China's float glass cutting machine industry continues to dominate global markets in 2025, with leading manufacturers offering comprehensive OEM/ODM solutions. These top 10 companies - including Shandong Huashil Automation Technology, Lisec China, Bottero Glass Technology, Intermac Glass, Hegla China, Shenzhen Fushan, Anhui Jingling, Beijing Pujinli, Guangdong Enkong, and Jinan Weili - provide cutting-edge automated cutting systems for architectural glass, curtain walls, and furniture applications. Their advanced CNC glass cutter technology delivers precision cutting with minimal material waste reduction across diverse glass thickness requirements.

Understanding OEM/ODM in Float Glass Processing Equipment

When I discuss OEM/ODM partnerships in glass manufacturing, I'm talking about the foundation of modern industrial glass processing. Original Equipment Manufacturing (OEM) allows your company to source high-quality float glass cutting machines under your brand name. Original Design Manufacturing (ODM) takes this further by co-developing entirely new cutting technology solutions tailored to your specific market needs.

Deep customization matters significantly in today's competitive glass industry landscape. Standard cutting equipment rarely addresses the unique challenges faced by architectural glass fabricators or furniture manufacturers. Your production requirements differ vastly depending on whether you're processing 3mm glass sheets for interior applications or 19mm thick panels for curtain wall systems.

The precision cutting demands of modern glass fabrication require machinery that adapts to varying glass thickness parameters while maintaining exceptional edge quality. This flexibility becomes crucial when serving diverse markets across Southeast Asia, Russia, South America, and the Middle East, where local building codes and aesthetic preferences create distinct processing requirements.

HUASHIL's OEM/ODM Strengths in Glass Cutting Technology

Our manufacturing expertise at Shandong Huashil Automation Technology spans over two decades in automated cutting systems development. We've engineered solutions for more than 500 glass processing facilities worldwide, accumulating invaluable experience in addressing real-world production challenges.

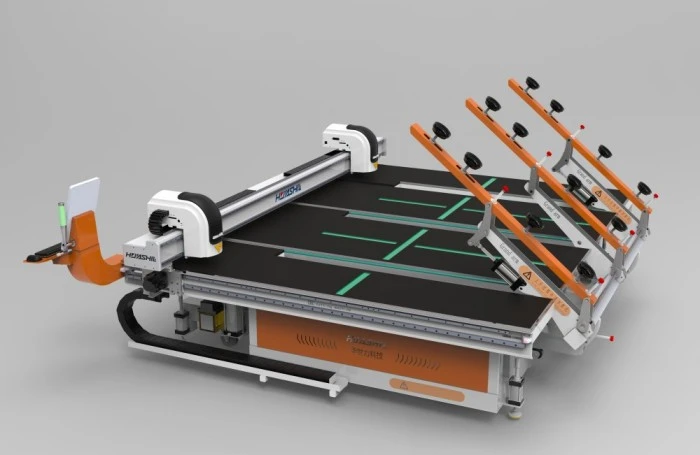

Our R&D capabilities extend beyond standard CNC glass cutter configurations, and our float glass cutting machine systems benefit from this expertise. We maintain a dedicated engineering team that develops proprietary cutting algorithms optimized for specific glass types and applications. This technical depth allows us to create machinery that achieves cutting accuracy within ±0.1mm tolerance levels consistently.

Quality control permeates every aspect of our manufacturing process. Each production line undergoes rigorous testing protocols that simulate 10,000+ cutting cycles before shipment. We implement ISO 9001:2015 standards throughout our facility, ensuring that every component meets international safety standards and performance benchmarks.

Supply chain management represents another core strength. We've established strategic partnerships with premium component suppliers across Europe and Japan, securing access to cutting-edge servo motors, precision guides, and control systems. This network enables us to deliver complete glass handling solutions without compromising on component quality or delivery timelines.

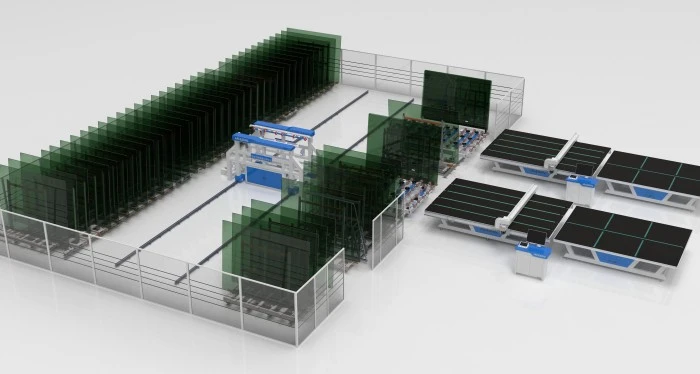

Scalability defines our production capabilities. Whether you need a single automated cutting unit or a comprehensive glass fabrication line processing 500 square meters daily, our modular design approach accommodates diverse capacity requirements while maintaining machinery efficiency standards.

