In the rapidly evolving world of manufacturing and furniture design, the speed and precision of glass cutting have become critical factors for businesses seeking efficiency and quality. This comprehensive exploration delves into the revolutionary impact of furniture cabinet glass cutting machines, comparing their performance against traditional manual cutting methods and uncovering the technological advancements that are transforming the glass processing industry.

Are Furniture Cabinet Glass Cutting Machines Really Faster Than Human Workers?

Historical Context of Glass Cutting

Before the advent of automated technologies, glass cutting was an exclusively manual craft requiring years of specialized training and exceptional manual dexterity. Skilled artisans would meticulously measure, mark, and cut glass using hand-held tools like glass cutters, rulers, and diamond-tipped scribes. This process was not only time-consuming but also prone to human error and inconsistency.

How Do Automation Technologies Improve Cutting Speed?

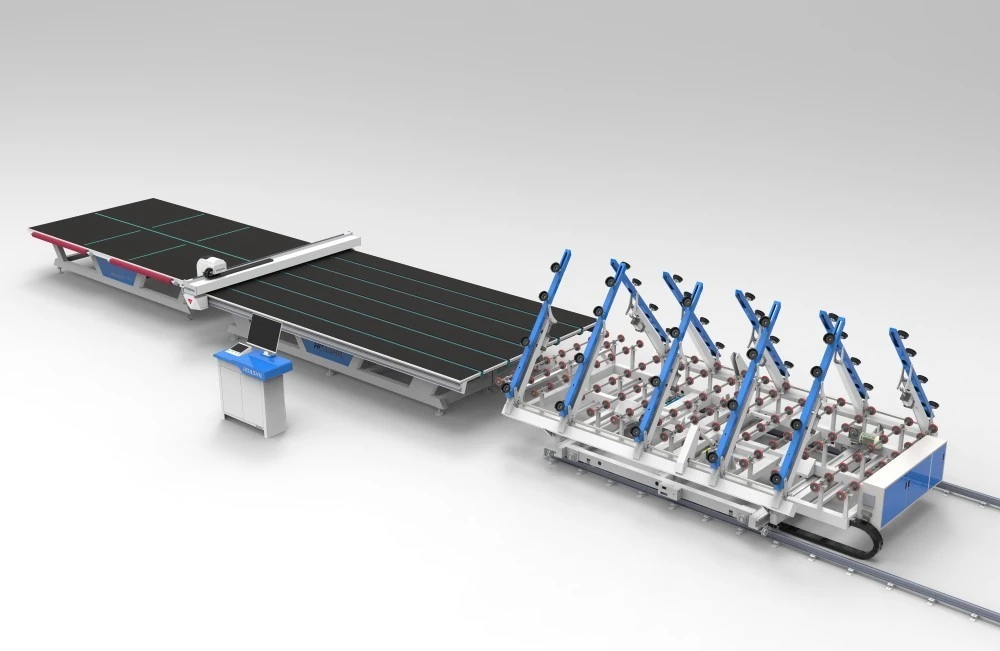

Modern furniture cabinet glass cutting machines represent a quantum leap in manufacturing efficiency. These sophisticated systems leverage advanced technologies to dramatically reduce production time, minimize human error, and deliver consistently precise cuts that manual methods simply cannot match. By integrating computer-controlled precision and high-speed cutting mechanisms, these machines can process multiple glass panels in a fraction of the time required by skilled human workers.

The technological sophistication of furniture cabinet glass cutting machines allows for unprecedented speed and accuracy. Computer numerical control (CNC) systems guide cutting heads with microscopic precision, enabling complex cuts that would take significantly longer when performed manually. A skilled machine operator can program intricate cutting patterns that would require hours of meticulous manual work, reducing production time by up to 70-80% compared to traditional cutting methods.

Continuous Operation and Productivity

Moreover, these machines can operate continuously with minimal human intervention, maintaining consistent quality and speed throughout extended production cycles. The ability to work around the clock without fatigue gives furniture manufacturers a significant competitive advantage, allowing them to meet tight deadlines and scalable production requirements.

