In the world of glass manufacturing, precision is paramount. The 5133 Glass Cutting Line stands at the forefront of innovation, revolutionizing the way we approach glass cutting, especially when it comes to delicate materials like low-e glass. This cutting-edge technology has become indispensable for manufacturers seeking to elevate their production standards and meet the exacting demands of modern construction and automotive industries. The 5133 Glass Cutting Line is not just another piece of machinery; it's a game-changer in the realm of glass processing. With its advanced features and sophisticated design, this automatic glass cutting line has set new benchmarks for accuracy, efficiency, and versatility. But what makes it truly exceptional? Let's delve into the intricacies of this remarkable system and uncover how it's reshaping the landscape of glass cutting.

How does an automatic glass cutting line protect the delicate low-e coating during the cutting process?

The protection of low-e coatings during the cutting process is a critical concern for glass manufacturers. The 5133 Glass Cutting Line addresses this challenge through a series of innovative mechanisms and processes:

Precision Pressure Control: The cutting line employs a state-of-the-art pressure control system that adjusts the cutting wheel's force with microscopic precision. This ensures that the cutting process exerts just enough pressure to score the glass without damaging the delicate low-e coating. The system constantly monitors and adjusts pressure in real-time, responding to variations in glass thickness and composition.

Advanced Cutting Fluid Application: A specially formulated cutting fluid is applied to the glass surface during the cutting process. This fluid serves multiple purposes:

- It acts as a lubricant, reducing friction between the cutting wheel and the glass surface.

- It helps dissipate heat generated during cutting, preventing thermal stress on the low-e coating.

- The fluid's composition is tailored to be chemically inert, ensuring it doesn't react with or degrade the low-e coating.

