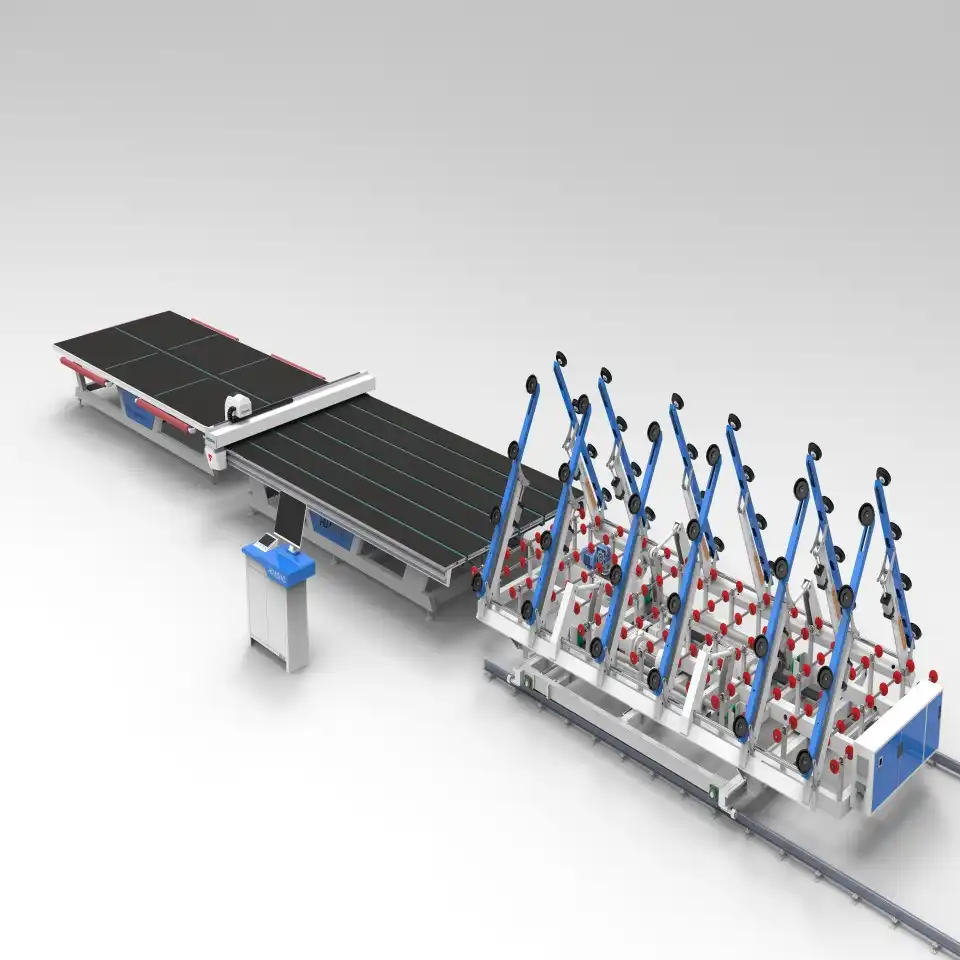

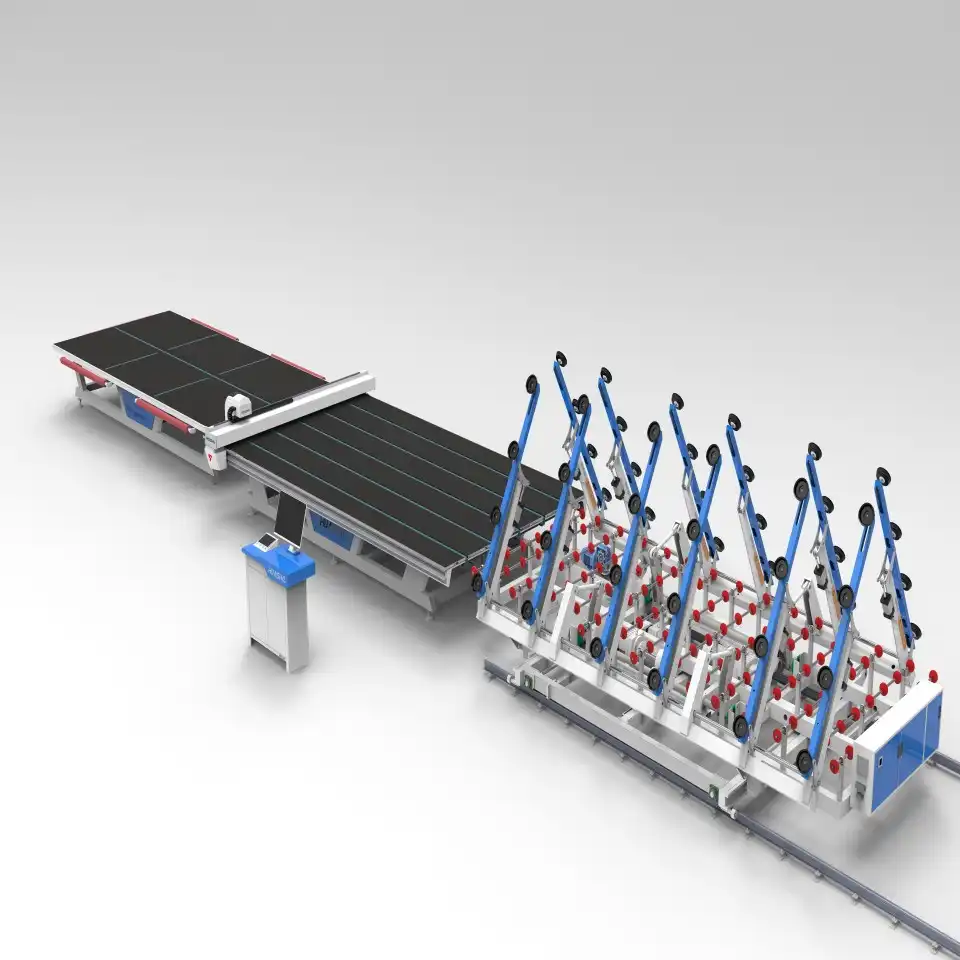

In today's rapidly evolving glass manufacturing industry, efficiency, precision, and automation have become critical factors for success. CNC glass cutting assembly lines represent a significant technological advancement that has revolutionized how glass is processed across various sectors. These sophisticated systems combine cutting-edge software control with precision mechanical components to deliver superior results compared to traditional glass cutting methods. This article explores the numerous advantages that CNC glass cutting assembly lines bring to manufacturers, from enhanced productivity and quality to reduced waste and expanded design capabilities.

How does a CNC glass cutting assembly line improve production efficiency?

Streamlining the Manufacturing Process with Automation

The implementation of a CNC glass cutting assembly line dramatically streamlines the manufacturing process through comprehensive automation. Unlike traditional manual cutting methods that require extensive operator intervention, these advanced systems handle the entire cutting process with minimal human oversight. Operators simply input cutting specifications into the control software, and the system manages everything from material handling to precise cutting and sorting. This level of automation significantly reduces production cycle times, with some manufacturers reporting efficiency improvements of up to 40% after transitioning to CNC glass cutting assembly line technology. The seamless integration of various production stages creates a smooth workflow that maximizes throughput while maintaining exceptional quality standards.

Reducing Labor Costs While Increasing Output

A compelling economic advantage of implementing a CNC glass cutting assembly line is the substantial reduction in labor requirements coupled with increased production output. These systems can operate with significantly fewer personnel than traditional cutting methods while simultaneously producing more finished glass products. A typical CNC glass cutting assembly line can be managed by 2-3 operators, compared to the 8-10 workers required for equivalent output using conventional methods. This labor efficiency translates directly to reduced operational costs and higher profit margins for manufacturers. Additionally, the reduction in labor-intensive tasks decreases workplace injuries and associated costs. Many glass fabricators report that their investment in CNC glass cutting assembly line technology achieves return on investment within 18-24 months primarily through these labor cost savings and output increases.

