Investing in a mirror loading and cutting machine can significantly boost your manufacturing efficiency and product quality. However, making the right choice requires careful consideration of several crucial factors. This comprehensive guide will walk you through the key elements to evaluate before purchasing this advanced equipment for your production line.

How to determine the required machine size and capacity?

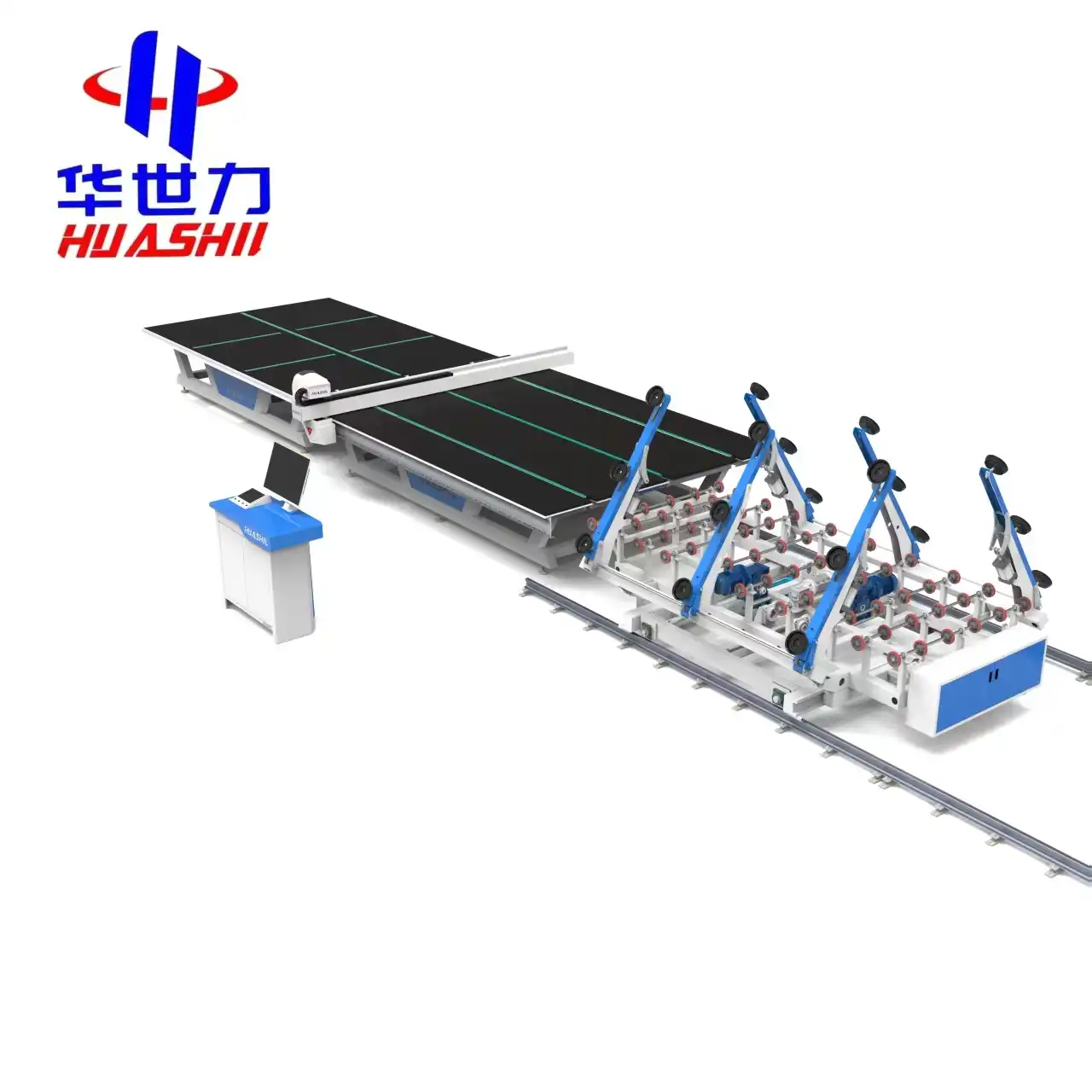

Selecting the appropriate size and capacity for your mirror loading and cutting machine is paramount to optimizing your production process. A Customized mirror loading and cutting machine factory can provide tailored solutions that align with specific production requirements, ensuring the right balance between efficiency, precision, and scalability. Consider the following aspects:

- Production volume: Assess your current and projected production needs. A machine that's too small may create bottlenecks, while an oversized one could lead to unnecessary expenses and underutilization.

- Mirror dimensions: Evaluate the range of mirror sizes you typically work with. Ensure the machine can accommodate your largest mirrors while also efficiently handling smaller ones.

- Material thickness: Different mirror thicknesses may require specific cutting capabilities. Verify that the machine can handle your entire range of mirror thicknesses.

- Cutting speed: Look for machines that offer adjustable cutting speeds to optimize performance for different mirror types and thicknesses.

- Loading capacity: Consider how many mirrors the machine can load simultaneously. Higher loading capacity can significantly reduce cycle times and increase overall productivity.

To accurately determine your needs, analyze your production data over the past year and factor in any anticipated growth or changes in product offerings. This information will guide you towards selecting a machine with the ideal size and capacity for your specific requirements.