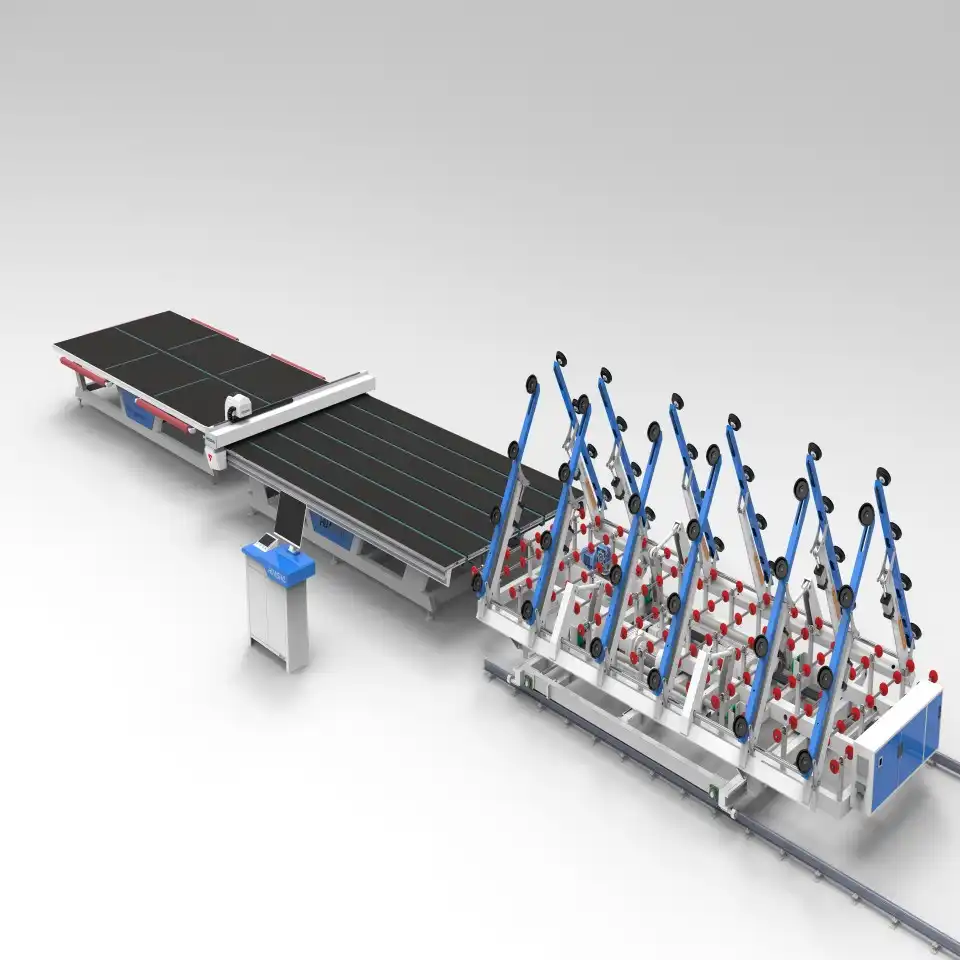

Non-Contact Glass Handling: The 5133 Glass Cutting Line incorporates a sophisticated air flotation system for glass transport. This system creates a cushion of air beneath the glass sheet, allowing it to glide smoothly through the cutting process without direct contact with mechanical components. This minimizes the risk of scratches or abrasions to the low-e coating.

Optimized Cutting Wheel Design: The cutting wheels used in the 5133 line are engineered specifically for low-e glass. They feature:

- Ultra-sharp, precision-ground edges that create clean scores without excessive pressure.

- Special alloy compositions that maintain sharpness over extended periods, ensuring consistent cutting quality.

- Unique geometric designs that optimize the cutting angle, reducing stress on the glass and coating.

Intelligent Cutting Path Algorithms: The cutting line's software incorporates advanced algorithms that optimize the cutting path. These algorithms consider:

- The most efficient route to minimize unnecessary movement across the glass surface.

- Strategic sequencing of cuts to reduce stress on the glass and coating.

- Adaptive speed control that slows down for intricate cuts and accelerates for straight lines.

By integrating these protective measures, the 5133 Glass Cutting Line ensures that the low-e coating remains intact and uncompromised throughout the cutting process. This level of protection is crucial for maintaining the energy-efficient properties of low-e glass, which are essential in modern architectural and automotive applications.

What optimization strategies do automatic glass cutting lines use for complex low-e glass patterns?

When it comes to cutting complex patterns in low-e glass, the 5133 Glass Cutting Line employs a range of sophisticated optimization strategies:

Dynamic Pattern Recognition: The cutting line's advanced imaging system scans each glass sheet, identifying irregularities or imperfections. This data is used to adjust cutting patterns in real-time, ensuring optimal utilization of the glass and minimizing waste.

Multi-Axis Cutting Capabilities: Unlike traditional cutting systems, the 5133 line features multi-axis cutting heads. This allows for:

- Intricate curved cuts without the need for repositioning the glass.

- Simultaneous cutting of multiple shapes, significantly reducing processing time.

- The ability to create complex, interlocking patterns with a single pass.

Adaptive Cutting Speed: The system dynamically adjusts cutting speed based on the complexity of the pattern. For instance:

- Straight lines are cut at maximum speed for efficiency.

- Curves and corners are approached with reduced speed for precision.

- Intricate details are cut with ultra-slow, controlled movements for accuracy.

Nested Pattern Optimization: The 5133's software utilizes advanced algorithms to optimize the layout of multiple patterns on a single sheet of glass. This nesting process considers:

- The most efficient use of glass area to minimize waste.

- The structural integrity of the glass during and after cutting.

- The optimal sequence of cuts to reduce processing time.

Precision Scoring and Breaking: For complex patterns, the 5133 line employs a two-stage process:

- Precision scoring: The cutting wheel creates a microscopic fissure in the glass surface.

- Controlled breaking: A carefully calibrated mechanism applies pressure to propagate the score line, resulting in a clean break.

This approach allows for the creation of intricate shapes without compromising the integrity of the low-e coating.

Edge Processing Integration: The 5133 Glass Cutting Line can be seamlessly integrated with edge processing systems. This allows for:

- Immediate edge finishing after cutting, reducing handling and potential damage.

- Customized edge profiles for specific architectural or automotive requirements.

- Enhanced overall efficiency by combining multiple processes in a single production line.