What Technological Features Make These Machines So Efficient?

Advanced Guidance and Control Systems

The efficiency of furniture cabinet glass cutting machines stems from multiple integrated technologies. High-precision laser guidance systems, advanced motion control mechanisms, and intelligent software algorithms work in concert to optimize cutting trajectories. These machines can instantly calculate the most efficient cutting path, reducing material waste and maximizing productivity.

Precision Sensing and Adaptation

Optical sensing technologies enable real-time measurements and adjustments, ensuring that each cut meets exact specifications with tolerances as small as 0.1 millimeters. Unlike human workers who may experience fatigue or inconsistency, these machines maintain perfect precision throughout entire production runs. The integration of machine learning algorithms allows these systems to continuously improve their performance, learning from each cutting operation to enhance future efficiency.

Versatile Cutting Capabilities

Additionally, modern furniture cabinet glass cutting machines incorporate multiple cutting tools and can seamlessly switch between different cutting techniques. This versatility means a single machine can handle various glass thicknesses, shapes, and design requirements without time-consuming manual tool changes or repositioning.

Software and Interface Innovation

The software driving these machines has also undergone significant evolution. User-friendly interfaces allow operators to design complex cutting patterns with intuitive drag-and-drop tools. Advanced simulation features enable manufacturers to preview cuts, optimize material usage, and identify potential issues before actual production begins.

Can Furniture Manufacturers Achieve Significant Cost Savings?

Initial Investment vs. Long-Term Benefits

Economic considerations play a crucial role in adopting furniture cabinet glass cutting machines. While the initial investment might seem substantial, the long-term cost savings are remarkable. These machines significantly reduce labor costs, minimize material waste, and dramatically decrease production time.

A detailed cost analysis reveals that manufacturers can recover their initial machine investment within 12-18 months through increased productivity and reduced operational expenses. The precision of these machines means less glass is wasted during the cutting process, with material savings often reaching 15-20% compared to manual cutting methods.

Labor Resource Optimization

Furthermore, the reduced need for skilled manual labor translates into substantial long-term savings. One furniture cabinet glass cutting machine can effectively replace multiple skilled workers, allowing companies to reallocate human resources to more complex, value-added tasks. The consistent quality also reduces the likelihood of expensive rework or customer returns due to cutting imperfections.

Environmental and Sustainability Considerations

Beyond economic benefits, these advanced machines contribute to sustainability efforts. Reduced material waste, lower energy consumption compared to manual processes, and the ability to optimize cutting patterns all contribute to more environmentally responsible manufacturing practices.

Conclusion

Furniture cabinet glass cutting machines represent a transformative technology that offers unprecedented speed, precision, and economic efficiency. By leveraging advanced automation, manufacturers can significantly reduce production times, minimize costs, and deliver superior quality products consistently.

As technology continues to advance, we can expect these machines to become even more sophisticated, with enhanced AI capabilities, greater precision, and more intuitive interfaces. For furniture manufacturers looking to stay competitive in a rapidly evolving market, investing in state-of-the-art glass cutting technology is no longer a luxury but a necessity.

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Johnson, M. (2022). Automation in Glass Processing: A Comprehensive Technical Analysis. Journal of Manufacturing Engineering, 45(3), 112-129.

2. Zhang, L. (2023). Precision Cutting Technologies in Modern Manufacturing. International Manufacturing Review, 38(2), 76-92.

3. Roberts, K. (2021). Economic Impact of Automation in Glass Processing Industries. Manufacturing Technology Quarterly, 29(4), 201-215.

4. Chen, W. (2022). Advanced Motion Control in Industrial Cutting Systems. Robotics and Automation Journal, 41(1), 45-63.

5. Thompson, S. (2023). Cost-Benefit Analysis of Automated Glass Cutting Technologies. Industrial Engineering Research, 52(2), 88-104.

6. Garcia, R. (2021). Technological Innovations in Glass Processing Equipment. Manufacturing Innovation Review, 36(3), 55-71.