The lubrication system in a CNC glass cutting machine plays a crucial role in ensuring smooth operation and longevity of the equipment. Understanding how this system works is essential for operators and maintenance personnel alike. In this comprehensive guide, we'll explore the intricacies of lubrication systems in CNC glass cutting machines, their importance, and best practices for maintenance.

Purpose of Lubrication: Reducing Friction and Heat on Moving Parts

The primary purpose of lubrication in a CNC glass cutting machine is to reduce friction and heat generated by moving parts. This is particularly important in precision machinery where even the slightest wear can affect performance. Here's how lubrication achieves this:

- Friction Reduction: Lubricants create a thin film between moving surfaces, minimizing direct contact and reducing friction. This results in smoother operation and less wear on components.

- Heat Dissipation: As the machine operates, heat is generated due to friction and mechanical work. Lubricants help dissipate this heat, preventing overheating and potential damage to sensitive components.

- Corrosion Prevention: Many lubricants also have anti-corrosive properties, protecting metal surfaces from oxidation and environmental factors.

- Debris Removal: The flow of lubricant can help flush away small particles and debris that might otherwise accumulate and cause damage.

In CNC glass cutting machines, proper lubrication is essential for maintaining precision and extending the life of critical components such as ball screws, linear guides, and spindles. Without adequate lubrication, these parts would quickly wear out, leading to decreased accuracy and potential machine failure.

Types of Lubricants Used for Guide Rails and Ball Screws

Selecting the right lubricant for different components of a CNC glass cutting machine is crucial for optimal performance. Let's examine the types of lubricants commonly used for guide rails and ball screws:

Guide Rails

Guide rails in CNC glass cutting machines require lubricants that can withstand high loads and maintain a consistent film thickness. Common types include:

- Lithium-based Greases: These offer good adhesion and water resistance, making them suitable for guide rails exposed to coolants or moisture.

- Synthetic Oils: These provide excellent lubrication at high speeds and temperatures, ideal for high-performance machines.

- PTFE-enhanced Lubricants: These reduce friction even further and are often used in precision applications.

Ball Screws

Ball screws require lubricants that can penetrate the ball-and-race assembly effectively. Typical choices include:

- Low-viscosity Oils: These can easily reach all parts of the ball screw mechanism, ensuring comprehensive lubrication.

- Molybdenum Disulfide Greases: These provide excellent load-bearing capabilities and are often used in heavy-duty applications.

- Food-grade Lubricants: In industries where contamination is a concern, such as food packaging, specialized food-grade lubricants are used.

The choice of lubricant often depends on factors such as operating speed, load, temperature, and environmental conditions. China CNC glass cutting machine manufacturers typically provide recommendations for suitable lubricants based on their specific machine designs and intended applications.

Lubrication Schedule as Part of Preventive Maintenance

A well-planned lubrication schedule is a critical component of preventive maintenance for CNC glass cutting machines. Proper scheduling ensures that all components receive adequate lubrication at the right intervals, preventing premature wear and unexpected downtime. Here's how to develop and implement an effective lubrication schedule:

Frequency Determination

The frequency of lubrication depends on several factors:

- Machine Usage: Machines used more frequently or for longer periods may require more frequent lubrication.

- Environmental Conditions: Dusty or humid environments may necessitate more frequent lubrication to prevent contamination or moisture-related issues.

- Manufacturer Recommendations: Always consult the machine's manual for specific lubrication intervals recommended by the manufacturer.

- Component-specific Requirements: Different parts of the machine may have varying lubrication needs. For example, ball screws might need more frequent attention than guide rails.

Lubrication Points

Identify all lubrication points on the CNC glass cutting machine. Common points include:

- Linear Guide Rails

- Ball Screws

- Bearings

- Gears and Gear Racks

- Spindle Assemblies

Documentation and Tracking

Maintain detailed records of lubrication activities:

- Create a lubrication chart that maps out all lubrication points on the machine.

- Use a logbook or digital system to track when each point was last lubricated.

- Note any observations or issues encountered during lubrication procedures.

Training and Consistency

Ensure that all personnel involved in machine maintenance are properly trained:

- Provide training on correct lubrication techniques and safety procedures.

- Emphasize the importance of using the right type and amount of lubricant for each component.

