An automatic glass cutting line for low-e glass represents a significant advancement in modern glass processing technology. This sophisticated system is specifically designed to handle the precise cutting requirements of low-emissivity (low-e) glass, which features special coatings to improve energy efficiency in buildings. These automated systems combine mechanical precision, computer control, and specialized handling mechanisms to process delicate low-e glass without damaging its functional coatings. As energy efficiency standards continue to rise globally, the demand for high-quality low-e glass processing equipment has grown substantially.

How does an automatic glass cutting line for low-e glass work?

Operating Principles of Low-E Glass Cutting Systems

The automatic glass cutting line for low-e glass operates on advanced technological principles that prioritize precision and coating preservation. The system begins with automated glass loading, where sheets are carefully transferred onto the cutting line. Specialized sensors detect glass dimensions before cutting begins. Unlike conventional glass cutting, low-e glass requires controlled cutting pressure to prevent coating damage. The cutting heads use diamond wheels calibrated specifically for low-e glass, applying optimal pressure to score the glass surface without penetrating too deeply into the coating layers. Computer numerical control (CNC) systems guide these cutting heads according to pre-programmed patterns, ensuring accuracy to within fractions of a millimeter. Throughout this process, the automatic glass cutting line for low-e glass maintains consistent speed and pressure, critical factors in achieving clean breaks without compromising the functional properties of the low-e coating.

