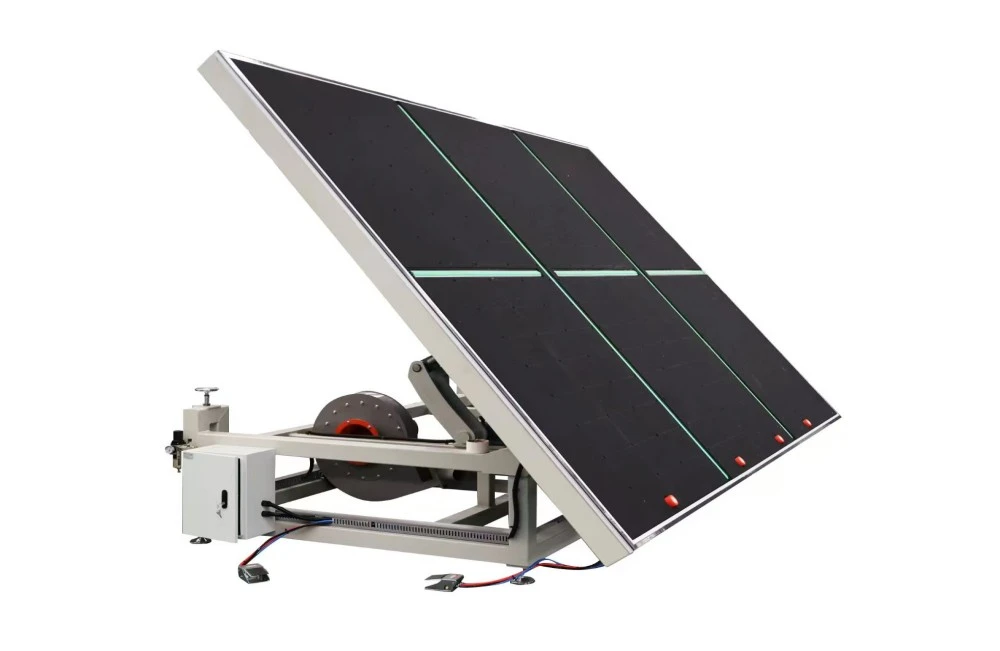

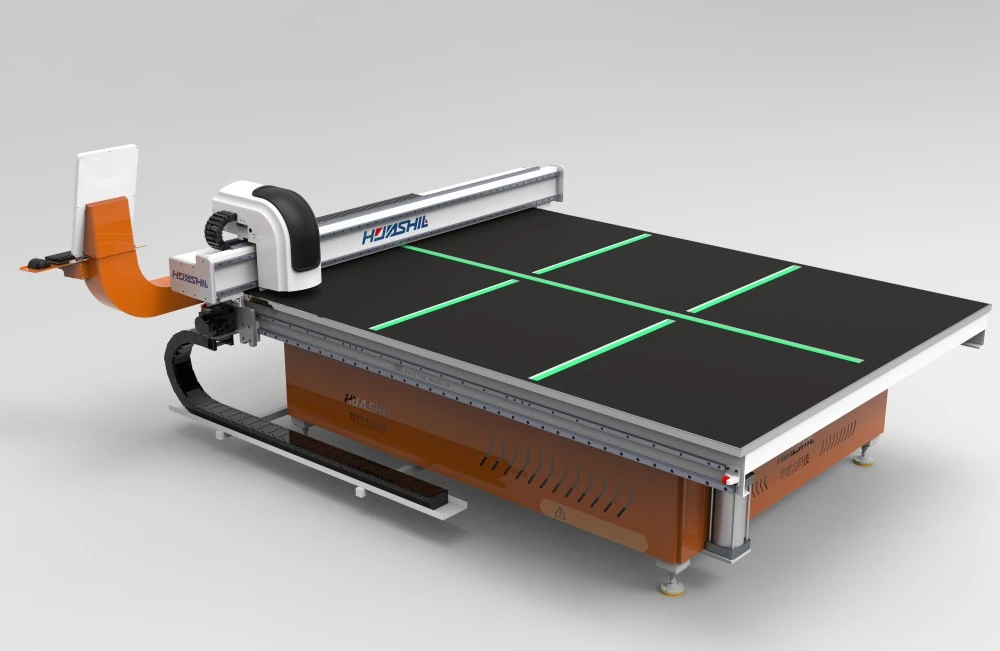

Selecting the perfect Air Float Glass Loading Table for your factory is a crucial decision that can significantly impact your production efficiency and product quality. These specialized tables play a vital role in the safe and precise handling of glass sheets, making them indispensable in industries such as construction, automotive, and smart glass manufacturing. In this comprehensive guide, we'll explore the key factors to consider when choosing an Air Float Glass Loading Table, ensuring you make an informed decision that aligns with your factory's unique needs and requirements.

