How proper edge deletion affects window performance specifications?

Edge deletion is a process that involves removing the Low-E coating from the edges of the glass. This step is far more than just a minor detail in glass preparation; it's a crucial factor that directly influences the performance of windows and glazing systems.

The primary reason for edge deletion is to ensure proper adhesion between the glass and the sealant used in insulated glass units (IGUs). Without proper edge deletion, the Low-E coating can interfere with this adhesion, potentially leading to seal failure and compromised insulation properties.

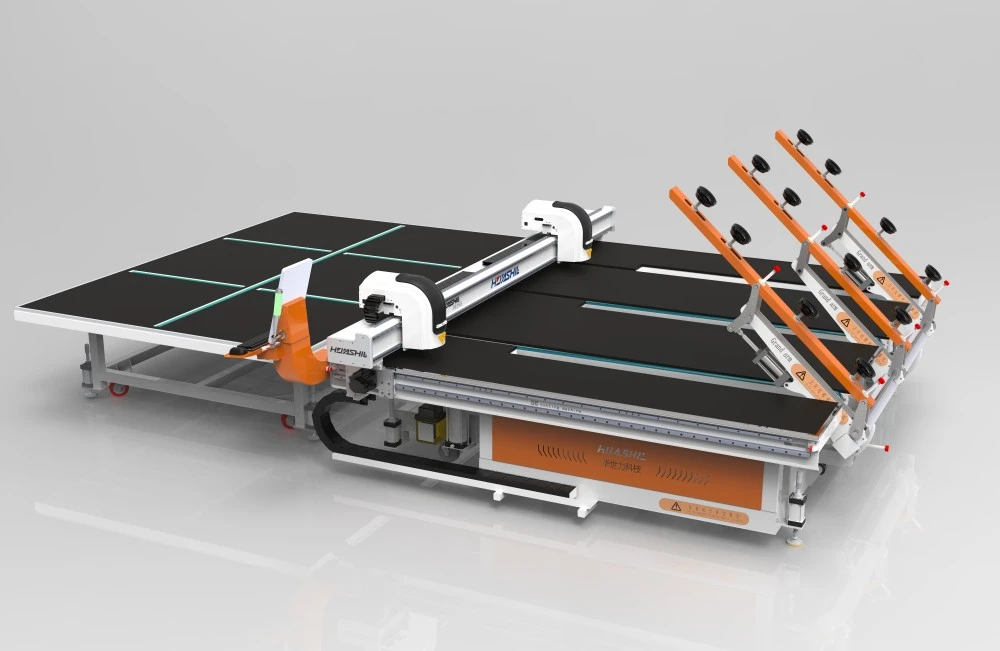

A low e glass edge deletion machine plays a vital role in this process. These specialized machines are designed to precisely remove the coating along the edges of the glass, ensuring a clean and uniform deletion that meets industry standards.

The impact of proper edge deletion on window performance specifications is multifaceted:

- Thermal Performance: Proper edge deletion helps maintain the thermal insulation properties of Low-E glass. By ensuring a strong seal in IGUs, it prevents heat transfer and maintains the energy efficiency of the windows.

- Durability: A clean edge deletion allows for better adhesion of sealants, enhancing the overall durability of the window unit. This can significantly extend the lifespan of the glazing system.

- Moisture Resistance: Effective edge deletion and subsequent sealing prevent moisture ingress into the IGU, reducing the risk of condensation between panes and potential fogging issues.

- Structural Integrity: The adhesion provided by proper edge deletion contributes to the structural integrity of the entire window system, crucial for withstanding wind loads and other environmental stresses.

Architects and builders recognize that these performance specifications are not just technical details but directly impact the overall quality and efficiency of their projects. A high-quality low e glass edge deletion machine from a low e glass edge deletion machine factory ensures that these specifications are met consistently across all glass panels used in a project.

The aesthetic impact of clean edge deletion on finished glass products

While the technical aspects of edge deletion are crucial, the aesthetic impact is equally important, especially for architects who prioritize the visual appeal of their designs. Clean edge deletion contributes significantly to the overall appearance of finished glass products.

The aesthetic benefits of proper edge deletion include:

- Uniform Appearance: A precise and clean edge deletion creates a uniform appearance along the edges of the glass. This uniformity is particularly noticeable in large glazing systems and curtain walls, where any inconsistencies would be readily apparent.

- Enhanced Transparency: Properly deleted edges allow for cleaner sealing, which in turn contributes to the overall transparency and clarity of the glass. This is particularly important in designs that emphasize views and natural light.

- Reduced Visual Distortions: Inconsistent or poor edge deletion can lead to visual distortions, especially at the edges of the glass. Clean deletion minimizes these distortions, maintaining the intended visual effect of the glass.

- Improved Light Transmission: Clean edges contribute to better light transmission through the glass, enhancing the natural lighting within the building.

The aesthetic quality of edge deletion becomes even more critical in high-end architectural projects where every detail matters. Luxury residential buildings, high-profile commercial spaces, and iconic architectural structures often require flawless glass installations that contribute to the overall design aesthetic.

