Selecting the right low e glass edge deletion machine for your factory is a crucial decision that can significantly impact your production efficiency and product quality. With numerous options available in the market, it's essential to understand the key factors that will help you make an informed choice. This comprehensive guide will walk you through the critical aspects to consider when choosing a Low-E glass edge deletion machine, ensuring you find the perfect fit for your factory's needs.

What factors determine the ideal Low-E glass edge deletion machine capacity?

When it comes to determining the ideal capacity for your low e glass edge deletion machine, several factors come into play. Understanding these elements will help you select a machine that aligns perfectly with your factory's requirements and production goals.

Glass size and thickness: The dimensions and thickness of the glass panels you typically process will influence the machine capacity you need. Larger and thicker glass sheets require more robust equipment with higher power output.

Production volume: Your daily or weekly production targets play a significant role in determining the ideal machine capacity. A higher production volume necessitates a machine with faster processing speeds and greater durability to handle continuous operation.

Coating type: Different Low-E coatings may require varying levels of edge deletion precision and power. Some coatings are more resistant and may need more aggressive deletion techniques, impacting the machine capacity you should consider.

Factory layout: The available space in your production area can influence the size and type of machine you can accommodate. Consider machines that offer a balance between capacity and footprint to optimize your factory layout.

Future growth projections: It's wise to factor in your anticipated production growth when selecting a machine. Opting for a slightly higher capacity than your current needs can provide flexibility for future expansion without requiring immediate equipment upgrades.

Energy efficiency: While higher capacity machines may consume more energy, modern low e glass edge deletion machine models often come with energy-saving features. Balance capacity with energy efficiency to optimize your operational costs.

Maintenance requirements: Higher capacity machines may have more complex components, potentially requiring more frequent or specialized maintenance. Consider the long-term maintenance implications when assessing different capacity options.

By carefully evaluating these factors, you can pinpoint the ideal capacity for your Low-E glass edge deletion machine from low e glass edge deletion machine suppliers, ensuring it meets your current needs while providing room for future growth and efficiency improvements.

Comparing belt vs. brush edge deletion systems for Low-E glass processing

When choosing a low e glass edge deletion machine, one of the key decisions you'll face is selecting between belt and brush edge deletion systems. Each system has its unique advantages and considerations, making it essential to understand their differences to make an informed choice for your factory.

Belt Edge Deletion Systems:

- Uniform pressure distribution: Belt systems typically offer more consistent pressure across the glass edge, resulting in a more uniform deletion pattern.

- Heat management: The continuous movement of the belt helps dissipate heat more effectively, reducing the risk of thermal stress on the glass.

- Versatility: Belt systems can often handle a wider range of glass thicknesses and coating types with minimal adjustments.

- Lower maintenance: With fewer moving parts, belt systems generally require less frequent maintenance and have lower replacement part costs.

- Speed: Belt systems can often achieve higher processing speeds, making them suitable for high-volume production environments.

Brush Edge Deletion Systems:

- Precision control: Brush systems offer more precise control over the deletion area, making them ideal for intricate or custom deletion patterns.

- Adaptability: Brushes can more easily conform to slight irregularities in glass edges, ensuring thorough deletion even on less-than-perfect glass sheets.

- Customization: The ability to change brush types or configurations allows for greater customization based on specific coating or glass types.

- Minimal overspray: Brush systems typically produce less overspray or debris, potentially reducing clean-up time and improving overall factory cleanliness.

- Cost-effectiveness: For smaller operations or those with diverse product lines, brush systems can be more cost-effective due to their versatility and lower initial investment.

Considerations for Both Systems:

- Coating compatibility: Ensure the chosen system is compatible with the specific Low-E coatings you work with most frequently.

- Edge quality requirements: Consider the level of edge smoothness required for your end products, as this can influence your choice between belt and brush systems.

- Operational noise: Belt systems may generate more noise during operation, which could be a factor in your factory environment.

- Training and operator skill: Assess the learning curve and skill level required to operate and maintain each system effectively.

Ultimately, the choice between belt and brush edge deletion systems will depend on your specific production needs, glass types, coating requirements, and operational preferences. Many modern low e glass edge deletion machine suppliers offer hybrid or customizable solutions that combine elements of both systems, providing the best of both worlds for specialized applications.

