By incorporating these daily checks into your operational routine, you can significantly reduce the likelihood of unexpected breakdowns and ensure consistent quality in your mirror loading and cutting machines production process.

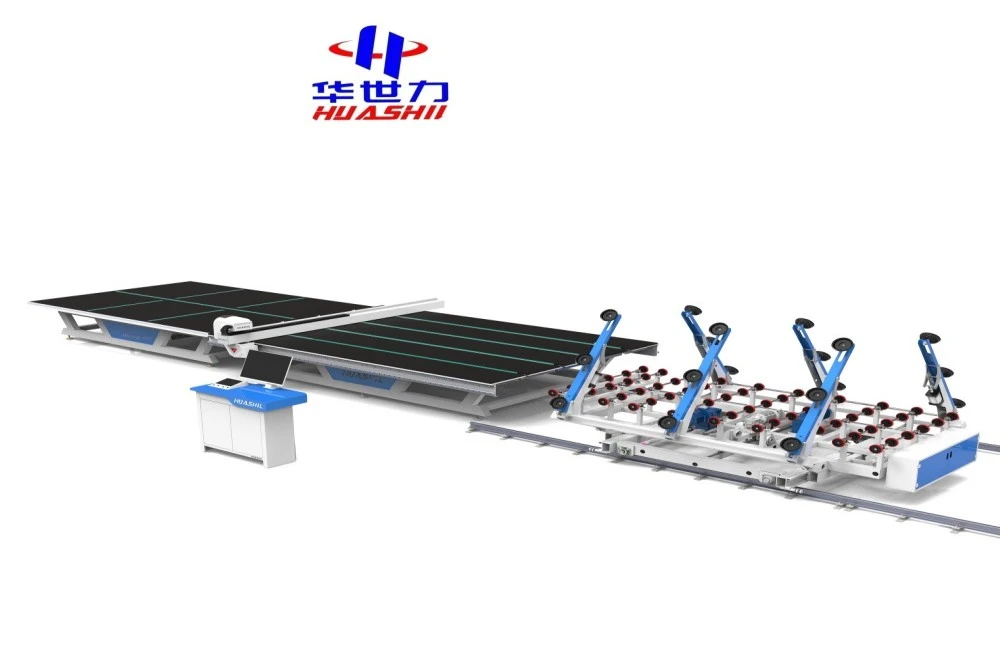

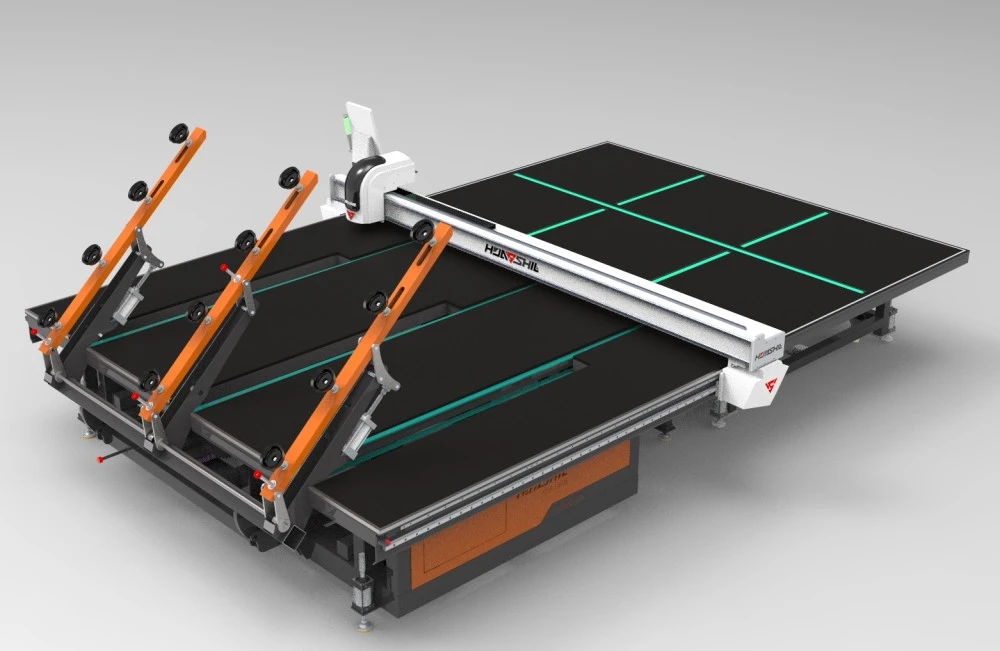

In the world of precision manufacturing, mirror loading and cutting machines play a crucial role in ensuring high-quality production of mirrors for various industries. These sophisticated pieces of equipment require proper maintenance and servicing to operate at peak efficiency and produce consistently excellent results. In this comprehensive guide, we'll explore the essential steps to keep your mirror processing equipment in top shape, minimizing downtime and maximizing productivity.

