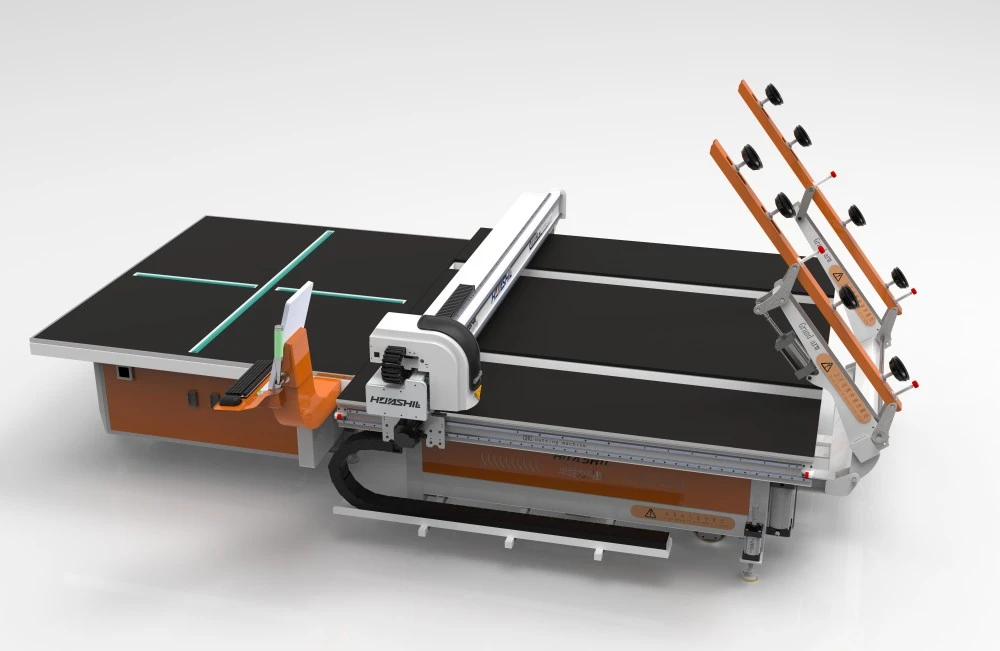

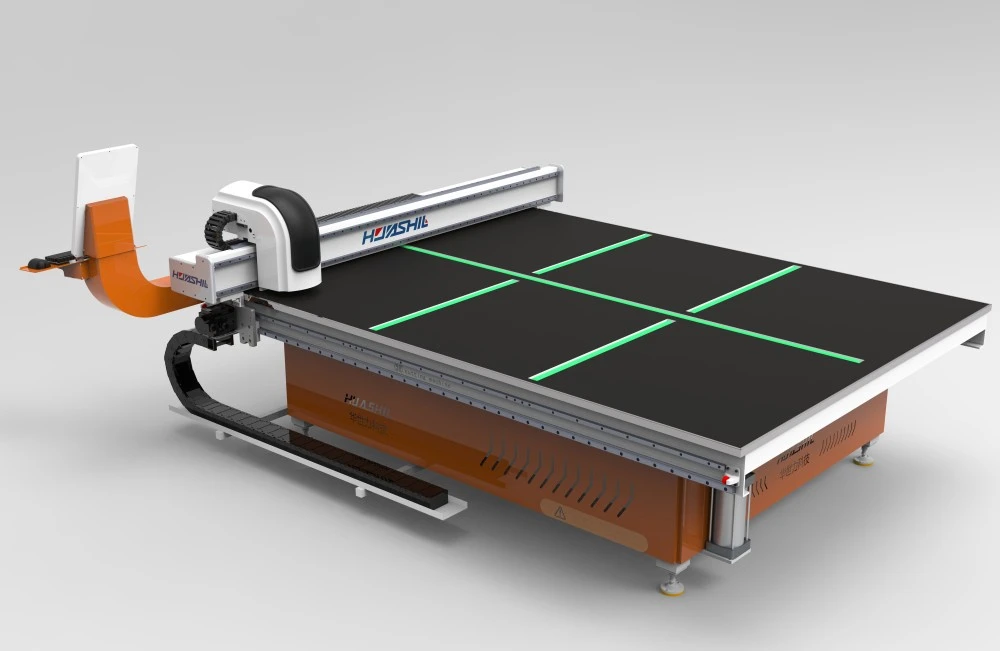

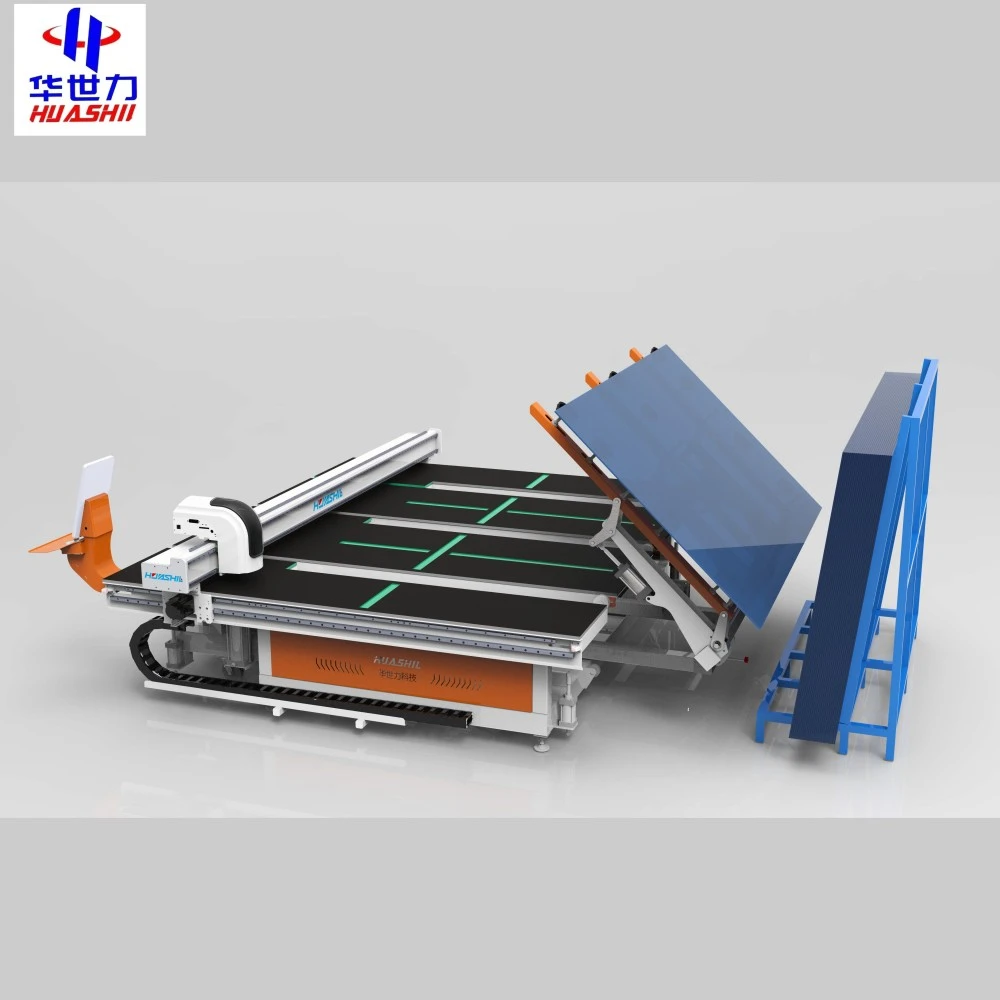

In the world of precision glass cutting, small CNC glass cutting machines have revolutionized the industry. These compact powerhouses offer unparalleled accuracy and efficiency, making them indispensable for businesses of all sizes. But what exactly sets these machines apart? Let's dive into the key features that make small CNC glass cutting machines a game-changer for manufacturers and artisans alike.

Non-Negotiable Features: Vacuum Table, High-Frequency Spindle, and GRBL Control

When it comes to small CNC glass cutting machines, certain features are absolutely essential for optimal performance. First and foremost, a vacuum table is crucial. This feature ensures that the glass remains firmly in place during the cutting process, preventing any unwanted movement that could lead to inaccuracies or damage.

