Smart scheduling: Maximizing machine uptime

One of the most effective ways to optimize your CNC glass cutting line is through intelligent scheduling. By strategically planning your production runs, you can minimize downtime and maximize the utilization of your equipment.

Implementing a robust production planning system allows you to:

- Prioritize orders based on urgency and complexity

- Group similar cuts to reduce tool changes and setup times

- Balance workload across multiple machines, if available

- Schedule maintenance during natural production lulls

Advanced scheduling software can help you achieve this level of optimization. These tools can analyze historical data, current orders, and machine capabilities to create the most efficient cutting schedules for your customized CNC glass cutting line. By leveraging such technology, you can significantly reduce idle time and increase overall productivity.

Moreover, consider implementing a just-in-time (JIT) production approach. This method aligns your glass cutting operations with actual demand, reducing excess inventory and minimizing waste. With JIT, you can respond more flexibly to market changes and customer requirements, further enhancing your operational efficiency.

Regular calibration: Ensuring consistent quality

Maintaining the precision of your Customized CNC glass cutting line is paramount for consistent, high-quality output. Regular calibration of your equipment ensures that every cut meets the exacting standards required in industries such as automotive and smart mirror manufacturing.

To maintain optimal performance:

- Establish a routine calibration schedule

- Use high-precision measuring tools to verify accuracy

- Document all calibration procedures and results

- Train operators to recognize signs of misalignment or wear

Implementing a predictive maintenance strategy can take your calibration efforts to the next level. By using sensors and data analytics, you can monitor your CNC glass cutting line's performance in real-time. This approach allows you to detect potential issues before they impact production, scheduling maintenance only when necessary, thus reducing downtime and extending equipment lifespan.

Additionally, consider investing in self-calibrating CNC systems. These advanced machines can automatically adjust their settings based on environmental factors and wear, ensuring consistent cutting accuracy over time. While the initial investment may be higher, the long-term benefits in terms of quality and reduced maintenance costs can be substantial.

Operator training: Human skills in automation

While CNC glass cutting lines are highly automated, the role of skilled operators remains crucial. Investing in comprehensive training programs for your staff can significantly enhance the efficiency and output of your production line.

Key areas to focus on in operator training include:

- Understanding the intricacies of CNC programming

- Troubleshooting common issues

- Optimizing cutting paths and tool selection

- Interpreting quality control data

- Implementing safety protocols

Consider developing a tiered training program for operators of the customized CNC glass cutting line that allows them to continuously improve their skills. This approach not only enhances efficiency but also provides a clear career path, improving employee retention and satisfaction.

Augmented reality (AR) training tools can be particularly effective in this context. AR can provide interactive, hands-on training experiences without the risk of damaging expensive equipment. It allows operators to practice complex procedures and learn to handle various scenarios in a safe, virtual environment.

Furthermore, fostering a culture of continuous improvement among your operators can lead to valuable insights and innovations. Encourage your team to share ideas for process improvements and reward suggestions that lead to measurable efficiency gains.

