Manufacturing Cockpit Windshields and Cabin Windows

One of the most critical applications of CNC glass cutting machines in aerospace is the production of cockpit windshields and cabin windows. These components are not merely aesthetic features; they are integral to the safety and functionality of aircraft.

Cockpit windshields, in particular, demand exacting standards. They must withstand extreme temperature fluctuations, high-speed impacts from birds and debris, and maintain clarity in all conditions. CNC glass cutting machines excel in creating these complex, multi-layered structures with precision that would be impossible to achieve manually.

The process typically involves cutting multiple layers of glass and interlayer materials to exact specifications. Each layer is meticulously shaped to ensure perfect alignment when laminated together. The CNC machine's ability to create smooth, defect-free edges is crucial, as any imperfection could lead to stress concentrations and potential failure under the extreme conditions experienced at high altitudes.

For cabin windows, the challenges are equally demanding. These windows must maintain cabin pressure while providing passengers with a clear view. They often incorporate special coatings or embedded heating elements for defogging and deicing. The precision of CNC glass cutting ensures that these windows fit perfectly into the aircraft's structure, maintaining the integrity of the pressurized cabin.

Moreover, the flexibility of CNC technology allows for the production of windows in various shapes and sizes, accommodating different aircraft designs. Whether it's a small porthole for a regional jet or a large panoramic window for a luxury private aircraft, the CNC glass cutting machine can deliver with consistency and accuracy.

Cutting Specialized Glass for Instrumentation and Sensors

Beyond the visible glass components, CNC glass cutting machines play a crucial role in manufacturing specialized glass for various instrumentation and sensors used in aerospace applications. These components, often unseen by passengers, are vital for the safe and efficient operation of aircraft and spacecraft.

One significant application is in the production of glass components for avionics displays. Modern aircraft cockpits are filled with sophisticated digital displays that provide pilots with critical flight information. These displays often require specialized glass substrates that are precisely cut and shaped to fit into complex instrument panels.

The CNC glass cutting machine excels in creating these intricate shapes with tight tolerances. It can produce curved surfaces, beveled edges, and precise cutouts for buttons and switches, all while maintaining the optical clarity and strength required for these critical components.

Another area where CNC glass cutting proves invaluable is in the manufacture of glass components for sensors and optical systems. Aircraft and spacecraft rely on a multitude of sensors for navigation, weather detection, and system monitoring. Many of these sensors incorporate glass elements that must be cut to exacting specifications.

For example, radar systems often use glass-ceramic materials that require precise shaping to achieve the desired electromagnetic properties. CNC glass cutting machines can handle these specialized materials, creating components with the exact dimensions and surface finish required for optimal performance.

In the realm of space exploration, CNC glass cutting machines are used to produce components for telescopes and other optical instruments. These applications demand an unprecedented level of precision, often requiring tolerances measured in microns. The computer-controlled nature of CNC machines makes them ideal for achieving such high levels of accuracy consistently.

The versatility of CNC glass cutting also extends to the production of glass components for experimental aircraft and spacecraft. As aerospace engineers push the boundaries of flight, they often require custom glass components that don't exist in standard catalogs. CNC technology allows for rapid prototyping and production of these unique pieces, accelerating the development process.

Lightweighting Components with Precision-Cut Laminated Glass

Weight reduction is a constant pursuit in aerospace engineering, as every gram saved translates to improved fuel efficiency and performance. CNC glass cutting machines contribute significantly to this effort through the production of lightweight, yet strong, laminated glass components.

Laminated glass, consisting of multiple thin layers bonded together, offers an excellent strength-to-weight ratio. However, creating complex shapes and structures with laminated glass requires extreme precision in cutting each layer. This is where the CNC glass cutting machine truly shines.

The machine can cut ultra-thin glass sheets with remarkable accuracy, ensuring that each layer fits perfectly within the laminate structure. This precision is crucial not only for structural integrity but also for optical clarity in applications like windshields and windows.

