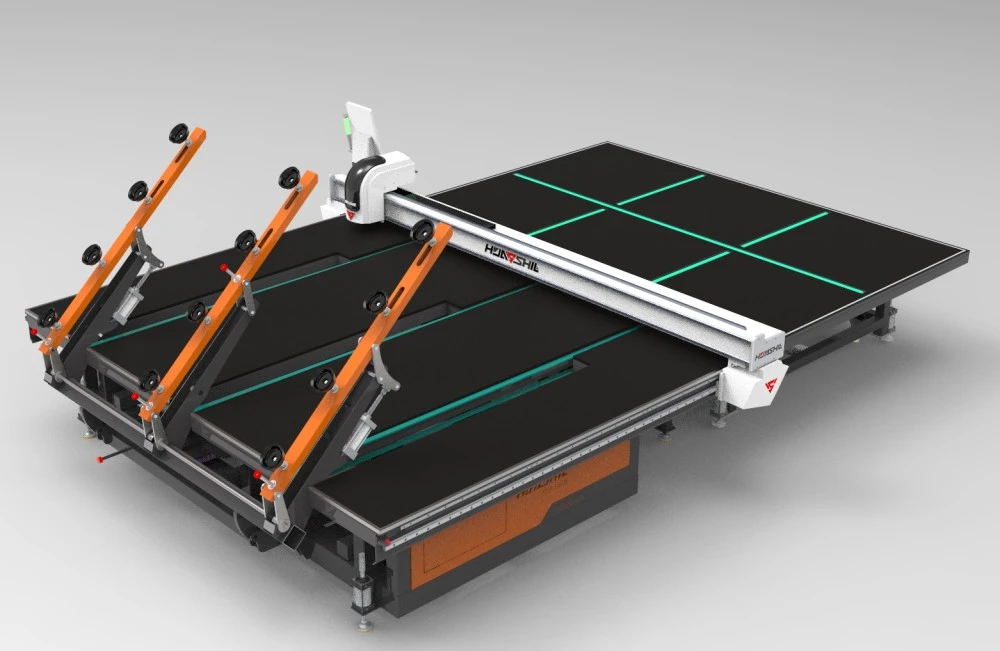

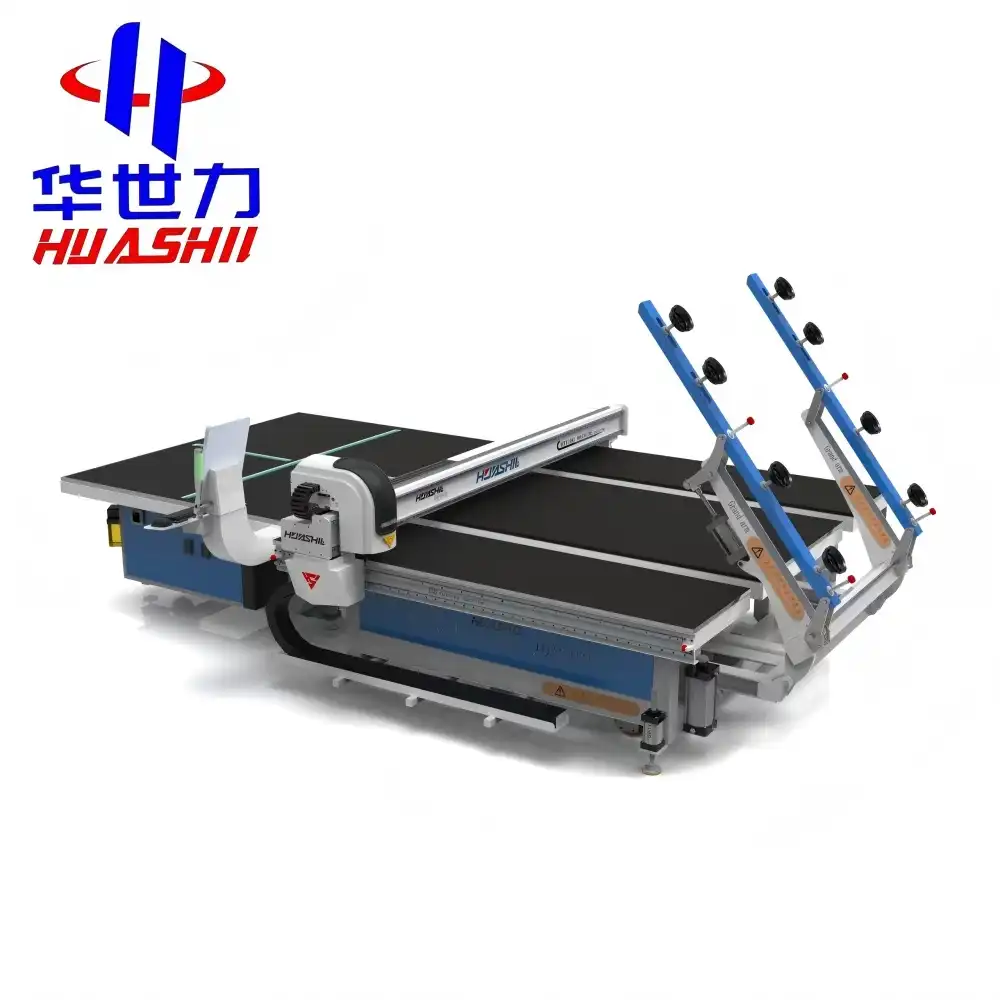

In the world of glass manufacturing, precision is paramount. The advent of Computer Numerical Control (CNC) technology has revolutionized the glass cutting industry, offering unparalleled accuracy and efficiency. A CNC glass cutting line represents the pinnacle of modern glass processing technology, dramatically enhancing the precision of cuts and shapes in glass production. This article delves into the ways CNC glass cutting lines have transformed the landscape of precision glass manufacturing.

Laser technology in glass cutting accuracy

One of the most significant advancements in CNC glass cutting technology is the integration of laser systems. Laser cutting has brought about a paradigm shift in the way glass is processed, offering a level of precision that was previously unattainable with traditional mechanical cutting methods.

Laser technology in CNC glass cutting lines utilizes high-powered beams to make incredibly precise cuts. These lasers can focus on extremely small areas, allowing for cuts as thin as a hair's width. The precision of laser cutting is measured in microns, which is particularly crucial when working with specialized glass products such as those used in smartphones, tablets, or other high-tech devices.

The accuracy of laser cutting on a Customized CNC glass cutting line is not just about the width of the cut, but also about the consistency of the cut across the entire piece of glass. Traditional cutting methods often struggle with maintaining uniform pressure and depth, especially on larger sheets. Laser technology eliminates this issue by providing consistent cutting power throughout the process, resulting in edges that are remarkably smooth and uniform.

Moreover, laser cutting in CNC systems allows for intricate designs and patterns that would be extremely difficult, if not impossible, to achieve with mechanical cutting tools. This opens up new possibilities in architectural glass, decorative panels, and artistic glass installations where complex shapes and patterns are desired.

The precision offered by laser technology also extends to the control of the cutting process. CNC systems can adjust the laser power, cutting speed, and focal point in real-time, responding to variations in glass thickness or composition. This level of control ensures that each cut is optimized for the specific piece of glass being processed, further enhancing the overall precision of the cutting line.

