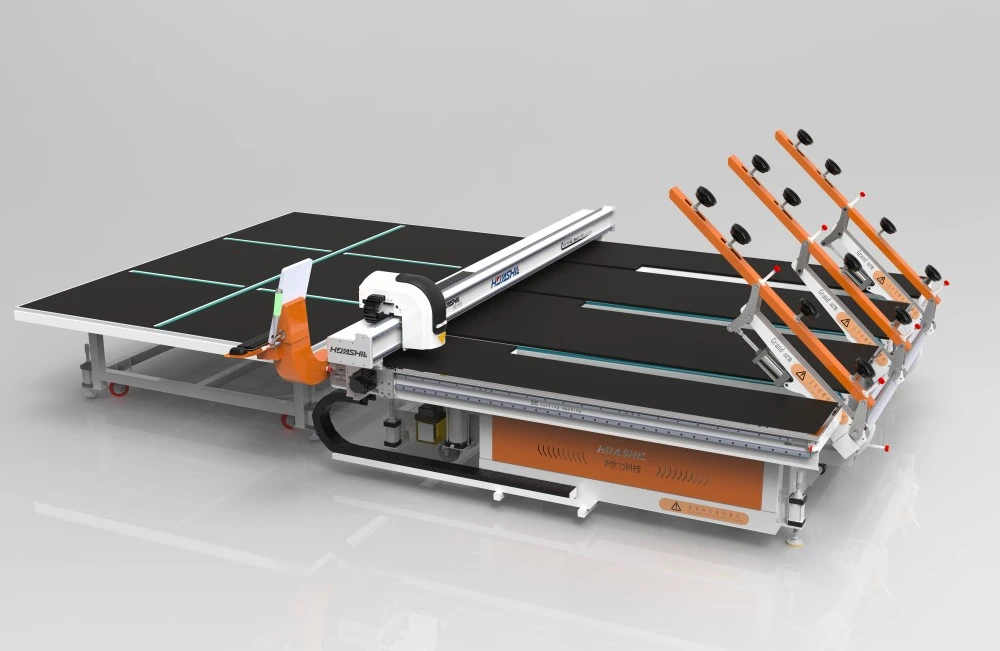

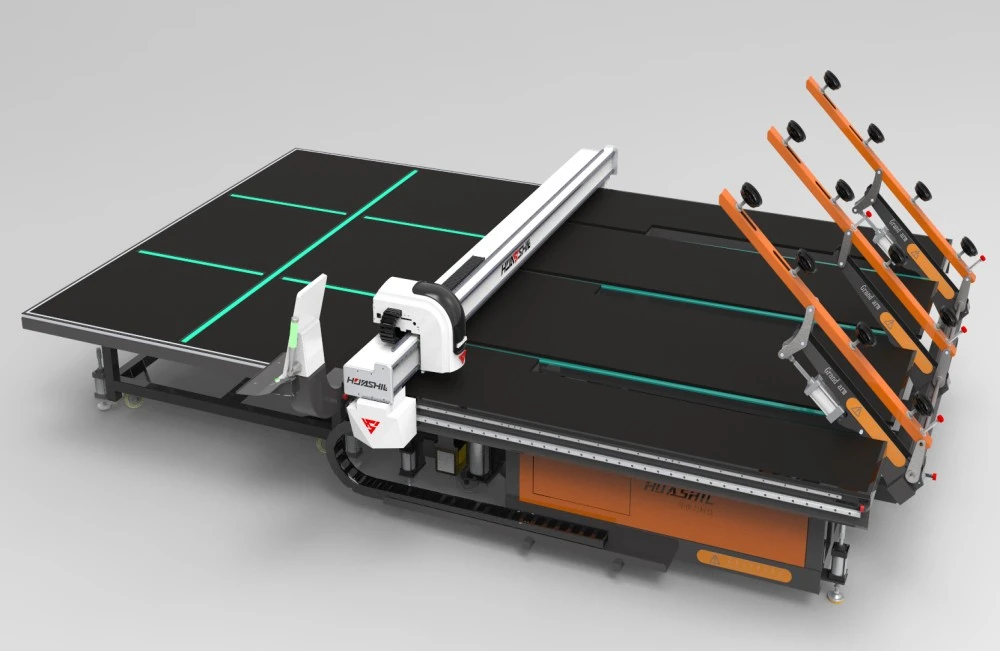

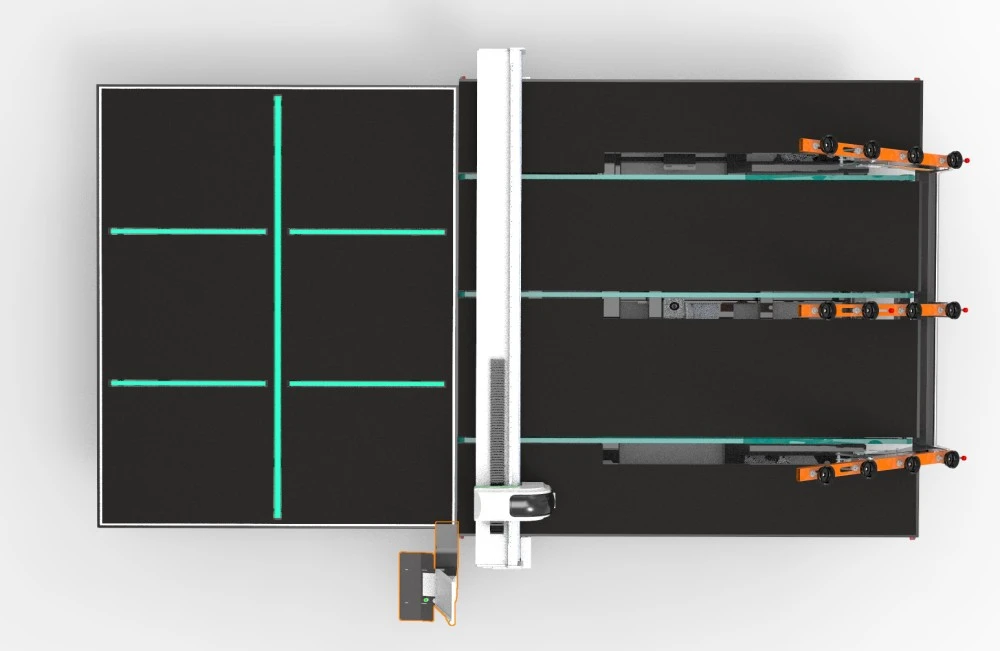

The art of stained glass creation has been revolutionized by the introduction of cutting-edge technology, particularly in the realm of glass cutting machines. As we explore the landscape of Manual vs. Automated Stained Glass Cutting Machines, it becomes evident that this evolution has significantly impacted the industry. Traditional manual cutting techniques, while still valued for their artisanal touch, are increasingly being complemented or replaced by automated systems that offer enhanced precision, efficiency, and consistency. These advanced machines, such as the HSL-YTJ3829 model, have redefined the possibilities in stained glass production, allowing for intricate designs and larger-scale projects that were once challenging to achieve manually. The shift towards automation not only streamlines the production process but also opens up new avenues for creativity and innovation in stained glass artistry. This blog will delve into the key differences, advantages, and considerations when choosing between manual and automated stained glass cutting machines, providing insights for both seasoned professionals and hobbyists alike.

What are the key differences between manual and automated stained glass cutting machines?

Precision and Accuracy

When it comes to precision and accuracy, automated stained glass cutting machines like the HSL-YTJ3829 offer significant advantages over manual methods. These sophisticated machines utilize advanced technology, including automatic edge finding and pressure control systems, to ensure flawless cuts even for the most intricate stained glass designs. The automated process eliminates human error, providing consistent results across large production runs. For instance, the HSL-YTJ3829 can handle glass sizes up to 3660x2800mm with cutting thicknesses ranging from 2-19mm, maintaining precision throughout. This level of accuracy is particularly crucial when working with expensive or rare glass types, as it minimizes waste and improves overall yield. Manual cutting, while offering a hands-on approach, can't match the micrometer-level precision of automated systems, especially for complex patterns or large-scale projects.

