What production bottlenecks can an automatic glass cutting line solve?

Glass manufacturing facilities often face numerous challenges that hinder productivity and efficiency. Customized automatic glass cutting line solutions can effectively address these issues, transforming your production floor into a well-oiled machine. Let's delve into some of the most common bottlenecks and how automation can resolve them:

Manual Cutting Inefficiencies

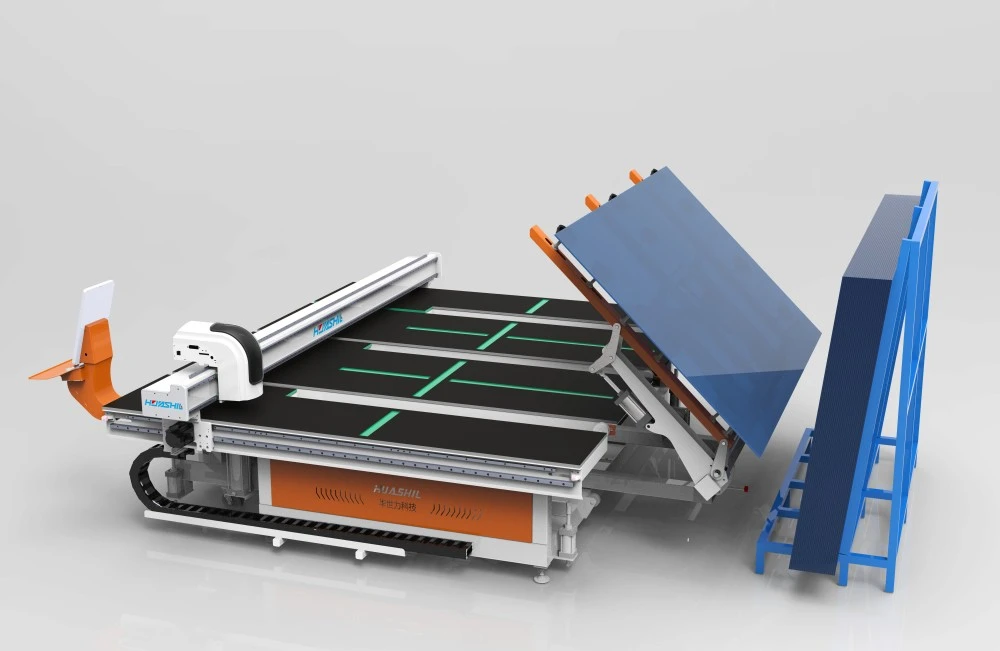

Traditional manual glass cutting methods are time-consuming and prone to human error. Operators may struggle with consistency, especially when dealing with complex shapes or large volumes. Automatic glass cutting systems eliminate these issues by providing precise, repeatable cuts at high speeds. This not only increases throughput but also significantly reduces material waste.

Limited Flexibility in Product Variations

As market demands evolve, manufacturers need to adapt quickly to produce different glass sizes, shapes, and specifications. Manual processes often struggle to keep up with these changing requirements. Advanced automatic cutting lines offer unparalleled flexibility, allowing for rapid changeovers between product types without compromising quality or efficiency.

Quality Control Challenges

Maintaining consistent quality across large production runs can be challenging with manual cutting methods. Automatic systems incorporate advanced sensors and computer-controlled cutting mechanisms to ensure each piece meets exact specifications. This level of precision minimizes defects and rework, ultimately boosting overall product quality and customer satisfaction.

Labor Shortages and Skill Gaps

Many industries face difficulties in recruiting and retaining skilled workers for specialized tasks like glass cutting. A customized automatic glass cutting line reduces reliance on manual labor, allowing you to reallocate your workforce to higher-value tasks. This not only addresses labor shortages but also improves overall operational efficiency.

Production Scalability Limitations

As your business grows, scaling up production to meet increased demand can be challenging with manual processes. Automatic glass cutting lines offer the flexibility to ramp up output quickly without sacrificing quality or efficiency. This scalability ensures your facility can adapt to market fluctuations and seize new opportunities.

Best strategies to integrate automatic cutting into existing workflows

Implementing an automatic glass cutting line requires careful planning and execution to ensure a smooth transition and maximize the benefits. Here are some proven strategies to help you successfully integrate this technology into your existing workflows:

Conduct a Comprehensive Workflow Analysis

Before introducing automation, thoroughly assess your current production processes. Identify bottlenecks, inefficiencies, and areas where automatic cutting can have the most significant impact. This analysis will help you determine the optimal configuration for your new system and ensure it aligns with your specific needs.