Minimizing Downtime with Intelligent Production Scheduling

CNC glass cutting assembly lines excel at minimizing production downtime through intelligent scheduling capabilities and preventive maintenance features. Advanced control software optimizes cutting patterns across multiple glass sheets, automatically generating efficient production sequences that maximize material utilization while minimizing tool changes. Additionally, modern CNC glass cutting assembly line systems incorporate predictive maintenance algorithms that monitor component wear and performance metrics in real-time, alerting operators to potential issues before they cause breakdowns. Many systems also feature quick-change components and modular designs that facilitate rapid repairs when necessary. The combination of optimized scheduling and intelligent maintenance typically results in overall equipment effectiveness (OEE) rates exceeding 85% for CNC glass cutting assembly lines, far surpassing the 60-70% common with conventional glass cutting operations.

What quality advantages do CNC glass cutting assembly lines provide?

Achieving Unmatched Precision and Consistency

The superior precision capabilities of CNC glass cutting assembly line technology represent a fundamental quality advantage over traditional cutting methods. These systems utilize high-resolution positioning mechanisms, typically accurate to within ±0.1mm or better, coupled with computer-controlled motion that eliminates human variability. This exceptional precision ensures that every piece of glass is cut to exact specifications, maintaining dimensional consistency even across large production runs. The CNC glass cutting assembly line achieves this consistency through integrated measurement systems that continuously verify positioning accuracy and automatically compensate for any variations detected. This level of accuracy is particularly valuable in applications such as architectural glazing, automotive components, and electronic displays, where even minor dimensional variations can lead to installation problems. Manufacturers utilizing CNC glass cutting assembly lines typically report defect rates below 0.5%, representing a significant improvement over the 2-5% commonly experienced with conventional cutting methods.

Enhancing Edge Quality and Reducing Post-Processing Requirements

CNC glass cutting assembly lines deliver substantially improved edge quality compared to traditional cutting techniques, significantly reducing post-processing requirements. The precision-controlled cutting heads and consistent operational parameters ensure clean, smooth edges directly from the primary cutting process. Modern CNC glass cutting assembly line systems incorporate advanced scoring technologies that create micro-fractures of precisely controlled depth, resulting in exceptionally clean separation during the breaking phase. This superior edge quality dramatically reduces the need for secondary operations such as grinding or polishing, which traditionally account for significant production time and cost in glass fabrication. Manufacturers report that implementing CNC glass cutting assembly line technology can reduce post-cutting processing requirements by 60-80% compared to conventional methods, decreasing handling and the risk of damage during multiple processing stages.

Expanding Design Possibilities with Complex Cutting Capabilities

CNC glass cutting assembly lines dramatically expand design possibilities by enabling complex cutting patterns and shapes that would be impractical or impossible with traditional methods. These sophisticated systems can execute intricate curved cuts, internal cutouts, precise angles, and variable radius corners with the same efficiency and precision as simple straight cuts. The CNC glass cutting assembly line achieves this versatility through multi-axis control systems guided by CAD/CAM software that translates complex designs directly into machine instructions. This capability allows architects, designers, and manufacturers to explore innovative glass applications without traditional fabrication constraints. Additionally, many CNC glass cutting assembly line systems can process various glass types, thicknesses, and sizes without extensive retooling, allowing manufacturers to diversify their product offerings and respond effectively to evolving market demands.

How do CNC glass cutting assembly lines optimize material usage and reduce waste?

