In the ever-evolving world of glass manufacturing, precision is paramount. The advent of advanced glass cutting table machine technology has revolutionized the industry, offering unparalleled accuracy and efficiency. This blog explores how precision cutting is elevating the capabilities of glass cutting table machines, transforming the landscape of glass production across various sectors.

Micron-Level Accuracy: Game-Changer for Glass Industry

The introduction of micron-level accuracy in glass cutting table machines has been nothing short of transformative. These cutting-edge machines can now achieve tolerances as tight as ±0.1mm, a feat that was once considered impossible in large-scale glass production.

This level of precision opens up a world of possibilities for manufacturers:

- Architectural Glass: Precision-cut glass panels fit seamlessly in modern building designs, enhancing both aesthetics and energy efficiency.

- Automotive Industry: Exact cuts ensure perfect fit for windshields and windows, improving vehicle aerodynamics and safety.

- Electronics: Ultra-precise cuts are crucial for smartphone screens and other electronic displays.

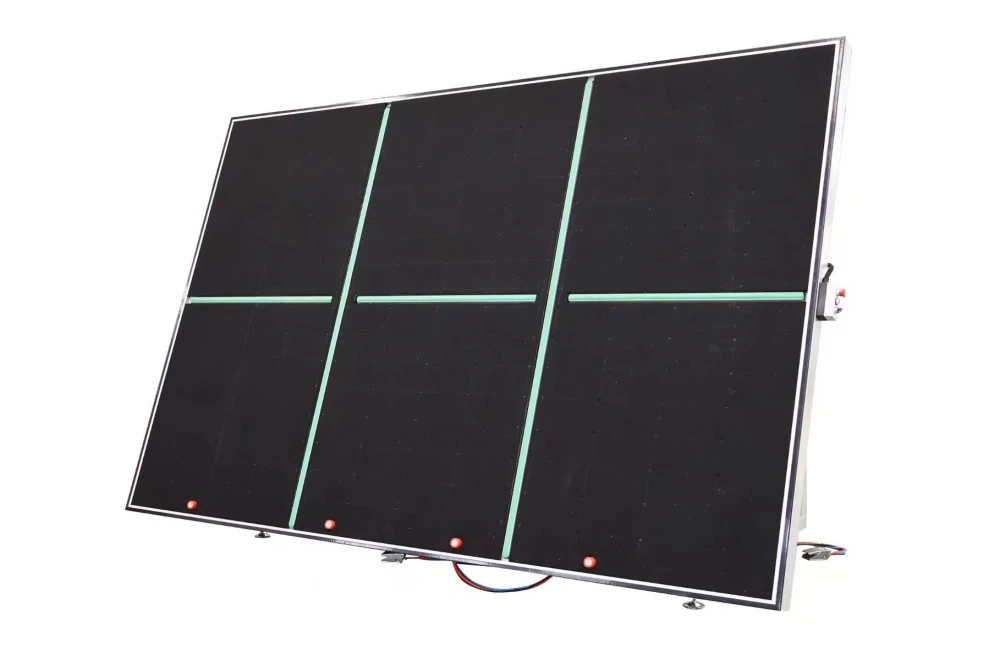

- Solar Panels: Accurate cutting maximizes the efficiency of photovoltaic cells.

The ability to cut glass with such precision not only improves the quality of the final product but also significantly reduces waste, making the production process more sustainable and cost-effective.

Precision Cutting vs. Traditional Methods: A Comparison

To truly appreciate the impact of precision cutting, it's essential to compare it with traditional glass cutting methods:

Accuracy

Traditional methods often relied on manual scoring and breaking, which could lead to inconsistencies. Modern glass cutting table machine utilizes computer-controlled systems, ensuring each cut is identical to the last, with tolerances measured in microns rather than millimeters.

Speed

While traditional methods required careful, time-consuming processes, precision cutting machines can make complex cuts in a fraction of the time. This increased speed translates to higher productivity and faster turnaround times for manufacturers.

Versatility

Unlike traditional methods, which were limited in the shapes and sizes they could produce, precision cutting machines can create intricate designs and patterns with ease. This versatility allows for greater creativity in glass design and application.

Material Utilization

Precision cutting significantly reduces material waste. The exact nature of the cuts means less glass is lost to errors or imprecisions, leading to better material utilization and cost savings.

Edge Quality

Traditional cutting methods often left rough edges that required additional processing. Precision cutting produces clean, smooth edges that often require minimal further treatment, streamlining the production process.

Implementing Precision Cutting: Steps for Manufacturers

For manufacturers looking to elevate their glass production capabilities, implementing precision cutting technology is a strategic move. Here's a step-by-step guide to making this transition:

Assess Current Needs and Future Goals

Before investing in new technology, it's crucial to evaluate your current production processes and identify areas where precision cutting could make the most significant impact. Consider your product range, production volume, and future expansion plans.

