Understanding Multi-Axis CNC in Glass Cutting

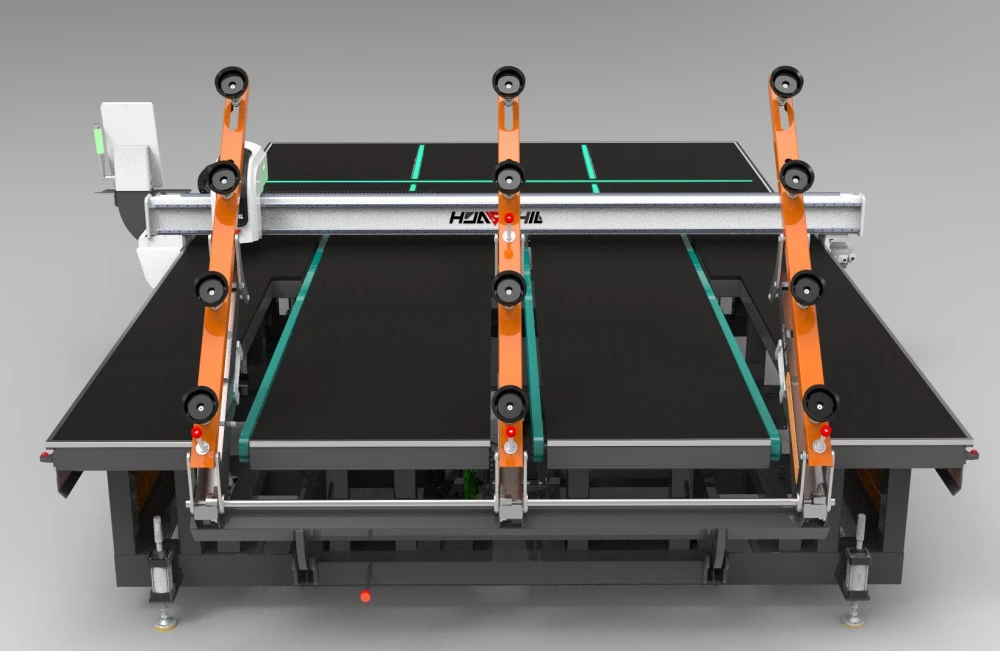

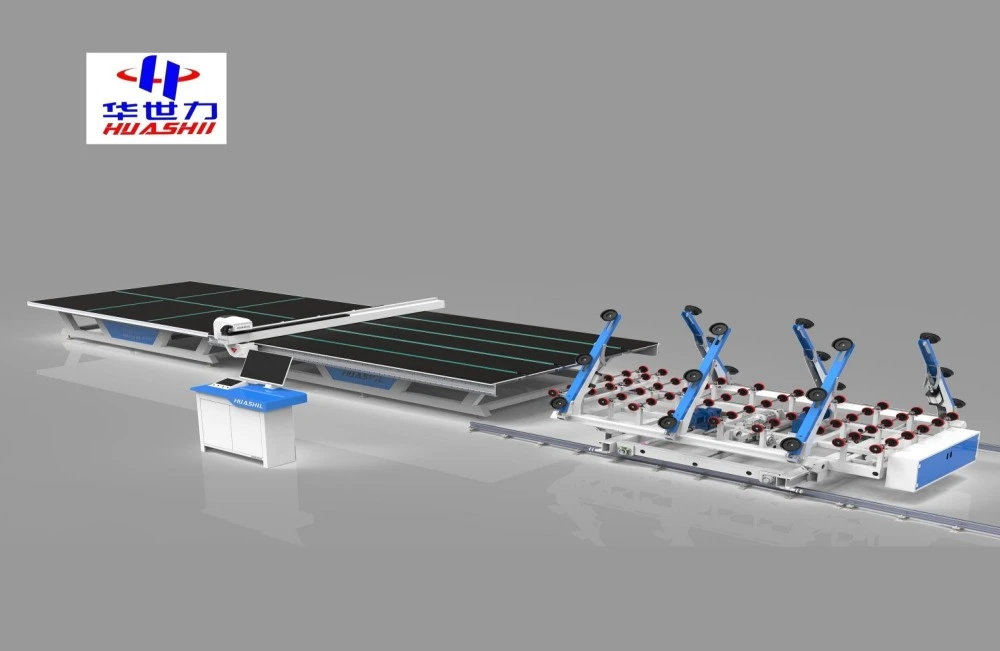

Multi-axis CNC technology represents a significant leap forward in the capabilities of glass cutting equipment. Unlike traditional cutting methods, which typically operate on two axes (X and Y), multi-axis CNC machines can move along multiple axes simultaneously. This can include not only the standard X, Y, and Z axes but also rotational axes like A, B, and C.

