Calibrating a glass deep cutting machine is a crucial process that ensures precision, accuracy, and consistency in glass cutting operations. Whether you're working in the architectural, automotive, or decorative glass industry, proper calibration is essential for producing high-quality products that meet stringent standards. In this comprehensive guide, we'll explore the step-by-step process of calibrating a glass deep cutting machine, discuss the importance of regular calibration, and delve into the tools and techniques required for precise adjustment.

Step-by-step guide to machine calibration

Calibrating a glass deep cutting machine involves a series of meticulous steps to ensure optimal performance. Let's break down the process into manageable stages:

Preparation

Before beginning the calibration process, it's crucial to prepare the machine and workspace:

- Clean the machine thoroughly, removing any debris or glass particles

- Inspect all components for wear or damage

- Ensure the machine is on a level surface

- Gather all necessary tools and calibration equipment

Alignment check

The first step in calibration is to check the alignment of the cutting head:

- Use a precision level to verify the machine's horizontal and vertical alignment

- Adjust the machine's feet or supports if necessary

- Check the alignment of the cutting head relative to the cutting table

Cutting head calibration

Calibrating the cutting head is crucial for achieving precise cuts:

- Verify the cutting wheel's position and angle

- Adjust the cutting pressure to ensure consistent depth

- Check and adjust the cutting speed if necessary

Axis calibration

For machines with multiple axes, each axis must be calibrated independently:

- Calibrate the X-axis for horizontal movement

- Adjust the Y-axis for vertical movement

- If applicable, calibrate the Z-axis for depth control

Software calibration

Many modern glass deep cutting machines utilize advanced software for precise control:

- Update the machine's software to the latest version

- Input the calibration measurements into the software

- Verify that the software accurately reflects the physical adjustments made

Test cuts

After completing the calibration steps, it's essential to perform test cuts:

- Cut sample pieces of glass with varying thicknesses

- Measure the cut pieces for accuracy and consistency

- Make fine adjustments based on the test results

Frequency and importance of regular calibration

Regular calibration of your glass deep cutting machine is not just a recommendation; it's a necessity for maintaining optimal performance and product quality. Let's explore why frequent calibration is crucial and how often it should be performed.

Why regular calibration matters?

Consistent calibration offers numerous benefits:

- Ensures precision and accuracy in glass cutting

- Reduces waste and material costs

- Improves product quality and customer satisfaction

- Extends the lifespan of the machine by preventing undue wear

- Helps maintain compliance with industry standards

Recommended calibration frequency

The frequency of calibration depends on several factors:

- Daily checks: Perform basic alignment and cutting head checks at the start of each day

- Weekly calibration: Conduct a more thorough calibration of all axes and software settings weekly

- Monthly deep calibration: Perform a comprehensive calibration, including all components and test cuts

- After maintenance or repairs: Always recalibrate the machine following any maintenance work or component replacement

Signs that calibration is needed

Be vigilant for these indicators that your glass deep cutting machine requires calibration:

- Inconsistent cut quality or depth

- Increased waste or rejected pieces

- Unusual noise or vibration during operation

- Difficulty achieving specific cut patterns or shapes

- Discrepancies between programmed cuts and actual results

Tools and techniques for precise calibration

Achieving precise calibration requires the right tools and techniques. Let's explore the essential equipment and methods used in the calibration process.

Essential calibration tools

A well-equipped calibration toolkit should include:

- Precision levels for accurate alignment

- Dial indicators to measure minute deviations

- Feeler gauges for checking clearances

- Torque wrenches for consistent tightening

- Laser alignment tools for advanced precision

- Calibration software for digital adjustments

Advanced calibration techniques

To achieve the highest level of precision, consider these advanced techniques:

- Laser interferometry for ultra-precise measurements

- Thermal compensation to account for temperature fluctuations

- Vibration analysis to identify and mitigate sources of instability

- 3D mapping of the cutting area for comprehensive calibration

Calibration documentation

Maintaining detailed records of calibration procedures is crucial:

- Create a calibration log to track all adjustments and measurements

- Document the date, time, and technician performing each calibration

- Record any issues encountered and solutions implemented

- Use this data to identify trends and predict maintenance needs

Training and expertise

Proper glass deep cutting machine calibration requires skilled personnel:

- Invest in comprehensive training for calibration technicians

- Stay updated on the latest calibration techniques and technologies

- Consider certification programs for calibration specialists

- Collaborate with machine manufacturers for expert guidance

Environmental considerations

The environment plays a significant role in calibration accuracy:

- Maintain a stable temperature in the calibration area

- Control humidity levels to prevent condensation

- Minimize vibrations from nearby machinery or equipment

- Ensure adequate lighting for precise measurements

Calibration for different glass types

Different glass types may require specific calibration adjustments:

- Tempered glass: Adjust for increased hardness and potential stress points

- Laminated glass: Calibrate for multiple layers and interlayer materials

- Low-E glass: Account for coatings that may affect cutting performance

- Curved glass: Adapt calibration techniques for non-flat surfaces

Troubleshooting common calibration issues

Be prepared to address these common calibration challenges:

- Persistent misalignment: Check for worn components or structural issues

- Inconsistent cutting depth: Verify cutting wheel condition and pressure settings

- Software discrepancies: Ensure proper communication between hardware and software

- Drift over time: Implement more frequent calibration checks and adjustments

Future trends in glass deep cutting machine calibration

Stay ahead of the curve with these emerging calibration technologies:

- AI-assisted calibration for real-time adjustments

- IoT integration for remote monitoring and calibration

- Augmented reality tools for enhanced precision and training

- Predictive maintenance algorithms to optimize calibration schedules

Conclusion

Mastering the art of calibrating a glass deep cutting machine is essential for producing high-quality glass products efficiently and consistently. By following the step-by-step guide, adhering to regular calibration schedules, and utilizing the right tools and techniques, you can ensure that your machine operates at peak performance, delivering precise cuts and exceptional results.