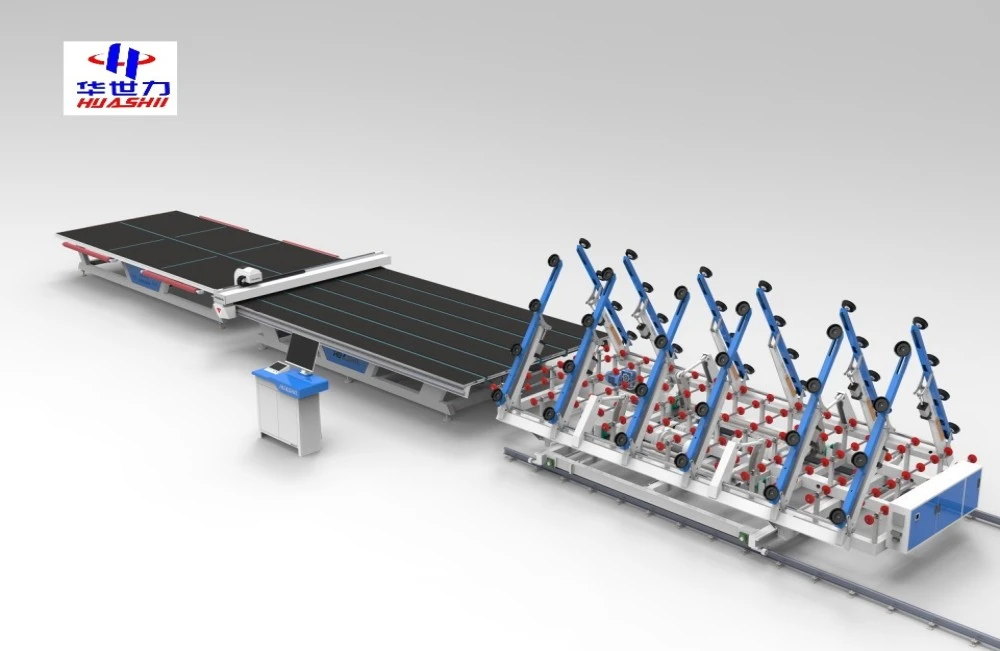

Choose the Right Equipment

Selecting the appropriate glass cutting table machine is critical. Factors to consider include:

- Cutting bed size

- Precision capabilities

- Cutting speed

- Software compatibility

- Automation features

Training and Skill Development

Investing in employee training is essential. While modern glass cutting machines are designed to be user-friendly, proper training ensures optimal use of the equipment and minimizes the risk of errors.

Integration with Existing Systems

Consider how the new precision cutting equipment will integrate with your existing production line. This may involve updating other machinery or processes to maintain efficiency throughout the production chain.

Quality Control Measures

Implement robust quality control measures to ensure that the precision cutting machine consistently meets your accuracy standards. This may include regular calibration and maintenance schedules.

Optimize Material Flow

Reorganize your production floor to optimize the flow of materials to and from the precision cutting station. This can significantly improve overall efficiency and reduce handling time.

Software Integration

Utilize cutting-edge software that can seamlessly integrate with your precision cutting machine. This allows for easy transfer of complex designs and patterns from CAD systems to the cutting table.

Regular Maintenance

Establish a regular maintenance schedule to keep your precision cutting equipment in top condition. This proactive approach can prevent downtime and ensure consistent performance.

Data Collection and Analysis

Implement systems to collect and analyze data from your precision cutting operations. This can provide valuable insights into efficiency, material usage, and areas for further improvement.

Continuous Improvement

Stay informed about the latest developments in precision cutting technology. Regularly assess your processes and be open to upgrading or refining your systems as new advancements become available.

The implementation of precision cutting technology in glass manufacturing is not just about adopting new machinery; it's about embracing a new paradigm in production quality and efficiency. By following these steps, manufacturers can position themselves at the forefront of the industry, capable of meeting the most exacting standards of modern glass applications.

As the demand for high-precision glass products continues to grow across industries, from architecture to electronics, the role of advanced glass cutting table machines becomes increasingly crucial. These machines are not just tools; they are the catalysts for innovation in glass design and application.

The journey towards precision cutting is one of continuous improvement and adaptation. It requires a commitment to quality, a willingness to invest in technology and training, and an eye towards future possibilities. For those willing to make this commitment, the rewards are substantial: increased productivity, reduced waste, expanded capabilities, and the ability to meet the most demanding customer requirements.

In conclusion, precision cutting is more than just a feature of modern glass cutting table machines; it's a paradigm shift that is redefining what's possible in glass manufacturing. As we look to the future, it's clear that this technology will play a pivotal role in shaping the glass industry, driving innovation, and opening up new possibilities for glass applications across various sectors.

Are you ready to elevate your glass cutting capabilities? At Shandong Huashil Automation Technology Co., LTD, we specialize in cutting-edge glass cutting table machines that deliver unparalleled precision and efficiency. With years of experience in automated R&D, manufacturing, and sales, we offer advanced techniques, stable quality, and excellent service that have made us a favorite among customers worldwide. Don't let outdated technology hold your business back. Contact us today at salescathy@sdhuashil.com to discover how our precision glass cutting solutions can transform your production process and give you a competitive edge in the market.

References

1. Smith, J. (2023). "Advancements in Precision Glass Cutting Technology". Journal of Glass Manufacturing, 45(2), 112-128.

2. Johnson, A. & Lee, S. (2022). "Comparative Analysis of Traditional and Precision Glass Cutting Methods". International Glass Technology Review, 18(4), 203-217.

3. Zhang, L. et al. (2023). "Impact of Micron-Level Accuracy on Glass Industry Applications". Advanced Materials Processing, 31(3), 456-470.

4. Brown, R. (2022). "Implementation Strategies for Precision Cutting in Glass Manufacturing". Industrial Automation Quarterly, 27(1), 78-92.