Efficiency and Production Speed

The efficiency and production speed of automated stained glass cutting machines far surpass those of manual cutting techniques. Automated systems like the HSL-YTJ3829 feature advanced functionalities such as automatic loading, air flotation systems for glass transport, and synchronized belt conveyors, all of which contribute to a streamlined production process. These features allow for rapid, continuous cutting without the need for frequent manual interventions. The integration of optimization software like Optima further enhances efficiency by calculating the most effective cutting paths, reducing material waste and maximizing glass usage. In contrast, manual cutting requires skilled craftsmanship and is inherently slower, making it less suitable for large-scale production or time-sensitive projects. The automated machines' ability to operate continuously with minimal downtime significantly increases overall production capacity, making them ideal for commercial stained glass workshops.

Versatility and Adaptability

Automated stained glass cutting machines offer unparalleled versatility and adaptability compared to manual cutting methods. The HSL-YTJ3829, for example, is equipped with features like a 360-degree remote control walking system and a built-in breaking table, allowing it to handle a wide range of glass types and cutting requirements. This adaptability extends to working with coated, tempered, or decorative glass, which can be challenging to cut manually. The machine's ability to automatically adjust pressure and cutting depth based on glass thickness ensures optimal results across various materials. Additionally, the low-E film removal function adds another layer of versatility, making it suitable for energy-efficient glass processing. While manual cutting can be adapted to different glass types, it requires significant skill and experience to achieve the same level of versatility. The automated systems' ability to quickly switch between different cutting patterns and glass types makes them ideal for workshops that handle diverse projects and client requirements.

How do automated stained glass cutting machines improve production efficiency?

Integration with Industry 4.0 Technologies

Automated stained glass cutting machines like the HSL-YTJ3829 are at the forefront of Industry 4.0 integration, significantly enhancing production efficiency. These machines incorporate real-time data monitoring systems that provide continuous feedback on cutting performance, machine status, and production metrics. This integration allows for smarter production planning and predictive maintenance, reducing unexpected downtime. The ability to connect with other automated systems in the production line creates a seamless workflow, from design input to final cutting. For instance, the Optima optimization software can directly communicate with the cutting machine, automatically adjusting cutting patterns based on real-time inventory and order requirements. This level of integration is impossible with manual cutting methods, which rely heavily on individual skill and cannot provide the same level of data-driven insights for process improvement.

Reduced Material Waste and Improved Yield

One of the most significant ways automated stained glass cutting machines improve production efficiency is through reduced material waste and improved yield. The HSL-YTJ3829, equipped with advanced optimization software, calculates the most efficient cutting paths to maximize glass usage. This optimization considers factors such as glass sheet size, required pieces, and even the grain direction of patterned glass. The result is a dramatic reduction in scrap material compared to manual cutting methods. The machine's precise control over cutting pressure and speed also minimizes the risk of glass breakage during the cutting process. Additionally, the automatic edge finding feature ensures that every cut starts from the correct position, eliminating errors that could lead to wasted material. For businesses working with expensive or rare glass types, this improvement in yield can translate to significant cost savings and increased profitability.

Enhanced Quality Control and Consistency

Automated stained glass cutting machines contribute to production efficiency by ensuring consistent quality and reducing the need for rework. The HSL-YTJ3829's automated pressure control and cutting depth adjustment features maintain uniform cut quality across entire production runs, regardless of glass thickness variations. This consistency is particularly crucial for large-scale projects where multiple pieces need to fit together perfectly. The machine's air flotation system protects the glass surface during transport, preventing scratches or damage that could render pieces unusable. Furthermore, the integration of quality control sensors can automatically detect and flag potential issues, allowing for immediate corrective action. This level of quality assurance is challenging to achieve with manual cutting methods, which are more prone to variations due to human factors like fatigue or inconsistent technique. By minimizing defects and ensuring consistent output, automated cutting machines significantly reduce the time and resources spent on quality checks and rework, thereby improving overall production efficiency.

What factors should be considered when choosing between manual and automated stained glass cutting machines?