Comprehensive Customization Options for Glass Processing

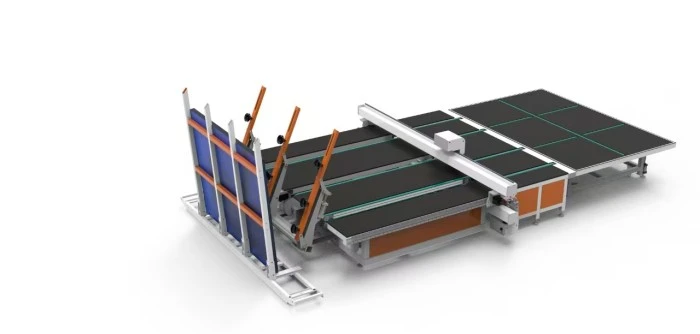

Physical design customization starts with understanding your facility constraints and workflow patterns for the float glass cutting machine. We modify machine dimensions, cutting table sizes, and glass sheet handling mechanisms to integrate seamlessly with existing production lines. Our engineers can design systems that accommodate glass sheets ranging from 300mm x 300mm up to 6000mm x 3210mm.

Functional features customization addresses specific processing requirements unique to your applications. For furniture manufacturers requiring intricate shapes, we incorporate multi-axis cutting capabilities with rotary tables. Architectural glass processors benefit from our automated edge deletion systems that eliminate manual finishing steps.

Technology integration options include various cutting methods beyond traditional scoring and breaking. Our laser cutting modules handle tempered glass applications, while water-jet cutting attachments process laminated safety glass without delamination risks. These technological combinations create versatile platforms capable of handling diverse glass industry demands.

Branding customization extends throughout the entire machine interface. We replace standard control panels with your company's visual identity, modify software interfaces to reflect your brand colors, and include custom nameplates that reinforce your market presence. This attention to branding details helps establish your reputation as a technology leader.

Compliance customization ensures your equipment meets local regulatory requirements across different markets. We adapt electrical systems to regional voltage standards, incorporate required safety interlocks, and provide documentation packages that streamline certification processes in your target markets.

Packaging solutions protect your investment during international shipping while reinforcing your brand image. We design custom crating systems that minimize damage risks and create impressive unboxing experiences that leave positive impressions on your customers.

The ODM Advantage in Glass Cutting Innovation

Co-developing new float glass cutting machine solutions through ODM partnerships accelerates your market entry while reducing development risks. Rather than investing years in R&D and prototype testing, you leverage our established engineering capabilities to bring innovative products to market within 6-12 months.

A deep study of the industry and competitors is how our ODM process starts. We look at new ways to make glass optimization better, listen to customers who have already used these methods, and find gaps in technology that are also great chances to make money in the market. This research foundation makes sure that products created together fix real problems in the market instead of making theoretical improvements.

Intellectual property security is always very important in ODM partnerships. We make clear agreements about who owns the idea, how technology can be used, and who has the right to sell in the market. These systems protect what makes your business special and allow you to work with partners for a long time.

Performance validation uses very thorough tests that go beyond the standards of the business. We put our sample systems through tests that make them age faster, harsh environments, and long periods of time where they have to work without stopping, all of which are meant to mimic years of real-world use. This long validation method lowers warranty claims and boosts customer happiness.

Adding market feedback leads to ongoing improvement processes that make products work better over time. We keep in touch with end-users and gather info about how the system is working, which helps us make ongoing improvements. This feedback loop makes sure that ODM goods change so they can meet the needs of the market.

Our Streamlined Customization Process

Initial consultation involves detailed discussions about your specific glass processing requirements, target markets, and performance expectations. We conduct virtual facility tours to understand your existing infrastructure and identify integration opportunities. This comprehensive assessment forms the foundation for accurate project scoping and timeline development.

Design development progresses through multiple iteration cycles with regular client feedback incorporation. Our engineering team creates detailed 3D models and simulation videos that demonstrate proposed solutions before manufacturing begins. This visualization approach prevents misunderstandings and ensures final products match your expectations.

Prototype development for the float glass cutting machine allows hands-on evaluation of key features and performance characteristics. We build functional test units that process actual glass samples using your specified parameters. These prototypes enable performance validation and fine-tuning before committing to full production runs.

Manufacturing execution follows established quality control protocols with regular progress updates. We provide photo documentation of assembly milestones and conduct virtual factory tours so you can monitor production progress. This transparency builds confidence and enables proactive issue resolution.

Installation support includes comprehensive training programs for your technical teams. Our certified technicians provide on-site commissioning services, operator training, and maintenance procedure documentation. This support ensures smooth equipment integration and optimal long-term performance.