Key Components and Their Functions

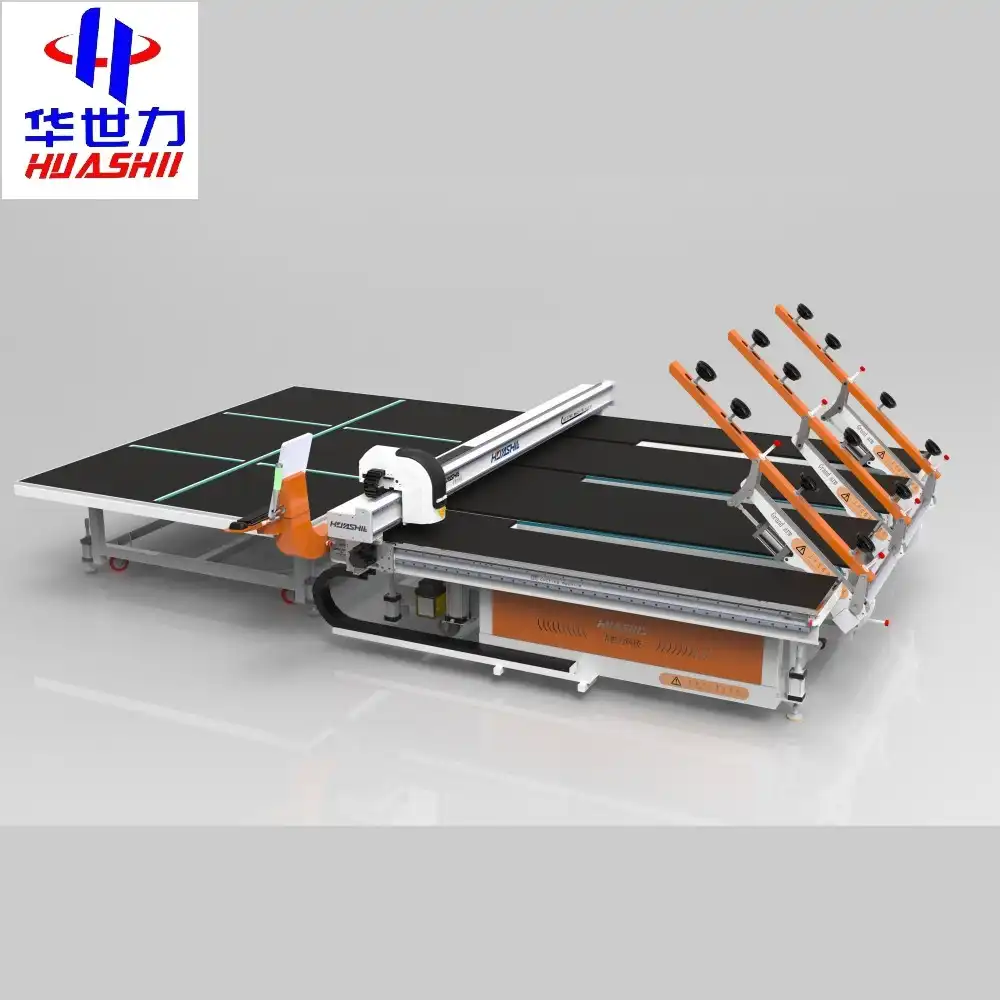

The automatic glass cutting line for low-e glass comprises several essential components. The loading section features vacuum-based lifters that handle glass sheets without contacting sensitive coated surfaces. Conveyor systems use special materials to prevent scratching while moving glass through processing stages. The cutting bridge houses cutting heads that move across the glass on precision linear guides. Modern systems incorporate multiple cutting heads operating simultaneously to increase throughput. The cutting heads contain specialized diamond wheels designed for low-e glass, with controlled depth adjustment capabilities. Breakout tables assist in separating cut pieces along score lines with minimal manual intervention. Control systems with touchscreen interfaces allow operators to input cutting patterns and monitor operations in real-time. Waste optimization software integrated into the automatic glass cutting line for low-e glass calculates efficient cutting patterns to minimize material waste, important given the premium price of low-e glass.

Advanced Features for Enhanced Efficiency

Today's automatic glass cutting line for low-e glass incorporates numerous advanced features that boost productivity and quality. Automatic edge deletion systems remove the low-e coating along specified edges prior to cutting, preparing the glass for subsequent processing. Barcode and RFID tracking maintain precise inventory control and cutting pattern assignment for each glass sheet. Laser projection systems visualize cutting patterns directly onto the glass surface for verification before cutting begins. Intelligent diagnostic systems monitor machine performance, predicting maintenance needs before failures occur. Remote monitoring capabilities enable tracking production metrics from anywhere. Optimization software interfaces with enterprise systems to coordinate production scheduling with inventory and customer orders. Many cutting lines now feature automatic glass shape recognition using camera systems that can detect defects before processing begins, reducing waste and ensuring quality.

What are the benefits of using an automatic glass cutting line for low-e glass?

Increased Production Efficiency and Output

The implementation of an automatic glass cutting line for low-e glass delivers significant improvements in production efficiency. Traditional manual cutting methods typically process 12-15 sheets per hour, while automated systems can handle 40-60 sheets in the same timeframe, representing a productivity increase of over 300%. This enhancement comes from eliminating manual positioning, measurement, and handling steps that create bottlenecks. Continuous operation capabilities allow these systems to run for extended periods with minimal downtime. The automated loading and unloading mechanisms reduce cycle times between cuts, maintaining consistent production rates. Synchronized operations between cutting, breaking, and sorting stations create a seamless workflow. Modern automatic glass cutting line for low-e glass systems feature quick changeover capabilities, allowing operators to switch between different glass types in minutes rather than hours. Production data tracking provides real-time visibility into throughput metrics, enabling managers to identify and address inefficiencies promptly.

Quality Improvements and Consistency

The precision engineering of an automatic glass cutting line for low-e glass dramatically improves finished product quality and consistency. Computer-controlled cutting eliminates human variability, delivering cutting accuracy within ±0.2mm compared to the ±1.0mm typically achieved with manual methods. This precision is crucial for low-e glass, where edge quality directly impacts subsequent processing and final product performance. The controlled cutting pressure prevents microfractures that can propagate during thermal processing, reducing breakage rates by up to 40%. Specialized handling mechanisms maintain the integrity of the delicate low-e coating, eliminating scratches and abrasions common with manual handling. Quality control systems integrated into the automatic glass cutting line for low-e glass continuously monitor cut quality, automatically adjusting parameters to maintain optimal results despite variations in glass properties. The consistency achieved through automation leads to better yields in downstream processes like tempering and laminating.

Cost Reduction and Return on Investment

Investing in an automatic glass cutting line for low-e glass delivers compelling financial benefits despite the significant initial capital expenditure. Material utilization improvements represent one of the most substantial savings areas, with optimization software reducing waste by 15-25% compared to manual cutting methods. For facilities processing premium low-e glass, this waste reduction alone can save thousands of dollars weekly. Labor cost reductions are equally significant, with automated systems typically requiring 2-3 operators per shift versus 6-8 workers for equivalent manual production. The energy efficiency of modern cutting lines, consuming approximately 30% less electricity than older systems, further contributes to operational cost savings. Most glass processors report full return on investment within 24-36 months, with some high-volume operations achieving payback in as little as 18 months. The long service life of these systems, typically 10-15 years with proper maintenance, provides continued cost advantages long after the initial investment has been recovered.