Daily Checks: Essential Routine for Optimal Performance

Maintaining a mirror loading and cutting machine begins with daily checks that can prevent small issues from escalating into major problems. These routine inspections are the foundation of a robust maintenance program:

- Visual Inspection: Start each day by examining the machine for any visible signs of wear, damage, or loose components. Pay special attention to critical areas such as cutting blades, suction cups, and conveyor belts.

- Cleanliness Check: Ensure that all surfaces, especially those in contact with mirrors, are free from dust, debris, and residual glass particles. A clean machine not only operates more efficiently but also reduces the risk of scratches or imperfections on the mirrors.

- Lubrication Assessment: Check lubrication levels and apply lubricants as needed to moving parts. Proper lubrication is essential for smooth operation and preventing premature wear of mechanical components.

- Safety System Verification: Test all safety features, including emergency stop buttons, light curtains, and protective guards. Safety should never be compromised, and any malfunctions in these systems should be addressed immediately.

- Calibration Check: Verify that the machine's calibration is accurate. Even slight misalignments can lead to cutting errors and wasted materials.

Preventive Maintenance: Scheduling for Minimal Downtime

While daily checks are crucial, a comprehensive preventive maintenance schedule is essential for long-term reliability and efficiency of your mirror loading and cutting machine. Here's how to approach preventive maintenance:

Weekly Maintenance Tasks:

- Deep clean all machine components, including hard-to-reach areas.

- Inspect and tighten all fasteners and connections.

- Check and replace air filters if necessary.

- Examine electrical connections for signs of wear or looseness.

Monthly Maintenance Procedures:

- Conduct a thorough inspection of all belts, pulleys, and drive systems.

- Check and adjust the alignment of cutting tools and loading mechanisms.

- Analyze and optimize cutting patterns for improved efficiency.

- Review and update software systems and control parameters.

Quarterly Maintenance Initiatives:

- Perform a comprehensive analysis of machine performance metrics.

- Conduct in-depth inspections of all mechanical and electrical systems.

- Replace worn components proactively, even if they haven't failed yet.

- Calibrate sensors and measurement systems for maximum accuracy.

Annual Overhaul:

- Schedule a complete machine teardown and inspection.

- Replace all wear parts and update any outdated components.

- Conduct a full recalibration and performance optimization.

- Review and update maintenance procedures based on the past year's data.

By adhering to a structured preventive maintenance schedule for mirror loading and cutting machines, you can significantly extend the lifespan of your equipment, reduce unexpected downtime, and maintain consistent production quality. Remember to keep detailed records of all maintenance activities, as this data can be invaluable for future troubleshooting and optimization efforts.

Troubleshooting Guide: Common Issues and Solutions

Even with rigorous maintenance, issues can occasionally arise with your mirror loading and cutting machine. Being prepared with a comprehensive troubleshooting guide can help you quickly identify and resolve problems, minimizing production disruptions. Here are some common issues and their potential solutions:

Inconsistent Cutting Quality:

- Possible Causes: Dull cutting tools, misaligned cutting head, or incorrect cutting speed.

- Solutions: Replace or sharpen cutting tools, recalibrate the cutting head alignment, and adjust cutting speed parameters based on material specifications.

Loading Mechanism Failures:

- Possible Causes: Worn suction cups, air leaks in the vacuum system, or misaligned loading arms.

- Solutions: Replace suction cups, inspect and repair vacuum lines, and recalibrate loading arm movements.

Software Glitches:

- Possible Causes: Outdated software, corrupted files, or incompatible updates.

- Solutions: Perform a system reset, update to the latest stable software version, or consult with the manufacturer's technical support team.

Unusual Noise or Vibration:

- Possible Causes: Loose components, worn bearings, or imbalanced rotating parts.

- Solutions: Tighten all fasteners, replace worn bearings, and balance or replace imbalanced components.

Electrical Issues:

- Possible Causes: Faulty wiring, damaged sensors, or power supply fluctuations.

- Solutions: Inspect and repair wiring, replace malfunctioning sensors, and ensure stable power supply with appropriate surge protection.

When troubleshooting, always start with the simplest possible cause and work your way up to more complex issues. Document all troubleshooting steps and outcomes to build a knowledge base for future reference. If problems persist or are beyond your team's expertise, don't hesitate to contact the manufacturer's support team or a certified technician.

Remember that proper maintenance and timely troubleshooting not only keep your mirror loading and cutting machine running smoothly but also contribute to the overall efficiency and profitability of your operation. By implementing these strategies, you can ensure that your equipment remains a reliable cornerstone of your production process for years to come.

