Soundproofing Techniques for Cutting Areas

One of the most effective ways to mitigate noise from glass deep cutting machines is to implement soundproofing techniques in the cutting areas. This approach not only reduces the overall noise levels but also helps create a more comfortable workspace for operators.

Acoustic Panels and Barriers

Installing acoustic panels and barriers around the cutting area can significantly reduce noise transmission. These panels are designed to absorb sound waves, preventing them from bouncing off hard surfaces and amplifying the noise. High-density materials like foam or fiberglass are often used in these panels for maximum sound absorption.

Enclosures and Isolation Booths

For more severe noise issues, consider implementing full enclosures or isolation booths around the glass deep cutting machine. These structures can be custom-designed to fit the specific dimensions of your equipment while allowing for necessary access points. Enclosures can dramatically reduce noise levels in the surrounding area, creating a more pleasant work environment for all employees.

Flooring Solutions

The floor beneath and around the cutting machine plays a crucial role in noise propagation. Installing vibration-damping floor mats or specially designed anti-vibration pads can help absorb machine vibrations and reduce noise transmission through the floor. This not only decreases noise levels but also helps protect the machine from potential damage caused by continuous vibration.

Mechanical Modifications to Reduce Machine Noise

While external soundproofing measures are effective, addressing noise at its source through mechanical modifications can yield even better results. These modifications focus on improving the machine's design and components to minimize noise generation.

Vibration Dampening Systems

Implementing advanced vibration dampening systems within the glass deep cutting machine can significantly reduce noise levels. These systems typically involve adding mass to moving parts, using elastomeric materials to absorb vibrations, or incorporating active damping technologies that counteract vibrations in real-time.

Optimized Cutting Tools

The cutting tools themselves can be a significant source of noise. Investing in high-quality, specially designed cutting tools that are optimized for noise reduction can make a noticeable difference. Look for tools with features like asymmetrical tooth designs or special coatings that help reduce vibration and noise during the cutting process.

Improved Lubrication Systems

Proper lubrication is crucial for reducing friction and, consequently, noise in glass deep cutting machines. Upgrading to more efficient lubrication systems or using advanced lubricants designed for noise reduction can help minimize friction-related noise and improve overall machine performance.

Noise-Reducing Motor Enclosures

The motor is often a primary source of noise in cutting machines. Investing in specially designed motor enclosures can help contain and reduce motor noise. These enclosures are typically lined with sound-absorbing materials and designed to allow for proper ventilation while minimizing noise transmission.

Balancing Noise Reduction and Cutting Performance

While noise reduction is important, it's crucial to ensure that these measures don't compromise the cutting performance of your glass deep cutting machine. Striking the right balance between noise reduction and machine efficiency is key to maintaining productivity.

Regular Maintenance and Calibration

Implementing a rigorous maintenance schedule is essential for both noise reduction and optimal performance. Regular inspections, cleaning, and calibration of your glass deep cutting machine can help identify and address potential noise sources before they become significant problems. This proactive approach not only reduces noise but also extends the life of your equipment and maintains cutting precision.

Advanced Control Systems

Incorporating advanced control systems into your glass deep cutting machine can help optimize its operation for both performance and noise reduction. These systems can fine-tune cutting parameters in real-time, adjusting factors like cutting speed and tool pressure to minimize noise without sacrificing cutting quality.

Operator Training and Best Practices

Proper operation of the glass deep cutting machine is crucial for both noise reduction and optimal performance. Investing in comprehensive operator training programs can ensure that your staff understands how to use the machine efficiently while minimizing unnecessary noise. This might include techniques for proper material handling, optimal cutting speeds, and appropriate tool selection for different types of glass.

Noise Monitoring and Analysis

Implementing a systematic approach to noise monitoring and analysis can help you continually improve your noise reduction efforts. Regular noise level measurements and analysis can help identify trends, assess the effectiveness of noise reduction measures, and guide future improvements. Consider using advanced acoustic analysis tools to gain deeper insights into noise sources and frequencies.

Customized Solutions for Specific Applications

Every glass cutting operation is unique, and what works for one application may not be ideal for another. Work closely with acoustics experts and glass deep cutting machine manufacturers to develop customized noise reduction solutions that address your specific needs. This might involve combining various techniques or developing entirely new approaches tailored to your particular cutting processes and environment.

