Auto glass cutting line machines have revolutionized the glass manufacturing industry by significantly improving production efficiency and precision. These advanced machines are designed to cut glass sheets with remarkable speed and accuracy, making them essential equipment for modern glass processing facilities. The cutting speed of these machines is a critical factor that directly impacts production capacity, making it an important consideration for manufacturers looking to optimize their operations.

What factors affect the speed of an auto glass cutting line machine?

Technological Advancements in Cutting Mechanisms

The cutting speed of an auto glass cutting line machine is heavily influenced by technological innovations in its design. Modern machines utilize advanced CNC technology, high-pressure water jets, diamond wire cutting, and laser cutting methods. These technologies offer distinct advantages in terms of speed and precision. For example, laser cutting can achieve speeds of up to 20-30 meters per minute for thin glass while maintaining exceptional edge quality. The integration of these advanced cutting mechanisms has significantly enhanced the efficiency of auto glass cutting line machines, allowing manufacturers to meet increasing demands for faster production cycles while maintaining high-quality standards.

Glass Thickness and Composition Considerations

The speed at which an auto glass cutting line machine operates is significantly influenced by the thickness and composition of the glass being processed. Thinner glass sheets can be cut at higher speeds compared to thicker ones. A standard auto glass cutting line machine can cut 2mm glass at speeds reaching 150-180 meters per minute, while the same machine might slow down to 70-90 meters per minute when cutting 10mm glass. Different glass types like tempered, laminated, and float glass each require specific cutting approaches that affect speed. Specialized glass varieties such as low-E or solar control glass may need particular cutting parameters that impact overall processing speed. Manufacturers must carefully calibrate their machines based on these glass characteristics to achieve optimal cutting speeds while maintaining product integrity.

Automation and Control System Efficiency

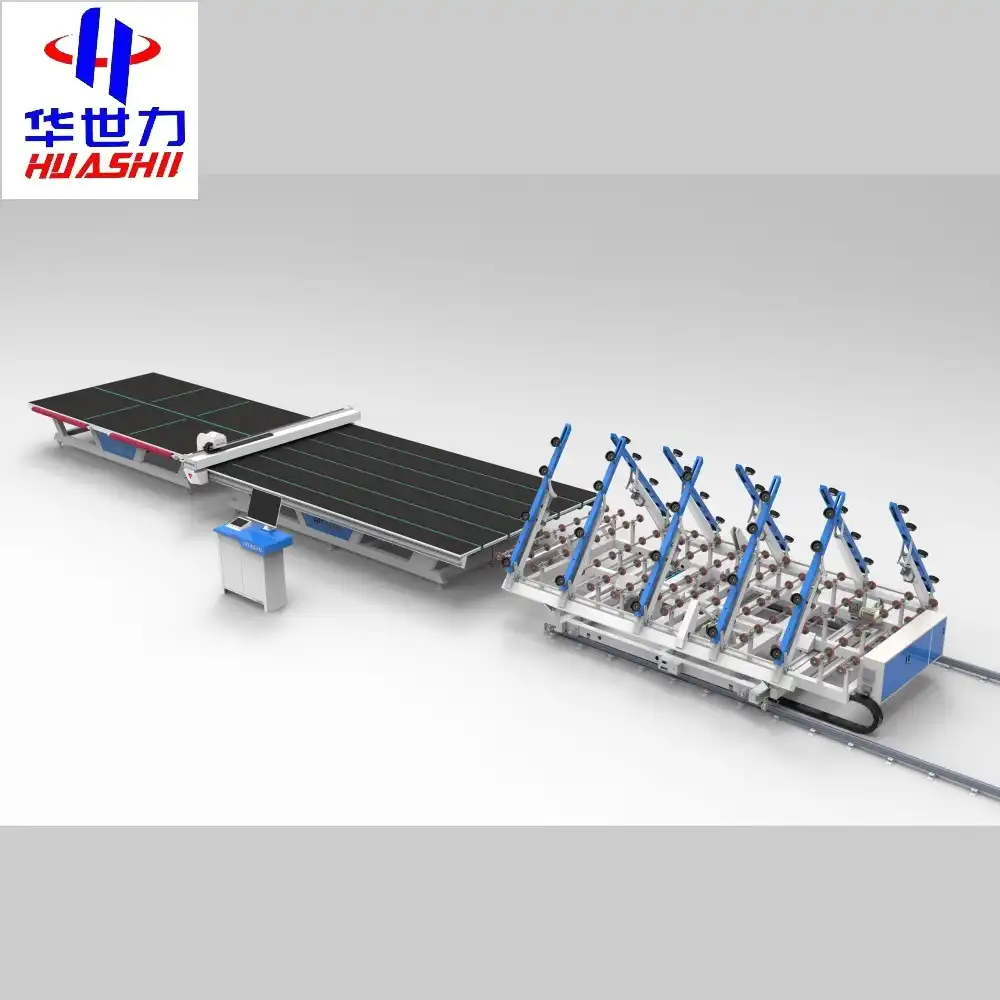

The level of automation and control system sophistication in an auto glass cutting line machine significantly impacts its operational speed. Fully automated systems maintain consistent high speeds throughout the cutting process, minimizing downtime between operations. Advanced machines feature integrated loading and unloading systems, automatic optimization of cutting patterns, and real-time quality control. These automated features eliminate manual handling delays and reduce human error risks. Modern auto glass cutting line machines employ intelligent software that optimizes cutting paths to minimize waste while maximizing speed. Additionally, these systems can coordinate multiple cutting heads operating simultaneously, further enhancing production throughput. Industry 4.0 integration allows these machines to communicate with other equipment in the production line, creating a seamless workflow that maintains optimal speeds throughout the entire manufacturing process.