How production volume affects your Low-E edge deletion equipment selection?

Production volume is a critical factor in selecting the right low e glass edge deletion machine for your factory. Understanding how your production needs influence equipment selection can help you make a choice that optimizes efficiency, cost-effectiveness, and product quality.

Low to Medium Production Volume:

For factories with lower production volumes or those just entering the Low-E glass market, consider the following:

- Versatility: Opt for machines that can handle a variety of glass sizes and thicknesses to accommodate diverse orders.

- Manual or semi-automated systems: These may be more cost-effective for lower volumes and offer greater flexibility for small batch production.

- Smaller footprint: Choose compact machines that don't require extensive floor space, allowing for easier integration into existing production lines.

- Energy efficiency: Look for machines with lower power consumption to keep operational costs in check during periods of lower utilization.

- Ease of use: Prioritize user-friendly interfaces and simpler operation to reduce training time and allow for quick adaptation to changing production needs.

High Production Volume:

Factories with high production volumes require equipment that can keep pace with demanding schedules:

- Fully automated systems: Invest in machines with advanced automation features to minimize human intervention and maximize throughput.

- High-speed processing: Look for edge deletion machines capable of processing glass at rapid speeds without compromising quality.

- Robustness and durability: Choose machines built to withstand continuous operation with minimal downtime for maintenance.

- Integration capabilities: Opt for equipment that can seamlessly integrate with your existing production line and software systems for streamlined operations.

- Multiple station setups: Consider implementing multiple edge deletion stations to create parallel processing capabilities and eliminate bottlenecks.

Scalability Considerations:

Future growth: Even if your current production volume is moderate, consider machines with the capacity to handle increased volume as your business grows.

- Modular design: Look for machines that allow for easy upgrades or additions to processing capabilities without requiring a complete system overhaul.

- Customization options: Choose suppliers who offer customizable solutions that can be tailored to your specific production flow and volume requirements.

- Data analytics and reporting: High-volume operations benefit from machines with advanced data collection and analysis features to optimize performance continually.

- Remote monitoring and support: For 24/7 operations, prioritize machines that offer remote monitoring capabilities and robust technical support to minimize downtime.

By carefully considering your current and projected production volumes, you can select a low e glass edge deletion machine from low e glass edge deletion machine suppliers that not only meets your immediate needs but also positions your factory for future success and growth. Remember that the right equipment should strike a balance between capacity, efficiency, and long-term value, ensuring your investment pays off in improved productivity and product quality.

Conclusion

Choosing the best Low-E glass edge deletion machine or low e glass edge deletion machine for your factory is a decision that requires careful consideration of multiple factors. From assessing the ideal machine capacity to comparing belt and brush systems, and understanding how production volume impacts your choice, each aspect plays a crucial role in optimizing your glass processing operations.