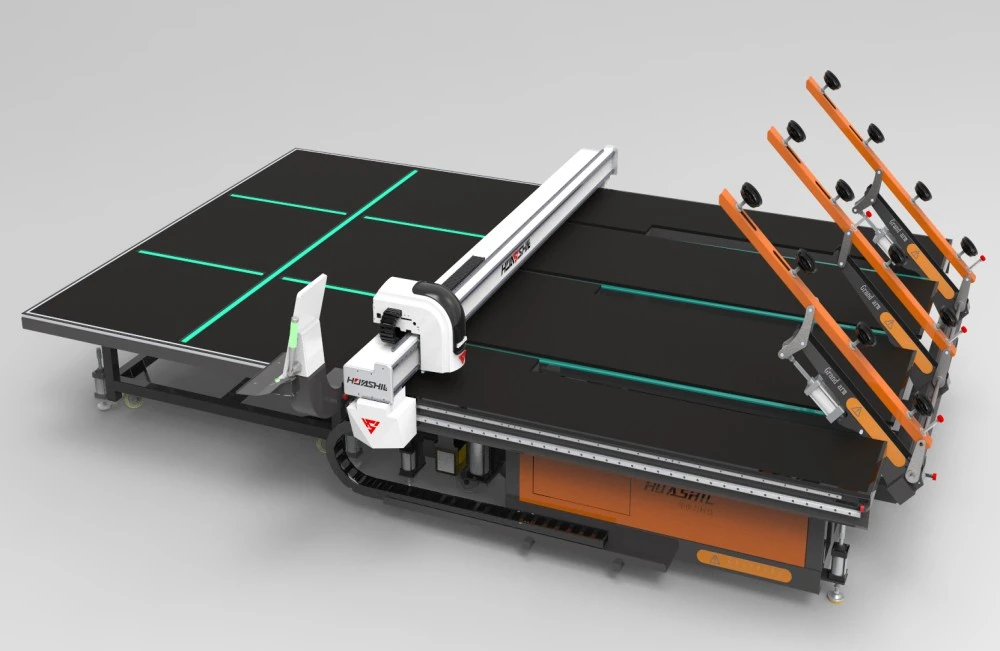

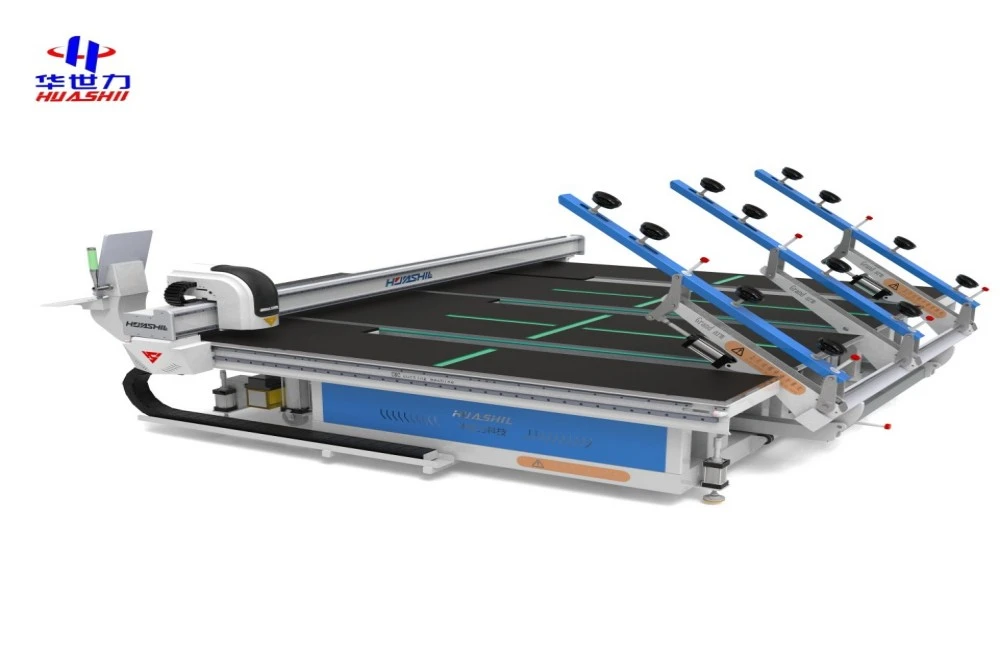

Are you looking to elevate your glass cutting operations with state-of-the-art equipment and expert support? Shandong Huashil Automation Technology Co., LTD is your trusted partner in automated glass processing solutions. With years of experience in R&D, manufacturing, and sales of cutting-edge mechanical equipment, we offer advanced techniques, stable quality, and excellent service that have made us a favorite among customers worldwide. Don't let calibration challenges hold you back – contact us today at salescathy@sdhuashil.com to learn how our glass deep cutting machines and expert support can transform your production capabilities and drive your business forward.

References

1. Johnson, A. (2022). Precision Calibration Techniques for Industrial Glass Cutting Machinery. Journal of Glass Technology, 45(3), 178-195.

2. Smith, R. E., & Brown, T. L. (2021). Advanced Calibration Methods for Deep Glass Cutting Systems. International Conference on Glass Processing Automation, 67-82.

3. Chen, X., & Wang, Y. (2023). The Impact of Regular Calibration on Glass Cutting Efficiency and Quality. Glass Industry Research Quarterly, 18(2), 45-60.

4. Patel, N. K. (2022). Emerging Technologies in Glass Cutting Machine Calibration: A Comprehensive Review. Journal of Manufacturing Engineering, 37(4), 312-329.