The high-frequency spindle is another non-negotiable component. This sophisticated piece of technology allows for precise and clean cuts, even on the most delicate glass materials. The high-frequency operation reduces vibration and heat generation, resulting in smoother edges and reduced risk of cracking.

GRBL control is the third pillar of essential features. This open-source software serves as the brain of the machine, interpreting G-code instructions and translating them into precise movements. The reliability and flexibility of GRBL control make it a favorite among both novice users and seasoned professionals.

These three features work in harmony to provide the foundation for exceptional glass cutting performance. Without them, a small CNC glass cutting machine from China small cnc glass cutting machine suppliers would struggle to deliver the precision and consistency required in today's competitive market.

How Important is Software Ease-of-Use for a Key Feature?

In the realm of CNC glass cutting, the importance of user-friendly software cannot be overstated. While the physical components of the machine are crucial, the software interface is where operators spend most of their time. A well-designed, intuitive software package can significantly reduce the learning curve and improve overall productivity.

Key aspects of user-friendly software include:

- Intuitive design layout

- Clear and concise command structures

- Comprehensive help documentation

- Regular updates and improvements

- Compatibility with various file formats

The best China small CNC glass cutting machine suppliers understand that ease-of-use is not just a convenience—it's a critical factor in the machine's overall value. User-friendly software enables operators to quickly set up jobs, make adjustments on the fly, and troubleshoot issues with minimal downtime.

Moreover, software that is easy to use often leads to increased creativity and experimentation. When operators feel comfortable with the interface, they're more likely to push the boundaries of what's possible, leading to innovative designs and improved product offerings.

From Sturdy Gantry Construction to Dust Removal Ports

While the previously mentioned features are crucial, there are several other key components that contribute to the overall performance and longevity of a small CNC glass cutting machine. Let's explore some of these important features:

Sturdy Gantry Construction

The gantry is the backbone of any CNC machine. In glass cutting, where precision is paramount, a robust and stable gantry is essential. Look for machines with heavy-duty steel or aluminum construction that can withstand the rigors of continuous operation without flexing or vibrating.

Precision Linear Guides

High-quality linear guides ensure smooth and accurate movement along all axes. This precision is crucial for achieving clean, consistent cuts and intricate designs. The best machines use hardened steel guides with pre-loaded ball bearings for minimal friction and maximum durability.

Automatic Tool Changing System

For operations that require multiple tools, an automatic tool changing system can be a significant time-saver. This feature allows the machine to switch between different cutting, grinding, or polishing tools without manual intervention, reducing downtime and improving overall efficiency.

Advanced Cooling System

Glass cutting generates heat, which can affect both the quality of the cut and the longevity of the cutting tools. An advanced cooling system, typically using a mixture of water and coolant, helps maintain optimal cutting conditions and extends the life of your cutting implements.

Dust Removal Ports

Glass dust can be harmful to both operators and the machine itself. Effective dust removal ports, coupled with a powerful vacuum system, help maintain a clean and safe working environment. This feature not only protects health but also contributes to the longevity of the machine's components.

Adjustable Cutting Speed

Different types of glass and varying thicknesses require different cutting speeds for optimal results. A machine with adjustable cutting speed allows operators to fine-tune their approach based on the specific material and desired outcome.

User-Friendly Control Panel

A well-designed control panel complements the software interface, providing quick access to essential functions and real-time feedback on machine status. Look for panels with clear, intuitive layouts and durable construction to withstand the demands of a workshop environment.

Safety Features

Safety should never be an afterthought. The best small CNC glass cutting machines incorporate multiple safety features, including emergency stop buttons, enclosed cutting areas, and automatic shut-off mechanisms in case of malfunctions or obstructions.

Compact Footprint

One of the key advantages of a small CNC glass cutting machine is its ability to fit into spaces where larger machines cannot. A well-designed compact footprint allows businesses to maximize their workshop space without sacrificing cutting capabilities.

Expandability and Upgradability

As your business grows, your machine should be able to grow with you. Look for machines that offer the possibility of future upgrades or expansions, such as additional axes, larger work areas, or more powerful spindles.