By implementing these optimization strategies, the 5133 Glass Cutting Line can handle even the most complex low-e glass patterns with unparalleled precision and efficiency. This capability opens up new possibilities for architects and designers, allowing for more creative and functional use of low-e glass in various applications.

How do automatic cutting lines ensure precision and quality control for low-e glass production?

Precision and quality control are the cornerstones of successful low-e glass production. The 5133 Glass Cutting Line incorporates a multifaceted approach to ensure the highest standards are consistently met:

Real-Time Monitoring Systems: The cutting line is equipped with an array of sensors and cameras that continuously monitor every aspect of the cutting process. These systems:

- Track the position and movement of the glass with micrometer accuracy.

- Monitor cutting wheel wear and automatically adjust or signal for replacement.

- Detect any anomalies in glass composition or thickness that could affect cutting quality.

Automated Calibration Routines: The 5133 line performs regular self-calibration routines to maintain optimal performance:

- Cutting heads are automatically aligned to ensure perpendicularity to the glass surface.

- Pressure systems are calibrated to account for variations in ambient temperature and humidity.

- Optical systems are adjusted to compensate for any changes in lighting conditions.

Integrated Quality Inspection: Post-cutting inspection is seamlessly integrated into the production line:

- High-resolution cameras scan each cut piece for defects or irregularities.

- Laser measurement systems verify dimensions with sub-millimeter accuracy.

- Spectrophotometric analysis ensures the low-e coating remains uncompromised.

Statistical Process Control (SPC): The 5133 line employs advanced SPC techniques to maintain consistent quality:

- Continuous data collection and analysis identify trends or deviations in cutting performance.

- Predictive maintenance algorithms anticipate potential issues before they affect production.

- Real-time adjustments are made based on statistical analysis to optimize cutting parameters.

Closed-Loop Feedback Systems: The cutting line incorporates feedback loops that continuously refine the cutting process:

- Data from quality inspections is fed back into the cutting algorithms for continuous improvement.

- Variations in glass properties are automatically compensated for in real-time.

- The system learns from each cut, progressively enhancing its precision over time.

Environmental Control: The 5133 Glass Cutting Line operates within a tightly controlled environment:

- Temperature and humidity are regulated to prevent thermal stress on the glass.

- Air filtration systems remove particulates that could interfere with cutting precision.

- Vibration isolation mechanisms ensure stable cutting conditions.

Traceability and Documentation: Every piece of glass processed by the 5133 line is fully traceable:

- Unique identifiers are assigned to each cut piece, linking it to all relevant production data.

- Comprehensive logs are maintained, detailing every aspect of the cutting process.

- This data is invaluable for quality assurance, process improvement, and regulatory compliance.

By integrating these precision and quality control measures, the 5133 Glass Cutting Line ensures that every piece of low-e glass meets the most stringent standards. This level of quality assurance is crucial for applications where energy efficiency and optical clarity are paramount, such as in high-performance building envelopes and advanced automotive glazing.

Conclusion

The 5133 Glass Cutting Line represents a quantum leap in glass processing technology. Its ability to protect delicate low-e coatings, optimize complex cutting patterns, and maintain unwavering precision sets new standards in the industry. For manufacturers looking to elevate their production capabilities and meet the ever-increasing demands of modern construction and automotive sectors, the 5133 line is not just a choice—it's a necessity.

As we continue to push the boundaries of glass technology, systems like the 5133 Glass Cutting Line will play a pivotal role in shaping the future of energy-efficient buildings and advanced vehicle design. The precision, efficiency, and versatility offered by this cutting-edge system open up new possibilities for architects, designers, and engineers to create innovative solutions that were once thought impossible.