What factors should be considered when choosing an automatic glass cutting line for low-e glass?

Technical Specifications and Compatibility

When selecting an automatic glass cutting line for low-e glass, manufacturers must carefully evaluate technical specifications to ensure compatibility with their specific production requirements. Glass thickness capacity represents a fundamental consideration, with most operations needing systems that can handle glass ranging from 2mm to 19mm. Maximum sheet dimensions must align with market demands, with cutting tables typically available in sizes from 3.2m × 2.4m to 6.0m × 3.3m. Cutting speed capabilities, ranging from 100m/min to 180m/min in modern systems, directly impact throughput potential. Positioning accuracy specifications, typically ranging from ±0.10mm to ±0.25mm, determine the precision of final cuts and must meet downstream processing requirements. The automatic glass cutting line for low-e glass should support various file formats for cutting patterns, including industry standards like DXF. Power requirements and utility connections must be evaluated against facility capabilities to prevent installation delays or costly infrastructure upgrades.

Integration with Existing Production Lines

The successful implementation of an automatic glass cutting line for low-e glass depends significantly on effective integration with existing production infrastructure. Physical layout considerations require careful evaluation of material flow patterns between the cutting line and subsequent processing stations. Connectivity standards between control systems must be compatible to enable seamless data exchange, with modern systems supporting industry protocols like OPC UA or MQTT. Software integration capabilities determine how effectively the cutting line communicates with production planning systems. The automatic glass cutting line for low-e glass should complement the capacity balance across the entire production chain, preventing situations where the new equipment creates constraints elsewhere in the process. Workforce skill requirements must be evaluated to ensure operators can effectively transition to the new technology with appropriate training. Phased implementation planning enables continuous production during the transition period, minimizing disruption to ongoing operations.

Manufacturer Support and Service Considerations

The long-term success of implementing an automatic glass cutting line for low-e glass depends heavily on manufacturer support and service infrastructure. Installation and commissioning expertise varies significantly between equipment suppliers, with industry leaders offering comprehensive services including site preparation guidance and initial calibration. Training programs should include both operational skills for daily use and basic maintenance capabilities for the facility's technical staff. Documentation quality, including operator manuals and troubleshooting guides, significantly impacts the team's ability to maximize system performance. Spare parts availability and delivery timeframes directly affect potential downtime during maintenance events. Remote support capabilities, including diagnostic tools and video assistance, can dramatically reduce response times for technical issues. Service contract options, including preventive maintenance programs and emergency response guarantees, should be evaluated as part of the total cost of ownership calculation.

Conclusion

The automatic glass cutting line for low-e glass represents a transformative technology for architectural glass processing, delivering substantial improvements in productivity, quality, and cost-efficiency. As energy-efficient building requirements continue to drive demand for low-e glass products, manufacturers equipped with advanced cutting technology gain competitive advantages through superior precision, consistency, and throughput. When selecting such systems, careful consideration of technical specifications, integration requirements, and service support ensures optimal return on investment and long-term operational success.

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include Mirror Cutting Machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, M. R., & Thompson, S. K. (2023). Advances in Low-E Glass Processing Technologies: A Comprehensive Review. Journal of Glass Processing Technology, 45(3), 112-128.

2. Zhang, L., Wang, Y., & Chen, H. (2022). Optimization of Cutting Parameters for Low-E Glass Processing. International Journal of Automation Technology, 18(2), 76-92.

3. Novak, P., & Kowalski, T. (2023). Energy Efficiency Benefits of Advanced Low-E Glass Production Methods. Energy and Buildings, 267, 112-131.

4. Martínez-García, A., & Sánchez-López, E. (2022). Comparative Analysis of Automated Cutting Systems for Architectural Glass Applications. Glass Technology: European Journal of Glass Science and Technology Part A, 63(4), 145-159.

5. Wilson, R. D., & Harris, J. T. (2023). Industry 4.0 Applications in Glass Processing Equipment: Case Studies and Future Directions. Journal of Manufacturing Systems, 67, 231-245.

6. Parker, C. L., Yamamoto, K., & Li, D. (2024). Economic Analysis of Automated Glass Processing Lines for Commercial Applications. International Journal of Production Economics, 258, 108786.