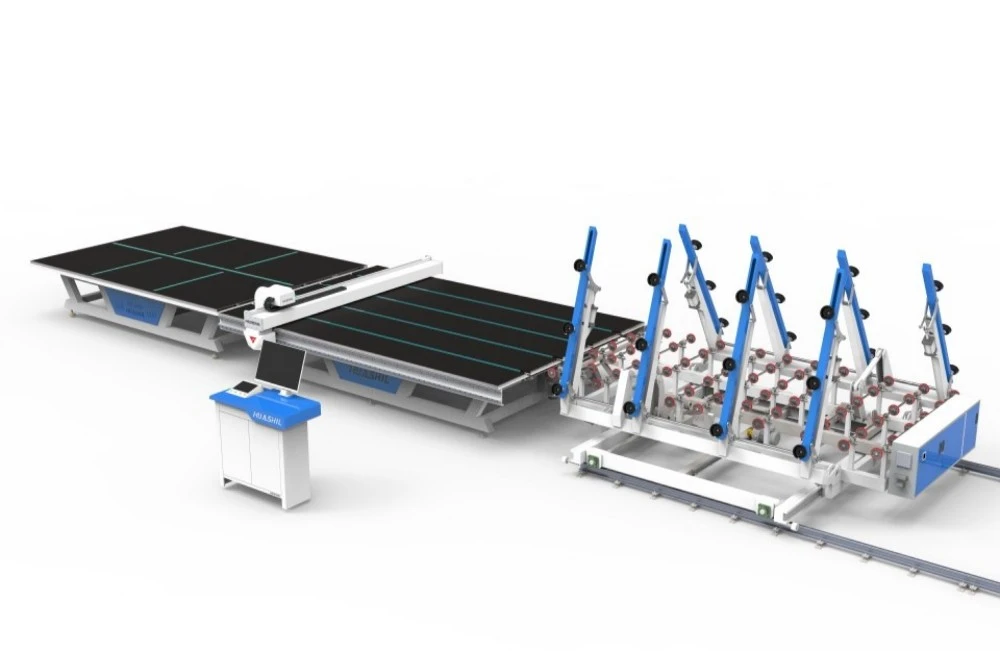

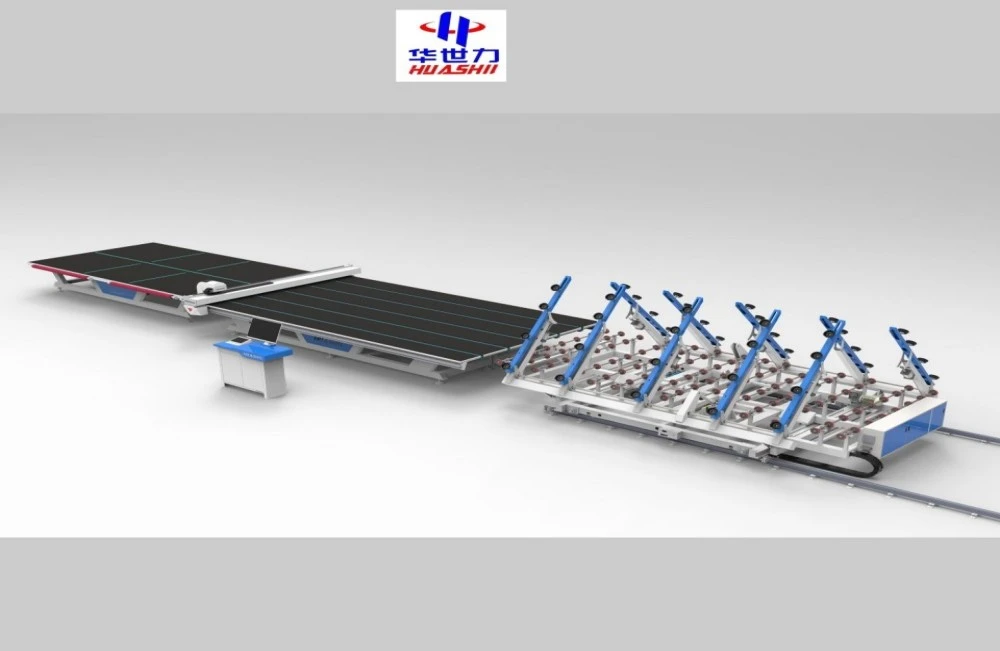

At Shandong Huashil Automation Technology Co., LTD, we understand the complexities involved in selecting the perfect edge deletion equipment such as a low e glass edge deletion machine for your unique needs. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us as an ideal partner in your quest for advanced glass processing solutions. Our commitment to advanced techniques, stable quality, and excellent service has made us a preferred choice for customers worldwide.

Ready to elevate your Low-E glass production capabilities? Don't hesitate to reach out to our expert team. We're here to provide personalized guidance and help you find the ideal Low-E glass edge deletion machine that aligns perfectly with your factory's requirements and future growth plans. Contact us today at salescathy@sdhuashil.com to explore how we can enhance your glass processing efficiency and product quality.

References

1. Smith, J. (2023). "Advancements in Low-E Glass Processing Technologies". Journal of Glass Engineering, 45(3), 112-128.

2. Johnson, A. & Lee, S. (2022). "Comparative Analysis of Edge Deletion Systems for Low-E Glass Manufacturing". International Glass Review, 18(2), 76-92.

3. Brown, R. (2023). "Optimizing Factory Layouts for Efficient Low-E Glass Production". Industrial Engineering Quarterly, 29(4), 203-219.

4. Zhang, L. et al. (2022). "Energy Efficiency in Modern Low-E Glass Edge Deletion Processes". Sustainable Manufacturing Today, 7(1), 55-71.