Invest in Employee Training and Development

While automation reduces the need for manual cutting, it requires skilled operators to manage and maintain the system. Invest in comprehensive training programs to equip your staff with the necessary skills to operate, troubleshoot, and maintain the new equipment. This investment will pay dividends in improved efficiency and reduced downtime.

Implement a Phased Approach

Rather than overhauling your entire production line at once, consider a phased implementation. Start by automating one section of your cutting process and gradually expand as you gain experience and confidence. This approach allows you to fine-tune the system and address any unforeseen challenges without disrupting your entire operation.

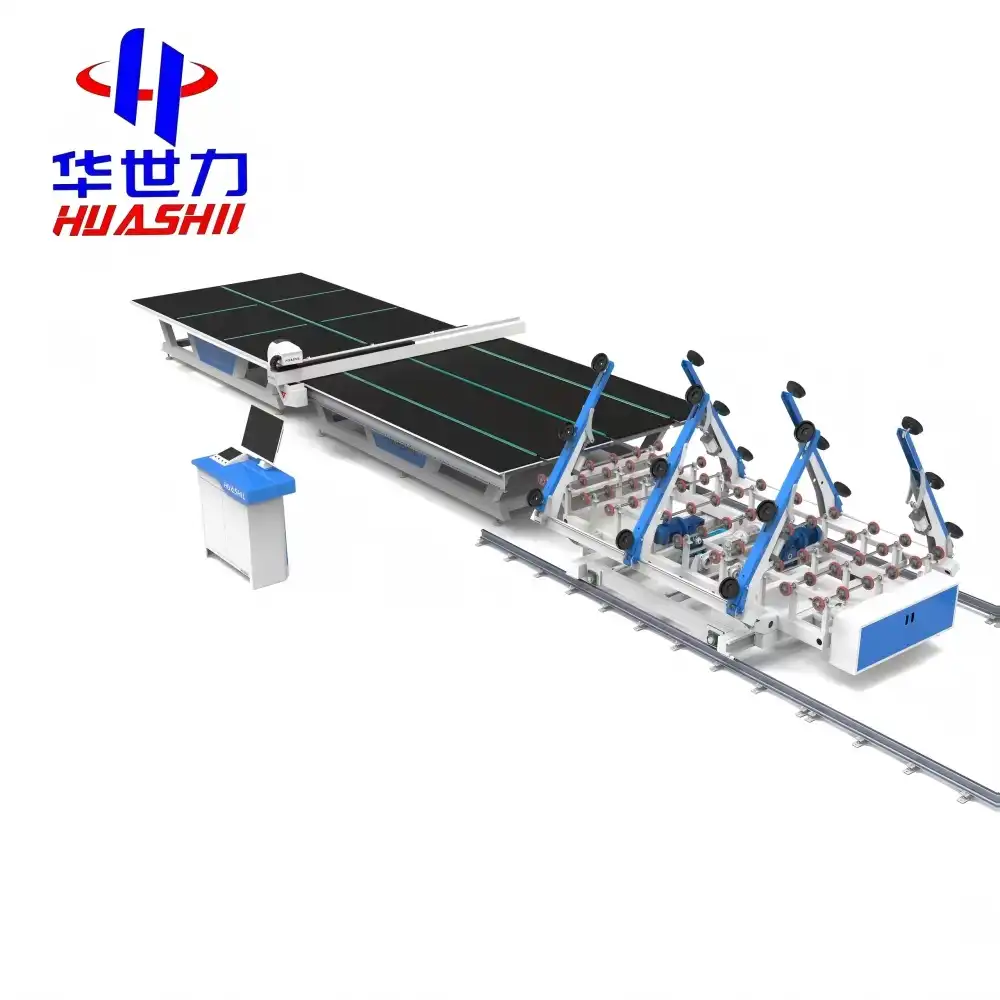

Optimize Material Flow and Handling

To fully capitalize on the speed and efficiency of automatic cutting, ensure your material handling processes can keep pace. Implement automated loading and unloading systems, conveyor belts, and storage solutions to create a seamless flow of glass sheets through the cutting line. This holistic approach will prevent bottlenecks and maximize the system's potential.

Leverage Data and Analytics

Modern automatic glass cutting systems, such as an automatic glass cutting line, generate vast amounts of data on production metrics, machine performance, and quality control. Implement robust data analytics tools to gain actionable insights from this information. Use these insights to continuously optimize your processes, predict maintenance needs, and make data-driven decisions to improve overall efficiency.

Establish Clear Communication Channels

Effective communication is crucial when integrating new technology into your workflow. Create clear channels for operators, maintenance teams, and management to share information, report issues, and collaborate on solutions. This open dialogue will help identify and address potential problems quickly, ensuring smooth operation of the automatic cutting line.

