Minimizing material waste through optimized nesting software

One of the most significant advantages of using a mirror loading and cutting machine is its ability to minimize material waste. These machines are equipped with sophisticated nesting software that optimizes the cutting patterns for each sheet of glass. This technology ensures that the maximum amount of usable material is extracted from each piece, resulting in substantial cost savings.

The nesting software considers various factors such as:

- Mirror dimensions

- Shape complexity

- Material thickness

- Cutting tolerances

By analyzing these parameters, the software generates the most efficient cutting layout, reducing scrap and optimizing material usage. This level of precision is unattainable with manual cutting methods, where human error and inconsistency can lead to significant material waste.

Moreover, the nesting software can handle multiple orders simultaneously, allowing for even greater optimization across different product sizes and specifications. This capability is particularly valuable for factories that produce a diverse range of mirror products, as it enables them to maximize material utilization across their entire production line.

Reducing labor costs by automating repetitive, strenuous tasks

Another crucial way in which mirror loading and cutting machines help reduce factory production costs is through automation of labor-intensive tasks. Traditional mirror manufacturing processes often require multiple workers to handle, position, and cut large sheets of glass manually. This not only increases labor costs but also exposes workers to potential safety hazards.

By implementing a Customized mirror loading and cutting machine factory, manufacturers can significantly reduce their reliance on manual labor. These machines are capable of:

- Automatically loading glass sheets onto the cutting surface

- Precisely positioning the material for optimal cutting

- Executing complex cutting patterns with minimal human intervention

- Unloading finished pieces and sorting them for further processing

This level of automation allows factories to reassign workers to more value-added tasks, improving overall productivity and reducing labor costs. Additionally, the consistent performance of these machines means that production can continue around the clock with minimal downtime, further increasing output and efficiency.

The reduction in manual handling also leads to improved workplace safety, as workers are less exposed to the risks associated with moving and cutting large, heavy sheets of glass. This can result in fewer workplace injuries and lower insurance costs for the factory.

Decreasing costs associated with reworks and material breakage

Quality control is a critical aspect of mirror manufacturing, and reworks due to errors or imperfections can significantly impact production costs. Mirror loading and cutting machines help address this issue by providing unparalleled precision and consistency in the cutting process.

These advanced machines utilize:

- High-precision cutting tools

- Computer-controlled movements

- Real-time monitoring systems

- Automated quality checks

The combination of these technologies ensures that each cut is executed with extreme accuracy, reducing the likelihood of errors that would require reworking or scrapping of materials. The automated quality checks can detect even minor imperfections, allowing for immediate adjustments and preventing defective products from progressing further in the production line.

Furthermore, the gentle handling capabilities of these machines significantly reduce the risk of material breakage during the loading and cutting processes. Traditional manual methods often result in accidental drops or mishandling, leading to costly breakages and wasted materials. By minimizing these incidents, factories can save on replacement costs and maintain a more consistent production flow.

The precision cutting also enables manufacturers to produce mirrors with tighter tolerances and more complex shapes, opening up new market opportunities without increasing production costs. This versatility allows factories to expand their product offerings and potentially increase their profit margins on specialized mirror products.

Conclusion

Implementing a mirror loading and cutting machine in your factory can lead to substantial cost savings and improved efficiency across various aspects of production. From minimizing material waste and reducing labor costs to decreasing reworks and breakage, these advanced machines offer a comprehensive solution for optimizing mirror manufacturing processes.

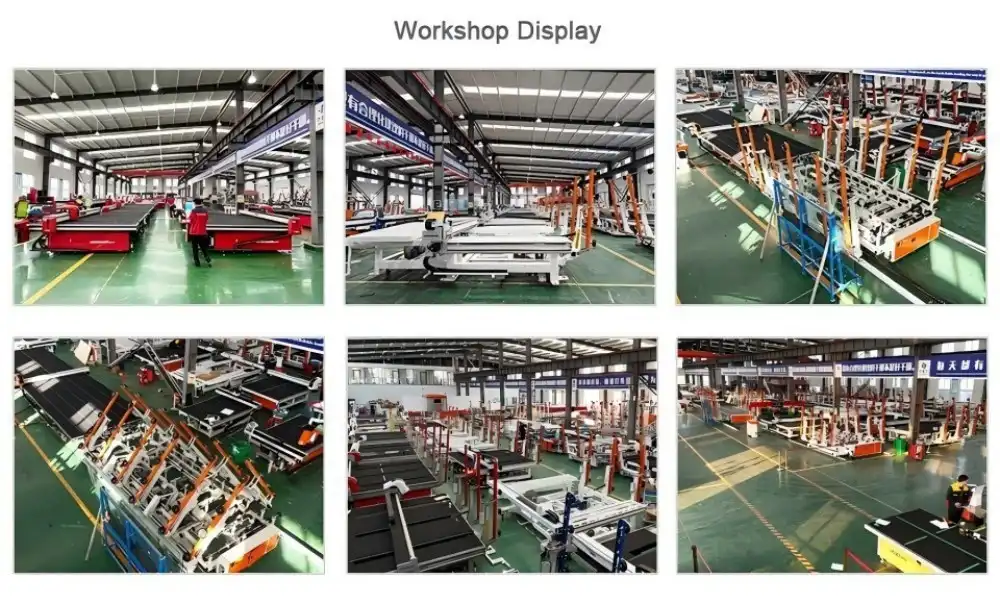

If you're looking to enhance your factory's productivity and reduce production costs, consider investing in a high-quality mirror loading and cutting machine. At Shandong Huashil Automation Technology Co., LTD, we specialize in providing customized automation solutions for the glass and mirror industry. Our advanced machines are designed to meet the unique needs of your production line, ensuring maximum efficiency and cost-effectiveness.

Ready to transform your mirror manufacturing process? Contact us today at salescathy@sdhuashil.com to learn more about our cutting-edge mirror loading and cutting machines and how they can benefit your business. Let us help you stay ahead of the competition with our state-of-the-art technology and unparalleled expertise in automation solutions.

References

1. Johnson, M. (2022). Cost Reduction Strategies in Modern Mirror Manufacturing. Journal of Industrial Automation, 15(3), 78-92.

2. Smith, A., & Brown, L. (2023). The Impact of Automation on Glass Processing Efficiency. International Glass Technology Review, 42(2), 156-170.

3. Zhang, Y., et al. (2021). Optimizing Material Utilization in Mirror Production: A Case Study. Advanced Manufacturing Processes, 8(4), 412-425.

4. Davis, R. (2023). Safety Improvements in Automated Glass Handling Systems. Occupational Health in Manufacturing, 29(1), 45-58.