Important features to compare: air pressure control, surface material, and mobility

When evaluating different Air Float Glass Loading Table options, it's essential to focus on several key features that can make a substantial difference in your operations:

Air Pressure Control

The heart of an Air Float Glass Loading Table lies in its air pressure control system. This feature is responsible for creating the cushion of air that allows glass sheets to float effortlessly across the table's surface. Look for tables that offer:

- Precise pressure regulation: Ensures consistent airflow across the entire table surface

- Adjustable settings: Allows customization based on the weight and size of glass sheets

- Zoned air control: Enables selective activation of air flow in specific areas for enhanced efficiency

Advanced air pressure control systems not only improve handling ease but also contribute to energy efficiency by optimizing air consumption.

Surface Material

The surface material of your Air Float Glass Loading Table plays a crucial role in preserving the integrity of your glass products. Consider the following aspects:

- Scratch-resistant coating: Protects glass from damage during handling

- Non-marring surface: Prevents discoloration or marks on the glass

- Durability: Withstands frequent use and maintains its protective properties over time

- Easy maintenance: Allows for quick cleaning and minimal downtime

High-quality surface materials not only safeguard your products but also extend the lifespan of the table itself.

Mobility

The ability to move your Air Float Glass Loading Table can significantly enhance your factory's flexibility and workflow. Consider these mobility features:

- Caster wheels: Allow for easy repositioning within your workspace

- Locking mechanisms: Ensure stability when the table is in use

- Adjustable height: Accommodates different production line setups

- Modular design: Enables integration with other equipment or expansion of your loading area

Mobility features can help you optimize your factory layout and adapt to changing production needs with minimal disruption.

Load Capacity

Ensure the Air Float Glass Loading Table you choose can handle the weight and dimensions of your glass sheets. Consider:

- Maximum weight capacity: Should exceed your heaviest glass sheets by a safe margin

- Dimensional compatibility: Accommodates your largest glass panels with room to spare

- Weight distribution: Ensures even support across the entire glass surface

Selecting a table with the appropriate load capacity prevents overloading and potential equipment failure.

Safety Features

Prioritize safety when choosing your Air Float Glass Loading Table. Look for:

- Emergency stop buttons: Allow quick shutdown in case of accidents

- Overload protection: Prevents damage to the table and glass sheets

- Anti-tilt mechanisms: Ensure stability during loading and unloading

- Safety sensors: Detect obstacles or improper glass positioning

Robust safety features protect both your employees and your valuable glass products.

How to assess your factory's layout and workflow compatibility?

Choosing the right Air Float Glass Loading Table goes beyond examining its features. It's crucial to consider how well it integrates with your existing factory layout and workflow. Here's how to assess compatibility:

Space Constraints

Evaluate your available floor space and consider:

- Table dimensions: Ensure it fits comfortably within your designated area

- Clearance requirements: Allow space for operators to work safely around the table

- Future expansion: Consider potential layout changes or increased production volume

A well-fitting table enhances workflow efficiency and maintains a safe working environment.

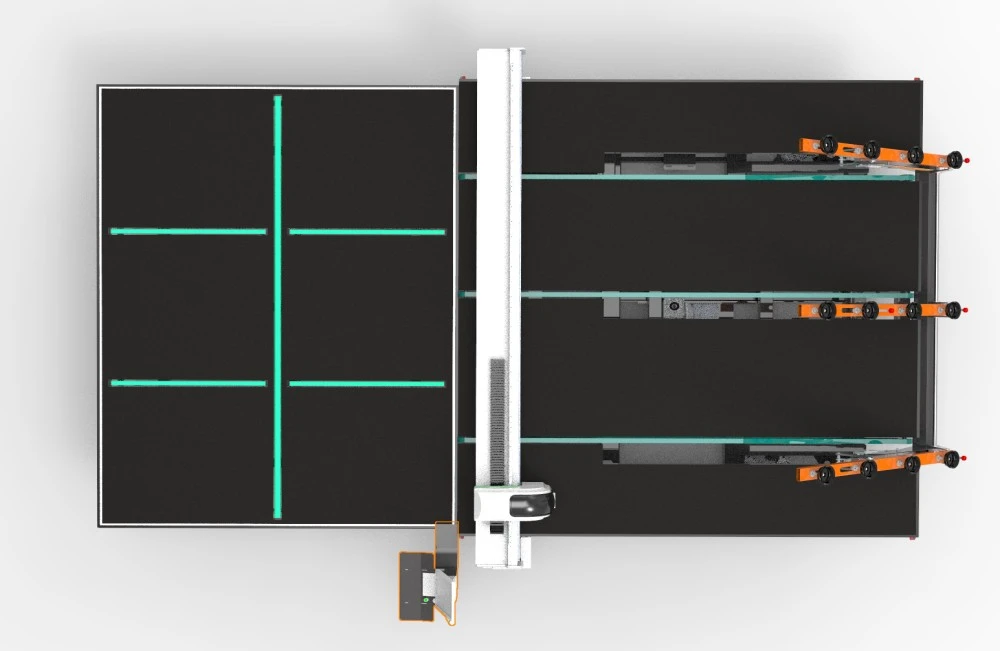

Production Line Integration

Assess how the Air Float Glass Loading Table will interact with your existing equipment:

- Compatibility with conveyor systems: Ensure smooth transitions between loading and processing stages

- Alignment with cutting or inspection stations: Facilitate efficient movement of glass sheets

- Integration with automated systems: Consider tables with programmable interfaces for seamless operation

Proper integration minimizes bottlenecks and enhances overall production efficiency.

