In the world of glass fabrication, precision and efficiency are paramount. Two technologies that have revolutionized the industry are CNC (Computer Numerical Control) and automatic shaped glass cutting machines. While both offer significant advantages over manual cutting methods, they have distinct characteristics that make them suitable for different applications. This article will delve into the key differences between these two cutting-edge technologies, helping you make an informed decision for your glass cutting needs.

When should you choose a CNC machine over an automatic shaped glass cutter?

The decision between a CNC machine and an automatic shaped glass cutting machine depends on various factors, including the complexity of your projects, production volume, and budget. Here are some scenarios where a CNC machine might be the better choice:

- Complex and intricate designs: CNC machines excel at cutting highly detailed and complex shapes. If your projects frequently involve intricate patterns or custom designs, a CNC machine's precision and flexibility make it the ideal choice.

- Small batch production: For businesses that deal with frequent design changes or small production runs, CNC machines offer greater versatility. They can be quickly reprogrammed for different designs without the need for physical template changes.

- Multi-functional requirements: Many CNC machines can perform additional tasks beyond cutting, such as drilling, engraving, and polishing. If your production process requires these extra capabilities, a CNC machine provides an all-in-one solution.

- High-value materials: When working with expensive or rare glass types, the precision of CNC cutting can minimize waste and maximize material utilization.

On the other hand, those looking to buy discount Automatic shaped glass cutting machine are often preferred in the following situations:

- High-volume production: For large-scale manufacturing of standard shapes, automatic cutters typically offer faster cycle times and higher throughput.

- Simpler shapes: If your product line primarily consists of straightforward geometric shapes, an automatic cutter can provide efficient and cost-effective production.

- Lower initial investment: Automatic shaped glass cutters are generally less expensive than CNC machines, making them a more accessible option for smaller businesses or those just starting out.

- Ease of operation: Automatic cutters often require less operator skill and training compared to CNC machines, which can be beneficial in environments with high staff turnover.

Accuracy comparison between CNC and automatic shaped glass cutting technology

Accuracy is a critical factor in glass cutting, as it directly impacts the quality of the final product and the efficiency of the production process. Both CNC and automatic shaped glass cutting technologies offer high levels of precision, but there are some notable differences:

CNC Glass Cutting Accuracy:

- Micron-level precision: CNC machines can achieve cutting accuracies down to a few microns, making them ideal for applications requiring extremely tight tolerances.

- Consistent repeatability: The computer-controlled nature of CNC machines ensures that each cut is identical, even across large production runs.

- 3D cutting capability: Advanced CNC machines can perform three-dimensional cuts, allowing for the creation of complex shapes and beveled edges.

- Adaptive cutting: Some CNC systems can adjust cutting parameters in real-time based on feedback from sensors, compensating for variations in glass thickness or composition.

Automatic Shaped Glass Cutting Accuracy:

- Template-based precision: The accuracy of automatic cutters is largely dependent on the quality of the templates or patterns used. Well-made templates can provide very high accuracy for consistent shapes.

- High-speed accuracy: Automatic cutters are designed for rapid production and can maintain good accuracy even at high cutting speeds.

- Simplified calibration: Many automatic cutters feature easy-to-use calibration systems that help maintain accuracy over time.

- Material-specific optimization: Some advanced automatic cutters can be fine-tuned for specific glass types, ensuring optimal cutting performance for different materials.

While both technologies offer excellent accuracy, CNC machines generally have the edge when it comes to precision, especially for complex or variable designs. However, for high-volume production of standard shapes, automatic shaped glass cutting machines can provide more than sufficient accuracy while offering faster cycle times.

Operational complexity: CNC programming vs. automated cutting systems

The operational complexity of glass cutting machinery can significantly impact productivity, training requirements, and overall production efficiency. Let's examine the operational aspects of both CNC and automatic shaped glass cutting systems:

CNC Programming:

- Programming skills required: Operating a CNC glass cutting machine typically requires knowledge of G-code programming or proficiency with CAD/CAM software. This can necessitate specialized training for operators.

