accuracy. These systems are capable of processing a wide range of glass types and thicknesses, from delicate decorative pieces to robust architectural panels.

Moreover, the development of ultrafast lasers has opened up new possibilities in glass processing. These lasers can make internal modifications to glass without affecting the surface, enabling the creation of complex 3D structures within the glass itself. This technology has applications in various fields, including optics, microfluidics, and data storage.

Internet of Things (IoT) Integration

The integration of IoT technologies in glass processing equipment has ushered in a new era of connectivity and data-driven decision-making. IoT-enabled machines can communicate with each other and with central control systems, sharing real-time data on production status, equipment health, and environmental conditions.

This interconnectedness allows for more efficient production planning, predictive maintenance, and remote monitoring capabilities. Manufacturers can access real-time information about their production lines from anywhere in the world, enabling quick responses to issues and opportunities for optimization.

Advanced Materials and Coatings

Innovations in materials science have led to the development of new types of glass and coatings that require specialized processing equipment. For instance, the growing demand for smart glass with switchable opacity or self-cleaning properties has spurred the creation of advanced coating systems that can apply these functionalities with precision and efficiency.

Similarly, the emergence of ultra-thin glass for flexible electronics and displays has necessitated the development of highly specialized handling and processing equipment capable of working with these delicate materials without causing damage.

3D Printing and Additive Manufacturing

While traditionally associated with plastics and metals, 3D printing technology is making inroads into glass processing. Specialized 3D printers capable of working with glass materials are opening up new possibilities for creating complex shapes and structures that were previously impossible or prohibitively expensive to produce using traditional methods.

This technology is particularly promising for producing custom glass components for scientific instruments, artistic installations, and specialized industrial applications. As 3D printing techniques for glass continue to evolve, they are likely to complement traditional glass processing methods, offering new avenues for innovation and customization.

Conclusion

The rapid evolution of glass processing equipment is transforming the industry, offering unprecedented levels of efficiency, precision, and versatility. From AI-driven automation to advanced laser technologies and IoT integration, these innovations are empowering manufacturers to meet the growing demands for high-quality, customized glass products across various sectors.

As we look to the future, it's clear that staying at the forefront of technological advancements in glass processing equipment will be crucial for companies aiming to maintain a competitive edge in this dynamic industry. By embracing these innovations, manufacturers can not only improve their production efficiency and reduce costs but also unlock new possibilities for glass applications that were once thought impossible.

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that cutting-edge glass processing equipment plays in driving industry innovation and efficiency. Our team of experts is dedicated to providing state-of-the-art solutions tailored to meet the unique needs of our clients in the glass manufacturing sector. Whether you're looking to upgrade your existing production line or explore new possibilities in glass processing, we're here to help you navigate the latest technological advancements and optimize your operations.

Ready to take your glass processing capabilities to the next level? Contact our team of specialists today at salescathy@sdhuashil.com to discover how our advanced equipment and expertise can transform your production efficiency and drive your business forward. Let's work together to shape the future of glass manufacturing!

References

1. Smith, J. (2023). "Advancements in Glass Processing Technologies: A Comprehensive Review." Journal of Industrial Automation, 45(2), 112-128.

2. Chen, L., & Wang, X. (2022). "Impact of AI and Machine Learning on Modern Glass Manufacturing." International Journal of Materials Processing, 18(4), 301-315.

3. Thompson, R. (2023). "Energy Efficiency in Glass Processing: Innovations and Best Practices." Sustainable Manufacturing Quarterly, 29(3), 78-92.

4. Patel, A., & Nguyen, T. (2022). "The Role of IoT in Optimizing Glass Production Lines." Smart Factory Technologies, 7(2), 155-169.