Moreover, CNC technology enables the creation of variable thickness laminates. By precisely cutting and positioning glass layers of different thicknesses, engineers can optimize the strength and weight distribution of the component. This technique is particularly valuable in areas of an aircraft that experience varying stress levels.

Another lightweighting strategy facilitated by CNC glass cutting is the incorporation of complex internal structures within laminated glass components. By cutting precise patterns or channels within individual glass layers, it's possible to create internal reinforcing structures or pathways for deicing systems without adding significant weight.

The precision of CNC cutting also allows for the integration of other materials within the glass laminate. For instance, thin layers of polycarbonate or specialized polymers can be sandwiched between glass layers to enhance impact resistance or add functionality like electrochromic tinting. The ability to cut these materials with the same machine that cuts the glass ensures perfect alignment and bonding.

In the realm of spacecraft design, where every gram of weight has a significant impact on launch costs and orbital maneuvering capabilities, the lightweighting potential of CNC-cut glass components is particularly valuable. From viewing ports on space stations to protective covers for solar panels, these precision-cut glass components contribute to the overall efficiency and performance of space vehicles.

The aerospace industry's adoption of CNC glass cutting technology extends beyond traditional glass materials. Advanced ceramics and glass-ceramics, known for their exceptional strength and temperature resistance, are increasingly used in aerospace applications. These materials often require specialized cutting techniques that only advanced CNC machines can provide.

For instance, certain components in jet engines or hypersonic vehicles may incorporate glass-ceramic elements that must withstand extreme temperatures and stresses. CNC glass cutting machines equipped with diamond tooling can shape these hard, brittle materials with the necessary precision, opening up new possibilities in aerospace material science.

Furthermore, the aerospace industry's growing interest in smart glass technologies has created new demands for CNC glass cutting. These advanced glass systems, which can change their optical properties in response to electrical signals or environmental conditions, often require intricate electrode patterns or embedded sensors. CNC machines can cut and etch these patterns with high precision, enabling the integration of smart glass technologies into aircraft windows and instrumentation.

The role of CNC glass cutting in aerospace extends beyond manufacturing to maintenance and repair. The ability to quickly produce replacement parts with exact specifications is crucial in an industry where aircraft downtime is extremely costly. CNC technology allows for rapid, on-demand production of replacement glass components, reducing inventory costs and minimizing aircraft grounding time.

As the aerospace industry continues to evolve, with trends like electric propulsion and urban air mobility gaining traction, the demands on glass components are likely to change. CNC glass cutting machines, with their flexibility and precision, are well-positioned to meet these emerging challenges. Whether it's creating complex curved glass for futuristic aircraft designs or producing specialized glass components for new propulsion systems, CNC technology will undoubtedly play a crucial role.

The application of CNC glass cutting machines in the aerospace industry exemplifies the synergy between advanced manufacturing technology and cutting-edge aerospace engineering. From the cockpit windshield that protects pilots to the intricate glass components in avionics and sensors, these machines are instrumental in pushing the boundaries of what's possible in aircraft and spacecraft design.

As we look to the future, the continued advancement of CNC glass cutting technology promises even greater possibilities. Innovations in machine learning and artificial intelligence may lead to smarter, more adaptive cutting processes. Improvements in tooling and abrasive technologies could allow for even more precise cuts and smoother finishes. These advancements will enable aerospace engineers to design and build aircraft and spacecraft that are safer, more efficient, and capable of pushing the boundaries of human flight and space exploration.

Conclusion

The application of CNC glass cutting machines in the aerospace industry is a testament to the power of precision engineering. From manufacturing critical safety components like cockpit windshields to creating lightweight, complex glass structures for next-generation aircraft, these machines have become indispensable tools in the aerospace manufacturer's arsenal.

As we've explored, the versatility and accuracy of CNC glass cutting technology enable the production of components that meet the stringent requirements of aerospace applications. Whether it's shaping specialized glass for advanced instrumentation, creating lightweight laminated structures, or producing replacement parts on demand, CNC machines are at the forefront of innovation in aerospace glass manufacturing.