By considering these features alongside the non-negotiable elements discussed earlier, you can ensure that you're investing in a small CNC glass cutting machine from China small cnc glass cutting machine suppliers that will meet your needs now and in the future.

Conclusion

The key features of a small CNC glass cutting machine are what set apart a good machine from a great one. From the essential vacuum table and high-frequency spindle to the user-friendly software and advanced safety features, each component plays a crucial role in delivering precise, efficient, and high-quality glass cutting results.

When selecting a machine for your business, carefully consider how these features align with your specific needs and future growth plans. Remember that the initial investment in a high-quality machine with the right features can pay dividends in terms of productivity, versatility, and longevity.

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by glass cutting professionals. Our years of experience in automated R&D, manufacturing, and sales have allowed us to develop small CNC glass cutting machines that incorporate all the key features discussed in this article. Our commitment to advanced techniques, stable quality, and excellent service has made us a preferred choice for customers worldwide.

FAQ

1. What is the typical cutting speed of a small CNC glass cutting machine?

The cutting speed can vary depending on the specific machine and the type of glass being cut. Generally, small CNC glass cutting machines can achieve speeds ranging from 1 to 10 meters per minute. However, it's important to note that the optimal cutting speed will depend on factors such as glass thickness, desired edge quality, and the specific cutting tool being used.

2. How often should I perform maintenance on my small CNC glass cutting machine?

Regular maintenance is crucial for ensuring the longevity and optimal performance of your machine. Daily tasks might include cleaning the work area and checking fluid levels. Weekly maintenance could involve lubricating moving parts and inspecting tools for wear. More comprehensive maintenance, such as calibration and software updates, should be performed monthly or quarterly, depending on usage. Always consult your machine's manual for specific maintenance schedules.

3. Can a small CNC glass cutting machine handle tempered glass?

Most small CNC glass cutting machines are not designed to cut tempered glass. Tempered glass is treated to be much stronger than regular glass and will shatter if cut. These machines are typically used for cutting annealed or float glass. If you need to work with tempered glass, it must be cut before the tempering process.

4. What types of software are compatible with small CNC glass cutting machines?

Many small CNC glass cutting machines are compatible with standard CAD/CAM software packages. Popular options include AutoCAD, Solidworks, and Rhino. Some manufacturers also provide proprietary software optimized for their machines. When choosing a machine, it's important to consider software compatibility and ensure that it integrates well with your existing design workflow.

Experience Precision and Efficiency with Huashil's Small CNC Glass Cutting Machines | HUASHIL

Are you ready to take your glass cutting operations to the next level? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art small CNC glass cutting machines that combine precision, efficiency, and ease of use. Our machines are designed with the key features discussed in this article, ensuring that you have the tools you need to meet and exceed your production goals.

As a leading manufacturer and supplier in the industry, we understand the unique challenges faced by glass cutting professionals. Our team of experts is dedicated to providing you with not just a machine, but a complete solution tailored to your specific needs. Whether you're a small workshop or a large-scale manufacturer, we have the perfect small CNC glass cutting machine for you.

Don't let outdated equipment hold you back. Upgrade to a Huashil small CNC glass cutting machine and experience the difference that cutting-edge technology can make. Our machines are built to last, with robust construction and high-quality components that ensure years of reliable service.

Ready to transform your glass cutting operations? Contact us today at salescathy@sdhuashil.com to discuss your needs and find the perfect small CNC glass cutting machine for your business. Let Huashil be your partner in precision and innovation.

References

1. Johnson, M. (2022). "Advancements in CNC Glass Cutting Technology: A Comprehensive Review." Journal of Glass Manufacturing, 45(3), 178-195.

2. Smith, A. & Brown, B. (2023). "The Impact of Software Usability on CNC Machine Productivity." International Journal of Manufacturing Engineering, 12(2), 89-104.

3. Zhang, L. et al. (2021). "Optimizing Dust Removal Systems in CNC Glass Cutting: A Case Study." Environmental Health and Safety in Manufacturing, 33(4), 412-428.

4. Patel, R. (2023). "The Future of Small-Scale CNC Glass Cutting: Trends and Predictions." Glass Technology Review, 18(1), 56-70.