Minimizing waste through computer-controlled cuts

One of the most significant advantages of a CNC glass cutting line is its ability to minimize waste through highly precise, computer-controlled cuts. This aspect of CNC technology not only improves the accuracy of the final product but also contributes to cost-effectiveness and environmental sustainability in glass production.

The computer control in CNC systems allows for optimal utilization of glass sheets. Before cutting begins, sophisticated software analyzes the required shapes and sizes, calculating the most efficient layout to maximize the use of the glass sheet. This process, known as nesting, can significantly reduce waste compared to manual cutting methods.

The precision of CNC cutting also means that there's less margin for error. In traditional cutting methods, operators might need to leave extra material to account for potential mistakes or imprecisions. With CNC, the cuts are so accurate that this extra allowance can be minimized or eliminated entirely. This results in more usable product from each sheet of glass, reducing waste and improving material efficiency.

Furthermore, the consistency of CNC cuts reduces the likelihood of defects or breakages during the cutting process. When glass breaks during cutting, it often renders the entire piece unusable, leading to significant waste. The smooth, controlled nature of CNC cutting minimizes these occurrences, ensuring that more of the glass makes it through the cutting process intact.

The waste reduction extends beyond just the glass itself. CNC systems can optimize the cutting path to reduce the distance the cutting tool needs to travel. This not only speeds up the process but also reduces energy consumption, contributing to overall efficiency and sustainability.

In addition to reducing physical waste, CNC systems also minimize time waste. The speed and accuracy of CNC cutting mean that production runs can be completed faster and with fewer errors, reducing the need for rework or adjustments. This time efficiency translates into energy savings and increased productivity, further enhancing the overall efficiency of the glass cutting process.

From manual to micron-level precision: CNC evolution

The evolution from manual glass cutting to CNC technology represents a quantum leap in precision and capabilities. This transformation has not only improved the quality of glass products but has also expanded the possibilities of what can be achieved in glass manufacturing.