- Flexibility in design: CNC programming allows for unlimited design possibilities. Operators can create or modify cutting patterns directly on the machine, enabling quick adaptation to new requirements.

- Setup time: Initial setup for a new design can be time-consuming, involving programming, tool path optimization, and test runs.

- Error correction: CNC systems often have built-in error checking and simulation features, allowing operators to identify and correct issues before actual cutting begins.

- Multi-parameter control: CNC programming enables fine control over various cutting parameters such as speed, depth, and tool orientation, allowing for optimization of the cutting process for different glass types and thicknesses.

Automated Cutting Systems:

- User-friendly interfaces: Most automatic shaped glass cutting machines feature intuitive touchscreen interfaces that simplify operation and reduce the learning curve for new users.

- Template-based operation: These systems often use pre-defined templates or patterns, which can be quickly selected and implemented without the need for complex programming.

- Rapid setup: Changing between different cutting patterns is typically a matter of selecting a new template, resulting in minimal downtime between jobs.

- Automated optimization: Many automatic cutters include software that optimizes glass utilization and cutting sequences automatically, reducing waste and improving efficiency.

- Simplified maintenance: Automated systems often have self-diagnostic capabilities and require less complex maintenance procedures compared to CNC machines.

While CNC machines offer unparalleled flexibility and precision, they come with a steeper learning curve and require more skilled operators. Those who buy discount Automatic shaped glass cutting machine, on the other hand, prioritize ease of use and rapid production, making them more accessible for operations with less specialized staff or frequent operator turnover.

The choice between CNC and automatic shaped glass cutting technology ultimately depends on your specific production needs, workforce capabilities, and long-term business strategy. For businesses requiring high flexibility and precision for complex designs, the investment in CNC technology and operator training can pay off in terms of versatility and quality. Conversely, for high-volume production of standard shapes, the simplicity and speed of automatic shaped glass cutters can lead to greater overall efficiency and cost-effectiveness.

As the glass fabrication industry continues to evolve, we're seeing advancements in both CNC and automatic cutting technologies. Some manufacturers are developing hybrid systems that combine the precision of CNC with the ease of use of automatic cutters, offering the best of both worlds. These innovations promise to further enhance productivity and quality in glass cutting operations across various industries.

Conclusion

Understanding the strengths and limitations of each technology is crucial for making an informed decision. By carefully evaluating your production requirements, workforce capabilities, and future growth plans, you can choose the glass cutting solution that best aligns with your business objectives.

