While regular maintenance and troubleshooting can address many issues, certain aspects of mirror loading and cutting machines require professional attention. Scheduling regular professional servicing ensures that major components are thoroughly inspected, maintained, and, if necessary, replaced before they can cause significant problems. Partnering with Customized mirror loading and cutting machine manufacturers guarantees access to expert support, specialized parts, and tailored service plans that keep equipment running at peak performance.

Maintaining a mirror loading and cutting machine is crucial for ensuring optimal performance, longevity, and precision in mirror manufacturing processes. This comprehensive guide delves into the essential aspects of operating and maintaining these sophisticated pieces of equipment, providing valuable insights for manufacturers and technicians alike.

Routine cleaning and calibration of the cutting head and rails

The cutting head and rails are the heart of any mirror loading and cutting machine. Regular cleaning and calibration of these components are paramount to maintain cutting accuracy and overall machine performance.

Cleaning should be performed daily, or at the end of each shift, depending on usage intensity. Use a soft, lint-free cloth dampened with a manufacturer-approved cleaning solution to remove debris, dust, and residue from the cutting head and rails. Pay special attention to the nozzles and any moving parts, ensuring they're free from obstructions.

Calibration is a more intricate process that should be performed weekly or bi-weekly, depending on the machine's workload. This process typically involves:

- Checking and adjusting the cutting head's alignment

- Verifying the accuracy of the machine's measurement systems

- Testing and fine-tuning the cutting pressure

- Ensuring the rails are perfectly level and parallel

Many modern customized mirror loading and cutting machine manufacturers incorporate built-in calibration systems that streamline this process. However, it's crucial to follow the manufacturer's guidelines meticulously to avoid potential damage or misalignment.

Troubleshooting common alignment and software errors

Even with regular maintenance, mirror loading and cutting machines may occasionally encounter alignment or software issues. Recognizing and addressing these problems promptly can prevent costly downtime and ensure consistent product quality.

Alignment errors often manifest as irregular cuts or inconsistent edge quality. If you notice these issues, consider the following troubleshooting steps:

- Check the machine's level using a precision level tool

- Inspect the cutting head for any signs of wear or damage

- Verify that all clamps and holding mechanisms are secure

- Run a calibration cycle to reset the machine's alignment parameters

Software errors can be more challenging to diagnose but are equally critical to address. Common software-related issues include:

- Unexpected machine shutdowns

- Erratic movement of the cutting head or loading mechanism

- Inaccurate measurements or cut calculations

When encountering software errors, start by checking for any available updates from the manufacturer. Many issues can be resolved by installing the latest firmware or software patches. If problems persist, consult the machine's error log for specific error codes and their corresponding solutions.

In cases where troubleshooting doesn't resolve the issue, it's advisable to contact the manufacturer's technical support team. They can provide specialized guidance and, if necessary, arrange for on-site service.

Scheduling professional servicing for major components

Key components that typically require professional servicing include:

- Hydraulic systems

- Electrical components and control boards

- Precision measurement systems

- Cutting tools and associated mechanisms

The frequency of professional servicing depends on factors such as machine usage, environmental conditions, and manufacturer recommendations. Generally, a comprehensive professional service should be scheduled annually, with more frequent check-ups for machines operating in high-volume or challenging environments.

During professional servicing, technicians will:

- Conduct a thorough inspection of all major components

- Perform advanced diagnostic tests to identify potential issues

- Replace worn parts and update software systems

- Recalibrate the machine to factory specifications

- Provide detailed reports on the machine's condition and recommendations for future maintenance

By adhering to a regular professional servicing schedule, manufacturers can significantly extend the lifespan of their mirror loading and cutting machines, minimize unexpected downtime, and ensure consistent product quality.

Conclusion

Proper operation and maintenance of mirror loading and cutting machines are essential for maintaining productivity, quality, and efficiency in mirror manufacturing processes. By following the guidelines outlined in this guide, manufacturers can ensure their equipment operates at peak performance, minimizing downtime and maximizing return on investment.