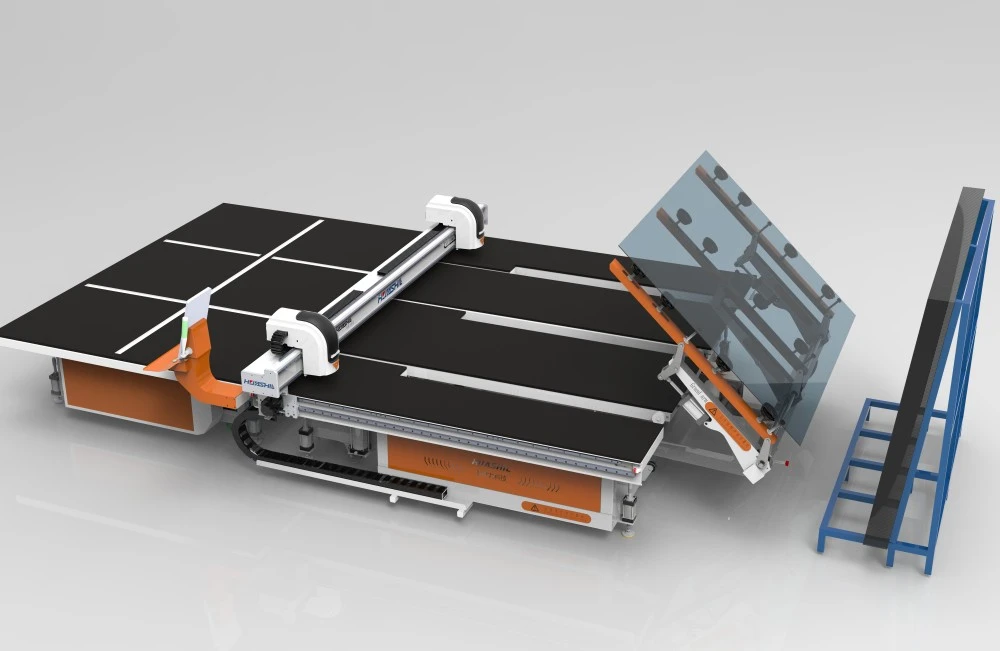

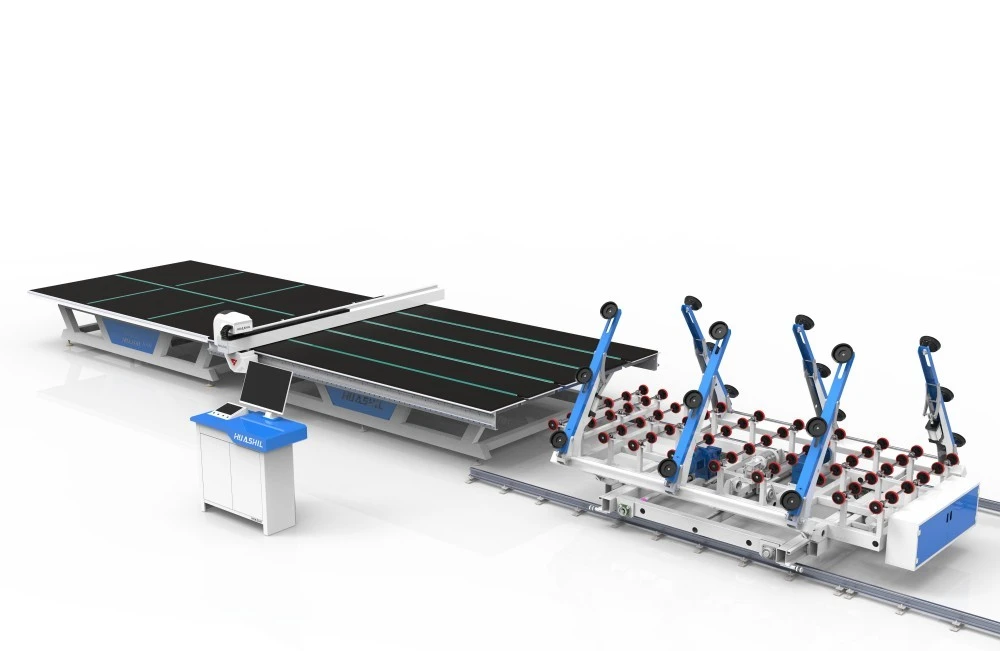

Optimizing material flow and handling

Efficient material handling is often overlooked but can significantly impact the overall efficiency of your CNC glass cutting line. Streamlining the flow of glass sheets from storage to cutting, and then to subsequent processing stages, can reduce bottlenecks and improve throughput.

Consider implementing:

- Automated storage and retrieval systems (AS/RS) for glass sheets

- Conveyor systems optimized for your facility's layout

- Robotic arms for loading and unloading glass sheets

- Smart inventory management systems to ensure optimal stock levels

By automating material handling, you can reduce the risk of damage to glass sheets, minimize manual labor, and ensure a steady supply of materials to your CNC cutting line. This optimization can lead to smoother operations and increased overall efficiency.

Leveraging data analytics for continuous improvement

In the era of Industry 4.0, data is a powerful tool for optimizing CNC glass cutting operations. Implementing a robust data collection and analysis system can provide valuable insights into your production processes, helping you identify areas for improvement and make data-driven decisions.

Key metrics to monitor include:

- Machine utilization rates

- Cutting speeds and feed rates

- Tool wear and replacement frequency

- Defect rates and quality control metrics

- Energy consumption

Advanced analytics tools can help you identify patterns and trends in this data, enabling you to fine-tune your operations for maximum efficiency. For example, you might discover that certain types of cuts are causing excessive tool wear, prompting you to adjust your cutting parameters or explore alternative tooling options.

Moreover, predictive analytics can help you anticipate maintenance needs, optimize inventory levels, and even forecast demand, allowing you to align your production more closely with market requirements.

Embracing sustainable practices

Optimizing your CNC glass cutting line isn't just about increasing output; it's also about improving sustainability. Implementing eco-friendly practices can not only reduce your environmental impact but also lead to significant cost savings and improved efficiency.

Consider these sustainable approaches:

- Implementing energy-efficient CNC machines and auxiliary equipment

- Optimizing cutting patterns to minimize glass waste

- Recycling glass offcuts and dust

- Using water-based coolants instead of oil-based alternatives

- Investing in solar panels or other renewable energy sources to power your facility

By adopting these practices, you can reduce your operational costs, appeal to environmentally conscious customers, and potentially access government incentives for sustainable manufacturing.

Conclusion

Optimizing a CNC glass cutting line for efficiency is a multifaceted endeavor that requires a holistic approach. By implementing smart scheduling, ensuring regular calibration, investing in operator training, streamlining material handling, leveraging data analytics, and embracing sustainable practices, you can significantly enhance your production efficiency and quality.

Remember, optimization is an ongoing process. Continuously monitor your operations, stay abreast of technological advancements, and be open to innovation. With dedication and the right strategies, you can ensure your CNC glass cutting line remains at the forefront of efficiency and productivity.

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by manufacturers in the glass industry. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us perfectly to help you optimize your CNC glass cutting operations. Our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide.

Ready to take your CNC glass cutting efficiency to the next level? Contact our team of experts today at salescathy@sdhuashil.com. Let's work together to tailor a solution that meets your specific needs and helps you stay ahead in today's competitive market.

References

1. Johnson, A. (2022). Advanced Techniques in CNC Glass Cutting: A Comprehensive Guide. Journal of Glass Technology, 45(3), 78-92.

2. Smith, B., & Brown, C. (2023). Optimizing Efficiency in Automated Glass Manufacturing Processes. International Journal of Industrial Engineering, 18(2), 210-225.

3. Lee, D. et al. (2021). The Impact of Operator Training on CNC Glass Cutting Line Productivity: A Case Study. Journal of Manufacturing Systems, 59, 345-358.

4. Zhang, X. (2023). Sustainable Practices in Glass Cutting: Balancing Efficiency and Environmental Responsibility. Green Manufacturing Review, 7(1), 45-60.