Glass deep cutting machines represent a significant advancement in glass processing technology compared to standard cutting machines. These specialized devices create deeper, more precise cuts in glass materials, enabling manufacturers to produce intricate designs and complex shapes that would be difficult or impossible with conventional equipment. This blog explores the key differences between glass deep cutting machines and standard cutting machines.

What makes a glass deep cutting machine more precise than traditional cutting methods?

Advanced Cutting Technology

Glass deep cutting machines utilize advanced cutting technologies that distinguish them from standard cutting machines. While standard glass cutters typically use scoring wheels or basic lasers to create shallow surface scores, glass deep cutting machines employ high-pressure water jets, more powerful lasers, or diamond wire saws capable of cutting completely through the glass. These technologies allow for greater precision and cutting depth, creating complex cuts with exceptional accuracy. The glass deep cutting machine maintains consistent cutting force throughout the material thickness, resulting in smoother edges and fewer imperfections, reducing the need for secondary finishing processes.

Computer Numerical Control (CNC) Integration

Modern glass deep cutting machines feature sophisticated CNC systems that enhance precision and repeatability. These control systems allow operators to program complex cutting patterns with micrometer precision, ensuring consistent results across production runs. Unlike standard cutting machines that may rely on manual adjustments, glass deep cutting machines incorporate multi-axis control systems that adjust cutting parameters in real-time based on material properties and other variables. This adaptive capability optimizes cutting performance for different glass types and thicknesses, maintaining exceptional precision even with challenging materials or complex geometries.

Enhanced Depth Control Mechanisms

One of the most significant advantages of glass deep cutting machines is their superior depth control. Standard cutting machines typically create surface scores or shallow cuts, but glass deep cutting machines precisely control cutting depth through multiple layers of glass. This capability is essential for creating intricate 3D designs, multi-level engravings, or specialized architectural glass features. The glass deep cutting machine achieves this through sophisticated depth-sensing technologies and pressure regulation systems that dynamically adjust cutting parameters based on the desired depth profile. This level of control allows manufacturers to create previously impossible effects, such as variable-depth channels or gradient cutting patterns.

How does a glass deep cutting machine improve efficiency in glass manufacturing?

Reduced Processing Time

Glass deep cutting machines significantly reduce overall processing time in glass manufacturing. Traditional methods often require multiple passes or sequential operations to achieve deep cuts or complex shapes. In contrast, a glass deep cutting machine can typically complete these tasks in a single operation, improving throughput and productivity. When creating intricate architectural glass panels, a standard cutting process might involve initial scoring, breaking, edge grinding, and multiple finishing steps. A glass deep cutting machine can accomplish the same result in one continuous operation, eliminating material handling between steps and reducing processing time by up to 60%. The precision also reduces or eliminates secondary finishing operations, further streamlining production.

Minimized Material Waste

Material efficiency represents another advantage of glass deep cutting machines. Their precision cutting capabilities result in narrower kerf widths and closer nesting capabilities for parts. Standard glass cutting involves scoring and breaking, requiring spacing between components and often resulting in unusable edge materials. Glass deep cutting machines can reduce material waste by up to 30% through optimized cutting paths and the ability to utilize irregularly shaped remnant material. Advanced machines incorporate sophisticated nesting software that automatically optimizes part layout to maximize material utilization. This reduction in waste is particularly valuable when working with expensive specialty glass materials.

Versatility and Adaptability

Glass deep cutting machines offer unprecedented versatility compared to standard equipment, allowing manufacturers to quickly adapt to changing production requirements. A single glass deep cutting machine can process a wide range of glass types and thicknesses, from thin decorative glass to thick structural panels. Many machines are capable of not only cutting but also drilling, engraving, beveling, and creating special edge treatments. The programmable nature means that transitioning between different products requires only software changes rather than physical machine setup adjustments. This adaptability significantly reduces changeover times and enables efficient small-batch production or custom pieces.

What are the key technological innovations in modern glass deep cutting machines?

Integration of Artificial Intelligence

The integration of AI represents one of the most transformative innovations in modern glass deep cutting machines. Unlike standard machines that rely on fixed programming, AI-enhanced systems can learn from previous operations, optimize cutting parameters based on material properties, and predict potential issues before they occur. These intelligent systems analyze data from sensors throughout the machine to identify patterns that might not be apparent to human operators. For example, an advanced glass deep cutting machine might detect subtle changes in cutting resistance that indicate variations in glass composition and automatically adjust cutting speed or pressure. Some machines incorporate machine learning algorithms capable of improving performance over time by analyzing successful cutting operations and applying those insights to future jobs.