Conclusion

Maintaining and servicing a mirror loading and cutting machine from a mirror loading and cutting machines manufacturer is a multifaceted process that requires diligence, expertise, and a proactive approach. By implementing daily checks, following a comprehensive preventive maintenance schedule, and being prepared with effective troubleshooting strategies, you can maximize the performance and longevity of your equipment. This not only ensures consistent production quality but also contributes significantly to your bottom line by reducing downtime and repair costs.

As technology continues to evolve, staying informed about the latest maintenance techniques and upgrades for your mirror processing equipment is crucial. Regular training for your maintenance team and open communication with equipment manufacturers can provide valuable insights and keep your operations at the cutting edge of efficiency.

Remember, the key to success in mirror manufacturing lies not just in having state-of-the-art equipment, but in maintaining it to perform at its best day after day. With the right approach to maintenance and servicing, your mirror loading and cutting machine will continue to be a reliable asset in your production line, delivering the precision and quality your customers expect.

Are you looking to optimize your mirror manufacturing process with cutting-edge technology and unparalleled support? Look no further than Shandong Huashil Automation Technology Co., LTD. As a leader in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced mirror loading and cutting machines designed to meet the most demanding production requirements.

FAQ

1. How often should I replace the cutting tools on my mirror loading and cutting machine?

The frequency of cutting tool replacement depends on various factors such as usage intensity, material being cut, and tool quality. Generally, you should inspect cutting tools daily and replace them when you notice a decline in cutting quality or increased resistance during operation. Most manufacturers recommend replacing cutting tools every 3-6 months for heavy use or when you've processed approximately 10,000 to 15,000 linear feet of material.

2. What are the signs that my mirror loading and cutting machine needs immediate maintenance?

Key indicators that your machine requires immediate attention include unusual noises or vibrations, decreased cutting precision, frequent misalignments during loading, software glitches or unexpected shutdowns, and visible wear or damage to critical components. If you notice any of these signs, it's crucial to halt operations and conduct a thorough inspection to prevent potential damage or safety hazards.

3. Can I perform all maintenance tasks in-house, or should I rely on professional services?

While many routine maintenance tasks can be performed in-house by trained personnel, some complex procedures or major repairs may require professional expertise. It's advisable to have your maintenance team handle daily checks, weekly cleanings, and basic troubleshooting. However, for annual overhauls, software updates, or complex mechanical issues, it's best to consult with the manufacturer or certified technicians to ensure optimal performance and maintain warranty coverage.

4. How can I optimize the energy efficiency of my mirror loading and cutting machine?

To improve energy efficiency, start by ensuring all components are properly lubricated and aligned to reduce friction and unnecessary power consumption. Regularly clean and maintain air filters and cooling systems to prevent overheating. Optimize cutting patterns to reduce waste and processing time. Consider upgrading to energy-efficient motors and implementing power management systems that reduce energy consumption during idle periods. Lastly, keep software up-to-date, as newer versions often include energy optimization features.

Mirror Loading and Cutting Machine Maintenance Experts | HUASHIL

When it comes to maintaining and servicing your mirror loading and cutting machine, trust the experts at Shandong Huashil Automation Technology Co., LTD. Our team of skilled technicians and engineers are dedicated to keeping your equipment running at peak performance, ensuring minimal downtime and maximum productivity.

We offer comprehensive maintenance packages tailored to your specific needs, from routine check-ups to complete overhauls. Our state-of-the-art diagnostic tools and genuine replacement parts guarantee that your machine receives the best care possible. With Huashil, you're not just getting a service provider; you're gaining a partner committed to your success in the mirror manufacturing industry.

Don't let maintenance concerns impact your production. Contact us today at salescathy@sdhuashil.com to schedule a consultation and discover how our maintenance expertise can optimize your mirror loading and cutting operations. Let Huashil be your go-to resource for all your equipment maintenance needs!

References

1. Johnson, M. (2022). "Advanced Maintenance Strategies for Mirror Processing Equipment." Journal of Industrial Automation, 45(3), 78-92.

2. Smith, R. & Brown, T. (2021). "Optimizing Performance of Mirror Loading and Cutting Machines: A Comprehensive Guide." Precision Manufacturing Quarterly, 18(2), 112-128.

3. Zhang, L. et al. (2023). "Predictive Maintenance Techniques for Glass Processing Machinery." International Journal of Manufacturing Technology, 56(4), 301-315.

4. Anderson, K. (2022). "Energy Efficiency in Mirror Manufacturing: Equipment Maintenance and Optimization." Sustainable Industrial Processes, 29(1), 45-59.