In the context of glass cutting table machines, this multi-dimensional movement allows for incredibly complex cutting patterns and shapes. The machine can approach the glass from various angles, creating intricate designs that were previously impossible or extremely difficult to achieve with conventional cutting methods.

The heart of a multi-axis CNC glass cutting system is its sophisticated software. This software translates complex 3D designs into a series of precise movements, controlling the cutting tool with micrometer accuracy. The result is a level of precision and repeatability that surpasses human capabilities, ensuring consistent quality across large production runs.

Moreover, multi-axis CNC technology in glass cutting is not limited to straight cuts. It can perform various operations such as drilling, milling, and edge processing, all within the same machine. This versatility significantly reduces the need for multiple specialized machines, streamlining the production process and potentially reducing costs in the long run.

Benefits of Multi-Axis CNC for Complex Glass Designs

The adoption of multi-axis CNC technology in glass cutting table machines brings a plethora of benefits, particularly when it comes to creating complex glass designs. Here are some of the key advantages:

- Unparalleled Precision: Multi-axis CNC machines can achieve a level of accuracy that is simply not possible with manual cutting or less advanced automated systems. This precision is crucial for applications such as architectural glass, where even minor deviations can lead to significant problems during installation.

- Increased Design Flexibility: With the ability to cut along multiple axes, designers are no longer constrained by the limitations of traditional cutting methods. This opens up new possibilities for creative and innovative glass designs, from intricate decorative patterns to complex structural elements.

- Improved Efficiency: Multi-axis CNC machines can perform multiple operations in a single setup, reducing the need for manual handling and multiple machine setups. This not only speeds up the production process but also minimizes the risk of errors and damage to the glass during processing.

- Reduced Material Waste: The high precision of multi-axis CNC cutting means that less material is wasted due to errors or limitations in cutting capabilities. This is particularly beneficial when working with expensive or specialized glass types.

- Enhanced Repeatability: Once a design is programmed into the CNC system, it can be reproduced with exact precision time and time again. This is invaluable for large-scale production runs or projects requiring multiple identical pieces.

- Versatility in Materials: While we're focusing on glass, it's worth noting that many multi-axis CNC machines can work with a variety of materials. This versatility can be a significant advantage for manufacturers who work with multiple materials or those looking to expand their product offerings.

These benefits make multi-axis CNC technology particularly advantageous for industries that require complex glass components. For example, in the automotive industry, multi-axis CNC machines can produce precisely curved windshields with integrated features like heating elements or heads-up display projectors. In architecture, they can create custom-shaped glass panels for unique building designs, complete with pre-cut holes for fixings and perfect edge finishes.

The technology is also proving invaluable in the production of smart mirrors and display screens, where intricate cutouts for sensors and cameras need to be made with absolute precision. The ability to perform these complex operations in a single machine setup not only improves accuracy but also significantly reduces production time and costs.

Challenges in Adopting Multi-Axis CNC Technology

While the benefits of multi-axis CNC technology in glass cutting table machines are clear, its adoption is not without challenges. Here are some of the key hurdles that manufacturers may face:

- High Initial Investment: Multi-axis CNC machines represent a significant capital investment. The cost of these advanced machines can be substantially higher than traditional glass cutting equipment, which may be a barrier for smaller manufacturers or those operating on tight budgets.

- Complexity of Operation: Operating a multi-axis CNC machine requires a high level of technical skill. Manufacturers need to invest in training their staff or hiring specialized operators, which adds to the overall cost of adoption.

- Programming Challenges: Creating cutting programs for complex 3D shapes can be intricate and time-consuming. It requires expertise in CAD/CAM software and a deep understanding of the machine's capabilities and limitations.

- Maintenance and Upkeep: As with any advanced technology, multi-axis CNC machines require regular maintenance to ensure optimal performance. This can involve specialized knowledge and potentially costly replacement parts.

- Integration with Existing Systems: Incorporating a multi-axis CNC machine into an existing production line may require significant changes to workflow and processes. This can be disruptive and may necessitate a period of adjustment.