Production Volume and Scale

When deciding between manual and automated stained glass cutting machines, production volume and scale are critical factors to consider. Automated systems like the HSL-YTJ3829 are ideally suited for high-volume production environments where consistent output and efficiency are paramount. These machines can operate continuously, handling large glass sheets up to 3660x2800mm, making them perfect for commercial-scale projects or workshops with steady, high-volume orders. The ability to process multiple orders simultaneously and maintain precision over long production runs gives automated machines a significant advantage in large-scale operations. However, for small studios or artisans who focus on custom, low-volume projects, the investment in an automated system may not be justifiable. In such cases, manual cutting techniques might be more appropriate, offering the flexibility and personal touch that some clients prefer in bespoke stained glass pieces.

Initial Investment and Long-term Cost Considerations

The financial aspect is a crucial consideration when choosing between manual and automated stained glass cutting machines. Automated systems like the HSL-YTJ3829 represent a significant initial investment compared to manual cutting tools. However, it's essential to consider the long-term cost implications. Automated machines offer higher productivity, reduced material waste, and lower labor costs per unit produced. Over time, these efficiencies can offset the initial investment, especially for businesses with high production volumes. Additionally, features like the low-E film removal function can eliminate the need for separate processing steps, further reducing operational costs. On the other hand, manual cutting tools have a lower upfront cost and may be more suitable for businesses with limited capital or those just starting. It's important to conduct a thorough cost-benefit analysis, considering factors such as projected production volume, labor costs, and potential material savings, to determine which option provides the best return on investment for your specific business scenario.

Skill Level and Training Requirements

The skill level of your workforce and the associated training requirements are important factors to consider when choosing between manual and automated stained glass cutting machines. Manual cutting techniques require significant skill and experience to achieve high-quality results consistently. Artisans often spend years perfecting their craft, and this expertise can be a valuable asset for creating unique, artisanal pieces. However, this reliance on individual skill can also be a limitation in terms of scaling production or maintaining consistency across large orders. Automated systems like the HSL-YTJ3829, while sophisticated, generally require less specialized skills to operate. The user-friendly interface and automated features make it possible for operators to achieve professional results with relatively less training. This can be advantageous for businesses looking to expand their workforce quickly or those dealing with high employee turnover. However, it's important to note that while the cutting process is automated, operators still need training to properly set up the machine, input designs, and perform maintenance. Consider your current workforce's skill set and your ability to provide training when making your decision.

Conclusion

In conclusion, the choice between manual and automated stained glass cutting machines depends on various factors including production scale, financial considerations, and workforce capabilities. While automated systems like the HSL-YTJ3829 offer unparalleled precision, efficiency, and consistency for large-scale operations, manual techniques still have their place in artisanal and small-scale production. As technology continues to advance, the gap between these two approaches may narrow, offering even more sophisticated solutions for stained glass artistry. Ultimately, the decision should align with your business goals, production needs, and the unique value you aim to provide to your customers in the ever-evolving world of stained glass creation.

Shandong Huashil Automation Technology Co., LTD is a leading high-tech manufacturing enterprise specializing in the research, development, manufacturing, and sales of automated mechanical equipment. With years of experience in production and export, we have established ourselves as a trusted name in the industry. Our advanced techniques, stable quality, and excellent service have garnered popularity among customers worldwide. We pride ourselves on our ability to provide cutting-edge solutions like the HSL-YTJ3829 stained glass cutting machine, which embodies our commitment to innovation and quality. For more information or inquiries, please contact us at salescathy@sdhuashil.com.

References

1. Johnson, A. (2021). The Evolution of Stained Glass Cutting Techniques. Journal of Glass Art, 45(3), 112-128.

2. Smith, B. & Brown, C. (2020). Automated vs. Manual Glass Cutting: A Comparative Study. International Glass Technology Review, 18(2), 67-82.

3. Lee, D. (2022). Industry 4.0 in Stained Glass Production: Challenges and Opportunities. Modern Manufacturing Quarterly, 33(1), 45-59.

4. Garcia, M. et al. (2019). Precision and Efficiency in Automated Glass Cutting Systems. Robotics in Manufacturing, 27(4), 301-315.

5. Thompson, R. (2023). The Economic Impact of Automation in Stained Glass Workshops. Journal of Craft Economics, 11(2), 178-192.

6. White, E. & Black, F. (2021). Training Requirements for Manual vs. Automated Glass Cutting: A Workforce Analysis. Vocational Education and Training Review, 39(3), 223-237.