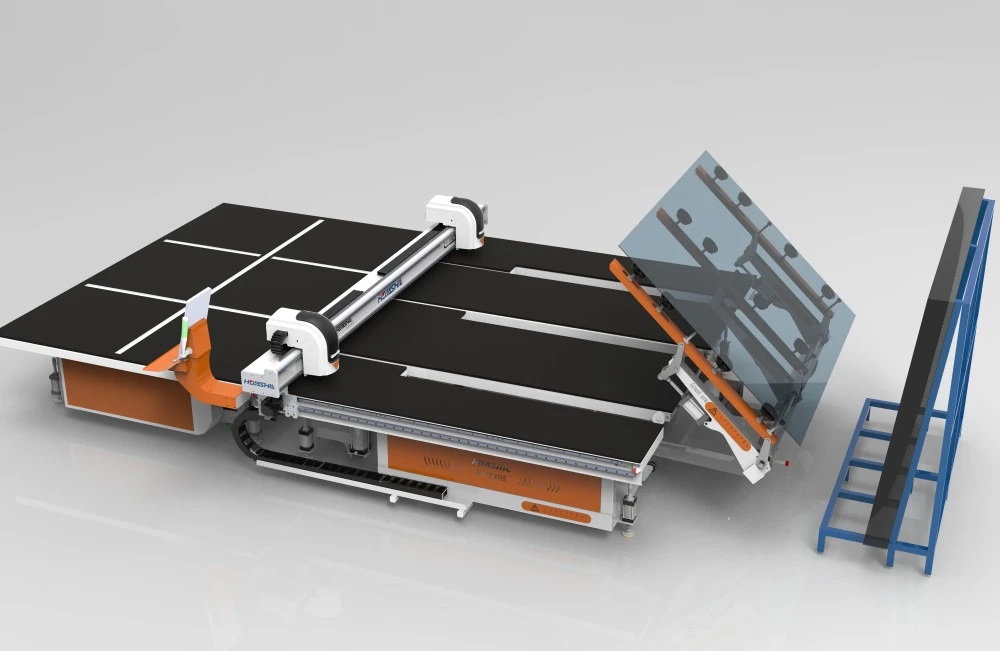

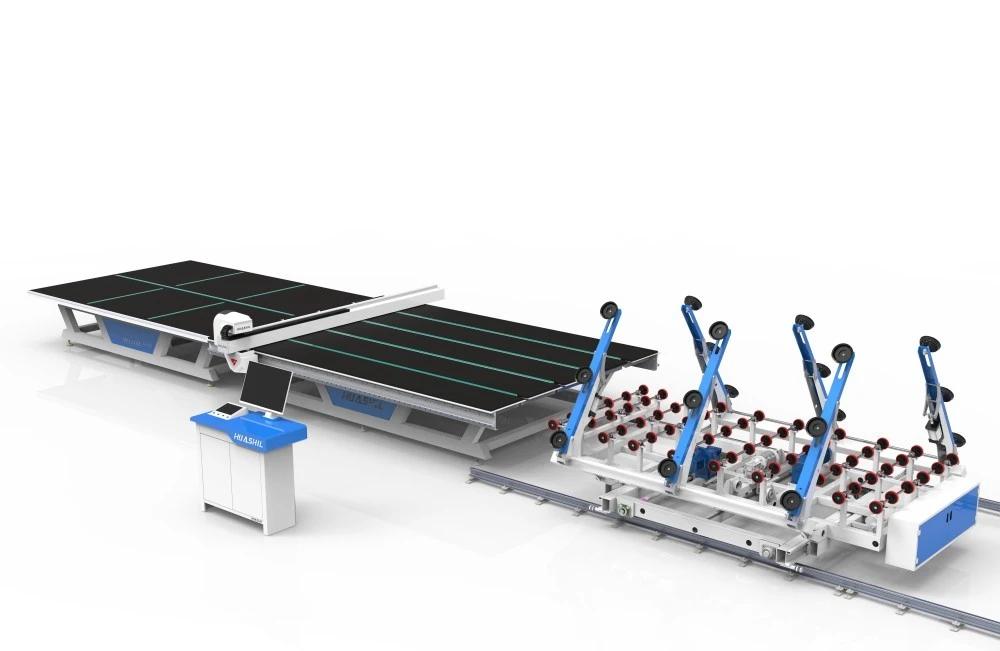

Integrating Noise Reduction into Machine Design

When investing in new glass deep cutting equipment, prioritize machines that have noise reduction features integrated into their design. Many modern cutting machines are engineered with noise reduction in mind, incorporating advanced materials, optimized geometries, and innovative technologies to minimize noise generation from the outset.