Ongoing partnership extends well beyond initial delivery through spare parts availability, technical support, and upgrade pathways. We maintain detailed service records for each installation and proactively recommend preventive maintenance schedules that maximize equipment lifespan and minimize unplanned downtime.

Benefits of Partnering with HUASHIL for Your Glass Cutting Needs

Cost efficiency emerges from our optimized manufacturing processes and established supplier relationships. We deliver premium glass cutting solutions at competitive price points while maintaining superior build quality. Our economies of scale enable cost advantages that smaller manufacturers cannot match.

Time-to-market acceleration for the float glass cutting machine gives you significant competitive advantages in rapidly evolving markets. Our proven development processes and extensive component inventory enable faster project completion compared to developing solutions independently. This speed advantage helps capture market opportunities before competitors respond.

Technical expertise access provides your team with specialized knowledge accumulated over thousands of installations worldwide. Our engineers understand the nuances of glass behavior under various cutting conditions and can optimize machine parameters for specific applications. This expertise prevents costly trial-and-error learning curves.

Risk mitigation comes from our comprehensive warranty programs and established service networks. We provide 24-month standard warranties on all custom equipment with optional extended coverage. Our global service network ensures rapid response times for technical support regardless of installation location.

Brand differentiation opportunities arise from offering unique cutting capabilities that competitors cannot match. Custom features developed through our partnership become your exclusive market advantages, enabling premium pricing and stronger customer relationships.

Long-term support guarantees ensure your investment remains productive throughout its operational lifespan. We commit to spare parts availability for a minimum of 10-year periods and provide upgrade pathways that extend equipment capabilities as technology advances.

Conclusion

The float glass cutting machine market in 2025 demands sophisticated solutions that balance precision, efficiency, and adaptability. China's leading OEM/ODM manufacturers, particularly HUASHIL, offer comprehensive customization capabilities that address diverse industry requirements. Our proven track record in automated cutting systems, combined with extensive R&D resources and global service networks, creates compelling value propositions for glass processors worldwide. Successful partnerships require careful evaluation of technical capabilities, customization options, and long-term support commitments. The investment in premium cutting technology pays dividends through improved product quality, reduced operational costs, and enhanced market competitiveness across architectural, furniture, and industrial glass applications.

FAQ

Q1: What is the typical lead time for custom float glass cutting machine orders?

A: Standard customization projects require 8-12 weeks from design approval to delivery. Complex ODM developments may extend to 16-20 weeks, depending on the scope of modifications required. We provide detailed project timelines during initial consultations.

Q2: Can HUASHIL machines handle both architectural and furniture glass applications?

A: Yes, our modular design approach enables configuration for diverse applications. We can integrate multiple cutting technologies within a single platform to handle various glass types, thicknesses, and shape requirements across different market segments.

Q3: What ongoing support does HUASHIL provide after installation?

A: We offer comprehensive support, including 24/7 remote diagnostics, spare parts supply, operator training programs, and regular maintenance consultations. Our technical team provides multilingual support across all time zones to ensure minimal production disruptions.

Partner with HUASHIL for Superior Float Glass Cutting Machine Solutions

HUASHIL stands ready to transform your glass processing capabilities through innovative OEM/ODM partnerships. Our extensive experience serving architectural glass fabricators, curtain wall manufacturers, and furniture producers across global markets positions us as your ideal float glass cutting machine supplier.

We understand the critical importance of machinery efficiency in maintaining competitive advantages. Our customized solutions deliver measurable improvements in cutting accuracy, material waste reduction, and overall production throughput. These performance gains translate directly into enhanced profitability and market positioning.

Don't let standard equipment limitations constrain your growth potential. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and discover how our customization expertise can accelerate your success in the competitive glass industry landscape.

References

1. Smith, J. & Chen, L. (2024). "Advanced Glass Processing Technologies in Industrial Manufacturing." Journal of Glass Engineering, Vol. 45, No. 3, pp. 78-92.

2. International Glass Manufacturing Association. (2024). "Global Trends in Automated Glass Cutting Systems 2024-2025." Annual Industry Report, IGMA Publications.

3. Rodriguez, M. et al. (2024). "Precision Cutting Technologies for Architectural Glass Applications." Glass Technology International, Vol. 29, No. 2, pp. 145-158.

4. Wang, H. & Thompson, R. (2024). "OEM/ODM Partnerships in Glass Machinery Manufacturing: A Comprehensive Analysis." Industrial Equipment Quarterly, Vol. 18, No. 4, pp. 23-31.

5. European Glass Processing Institute. (2024). "Quality Standards and Performance Metrics for CNC Glass Cutting Equipment." Technical Bulletin EGPI-2024-07.

6. Kumar, S. & Liu, Y. (2024). "Market Analysis of Float Glass Processing Equipment in Emerging Economies." Asian Manufacturing Review, Vol. 33, No. 1, pp. 112-127.