Develop a Preventive Maintenance Strategy

To maximize uptime and maintain peak performance, implement a comprehensive preventive maintenance program for your automatic glass cutting system. Regular inspections, cleaning, and component replacements will help prevent unexpected breakdowns and extend the lifespan of your investment.

Measuring productivity gains after implementing an automatic glass cutting system

Once you've successfully integrated an automatic glass cutting line into your production process, it's essential to quantify the impact on your overall productivity. By measuring key performance indicators (KPIs), you can demonstrate the return on investment and identify areas for further optimization. Here are some crucial metrics to consider:

Overall Equipment Effectiveness (OEE)

OEE is a comprehensive metric that combines availability, performance, and quality to provide a holistic view of your equipment's productivity. Monitor how your OEE improves after implementing the automatic cutting system, focusing on reduced downtime, increased cutting speeds, and improved quality rates.

Throughput and Cycle Time

Track the number of glass sheets processed per hour or shift, comparing it to your previous manual cutting methods. Additionally, measure the time it takes to complete a full cutting cycle, from loading to unloading. You should observe significant improvements in both metrics with an efficient automatic system.

Material Utilization and Waste Reduction

Automatic cutting systems often achieve higher material utilization rates due to their precision and optimized cutting patterns. Monitor your glass usage and scrap rates to quantify the reduction in waste and associated cost savings.

Labor Productivity

While the automatic system reduces the need for manual cutting, it's important to measure how it impacts overall labor productivity. Track metrics such as output per employee hour and the reallocation of workers to higher-value tasks within your operation.

Quality Metrics

Monitor defect rates, customer returns, and rework percentages to assess the impact of automation on your product quality. A well-implemented automatic cutting system, such as a customized automatic glass cutting line, should lead to noticeable improvements in these areas.

Energy Efficiency

Automatic cutting systems often operate more efficiently than manual processes. Track your energy consumption per unit of output to quantify potential cost savings and environmental benefits.

Setup and Changeover Times

Measure the time required to switch between different glass types or cutting patterns. Automatic systems typically offer significant reductions in setup and changeover times, contributing to improved overall efficiency.

Return on Investment (ROI)

Calculate the ROI of your automatic glass cutting system by comparing the initial investment and ongoing operational costs against the productivity gains, labor savings, and quality improvements. This comprehensive analysis will help justify the investment and guide future automation decisions.

Customer Satisfaction Metrics

While not directly tied to production metrics, improved quality and faster turnaround times often lead to increased customer satisfaction. Monitor metrics such as on-time delivery rates, customer feedback scores, and repeat business to gauge the broader impact of your automation efforts.

By consistently tracking these metrics, you can gain valuable insights into the performance of your automatic glass cutting system and identify opportunities for continuous improvement. Regular analysis of these KPIs will help you fine-tune your processes, maximize the benefits of automation, and stay ahead in the competitive glass manufacturing industry.

Conclusion

Implementing an automatic glass cutting system, such as an automatic glass cutting line, can revolutionize your glass manufacturing process, addressing common production bottlenecks and significantly boosting output. By carefully integrating this technology into your existing workflows and diligently measuring its impact, you can unlock new levels of efficiency, quality, and competitiveness in your operations.

Are you ready to transform your glass production facility with cutting-edge automation technology? At Shandong Huashil Automation Technology Co., LTD, we specialize in developing customized automatic glass cutting solutions tailored to your unique needs. With years of experience in R&D, manufacturing, and export, our advanced techniques and commitment to quality have made us a trusted partner for glass manufacturers worldwide.

Don't let outdated processes hold your business back. Contact us today at salescathy@sdhuashil.com to discover how our innovative automatic glass cutting systems can propel your factory into the future of glass manufacturing. Let's work together to optimize your production, reduce costs, and exceed your customers' expectations.

References

Smith, J. (2022). "Optimizing Glass Manufacturing with Automatic Cutting Technologies." Journal of Industrial Automation, 15(3), 78-92.

Johnson, M., & Brown, L. (2021). "Productivity Gains in Glass Fabrication: A Case Study on Automated Cutting Systems." International Glass Review, 42(2), 145-160.

Garcia, R. (2023). "Integration Strategies for Advanced Glass Cutting Equipment in Traditional Factories." Manufacturing Technology Quarterly, 28(1), 33-49.

Lee, S., & Park, H. (2022). "Measuring ROI in Glass Industry Automation: Metrics and Methodologies." Journal of Manufacturing Economics, 19(4), 212-228.