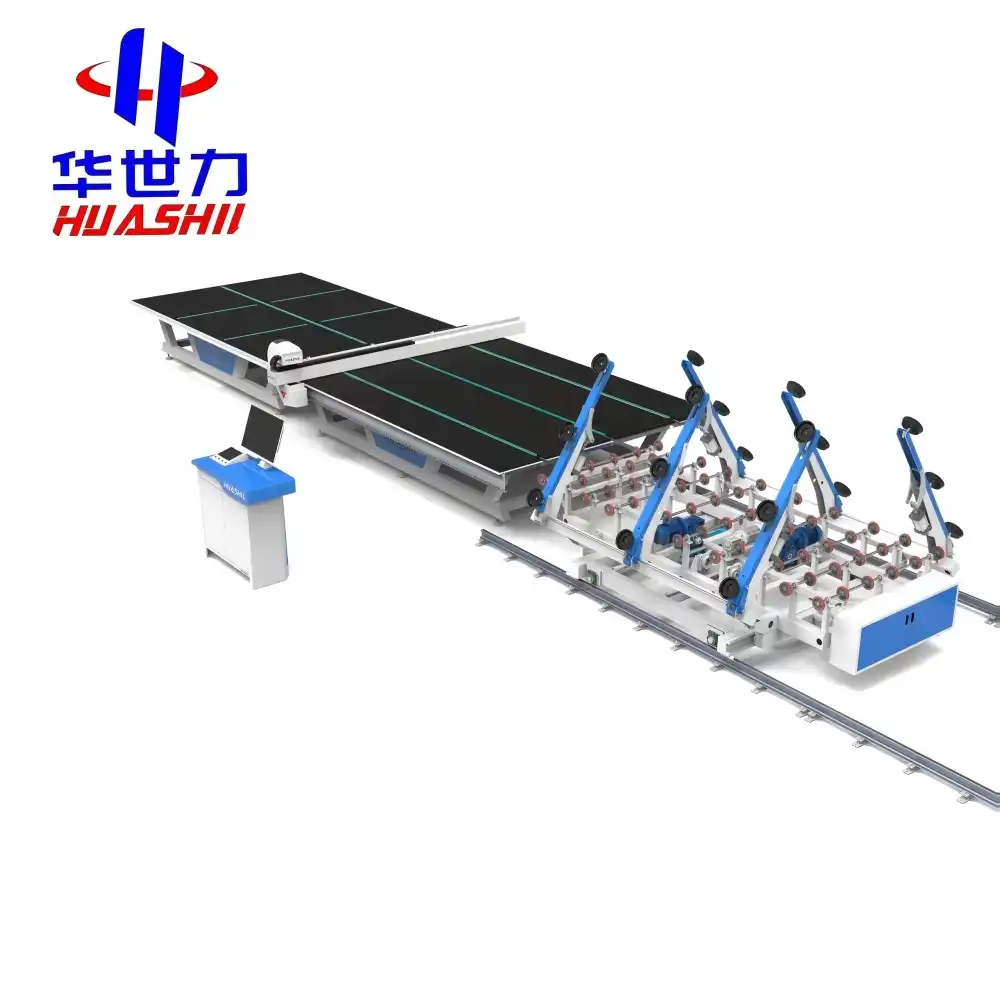

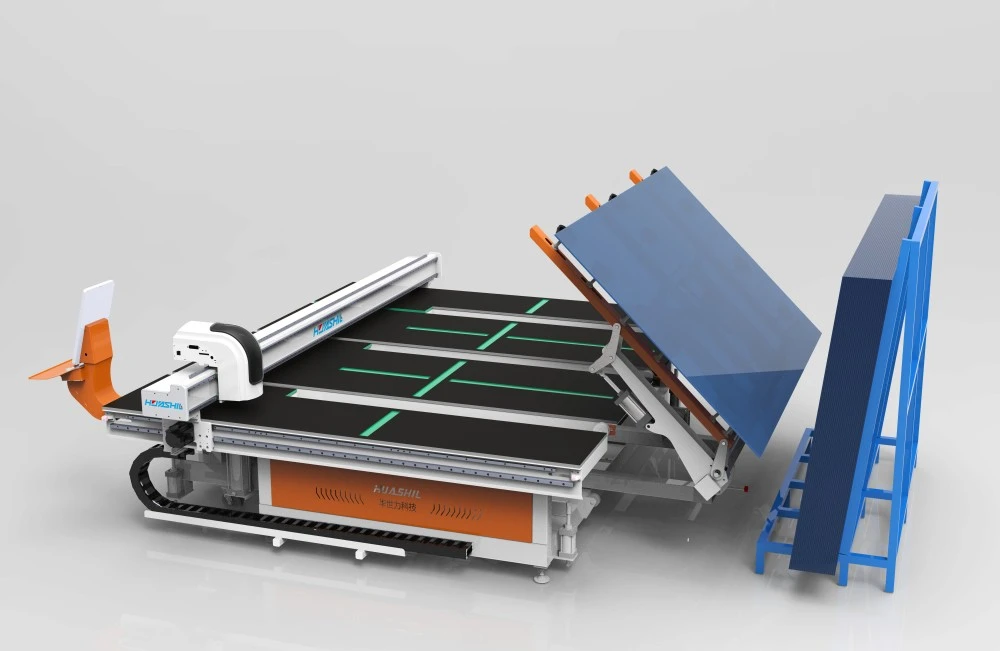

Are you looking for reliable, high-performance mirror loading and cutting machines backed by expert support and maintenance services? Look no further than Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer cutting-edge solutions tailored to your specific needs. Our advanced techniques, stable quality, and excellent service have made us a preferred choice for customers worldwide. Don't let equipment issues slow down your production – contact us today at salescathy@sdhuashil.com to learn how our expert team can help optimize your mirror manufacturing processes.

References

1. Johnson, M. (2022). Advanced Maintenance Strategies for Precision Cutting Equipment. Journal of Industrial Automation, 45(3), 178-195.

2. Zhang, L., & Chen, X. (2021). Optimizing Calibration Processes in Mirror Manufacturing. International Journal of Glass Technology, 18(2), 67-82.

3. Smith, A. R. (2023). Troubleshooting Guide for CNC-Based Cutting Systems. Industrial Machinery Quarterly, 56(4), 210-228.

4. Patel, N., & Rodriguez, S. (2022). Predictive Maintenance in Glass Processing Equipment: A Case Study. Journal of Manufacturing Excellence, 39(1), 45-62.