- Establish a routine that integrates lubrication tasks into regular maintenance schedules.

Regular Inspections

In addition to scheduled lubrication, implement regular inspections:

- Check for signs of inadequate lubrication, such as unusual noise or increased heat.

- Look for leaks or over-lubrication, which can attract dust and debris.

- Assess the condition of seals and wipers that help retain lubricants.

Adaptation and Optimization

Regularly review and adjust your lubrication schedule:

- Monitor machine performance and adjust lubrication frequency if needed.

- Stay informed about new lubricant technologies that might offer improved performance.

- Consider implementing automated lubrication systems for more consistent and efficient lubrication.

By following a well-structured lubrication schedule, operators can significantly extend the life of their CNC glass cutting machine and maintain its precision over time. This proactive approach not only reduces the risk of unexpected breakdowns but also ensures consistent quality in glass cutting operations.

Advanced Lubrication Technologies

As technology advances, so do lubrication systems for CNC glass cutting machines. Some cutting-edge developments include:

- Micro-dosing Systems: These deliver precise amounts of lubricant exactly where needed, reducing waste and improving efficiency.

- Smart Lubrication Systems: Equipped with sensors, these systems can monitor lubricant levels and condition, alerting operators when intervention is needed.

- Dry Lubrication Technologies: Some advanced materials and coatings can provide lubrication without traditional oils or greases, ideal for clean room environments.

These advancements not only improve machine performance but also contribute to more sustainable manufacturing practices by reducing lubricant consumption and waste.

Environmental Considerations

Modern lubrication practices for CNC glass cutting machines also take environmental factors into account:

- Biodegradable Lubricants: Many manufacturers now offer eco-friendly lubricants that break down naturally, reducing environmental impact.

- Recycling Programs: Some companies implement lubricant recycling programs to minimize waste and reduce the need for new oil production.

- Energy Efficiency: Proper lubrication can significantly reduce energy consumption by minimizing friction and heat generation.

By considering these environmental aspects, glass cutting operations can not only improve their machine performance but also contribute to more sustainable manufacturing practices.

Troubleshooting Lubrication Issues

Even with a robust lubrication system and schedule in place, issues can sometimes arise. Here are some common problems and their potential solutions:

- Excessive Wear: If components are wearing out faster than expected, it may indicate insufficient lubrication or the use of an incorrect lubricant type.

- Overheating: This could be a sign of inadequate lubrication or a blockage in the lubrication system.

- Lubricant Leakage: This might indicate worn seals or over-lubrication and should be addressed promptly to prevent contamination and waste.

- Inconsistent Machine Performance: If the machine's performance varies, it could be due to uneven lubrication across different components.

Regular monitoring and prompt addressing of these issues can prevent more serious problems and extend the life of the CNC glass cutting machine.

Conclusion

The lubrication system in a CNC glass cutting machine is a critical component that directly impacts the machine's performance, precision, and longevity. By understanding how these systems work and implementing best practices in lubrication management, operators can ensure optimal performance and minimize downtime.

Regular maintenance, proper lubricant selection, and adherence to a well-planned lubrication schedule are key to keeping your CNC glass cutting machine in top condition. As technology continues to evolve, staying informed about the latest advancements in lubrication systems and practices will help you maintain a competitive edge in the glass cutting industry.

FAQ

1. How often should I lubricate my CNC glass cutting machine?

The frequency of lubrication depends on various factors such as machine usage, environmental conditions, and manufacturer recommendations. Generally, high-use machines may require lubrication weekly or even daily, while less frequently used machines might need lubrication monthly. Always consult your machine's manual for specific guidelines.

2. Can I use any type of lubricant for my CNC glass cutting machine?

No, it's crucial to use lubricants specifically recommended for CNC machines. Different components may require different types of lubricants. Using the wrong type can lead to poor performance or even damage to the machine. Consult your machine's manual or contact the manufacturer for the correct lubricant specifications.

3. What are the signs that my CNC glass cutting machine needs lubrication?

Signs that your machine may need lubrication include increased noise during operation, reduced precision in cuts, visible wear on components, or unusual heat generation. If you notice any of these signs, it's important to check and replenish lubrication as needed.