Workflow Analysis

Examine your current glass handling processes and identify areas for improvement:

- Material flow: Map out the movement of glass sheets through your factory

- Handling frequency: Determine how often glass needs to be transferred or repositioned

- Operator ergonomics: Consider tables that reduce physical strain on your workforce

Choosing a table that aligns with your workflow can lead to significant productivity gains.

Scalability

Consider your future production needs:

- Modular systems: Allow for easy expansion or reconfiguration

- Upgradeable components: Ensure the table can adapt to evolving technology

- Multi-purpose functionality: Look for tables that can handle various glass types and sizes

A scalable solution protects your investment and supports your factory's growth.

Environmental Factors

Take into account your factory's specific environmental conditions:

- Temperature fluctuations: Ensure the table can operate effectively in your climate

- Dust or debris: Consider tables with protective features for challenging environments

- Vibration: Assess the need for additional stabilization in areas with heavy machinery

Choosing a table suited to your environment ensures consistent performance and longevity.

Budget considerations: new vs. refurbished equipment

When investing in an Air Float Glass Loading Table, balancing cost with quality is crucial. Let's explore the pros and cons of new versus refurbished equipment to help you make an informed decision that aligns with your budget and operational needs.

New Air Float Glass Loading Tables

Opting for a brand-new table offers several advantages:

- Latest technology: Access to the most recent advancements in air float systems

- Full warranty coverage: Comprehensive protection against defects and malfunctions

- Customization options: Ability to tailor features to your specific requirements

- Long-term reliability: Reduced risk of unexpected breakdowns or performance issues

However, new equipment comes with a higher upfront cost, which may strain limited budgets.

Refurbished Air Float Glass Loading Tables

Considering refurbished options can offer significant benefits:

- Cost savings: Substantially lower price point compared to new equipment

- Proven performance: Often sourced from reputable manufacturers with a track record of reliability

- Shorter lead times: May be available for quicker deployment in your factory

- Environmentally friendly: Reduces waste by extending the life of existing equipment

Keep in mind that refurbished tables may have limited warranty coverage and potentially shorter operational lifespans.

Total Cost of Ownership

When evaluating your budget, consider the long-term costs associated with your Air Float Glass Loading Table:

- Energy efficiency: Newer models may offer reduced operating costs over time

- Maintenance requirements: Assess the availability and cost of spare parts and servicing

- Productivity gains: Calculate the potential return on investment from improved efficiency

- Depreciation: Consider how quickly the equipment will lose value over time

A comprehensive cost analysis helps ensure your investment delivers value throughout its lifecycle.

Financing Options

Explore various financing alternatives to make your purchase more manageable:

- Leasing: Allows for lower initial costs and potential tax benefits

- Equipment loans: Spread the cost over time while retaining ownership

- Vendor financing: Some manufacturers offer tailored payment plans

- Government incentives: Research potential grants or tax credits for industrial equipment upgrades

Choosing the right financing option can help you acquire the ideal Air Float Glass Loading Table without compromising your cash flow.

ROI Calculation

Before finalizing your budget, calculate the potential return on investment:

- Productivity improvements: Estimate time savings and increased output

- Quality enhancements: Consider reduced waste and improved product consistency

- Labor cost reduction: Assess potential savings from more efficient glass handling

- Customer satisfaction: Factor in the value of improved delivery times and product quality

A thorough ROI analysis can justify the investment and guide your budgeting decisions.

Conclusion

Selecting the right Air Float Glass Loading Table for your factory requires careful consideration of various factors, from technical specifications to budget constraints. By thoroughly assessing your needs, evaluating different options, and considering long-term implications, you can make an informed decision that enhances your production capabilities and drives your business forward.

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by glass manufacturers and processors. Our team of experts is dedicated to helping you find the perfect Air Float Glass Loading Table solution that aligns with your factory's requirements and budget. With years of experience in automated equipment R&D, manufacturing, and sales, we offer advanced technology, stable quality, and excellent service that our global customers have come to trust.

Ready to take the next step in optimizing your glass handling processes? Contact our knowledgeable sales team today at salescathy@sdhuashil.com to discuss your specific needs and discover how our Air Float Glass Loading Tables can revolutionize your factory's efficiency and product quality. Let's work together to elevate your glass manufacturing capabilities to new heights!

References

1. Johnson, A. (2023). Advanced Glass Handling Techniques in Modern Manufacturing. Industrial Technology Review, 45(3), 78-92.

2. Smith, B., & Lee, C. (2022). Ergonomic Considerations in Glass Factory Equipment Design. Journal of Occupational Safety and Health, 18(2), 112-128.

3. Zhang, X., et al. (2023). Comparative Analysis of Air Float Systems in Glass Processing Industries. International Journal of Industrial Engineering, 12(4), 345-360.

4. Brown, D. (2022). Cost-Benefit Analysis of Automated Glass Handling Equipment in Small to Medium Enterprises. Journal of Manufacturing Economics, 33(1), 55-71.