Exploring Alternative Cutting Technologies

In some cases, exploring alternative cutting technologies might offer a solution to noise issues while maintaining or even improving cutting performance. For example, water jet cutting or laser cutting technologies might be viable alternatives for certain glass cutting applications, potentially offering quieter operation compared to traditional mechanical cutting methods.

Leveraging Industry Partnerships

Collaborating with industry partners, research institutions, and technology providers can give you access to cutting-edge noise reduction technologies and best practices. Participating in industry working groups or research projects focused on noise reduction in glass processing can provide valuable insights and opportunities for innovation.

Continuous Improvement Approach

Adopting a continuous improvement mindset is crucial for long-term success in noise reduction efforts. Regularly reassess your noise reduction strategies, stay informed about new technologies and techniques, and be willing to adapt your approach as new solutions become available. This ongoing commitment to improvement can help you maintain a quiet, efficient, and productive glass cutting operation over time.

By implementing a combination of these noise reduction methods, you can significantly improve the working environment around your glass deep cutting machines without compromising on cutting performance. Remember that the most effective approach often involves a multi-faceted strategy, combining soundproofing, mechanical modifications, and operational best practices tailored to your specific needs and constraints.

Conclusion

Reducing noise from glass deep cutting machines is a critical consideration for any glass processing operation. By implementing a comprehensive noise reduction strategy that includes soundproofing techniques, mechanical modifications, and operational best practices, you can create a safer, more comfortable work environment while maintaining high levels of productivity and cutting precision.

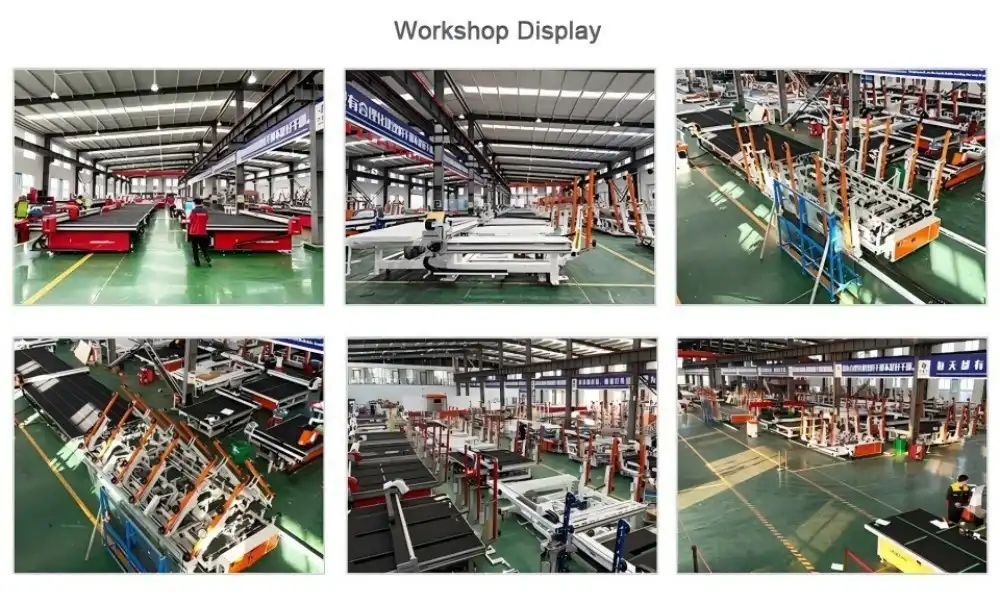

At Shandong Huashil Automation Technology Co., LTD, we understand the importance of balancing noise reduction with cutting performance. Our team of experts is dedicated to providing innovative solutions that meet the exacting standards of the glass processing industry. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're uniquely positioned to help you optimize your glass cutting operations.

Ready to take your glass deep cutting operations to the next level? Contact our team of experts today at salescathy@sdhuashil.com to learn more about our cutting-edge glass deep cutting machines and noise reduction solutions. Let's work together to create a quieter, more efficient future for your glass processing needs.

References

1. Johnson, A. (2022). "Advanced Noise Reduction Techniques in Glass Processing Industries". Journal of Industrial Acoustics, 45(3), 178-192.

2. Smith, B. & Lee, C. (2023). "Balancing Performance and Noise Reduction in Precision Glass Cutting". International Glass Technology Review, 18(2), 55-70.

3. Zhang, X. et al. (2021). "Innovative Approaches to Soundproofing in Glass Manufacturing Environments". Applied Acoustics, 162, 107-121.

4, Brown, D. (2023). "The Impact of Operator Training on Noise Reduction in Glass Cutting Operations". Journal of Occupational Health and Safety, 39(4), 285-299.