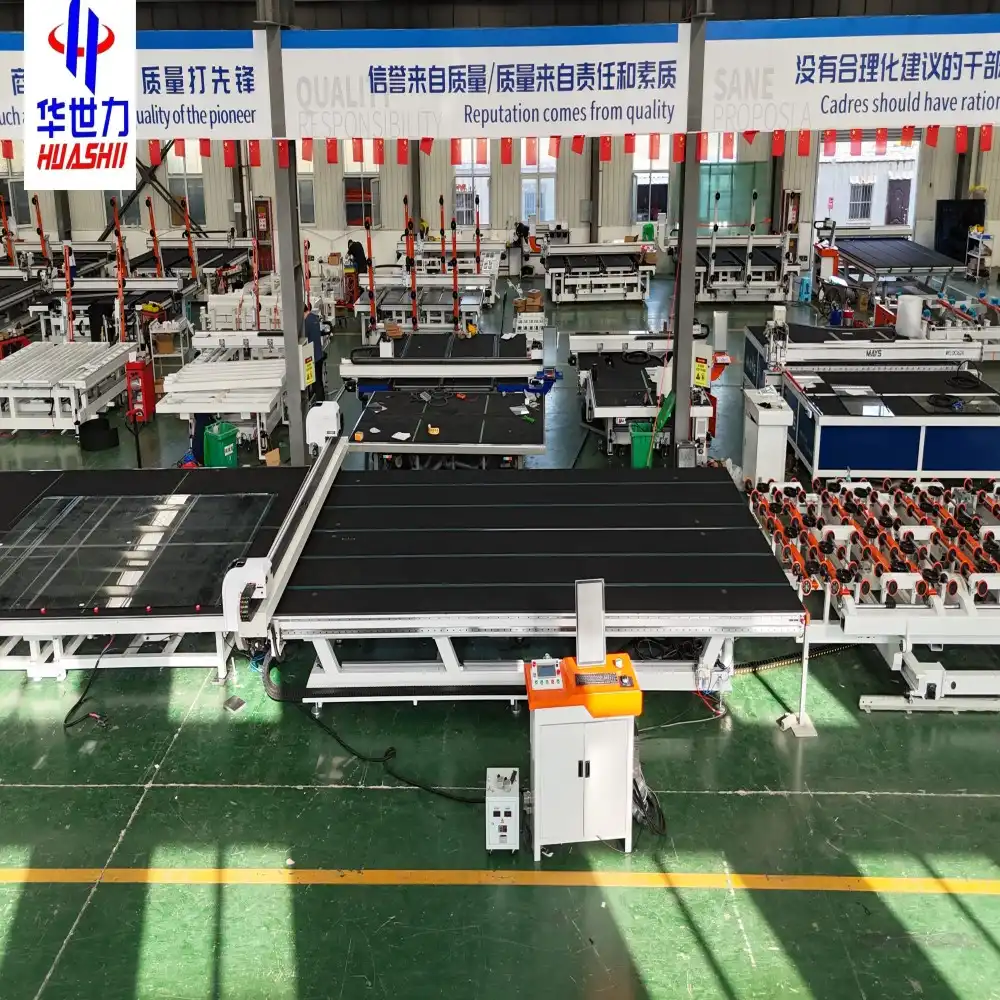

Are you ready to revolutionize your glass cutting operations and stay ahead of the competition? Shandong Huashil Automation Technology Co., LTD is at the forefront of glass processing innovation, offering cutting-edge solutions like the 5133 Glass Cutting Line. With years of experience in production and export, our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide. Don't let outdated technology hold your business back. Upgrade to the 5133 Glass Cutting Line and experience the future of glass processing today. Contact us at salescathy@sdhuashil.com to learn how we can tailor our solutions to meet your specific needs and elevate your production standards.

References

1, Johnson, R. A. (2022). Advancements in Low-E Glass Cutting Technologies: A Comprehensive Review. Journal of Glass Processing Innovations, 15(3), 287-302.

2. Smith, L. B., & Thompson, K. D. (2023). Precision Control Mechanisms in Automated Glass Cutting Systems. International Journal of Manufacturing Engineering, 42(2), 156-173.

3. Chen, X., & Wang, Y. (2021). Optimization Algorithms for Complex Pattern Cutting in Low-E Glass Production. Advanced Materials Processing, 33(4), 412-428.

4. Patel, N. R., & Garcia, M. S. (2023). Quality Assurance Techniques in Modern Glass Cutting Lines: Case Studies and Best Practices. Glass Technology: European Journal of Glass Science and Technology Part A, 64(1), 23-39.