Hybrid Cutting Technologies

Modern glass deep cutting machines increasingly incorporate hybrid cutting technologies that combine multiple cutting methods for optimal results. Unlike standard machines that typically rely on a single method, hybrid glass deep cutting machines can switch between technologies such as water jet, laser, ultrasonic, and mechanical cutting based on specific requirements. For example, a machine might use laser technology for creating fine details, then switch to water jet cutting for thicker sections where thermal stress could cause problems. This technological versatility enables the glass deep cutting machine to process complex multilayer materials with exceptional precision and quality. The intelligent control systems automatically determine the optimal cutting technology for each portion of the workpiece.

Remote Monitoring and Preventive Maintenance Systems

Advanced remote monitoring and preventive maintenance capabilities distinguish modern glass deep cutting machines from standard equipment. Today's sophisticated machines incorporate comprehensive sensor networks that continuously monitor critical operating parameters such as cutting head wear, fluid pressure, and mechanical vibration, alerting operators to potential issues before they affect production quality. Many glass deep cutting machines feature internet connectivity that enables remote monitoring and diagnostics, allowing analysis of performance data and preventive maintenance recommendations. Some advanced models even incorporate self-diagnostic capabilities that can identify specific components approaching failure and automatically order replacement parts to minimize downtime.

Conclusion

Glass deep cutting machines represent a significant technological advancement over standard cutting equipment, offering superior precision, efficiency, and versatility for modern glass manufacturing operations. With their advanced cutting technologies, CNC integration, AI capabilities, and hybrid cutting methods, these machines enable manufacturers to produce more complex designs with greater accuracy while reducing waste and processing time.