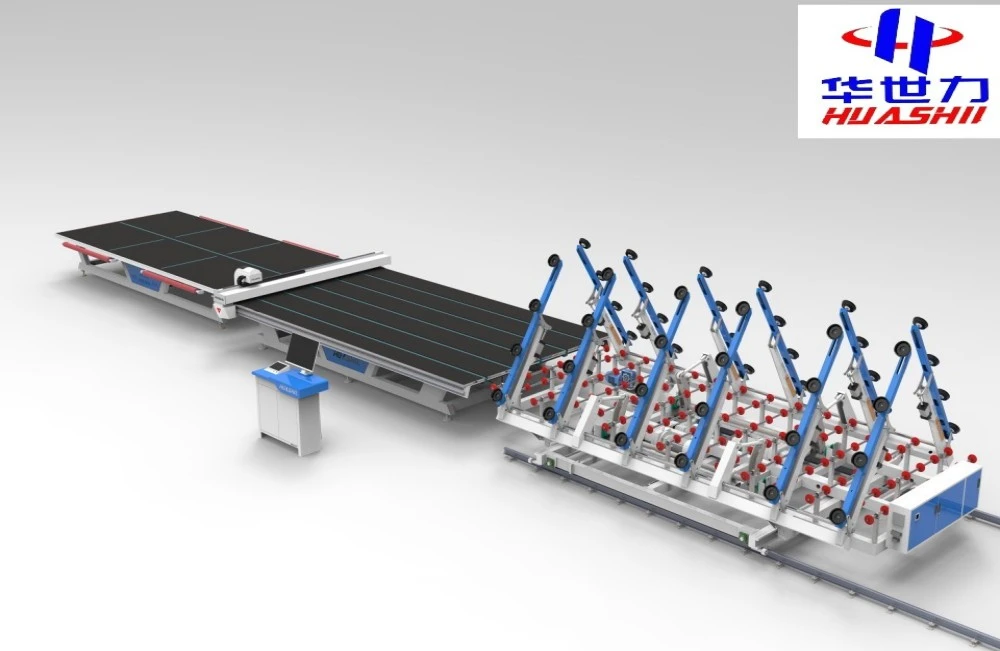

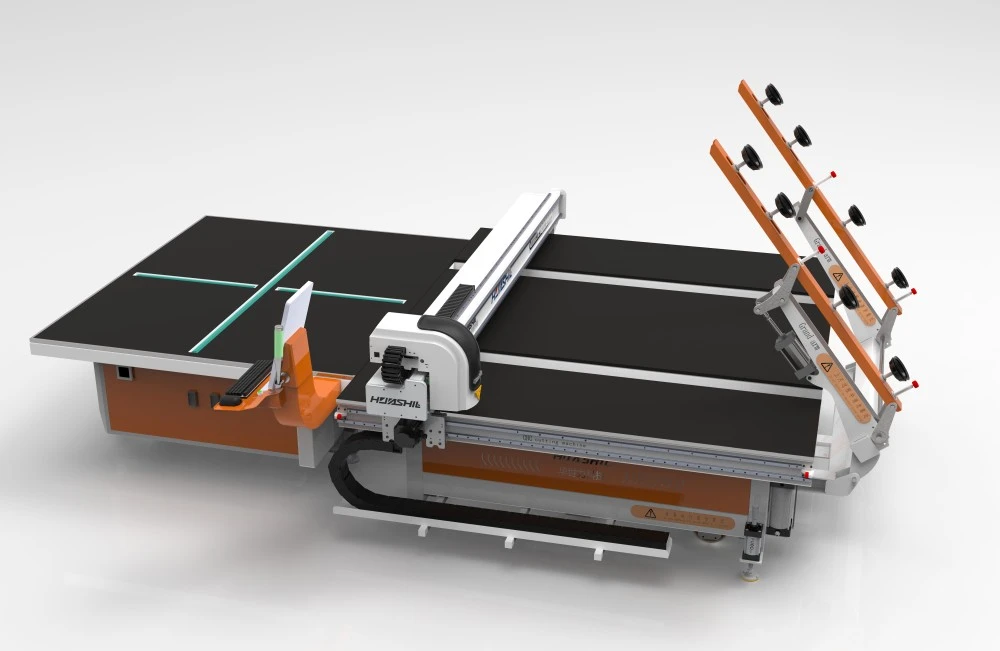

Are you looking to enhance your glass cutting capabilities? At Shandong Huashil Automation Technology Co., LTD, we specialize in advanced glass cutting solutions tailored to your specific needs. With years of experience in R&D, manufacturing, and sales of automated equipment, we offer cutting-edge technology combined with exceptional service. Our team of experts can help you determine whether a CNC or automatic shaped glass cutting machine is the right fit for your operations. Don't let outdated equipment hold your business back – contact us today at salescathy@sdhuashil.com to explore how our innovative glass cutting solutions can revolutionize your production process and give you a competitive edge in the market.

References

1. Glass Technology International. (2022). "Advancements in CNC Glass Cutting Machinery: Precision and Efficiency in Modern Fabrication"

2. Journal of Manufacturing Processes. (2021). "Comparative Analysis of CNC and Automatic Shaped Glass Cutting Technologies in Industrial Applications"

3. International Journal of Production Research. (2023). "Operational Efficiency and Quality Control in Glass Cutting: CNC vs. Automatic Systems"

4. Automation in Construction. (2022). "The Impact of Advanced Glass Cutting Technologies on Architectural Design and Production"