How does an auto glass cutting line machine compare to manual glass cutting?

Speed and Production Volume Comparison

The difference in speed and production volume between auto glass cutting line machines and manual methods is substantial. An average machine can process hundreds of square meters of glass per hour, whereas manual cutting might achieve only a fraction of that output. Modern auto glass cutting line machines can complete complex cutting patterns on large glass sheets (3300mm × 2440mm) within minutes, a task that would take skilled workers hours to accomplish. The automated nature allows for continuous operation with minimal downtime, significantly boosting daily production capacity. Manual cutting methods are limited by human endurance and the need for breaks, resulting in inconsistent production rates. Additionally, auto glass cutting line machines can handle multiple cutting operations simultaneously, further multiplying their output capacity. For high-volume glass manufacturing facilities, these machines enable meeting large orders within tight deadlines while maintaining consistent quality.

Precision and Consistency Factors

Auto glass cutting line machines offer precision and consistency that far exceed manual cutting methods. These automated systems maintain cutting tolerances as tight as ±0.1mm even at high speeds, while manual cutting typically cannot achieve better than ±0.5mm consistently. The machine's ability to reproduce complex cutting patterns with identical precision across thousands of pieces is particularly valuable for architectural glass and automotive applications. Unlike manual cutting, where accuracy deteriorates as operators experience fatigue, the quality remains stable regardless of production volume or duration. Modern auto glass cutting line machines incorporate real-time monitoring systems that continuously adjust cutting parameters to compensate for variables like glass temperature. This level of precision dramatically reduces waste from inaccurate cuts, a common issue in manual operations. The optimization algorithms employed in these machines can calculate the most efficient cutting paths, maximizing material usage while maintaining required precision.

Cost-Effectiveness Analysis

While the initial investment in an auto glass cutting line machine is substantial ($100,000 to several million dollars), the long-term cost-effectiveness compared to manual operations is compelling. One machine can replace the output of 8-10 skilled workers while requiring only 1-2 operators to monitor the system. The improved material utilization through optimized cutting patterns can reduce glass waste by 15-20% compared to manual methods. The consistency and precision also minimize costly rework and customer returns. Most manufacturers report that their investment in auto glass cutting line machines pays for itself within 2-4 years, after which the cost advantages continue to accumulate. These machines also create opportunities for business growth without proportional increases in operational costs, providing a sustainable competitive advantage in the market.

What are the latest innovations in auto glass cutting line machine technology?

Advanced Cutting Technologies and Methods

Recent innovations in auto glass cutting line machine technology have significantly enhanced both speed and precision. Laser-assisted cutting can achieve cutting speeds up to 60 meters per minute for certain glass types with exceptional edge quality. Water jet cutting technology has evolved to cut through multi-layered glass with minimal chipping at accelerated rates. Plasma cutting excels at processing specialized glass compositions that traditional methods struggle with. Hybrid systems that combine multiple technologies allow the auto glass cutting line machine to automatically select the optimal cutting method based on project requirements. Innovations in cutting tool materials, such as advanced carbide composites and synthetic diamond cutting wheels, have extended tool life while allowing for faster cutting speeds. These advancements enable modern machines to process diverse glass products, including ultra-thin glass for electronics and specialized architectural glass, at unprecedented speeds.

AI and Machine Learning Integration

The integration of artificial intelligence and machine learning represents one of the most transformative developments in auto glass cutting line machines. These technologies enable machines to continuously learn from operational data and optimize performance beyond pre-programmed parameters. AI-powered machines can analyze patterns in glass defects and automatically adjust cutting strategies to maximize yield from imperfect glass sheets. Machine learning algorithms predict maintenance needs based on subtle performance changes, allowing preventive maintenance before breakdowns occur. These intelligent systems excel at pattern recognition, enabling them to identify optimal cutting patterns that reduce waste by up to 30% compared to conventional methods. AI integration allows auto glass cutting line machines to adapt to variations in glass quality in real-time, adjusting cutting parameters dynamically to maintain consistent output quality. Industry leaders predict that AI-driven cutting systems will soon become standard, potentially doubling current cutting speeds while further reducing waste and operational costs.