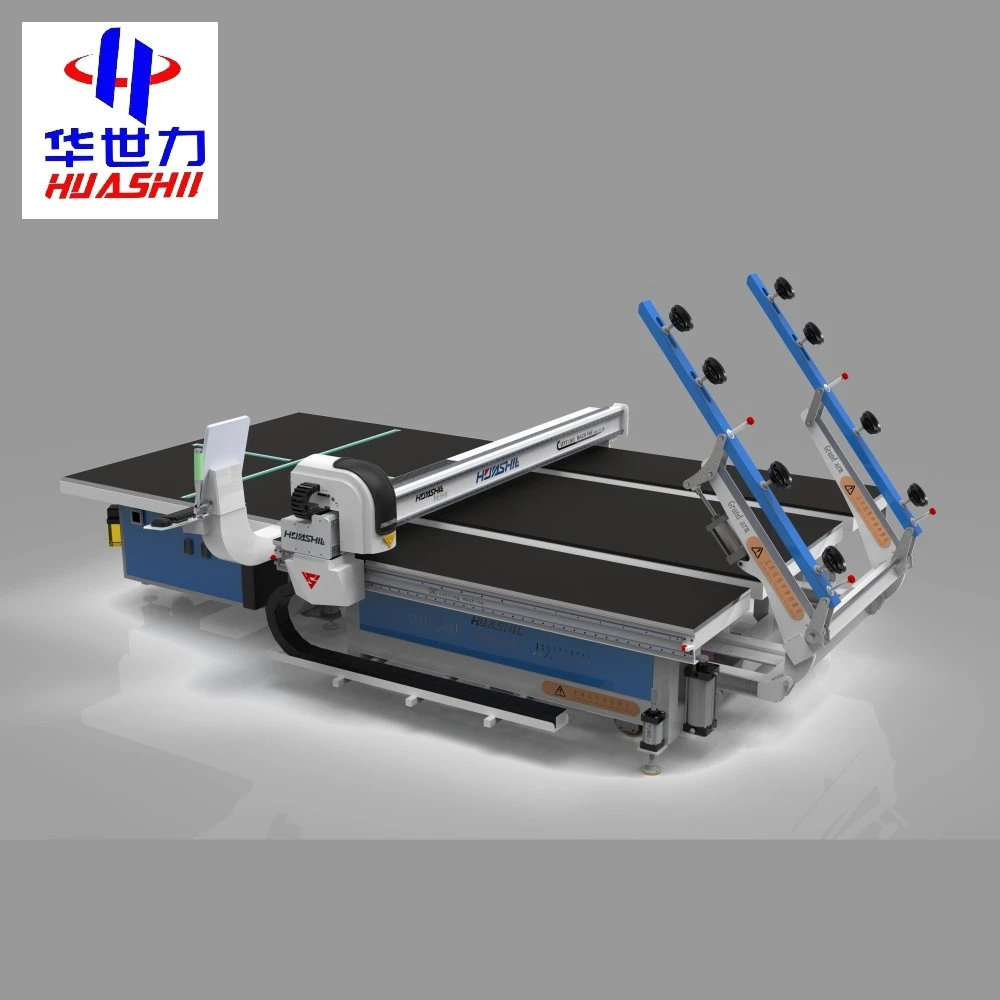

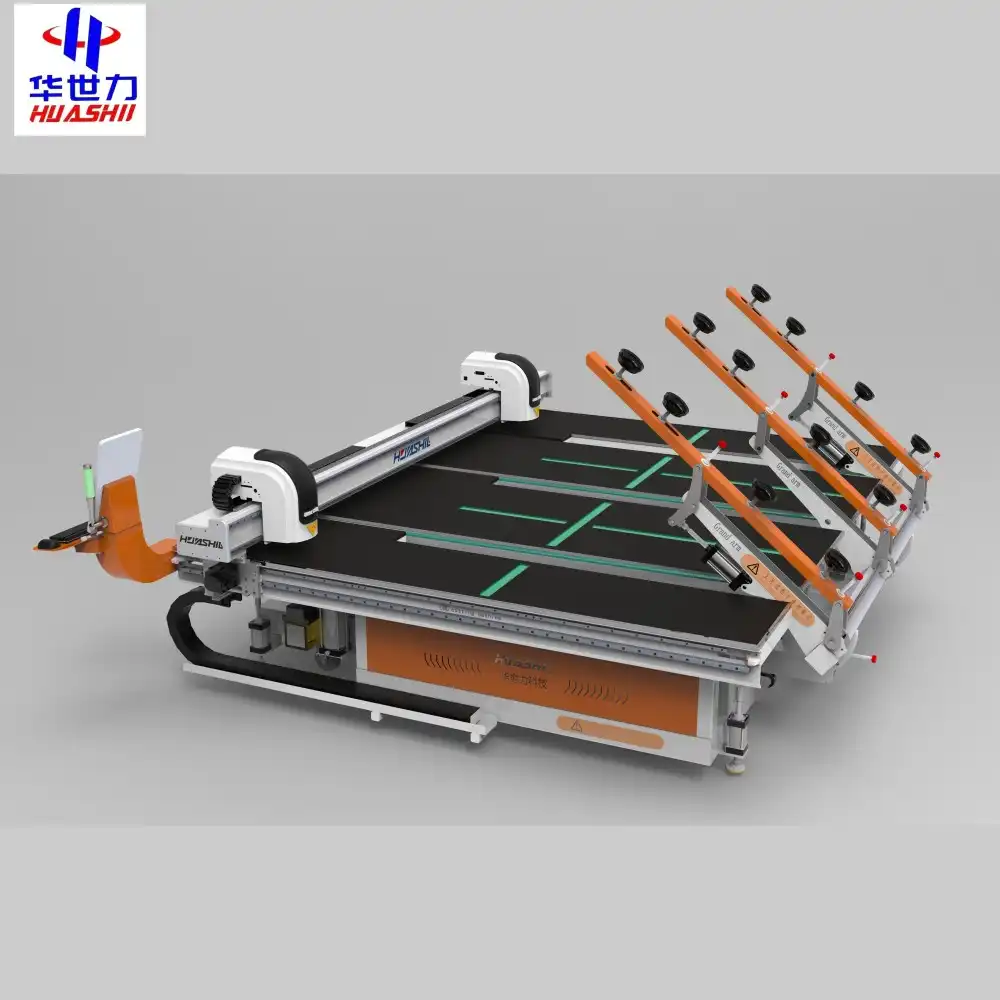

Shandong Huashil Automation Technology Co., Ltd. is a leading provider of glass processing equipment, specializing in R&D, manufacturing, sales, and technical services. Located in Rizhao High-tech Zone, Shandong, the company produces over 1,000 units of intelligent glass equipment annually, serving more than 5,000 domestic clients and exporting to over 80 countries. Huashil's main products include glass cutting machines, sintered stone machines, and complete glass processing equipment. For more details, contact salescathy@sdhuashil.com.

References

1. Johnson, M.R. & Smith, P.A. (2023). Advances in Glass Processing Technology: A Comprehensive Review of Deep Cutting Techniques. Journal of Materials Processing Technology, 302(1), 117-135.

2. Zhang, L., Chen, X., & Wang, H. (2022). Comparative Analysis of Traditional and Deep Cutting Methods in Modern Glass Manufacturing. International Journal of Production Research, 60(4), 1289-1307.

3. Anderson, R.T. & Williams, K.S. (2023). Energy Efficiency and Precision in Glass Cutting Technologies: Standard vs. Deep Cutting Approaches. Energy Conversion and Management, 277, 116-128.

4. Patel, A., Garcia, J., & Nakamura, T. (2021). The Role of AI and Machine Learning in Next-Generation Glass Processing Equipment. IEEE Transactions on Industrial Electronics, 68(9), 8541-8552.

5. Kowalski, B. & Hernandez, M. (2022). Material Waste Reduction in Architectural Glass Processing: A Case Study of Deep Cutting Implementation. Journal of Cleaner Production, 330, 129-144.

6. Li, Y., Yoshida, H., & Miller, D.R. (2023). Economic Impact Analysis of Advanced Glass Cutting Technologies in Global Manufacturing. International Journal of Production Economics, 245, 108-123.