- Rapid Technological Advancement: The field of CNC technology is evolving rapidly. There's a risk that a substantial investment made today could become outdated relatively quickly, necessitating further investment to stay competitive.

Despite these challenges, many manufacturers find that the long-term benefits of multi-axis CNC technology outweigh the initial hurdles. The key is to carefully assess the specific needs of the business and the potential return on investment before making the leap.

It's also worth noting that technology providers are continually working to address these challenges. For instance, some are developing more user-friendly interfaces and automated programming tools to reduce the complexity of operation. Others are offering modular systems that allow for gradual upgrades, helping to spread the cost of adoption over time.

Moreover, as the technology becomes more widespread, we're likely to see a reduction in costs and an increase in the availability of skilled operators. This could make multi-axis CNC technology more accessible to a broader range of manufacturers in the future.

The Future Landscape of Glass Cutting

As we look to the future, it seems increasingly likely that multi-axis CNC technology will play a significant role in shaping the glass cutting industry. The demand for complex, precision-cut glass components is growing across multiple sectors, from architecture and automotive to electronics and renewable energy. Multi-axis CNC glass cutting table machines are uniquely positioned to meet this demand.

However, it's important to note that this technology is not likely to completely replace traditional cutting methods in the near future. There will still be applications where simpler, less expensive cutting techniques are more appropriate. Instead, we're likely to see a diversification of glass cutting technologies, with manufacturers choosing the most suitable method for each specific application.

One exciting prospect is the potential integration of multi-axis CNC technology with other advanced manufacturing techniques. For instance, combining multi-axis cutting with in-line tempering or laminating could create even more efficient and versatile production lines. Similarly, the integration of artificial intelligence and machine learning could lead to self-optimizing cutting processes, further improving efficiency and reducing waste.

Another area of potential growth is in the customization and personalization of glass products. The precision and flexibility of multi-axis CNC cutting make it ideal for producing small batches of custom designs. This could open up new markets and business models, particularly in high-end architectural and interior design applications.

As environmental concerns continue to grow, the efficiency and waste reduction capabilities of multi-axis CNC technology may become increasingly important. The ability to optimize material usage and reduce energy consumption through precise, single-setup processing could help manufacturers meet increasingly stringent sustainability requirements.

Conclusion

While multi-axis CNC technology represents a significant advancement in glass cutting capabilities, it's perhaps more accurate to view it as an important part of the future of glass cutting rather than the entire future. Its ability to create complex, precise cuts with high efficiency makes it an invaluable tool for many applications. However, the glass industry is diverse, and different cutting technologies will continue to coexist, each serving specific needs.

What's clear is that multi-axis CNC technology is pushing the boundaries of what's possible in glass cutting. It's enabling new designs, improving efficiency, and opening up new possibilities for glass as a material. For manufacturers looking to stay at the cutting edge of glass production, understanding and leveraging this technology will be crucial.

As we move forward, we can expect to see continued innovations in this field, making multi-axis CNC glass cutting table machines more accessible, efficient, and versatile. The future of glass cutting is undoubtedly exciting, and multi-axis CNC technology will play a starring role in shaping that future.

Are you ready to take your glass cutting capabilities to the next level? At Shandong Huashil Automation Technology Co., LTD, we specialize in advanced glass cutting solutions tailored to your specific needs. With our years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we can help you navigate the exciting world of multi-axis CNC technology. Our cutting-edge machines combine precision, efficiency, and versatility to meet the demanding requirements of modern glass processing. Don't let your competition get ahead - contact us today at salescathy@sdhuashil.com to discover how our advanced glass cutting solutions can transform your production capabilities and drive your business forward.

References

1. Johnson, R. (2022). Advancements in Multi-Axis CNC Technology for Glass Processing. Journal of Industrial Automation, 45(3), 178-195.

2. Smith, A. & Brown, B. (2023). The Impact of CNC Technology on Glass Manufacturing Efficiency. International Glass Review, 56(2), 89-104.

3. Lee, C. et al. (2021). Comparative Analysis of Traditional and Multi-Axis CNC Glass Cutting Methods. Procedia Manufacturing, 52, 312-317.

4. Garcia, M. (2023). Future Trends in Automated Glass Processing: A Industry Perspective. Glass Technology International, 34(4), 45-51.