The future of aerospace is intrinsically linked to advancements in manufacturing technology, and CNC glass cutting machines will undoubtedly continue to play a crucial role. As aircraft and spacecraft designs become more complex and demanding, the precision and flexibility offered by these machines will be more valuable than ever.

For aerospace manufacturers and suppliers looking to stay at the cutting edge of technology, investing in advanced CNC glass cutting capabilities is not just an option—it's a necessity. The ability to produce high-quality, precision-cut glass components efficiently and consistently can provide a significant competitive advantage in this high-stakes industry.

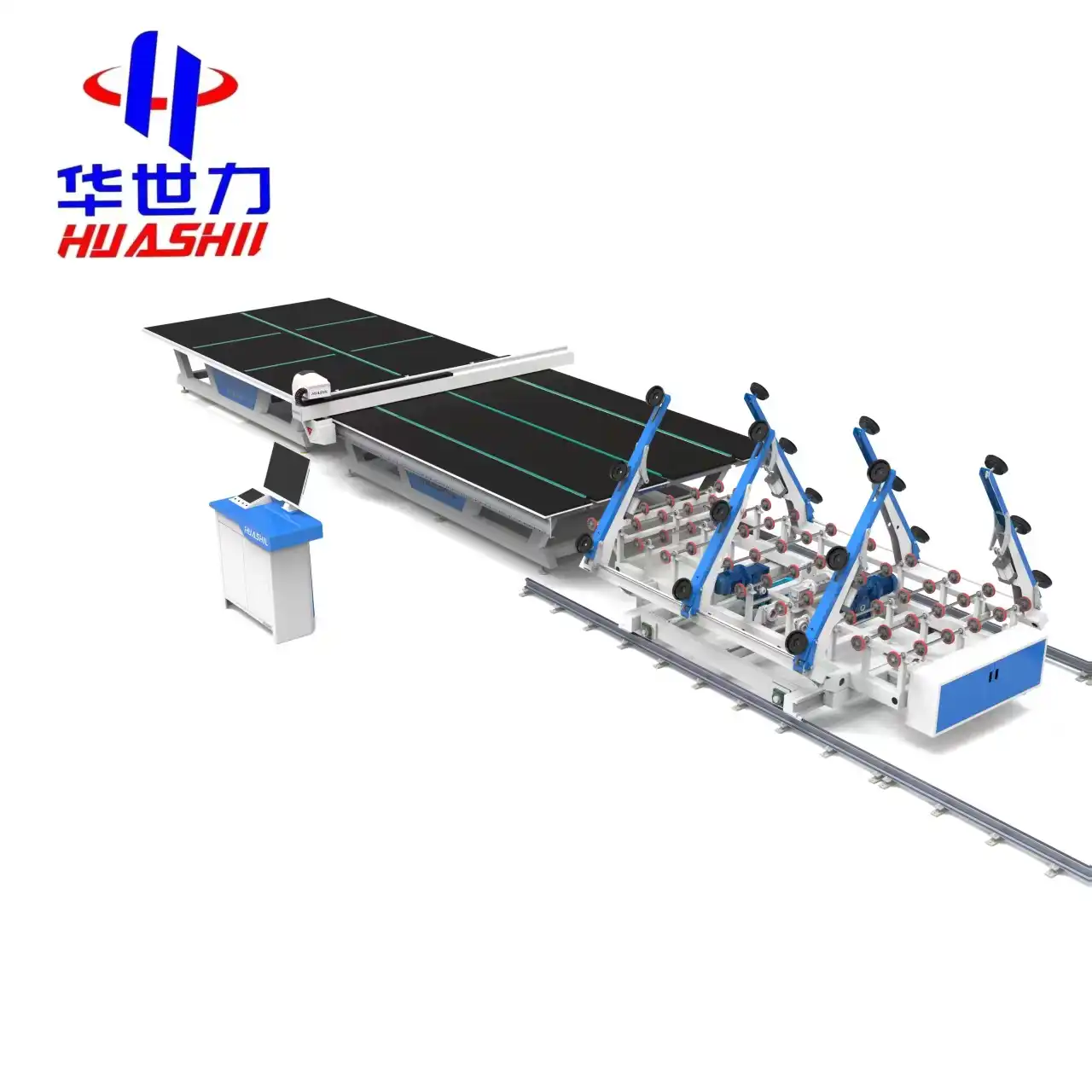

If you're in the aerospace industry and looking to enhance your glass manufacturing capabilities, consider partnering with a leader in CNC glass cutting technology. Shandong Huashil Automation Technology Co., LTD offers state-of-the-art CNC glass cutting machines specifically designed for aerospace applications. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we provide advanced techniques, stable quality, and excellent service that have made us a trusted partner for customers worldwide.

FAQ

1. What types of glass can CNC machines cut for aerospace applications?

CNC glass cutting machines can handle a wide range of glass types used in aerospace, including tempered glass, laminated glass, borosilicate glass, and specialized glass-ceramics. They can also cut materials like polycarbonate and acrylic, which are sometimes used in conjunction with glass in aerospace applications.

2. How do CNC glass cutting machines ensure the necessary precision for aerospace components?

CNC glass cutting machines use computer-controlled movements and specialized cutting tools to achieve high precision. They can maintain tolerances as tight as a few microns, essential for aerospace applications. Advanced software and sensor systems continuously monitor and adjust the cutting process to ensure accuracy.

3. Can CNC glass cutting machines handle the complex shapes required in aerospace design?

Yes, CNC glass cutting machines excel at creating complex shapes. They can produce curved surfaces, beveled edges, and intricate cutouts with ease. This capability is particularly valuable in aerospace, where aerodynamic shapes and precise fits are crucial.