A state-of-the-art low e glass edge deletion machine ensures consistency in the edge deletion process, which is crucial for maintaining the aesthetic standards required in premium architectural projects. These machines can handle various glass sizes and shapes, allowing architects to push the boundaries of design without compromising on the quality of the finished product.

Why deletion quality matters for high-profile architectural projects?

In high-profile architectural projects, every detail is scrutinized, and the quality of glass installations is no exception. The importance of deletion quality in these projects cannot be overstated, as it impacts both the performance and aesthetics of the building.

Key reasons why deletion quality is crucial in high-profile projects include:

- Reputation and Prestige: High-profile projects often serve as showcases for architectural firms and construction companies. The quality of every element, including glass installations, directly reflects on their reputation.

- Long-term Performance: These projects are expected to maintain their performance and appearance for decades. High-quality edge deletion contributes to the longevity of glass installations, reducing the need for replacements or repairs.

- Energy Efficiency Standards: Many high-profile projects aim for certifications like LEED (Leadership in Energy and Environmental Design). The energy efficiency of the building envelope, including windows, is a crucial factor in achieving these certifications.

- Visual Impact: In landmark buildings or structures with significant glass elements, the visual quality of the glass plays a major role in the overall architectural impact. Clean, uniform edge deletion enhances this visual appeal.

- Cost Implications: While the initial cost of high-quality edge deletion might be higher, it can lead to significant long-term savings by reducing maintenance needs and improving energy efficiency.

The use of a high-quality low e glass edge deletion machine is often seen as a necessity rather than a luxury in these projects. These machines offer precision and consistency that manual methods simply cannot match, ensuring that every panel of glass meets the exacting standards required for high-profile architectural works.

Moreover, the ability to customize edge deletion processes to specific project requirements is invaluable. Advanced edge deletion machines can be programmed to handle various glass thicknesses, coating types, and deletion patterns, providing the flexibility needed for innovative architectural designs.

Architects and builders involved in high-profile projects often work closely with glass processors to ensure that the edge deletion process aligns with their specific needs. This collaboration can involve:

- Specifying exact deletion widths and patterns

- Requiring samples and prototypes to verify quality

- Conducting on-site inspections of the edge deletion process

- Requesting detailed documentation of the edge deletion specifications for each glass panel

This level of attention to detail in the edge deletion process using equipment from a low e glass edge deletion machine factory is a testament to its importance in high-profile architectural projects. It's not just about meeting basic functional requirements; it's about achieving a level of quality that contributes to the overall excellence of the project.

The impact of high-quality edge deletion extends beyond the immediate visual and functional aspects. It also plays a role in:

- Acoustic Performance: Properly sealed edges contribute to better sound insulation, an important factor in urban environments or buildings with specific acoustic requirements.

- Safety and Security: In buildings where safety glass is required, proper edge deletion ensures that the glass performs as intended in case of breakage.

- UV Protection: Clean edge deletion helps maintain the integrity of UV-protective coatings, crucial for protecting interiors from sun damage.

Architects and builders also recognize that the quality of edge deletion can impact the overall timeline of a project. High-quality, efficient edge deletion processes can help keep projects on schedule by reducing the likelihood of glass-related issues during installation or post-installation.

Furthermore, in an era where sustainable building practices are increasingly important, the role of proper edge deletion in enhancing the energy efficiency of buildings cannot be overlooked. By contributing to better-performing Low-E glass installations, high-quality edge deletion aligns with the growing focus on sustainable architecture and green building practices.

The attention to detail in edge deletion also reflects a broader commitment to quality in architectural projects. It demonstrates a thorough understanding of how seemingly small aspects can have significant impacts on the overall performance and longevity of a building. This attention to detail often extends to other aspects of the project, contributing to overall excellence in design and construction.

Conclusion

The importance of Low-E glass edge deletion in architectural and construction projects cannot be overstated. From ensuring optimal window performance to enhancing aesthetic appeal and contributing to the success of high-profile projects, proper edge deletion is a critical process that architects and builders carefully consider.

The use of advanced low e glass edge deletion machine technology is key to achieving the precision and consistency required in modern architectural glass applications. As buildings become more complex and energy efficiency standards more stringent, the role of high-quality edge deletion will likely become even more pronounced.

For architects and builders looking to elevate their projects and ensure the highest standards of quality and performance in their glass installations, partnering with a reputable provider of edge deletion solutions is crucial. Shandong Huashil Automation Technology Co., LTD stands at the forefront of this technology, offering state-of-the-art low e glass edge deletion machines that meet the exacting standards of modern architecture and construction.

To learn more about how our advanced edge deletion solutions can enhance your architectural projects, please contact us at salescathy@sdhuashil.com. Our team of experts is ready to assist you in achieving the highest standards of quality and performance in your glass installations.

References

1. Smith, J. (2022). "The Impact of Low-E Glass Technology on Modern Architecture". Architectural Review Quarterly.

2. Johnson, A. et al. (2021). "Advancements in Glass Edge Deletion Techniques for Energy-Efficient Buildings". Journal of Sustainable Construction.

3. Garcia, M. (2023). "Quality Control in High-Performance Glazing Systems". Building Design & Construction Magazine.

4. Thompson, R. (2022). "The Role of Precision Engineering in Architectural Glass Processing". Engineering & Technology Review.