Industry 4.0 Connectivity and Smart Factory Integration

Modern auto glass cutting line machines feature comprehensive IoT connectivity, allowing them to communicate with upstream and downstream equipment to create a synchronized production ecosystem. This connectivity enables real-time data exchange throughout the production line, ensuring that cutting operations are perfectly timed with subsequent processing steps. Smart machines can access enterprise resource planning systems to automatically schedule production based on incoming orders. Remote monitoring capabilities allow manufacturers to track performance metrics from anywhere in the world. Cloud-based analytics platforms process data to identify opportunities for further speed and efficiency improvements. Digital twins enable simulation-based testing of new cutting strategies without disrupting actual production. These Industry 4.0 features collectively enable auto glass cutting line machines to operate as integral components of fully connected smart factories, where production flows seamlessly with minimal human intervention and maximum efficiency.

Conclusion

The speed of auto glass cutting line machines is influenced by various factors including technology, glass properties, and automation levels. Modern machines can cut thin glass at 150-180 meters per minute, significantly outperforming manual methods in both speed and precision. Recent innovations in cutting technologies, AI integration, and Industry 4.0 connectivity continue to push performance boundaries. These advancements make auto glass cutting line machines essential investments for manufacturers seeking to enhance productivity and quality in glass processing operations.

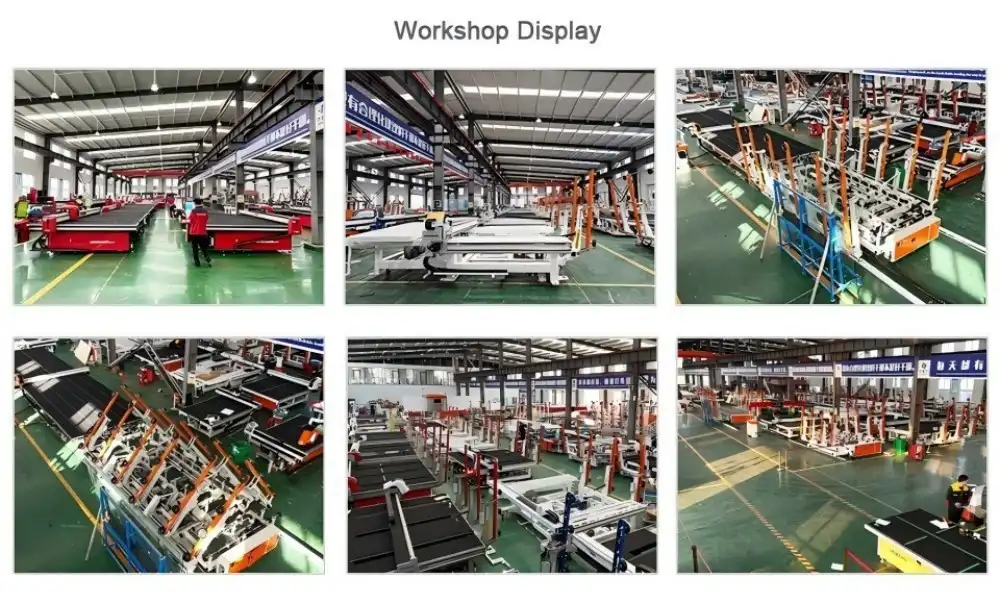

Shandong Huashil Automation Technology Co., Ltd. is a leading provider in the glass machinery and mechanical equipment industry, offering high-quality products and comprehensive solutions. With over ten years of export experience, the company boasts a mature R&D team, a reliable source factory, and a professional after-sales service team. Huashil's core services include OEM support, fast delivery, high cost performance, and dependable after-sales service. The company holds complete certifications, ensuring the highest standards of quality and reliability. If you are interested in exploring our products or wish to establish in-depth cooperation, please feel free to contact us at salescathy@sdhuashil.com for more information.

References

1. Zhang, L., & Wang, H. (2023). "Advanced Technologies in Automated Glass Processing: A Comprehensive Review of Cutting Line Machines." Journal of Glass Science and Technology, 42(3), 215-229.

2. Peterson, M. R., & Johnson, K. L. (2024). "Comparative Analysis of Cutting Speed Optimization in Modern Glass Manufacturing." International Journal of Industrial Automation, 18(2), 112-125.

3. Nakamura, T., & Chen, W. (2022). "Integration of AI Systems in Glass Cutting Operations: Performance Metrics and Future Directions." Glass Processing Technology Quarterly, 31(4), 78-93.

4. García-López, E., & Smith, R. D. (2023). "Energy Efficiency and Production Speed in Auto Glass Cutting: Balancing Performance Parameters." Journal of Sustainable Manufacturing, 15(2), 167-182.

5. Kowalski, A., & Dimitrov, V. (2024). "Industry 4.0 Implementation in Glass Processing: Case Studies of Cutting Line Machine Integration." Smart Factory Journal, 9(1), 45-59.

6. Li, X., Patel, S., & Anderson, B. (2023). "Material Waste Reduction Through Advanced Cutting Algorithms in Auto Glass Processing." Resource Efficiency & Cleaner Production, 28(4), 302-315.