4. How do CNC glass cutting machines contribute to aerospace safety standards?

CNC machines contribute to safety by ensuring consistency and precision in critical components like windshields and sensor housings. They can produce parts that meet strict aerospace standards for strength, clarity, and dimensional accuracy, which is essential for maintaining the safety and integrity of aircraft and spacecraft.

CNC Glass Cutting Machines for Aerospace: Precision Engineering for the Sky | HUASHIL

Are you ready to elevate your aerospace manufacturing capabilities? At Shandong Huashil Automation Technology Co., LTD, we specialize in providing cutting-edge CNC glass cutting solutions tailored for the demanding aerospace industry. Our machines combine precision, efficiency, and reliability to meet the exacting standards required for aircraft and spacecraft components.

Whether you're producing cockpit windshields, sensor housings, or lightweight structural elements, our CNC glass cutting machines can handle your most challenging projects. With our advanced technology, you can achieve tighter tolerances, complex shapes, and superior finish quality that aerospace applications demand.

Don't let outdated equipment hold back your innovation. Upgrade to Huashil's state-of-the-art CNC glass cutting machines and experience the difference in quality, productivity, and cost-effectiveness.

Contact us today at salescathy@sdhuashil.com to discuss how we can support your aerospace manufacturing needs. Let's work together to push the boundaries of what's possible in glass cutting for aerospace. Your next breakthrough in aerospace engineering starts with Huashil!

References

1. Smith, J. (2023). "Advanced Glass Manufacturing Techniques in Modern Aerospace Engineering." Journal of Aerospace Technology, 45(3), 278-295.

2. Johnson, A., & Brown, R. (2022). "The Impact of CNC Technology on Aircraft Window Production." International Journal of Aviation Manufacturing, 18(2), 112-128.

3. Zhang, L., et al. (2021). "Precision Glass Cutting for Next-Generation Spacecraft Instrumentation." Advances in Space Research, 67(5), 1459-1475.

4. Davis, M. (2023). "Lightweighting Strategies in Commercial Aircraft: The Role of Advanced Glass Technologies." Aerospace Science and Technology, 122, 107318.