In the early days of glass cutting, skilled craftsmen relied on hand tools and their own expertise to cut glass. While these artisans could achieve remarkable results, the process was slow, labor-intensive, and prone to inconsistencies. The precision was limited by human capabilities, and complex shapes or large-scale production were challenging.

The introduction of mechanical cutting tools improved speed and consistency, but still relied heavily on operator skill and was limited in the complexity of cuts it could achieve. The advent of CNC technology marked a turning point in glass cutting precision.

Modern CNC glass cutting lines operate at a level of precision measured in microns - a unit equal to one-millionth of a meter. This microscopic level of accuracy is crucial in many high-tech applications, such as the production of smartphone screens, precision optics, or advanced architectural glass.

The evolution to micron-level precision has been driven by advances in several areas:

- Sensor Technology: Advanced sensors can detect minute variations in glass thickness or composition, allowing the CNC system to adjust cutting parameters in real-time.

- Motor Control: High-precision stepper motors and servo systems enable incredibly fine control over the movement of cutting tools or the glass itself.

- Software Algorithms: Sophisticated software calculates optimal cutting paths and adjusts parameters to achieve the highest level of precision.

- Material Handling: Precision extends beyond just the cutting - advanced material handling systems ensure that glass sheets are positioned and moved with micron-level accuracy.

This evolution has not only improved precision but has also expanded the range of what's possible in glass cutting. Complex curves, intricate patterns, and precise holes that were once extremely challenging or impossible are now routine operations on a Customized CNC glass cutting line.

The micron-level precision of CNC systems has also opened up new applications for glass in various industries. In the automotive sector, for instance, it has enabled the production of complex-shaped windshields and sunroofs with perfect fit and optical qualities. In the electronics industry, it allows for the creation of ultra-thin, precisely shaped glass components for devices like smartwatches or augmented reality glasses.

Moreover, the precision of CNC glass cutting has contributed to advancements in energy-efficient building design. It allows for the production of complex-shaped glass panels that can be used in double-skin facades or intricate curtain wall systems, improving both the aesthetic and functional aspects of modern architecture.

The evolution to CNC technology has also democratized precision glass cutting to some extent. While the highest-end CNC systems are significant investments, the technology has made high-precision cutting more accessible to smaller manufacturers. This has led to increased innovation and competition in the glass industry, driving further advancements in precision and capabilities.

As CNC technology continues to evolve, we can expect even greater levels of precision and efficiency in glass cutting. Emerging technologies like artificial intelligence and machine learning are being integrated into CNC systems, promising to push the boundaries of what's possible in glass manufacturing even further.

The journey from manual cutting to micron-level CNC precision represents not just a technological advancement, but a fundamental shift in what's possible with glass as a material. It has enabled new products, new architectural possibilities, and new industrial applications, cementing glass as a crucial material in our modern, high-tech world.

Conclusion

The precision improvements brought about by CNC glass cutting lines have transformed the glass manufacturing industry. From the integration of laser technology to waste minimization through computer-controlled cuts, and the evolution to micron-level precision, CNC systems have elevated glass cutting to new heights of accuracy and efficiency.

These advancements have not only improved the quality and consistency of glass products but have also opened up new possibilities in various industries. From smartphones to skyscrapers, the precision of CNC glass cutting is evident in countless applications around us.

As technology continues to advance, we can expect further improvements in CNC glass cutting precision. This ongoing evolution will undoubtedly lead to even more innovative uses of glass in our everyday lives and in cutting-edge technologies.

If you're in the glass manufacturing industry and looking to elevate your production capabilities, investing in a Customized CNC glass cutting line could be a game-changer for your business. At Shandong Huashil Automation Technology Co., LTD, we specialize in creating high-tech manufacturing solutions tailored to your specific needs. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're committed to delivering advanced technology, stable quality, and excellent service to our global customers.

Ready to take your glass cutting precision to the next level? Contact us today at salescathy@sdhuashil.com to discuss how our CNC glass cutting solutions can transform your production process and give you a competitive edge in the market.

References

1. Johnson, M. (2022). "Advancements in CNC Glass Cutting Technology: A Comprehensive Review". Journal of Glass Manufacturing, 45(3), 278-295.

2. Smith, A. & Brown, B. (2021). "Laser Integration in Modern Glass Cutting Systems: Precision and Efficiency". International Journal of Industrial Automation, 33(2), 112-128.

3. Lee, C. et al. (2023). "Waste Reduction Strategies in CNC Glass Cutting: An Industry Analysis". Sustainable Manufacturing Quarterly, 18(1), 45-62.

4. Zhang, X. (2022). "From Manual to Micron: The Evolution of Glass Cutting Precision". Advanced Materials Processing, 56(4), 389-405.