4. How does proper lubrication affect the lifespan of a CNC glass cutting machine?

Proper lubrication significantly extends the lifespan of a CNC glass cutting machine by reducing friction and wear on moving parts. It also helps prevent overheating and corrosion. With consistent and appropriate lubrication, critical components like ball screws and guide rails can last much longer, reducing the need for repairs and replacements.

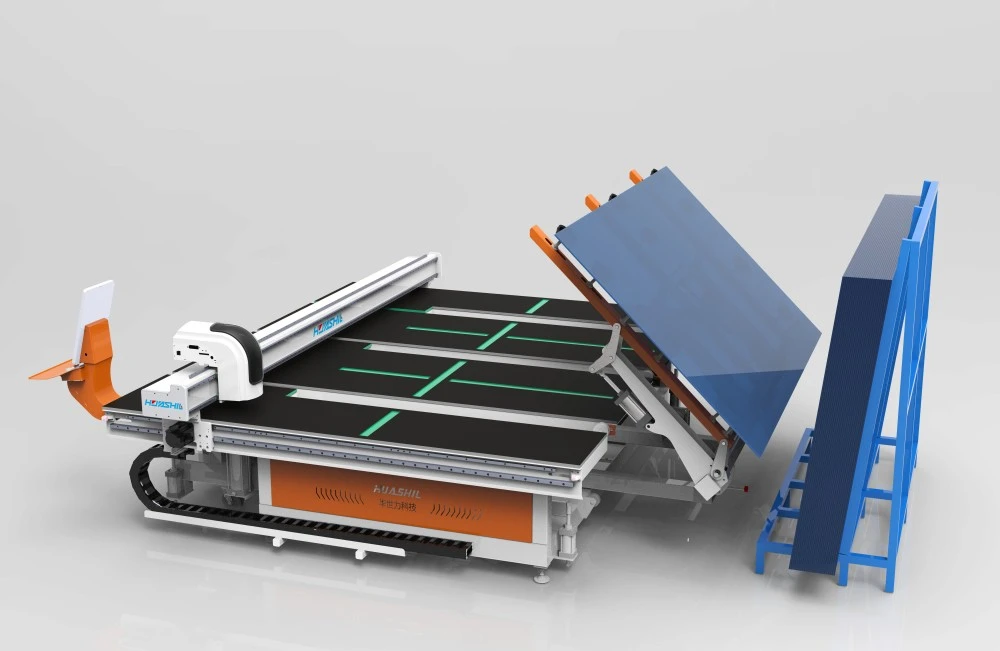

Choose the Best CNC Glass Cutting Machine for Your Needs | HUASHIL

When it comes to selecting the perfect CNC glass cutting machine for your business, Shandong Huashil Automation Technology Co., LTD is your trusted partner. As a leading manufacturer and supplier in the industry, we offer a wide range of cutting-edge solutions designed to meet the diverse needs of our global clientele.

Our CNC glass cutting machines are engineered with precision and durability in mind, featuring advanced lubrication systems that ensure smooth operation and long-lasting performance. Whether you're in the architectural glass, automotive, or specialty glass sector, we have the right machine to elevate your production capabilities.

Don't settle for less when it comes to your glass cutting needs. Invest in a Huashil CNC glass cutting machine and experience the perfect blend of innovation, reliability, and efficiency. Our team of experts is ready to guide you through the selection process and provide ongoing support to ensure your success.

Take the first step towards optimizing your glass cutting operations. Contact us today at salescathy@sdhuashil.com to discuss your specific requirements and discover how our CNC glass cutting machines can transform your business. Let Huashil be your partner in precision and productivity!

References

1. Johnson, M. (2022). Advanced Lubrication Systems for CNC Machinery. Journal of Industrial Automation, 45(3), 178-195.

2. Smith, A. R., & Brown, L. K. (2021). Preventive Maintenance Strategies for Glass Cutting Equipment. Glass Technology International, 33(2), 56-72.

3. Zhang, Y., et al. (2023). Environmental Impact of Lubrication Practices in Manufacturing. Sustainable Production and Consumption, 28, 1023-1035.

4. Miller, D. T. (2020). Optimizing CNC Machine Performance through Effective Lubrication. International Journal of Machine Tools and Manufacture, 159, 103615.