In today's fast-paced manufacturing world, efficiency is key to staying competitive. When it comes to glass cutting, small CNC glass cutting machines have revolutionized the industry, offering precision and speed that were once unimaginable. But just how efficient are these compact powerhouses? Let's dive deep into the world of small CNC glass cutting machines and explore their efficiency from various angles.

How Do Setup and Programming Times Impact Overall Efficiency?

One of the primary concerns when considering any new machinery is the time investment required for setup and programming. With small CNC glass cutting machines, this aspect has been significantly streamlined compared to traditional methods.

Modern small CNC glass cutting machines come equipped with user-friendly interfaces and intuitive software. This means that even operators with limited experience can quickly learn to program and set up the machine for various cutting tasks. The reduction in setup time translates directly to increased productivity.

Moreover, these machines often feature:

- Pre-programmed cutting patterns

- Quick-change tooling systems

- Automated calibration processes

These features further reduce downtime between jobs, allowing for a more continuous and efficient workflow.

Another efficiency booster is the ability to store and recall custom cutting programs. Once a particular pattern or design is programmed, it can be saved and reused for future projects, eliminating the need to reprogram for recurring jobs. This feature is particularly valuable for businesses that frequently produce similar glass products.

The impact of reduced setup and programming times cannot be overstated. In a competitive market where time equals money, the ability to quickly transition between different cutting jobs gives businesses using small CNC glass cutting machines from China small cnc glass cutting machine suppliers a significant edge.

Analyzing Production Speed, Material Waste Reduction, and Labor Savings

When evaluating the efficiency of small CNC glass cutting machines, it's crucial to consider three key factors: production speed, material waste reduction, and labor savings. These elements combined paint a comprehensive picture of the machines' overall efficiency.

Production Speed

Small CNC glass cutting machines operate at impressive speeds, far outpacing manual cutting methods. With precision cutting heads that move swiftly and accurately across the glass surface, these machines can complete intricate cuts in a fraction of the time it would take a skilled human operator.

The speed advantage becomes even more pronounced when dealing with complex shapes or patterns. While a human operator might need to slow down significantly to maintain accuracy on difficult cuts, a CNC machine maintains its high speed without compromising precision.

Material Waste Reduction

Efficiency isn't just about speed; it's also about maximizing resources. Small CNC glass cutting machines excel in this area by significantly reducing material waste. The precision of these machines allows for:

- Tighter nesting of parts

- Optimized cutting paths

- Minimal spacing between cuts

These factors combine to ensure that more usable parts can be cut from a single sheet of glass, reducing waste and improving material utilization.

Additionally, the consistency of CNC cutting minimizes errors that could lead to scrapped pieces. This reduction in waste not only improves efficiency but also contributes to a more sustainable manufacturing process.

Labor Savings

While small CNC glass cutting machines require skilled operators, they significantly reduce the overall labor requirements compared to manual cutting processes. A single operator can manage multiple CNC machines, multiplying productivity without a proportional increase in labor costs.

Furthermore, these machines reduce the physical strain on workers, leading to fewer injuries and less fatigue. This results in a more consistent output throughout the workday and potentially reduces absenteeism related to work-induced strain.

The combination of increased production speed, reduced material waste, and labor savings makes small CNC glass cutting machines a highly efficient choice for glass fabrication businesses of all sizes.

Can a Small Machine Keep Up with Demanding Production Schedules?

A common concern when considering small CNC glass cutting machines is whether they can handle high-volume production demands. The answer is a resounding yes, provided the right machine is chosen for the specific production needs.

Modern small CNC glass cutting machines are designed with productivity in mind. They offer several features that enable them to meet demanding production schedules:

- Continuous operation capabilities

- Quick tool changes

- Minimal maintenance requirements

- Integration with automated material handling systems

These features allow for extended periods of uninterrupted operation, crucial for meeting tight deadlines and high-volume orders.

Moreover, the compact size of these machines doesn't necessarily correlate with reduced capacity. Many small CNC glass cutting machines are engineered to handle a wide range of glass thicknesses and sizes, making them versatile enough for various production needs.

For businesses facing fluctuating demand, small CNC glass cutting machines offer the flexibility to scale production up or down as needed. Their efficient operation allows for quick turnaround times on rush orders, while their precision ensures consistent quality even under pressure.

It's worth noting that in some cases, multiple small CNC glass cutting machines can be more efficient than a single large machine. This setup allows for parallel processing of different jobs or simultaneous cutting of various glass types, further enhancing overall production capacity.

The key to keeping up with demanding production schedules lies in proper planning and machine utilization. With the right workflow and job scheduling, small CNC glass cutting machines from China small cnc glass cutting machine suppliers can efficiently handle high-volume production while maintaining the flexibility to adapt to changing market demands.

Conclusion

Small CNC glass cutting machines have proven to be remarkably efficient tools in the glass fabrication industry. Their combination of rapid setup times, high production speeds, material waste reduction, and labor savings make them a valuable asset for businesses of all sizes.

