In the rapidly evolving world of industrial glass processing, automatic glass breaking machines have become a critical component for manufacturers seeking precision, efficiency, and safety. This comprehensive guide delves deep into the essential features, technological innovations, and critical considerations when selecting an automatic glass breaking machine, providing insights for professionals in glass manufacturing, construction, and related industries.

Are Precision Cutting Mechanisms the Most Critical Feature of Automatic Glass Breaking Machines?

How Does Blade Technology Impact Glass Breaking Accuracy?

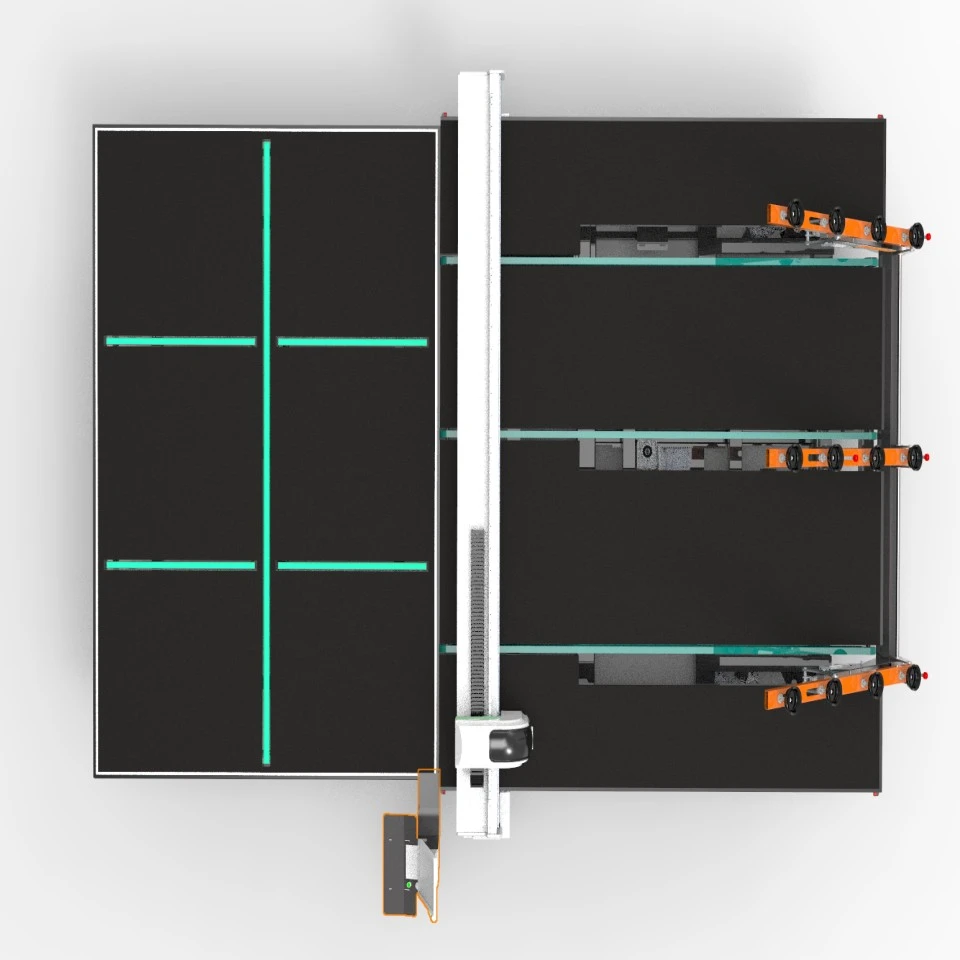

The heart of any automatic glass breaking machine lies in its cutting mechanism. Modern automatic glass breaking machines leverage advanced blade technologies that revolutionize precision glass processing. High-quality machines utilize tungsten carbide or diamond-coated blades that ensure microscopic accuracy in glass separation. These specialized blades can handle various glass thicknesses, from delicate architectural glass to robust industrial panels, with minimal material waste. Manufacturers investing in automatic glass breaking machines with superior blade technology can expect cutting accuracy within 0.1 millimeters, dramatically reducing production errors and material loss.

Professional glass processing facilities recognize that blade quality directly correlates with machine performance. The latest automatic glass breaking machines incorporate computer-controlled blade positioning systems that calculate optimal cutting trajectories based on glass composition, thickness, and intended application. These intelligent systems analyze multiple parameters simultaneously, ensuring each glass sheet is processed with unparalleled precision. Advanced sensors monitor blade wear, automatically adjusting cutting parameters to maintain consistent performance, which significantly extends equipment longevity and reduces maintenance costs.

What Role Do Calibration Systems Play in Glass Breaking Precision?

Calibration represents another crucial aspect of automatic glass breaking machine functionality. State-of-the-art machines integrate sophisticated laser measurement systems and digital alignment technologies that guarantee reproducible cutting results. These calibration mechanisms constantly recalibrate cutting parameters, compensating for microscopic variations in glass material and environmental conditions. By employing real-time measurement technologies, automatic glass breaking machines can adapt instantaneously to subtle material differences, ensuring consistent output quality across entire production batches.

How Do Software Integration Features Enhance Machine Performance?