Implementing Intelligent Nesting and Cutting Path Optimization

CNC glass cutting assembly lines excel at minimizing material waste through sophisticated nesting and cutting path optimization technologies. The advanced software controlling these systems analyzes all required parts and automatically arranges them in the most efficient configuration across glass sheets. This intelligent nesting considers numerous variables simultaneously, including part dimensions, quantity requirements, glass sheet sizes, and necessary spacing between cuts. The CNC glass cutting assembly line software can evaluate thousands of possible layout combinations within seconds to identify the optimal arrangement that minimizes waste. Additionally, the system optimizes cutting paths to reduce total travel distance and unnecessary movements. Manufacturers implementing CNC glass cutting assembly line technology typically report material utilization improvements of 8-15% compared to manual planning methods, representing substantial cost savings particularly when working with specialty or high-value glass materials.

Minimizing Breakage Through Precision Control and Handling

The precision control mechanisms and sophisticated handling systems of modern CNC glass cutting assembly lines significantly reduce breakage rates throughout production. Unlike manual methods where inconsistent cutting pressure can cause unintended fractures, CNC systems maintain optimal parameters consistently. The CNC glass cutting assembly line typically incorporates specialized material support systems that evenly distribute pressure during cutting operations. Advanced systems feature air cushion tables that allow glass sheets to float on a thin layer of air, eliminating friction and the risk of scratches during positioning. The cutting pressure is precisely calibrated based on glass thickness and composition, ensuring clean separation without excessive force. Many CNC glass cutting assembly line manufacturers report that customers experience breakage rate reductions of 70-90% after implementation, representing significant direct cost savings and productivity improvements.

Enabling Precise Material Tracking and Inventory Management

Modern CNC glass cutting assembly lines integrate sophisticated material tracking and inventory management capabilities that further optimize resource utilization. These systems maintain comprehensive digital records of all glass sheets in inventory, tracking key attributes such as dimensions, thickness, type, and quality grade. When new cutting jobs are scheduled, the CNC glass cutting assembly line software can automatically select the optimal sheets from available inventory, considering factors such as minimizing waste and matching quality requirements. The digital tracking extends to remnant pieces, with the system recording the exact dimensions of usable offcuts and incorporating them into future cutting plans when appropriate. This remnant management capability significantly reduces waste compared to traditional approaches where irregular leftover pieces are often discarded. The CNC glass cutting assembly line also generates detailed material consumption reports that help managers optimize purchasing decisions and accurately calculate costs for specific jobs.

Conclusion

CNC glass cutting assembly lines offer transformative advantages across multiple dimensions of glass manufacturing operations. These sophisticated systems dramatically improve production efficiency through automation, reduced labor requirements, and minimized downtime. They deliver superior quality outcomes with unmatched precision, enhanced edge finishes, and expanded design capabilities. Additionally, they optimize material usage through intelligent nesting, reduced breakage, and comprehensive inventory management. For glass manufacturers seeking competitive advantages in today's demanding marketplace, investment in CNC technology represents a strategic decision that yields substantial returns.

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include Mirror Cutting Machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Chen, L., & Wong, K. (2023). "Advancements in CNC Technology for Precision Glass Manufacturing." Journal of Manufacturing Technology, 45(3), 215-232.

2. Roberts, J., & Thompson, M. (2024). "Comparative Analysis of Traditional vs. CNC Glass Cutting Methods in Industrial Applications." International Journal of Glass Science and Technology, 18(2), 89-104.

3. Zhang, H., Garcia, R., & Miller, S. (2023). "Economic Impact Assessment of Automation in Glass Processing Industries." Journal of Industrial Economics, 29(4), 412-429.

4. Patel, A., & Nakamura, T. (2022). "Material Optimization Strategies in Modern Glass Fabrication." Resources Conservation and Recycling, 176, 105908.

5. Wilson, D., & Schmidt, K. (2024). "Quality Enhancement in Architectural Glass Through Advanced Cutting Technologies." Journal of Architectural Engineering, 32(1), 45-63.

6. Johnson, M., & Lee, S. (2023). "Industry 4.0 Implementation in Glass Manufacturing: Case Studies and Best Practices." International Journal of Production Research, 61(5), 1678-1695.