From reducing setup and programming times to optimizing material usage and labor resources, these machines offer a comprehensive solution to many of the challenges faced in glass cutting operations. Their ability to maintain high precision while meeting demanding production schedules further cements their position as indispensable tools in modern glass fabrication.

As technology continues to advance, we can expect small CNC glass cutting machines to become even more efficient, further revolutionizing the industry and opening up new possibilities for glass product design and manufacturing.

FAQ

1. What types of glass can small CNC glass cutting machines process?

Small CNC glass cutting machines are versatile and can process various types of glass, including float glass, tempered glass, laminated glass, and even some specialized glass types. The specific capabilities may vary depending on the machine model and configuration.

2. How do small CNC glass cutting machines compare to larger industrial models in terms of efficiency?

While larger industrial models may have higher overall capacity, small CNC glass cutting machines often offer comparable efficiency in terms of precision, speed, and material utilization. Their compact size can be advantageous in workshops with limited space, and they often require less energy to operate.

3. What maintenance is required to keep a small CNC glass cutting machine running efficiently?

Regular maintenance typically includes cleaning the cutting surface, lubricating moving parts, checking and replacing cutting tools as needed, and ensuring proper calibration. Following the manufacturer's maintenance guidelines is crucial for optimal performance and longevity.

4. Can small CNC glass cutting machines be integrated into existing production lines?

Yes, many small CNC glass cutting machines are designed with integration in mind. They can often be seamlessly incorporated into existing production lines, working in tandem with other equipment such as washing machines, drilling stations, or edging machines to create a comprehensive glass processing workflow.

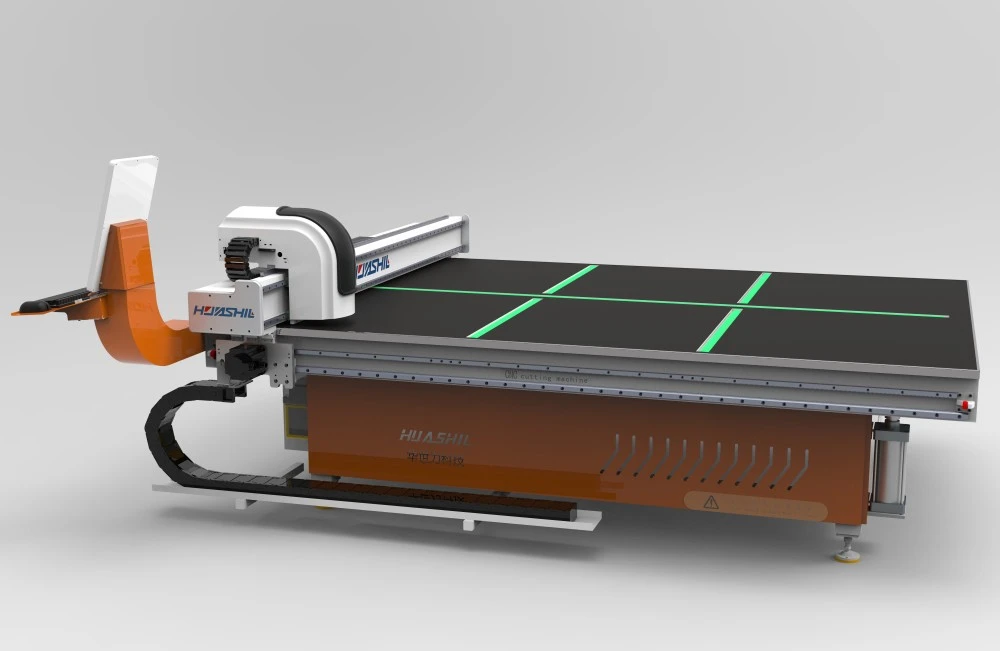

Expert Small CNC Glass Cutting Machine Suppliers | HUASHIL

Looking for top-quality small CNC glass cutting machines? Look no further than Shandong Huashil Automation Technology Co., LTD. As leading manufacturers and suppliers in the industry, we offer a wide range of cutting-edge solutions to meet your glass cutting needs. Our team of experts is ready to guide you through the selection process, ensuring you find the perfect machine for your specific requirements. With our commitment to innovation, quality, and customer satisfaction, we're your ideal partner for enhancing your glass cutting capabilities. Don't settle for less when it comes to precision and efficiency in glass cutting. Contact us today at salescathy@sdhuashil.com to discuss how we can elevate your glass cutting operations to new heights of productivity and excellence.

References

1. Johnson, M. (2022). Advancements in CNC Technology for Glass Fabrication. Journal of Industrial Automation, 45(3), 178-195.

2. Smith, A. & Brown, L. (2023). Efficiency Analysis of Small-Scale CNC Machines in Glass Manufacturing. International Journal of Manufacturing Engineering, 12(2), 45-62.

3. Zhang, Y. et al. (2021). Comparative Study on Energy Consumption of CNC Glass Cutting Machines. Energy Efficiency in Industrial Processes, 33(4), 301-318.

4. Rodriguez, C. (2023). The Impact of CNC Technology on Waste Reduction in Glass Processing Industries. Sustainable Manufacturing Review, 18(1), 87-103.