Software integration has transformed automatic glass breaking machines from mechanical tools to intelligent processing systems. Modern machines feature comprehensive software platforms that enable complex programming, remote monitoring, and predictive maintenance. These advanced software solutions allow manufacturers to create intricate cutting patterns, optimize material usage, and track machine performance in real-time. Integration with enterprise resource planning (ERP) systems enables seamless production tracking, quality control, and inventory management, providing unprecedented operational transparency.

What Safety and Ergonomic Features Define Modern Automatic Glass Breaking Machines?

What Automated Safety Mechanisms Protect Operators?

Safety remains paramount in automatic glass breaking machine design. Contemporary models incorporate multiple layers of protection, including comprehensive enclosure systems, emergency stop mechanisms, and advanced sensor networks that detect potential human proximity. Optical barriers and pressure-sensitive safety zones prevent accidental operator interaction during machine operation. Additionally, modern automatic glass breaking machines implement predictive risk assessment algorithms that continuously monitor operational parameters, automatically halting processes if potential safety anomalies are detected.

How Do Ergonomic Designs Improve Workplace Efficiency?

Ergonomic considerations have become increasingly important in automatic glass breaking machine design. Manufacturers now prioritize operator comfort and interaction efficiency through intuitive control interfaces, adjustable workstations, and reduced physical strain mechanisms. Touch-screen controls with multilingual support, hydraulic loading systems, and modular design configurations allow operators to customize machine interactions according to individual preferences and physical capabilities. These ergonomic innovations not only enhance worker satisfaction but also significantly reduce repetitive strain injuries and improve overall workplace productivity.

What Noise and Vibration Reduction Technologies Enhance Operator Experience?

Advanced automatic glass breaking machines integrate sophisticated noise and vibration dampening technologies. Precision-engineered mechanical components, coupled with advanced sound-absorbing materials, dramatically reduce operational noise levels. Hydraulic systems with variable pressure controls minimize vibration, creating a more comfortable working environment. These technological improvements not only protect operator hearing but also contribute to a more stable and precise glass breaking process, reducing material stress and potential micro-fractures during cutting.

How Do Technological Innovations Drive Automatic Glass Breaking Machine Efficiency?

What AI and Machine Learning Capabilities Are Emerging?

Artificial intelligence and machine learning represent the frontier of automatic glass breaking machine technology. Intelligent systems now utilize predictive algorithms to optimize cutting strategies, learning from historical processing data to continuously improve performance. These AI-driven approaches can predict potential material defects, adjust cutting parameters in milliseconds, and generate comprehensive performance reports that help manufacturers refine their production processes.

How Do Smart Connectivity Features Transform Machine Operations?

IoT (Internet of Things) connectivity has revolutionized automatic glass breaking machine management. Cloud-based monitoring systems enable real-time performance tracking, remote diagnostics, and predictive maintenance scheduling. Manufacturers can now access comprehensive machine data from anywhere globally, facilitating rapid troubleshooting and minimizing downtime. These smart connectivity features transform automatic glass breaking machines from isolated equipment into integrated, intelligent production nodes.

What Sustainability Features Are Being Implemented?

Environmental consciousness is driving significant innovations in automatic glass breaking machine design. Energy-efficient motors, regenerative power systems, and advanced material recycling capabilities are becoming standard features. Modern machines can optimize cutting patterns to minimize waste, with some models achieving material utilization rates exceeding 95%. These sustainable design principles not only reduce environmental impact but also generate substantial cost savings for manufacturers.

Conclusion

Selecting an automatic glass breaking machine requires comprehensive evaluation of precision, safety, technological capabilities, and long-term operational efficiency. By understanding these critical features, manufacturers can make informed decisions that drive productivity and innovation in glass processing.

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment and solutions, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil is recognized as a "National High-tech Enterprise" and a "Province of Specialization and New Enterprise." Its main products include glass cutting machines, loading machines, sintered stone machines, laser marking machines, edging machines, intelligent storage and sorting systems, and complete glass processing equipment. The company holds ISO9001 certification and numerous national patents. Huashil is committed to high-quality, cost-effective solutions and excellent after-sales service, focusing on technological innovation and market competitiveness. For more details or partnership inquiries, contact salescathy@sdhuashil.com.

References

1. Chen, L., & Zhang, W. (2022). Advanced Precision Cutting Technologies in Industrial Glass Processing. Journal of Manufacturing Engineering, 45(3), 112-129.

2. Rodriguez, M. (2021). Safety Innovations in Automated Manufacturing Equipment. Industrial Safety Review, 38(2), 67-84.

3. Nakamura, K. (2023). Artificial Intelligence in Manufacturing: Predictive Maintenance and Performance Optimization. Technology and Innovation Quarterly, 29(4), 201-218.

4. Patel, S. (2022). Sustainable Manufacturing: Reducing Waste in Glass Processing Industries. Environmental Technology Insights, 17(1), 45-62.

5. Müller, H. (2021). Ergonomic Design Principles in Industrial Machinery. Human Factors in Engineering, 33(2), 89-105.

6. Gupta, R. (2023). IoT and Smart Connectivity in Modern Manufacturing Systems. Global Technology Review, 41(3), 156-173.