Must-have features: CAD/CAM software compatibility and drill integration

When investing in a customized mirror loading and cutting machine factory, certain features are indispensable for maximizing efficiency and versatility:

CAD/CAM Software Compatibility

Integration with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software is crucial for modern mirror production. This compatibility offers several advantages:

- Design flexibility: Easily import complex mirror designs directly from CAD software to the cutting machine.

- Optimization: CAM software can automatically optimize cutting paths, reducing material waste and processing time.

- Precision: Digital designs ensure accurate replication of intricate patterns and shapes.

- Customization: Quickly adapt to changing customer requirements by modifying designs digitally.

Look for machines that support industry-standard file formats and offer seamless integration with popular CAD/CAM software packages.

Drill Integration

A mirror loading and cutting machine with integrated drilling capabilities can significantly streamline your production process:

- Efficiency: Perform cutting and drilling operations in a single setup, reducing handling time and potential for errors.

- Precision alignment: Ensure perfect alignment between cuts and drill holes, crucial for applications like bathroom mirrors with mounting points.

- Versatility: Accommodate various drilling requirements, such as countersunk holes, through-holes, or threaded inserts.

- Cost-effectiveness: Eliminate the need for separate drilling equipment and additional labor.

When evaluating drill integration, consider factors such as the range of drill bit sizes supported, drilling speed, and the ability to perform angled drilling if required by your products.

Evaluating your factory's power supply and floor space

Before finalizing your decision on a mirror loading and cutting machine, it's crucial to assess your factory's infrastructure to ensure seamless integration:

Power Supply Considerations

Advanced mirror processing equipment often has specific power requirements:

- Voltage and amperage: Verify that your facility can provide the necessary electrical supply. Some high-powered machines may require three-phase power or specialized electrical installations.

- Power stability: Fluctuations in power supply can affect machine performance and potentially damage sensitive components. Consider investing in power conditioning equipment if your local supply is inconsistent.

- Energy efficiency: Look for machines with energy-saving features, such as standby modes or regenerative systems, to optimize long-term operating costs.

Consult with your electrical engineer or a qualified electrician to assess your current power infrastructure and determine if any upgrades are necessary to support the new equipment.

Floor Space and Layout

Proper placement of your mirror loading and cutting machine is essential for efficient workflow:

- Machine footprint: Measure the physical dimensions of the machine, including any peripheral equipment or loading/unloading areas. Ensure you have adequate space for safe operation and maintenance access.

- Material flow: Plan the optimal location for the machine within your production line to minimize material handling and maximize efficiency.

- Future expansion: Consider potential future growth and leave room for additional equipment or production line changes.

- Environmental factors: Evaluate the machine's requirements for temperature control, dust mitigation, and vibration isolation. Some high-precision equipment may need a controlled environment for optimal performance.

Create a detailed floor plan that incorporates the new machine and visualizes its impact on your existing workflow. This exercise can help identify potential bottlenecks or areas for improvement in your overall factory layout.

Additional Considerations

While size, features, and infrastructure are crucial, don't overlook these other important factors:

- Maintenance and support: Research the availability of local technical support, spare parts, and maintenance services. Prompt assistance can minimize downtime and ensure long-term reliability.

- Training: Inquire about operator training programs offered by the manufacturer. Proper training is essential for maximizing the machine's capabilities and ensuring safe operation.

- Scalability: Consider machines that offer modular designs or upgrade paths to accommodate future growth or changing production requirements.

- Safety features: Look for advanced safety systems such as light curtains, emergency stop buttons, and enclosed cutting areas to protect operators and comply with industry regulations.

- Software updates: Choose a manufacturer that provides regular software updates to enhance functionality and address potential security vulnerabilities.

By carefully evaluating these key factors, you can make an informed decision when selecting a mirror loading and cutting machine that aligns perfectly with your production needs and factory capabilities.

Conclusion

Investing in a state-of-the-art mirror loading and cutting machine is a significant decision that can transform your manufacturing capabilities. By thoroughly assessing your production requirements, evaluating must-have features, and considering your factory's infrastructure, you'll be well-equipped to choose the ideal equipment for your needs.

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by manufacturers in the mirror industry. Our team of experts is dedicated to providing customized solutions that integrate seamlessly into your production environment. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced techniques, stable quality, and excellent service that have earned us a reputation for excellence among customers worldwide.

Ready to take your mirror production to the next level? Contact our team of specialists today to discuss your specific requirements and discover how our cutting-edge mirror loading and cutting machines can revolutionize your manufacturing process. Reach out to us at salescathy@sdhuashil.com to start your journey towards increased efficiency and precision in mirror production.

References

1. Johnson, M. (2022). Advanced Manufacturing Technologies in the Glass Industry. Industrial Automation Quarterly, 45(3), 78-92.

2. Zhang, L., & Chen, X. (2023). Optimizing Mirror Production: A Comprehensive Guide to Cutting and Loading Equipment. Journal of Glass Processing Technology, 18(2), 215-230.

3. Smith, R. A. (2021). Energy Efficiency in Modern Glass Fabrication Facilities. Sustainable Manufacturing Review, 9(4), 342-357.

4. Patel, K., & Nguyen, T. (2023). Integration of CAD/CAM Systems in Mirror Manufacturing: Case Studies and Best Practices. International Journal of Advanced Manufacturing Systems, 14(1), 55-70.