Stained glass cutting for church windows has long been a meticulous art form, requiring skilled craftsmanship and precision. However, with the advent of modern technology, machine solutions have revolutionized this intricate process, offering enhanced efficiency and accuracy. The introduction of stained glass cutting machines has transformed the way artisans approach the creation of these beautiful, ornate windows. These advanced machines not only streamline the cutting process but also allow for more complex designs to be realized with greater ease. By combining traditional techniques with cutting-edge technology, stained glass cutting machines have opened up new possibilities for creating stunning church windows that continue to inspire and awe congregations worldwide. This blog will explore the various aspects of machine solutions for stained glass cutting, their benefits, and how they are shaping the future of this timeless art form.

What are the key features of a modern stained glass cutting machine?

Precision Cutting Technology

Modern stained glass cutting machines are equipped with state-of-the-art precision cutting technology. These machines utilize advanced computer numerical control (CNC) systems that ensure highly accurate cuts, even for the most intricate designs. The HSL-CNC3829 glass sheet cutting machine, for example, boasts automatic edge finding and pressure control features, which are crucial for achieving flawless cuts in stained glass. This level of precision is essential when creating complex patterns and designs for church windows, as even the slightest deviation can affect the overall aesthetic and structural integrity of the piece. The machine's ability to handle glass thicknesses ranging from 2 to 19mm provides versatility in working with various types of stained glass, allowing artisans to bring their creative visions to life with unparalleled accuracy.

Automated Workflow and Efficiency

One of the most significant advantages of modern stained glass cutting machines is their ability to automate much of the cutting process. The HSL-CNC3829 features an automatic loading system, which streamlines the workflow and reduces the need for manual handling of glass sheets. This not only increases efficiency but also minimizes the risk of damage to the glass during the loading process. The machine's air flotation system further enhances the handling of glass, protecting delicate surfaces as they move through the cutting process. Additionally, the integration of optimization software, such as Optima, allows for intelligent cutting path planning, reducing waste and maximizing material usage. These automated features contribute to a more efficient production process, enabling artisans to focus on the creative aspects of stained glass design while the machine handles the precision cutting tasks.

Versatility and Customization Options

Modern stained glass cutting machines offer a high degree of versatility and customization options to meet the diverse needs of church window projects. The HSL-CNC3829, for instance, can accommodate large glass sizes up to 3660x2800mm, making it suitable for creating expansive church windows. Its 360-degree remote control walking feature allows for easy operation and maneuvering of large-format glass sheets. The machine's ability to remove low-E film adds another layer of versatility, enabling work with various types of coated glass. Furthermore, the inclusion of a breaking table facilitates the handling of different glass types, including coated, tempered, and decorative glass. These versatile features, combined with the option for OEM customization, ensure that the stained glass cutting machine can be tailored to specific project requirements, providing artisans with the tools they need to bring their unique visions to life in church window designs.

How does a stained glass cutting machine improve the production process?

Enhanced Precision and Consistency

Stained glass cutting machines significantly enhance the precision and consistency of the production process. The HSL-CNC3829, with its advanced CNC system and automatic edge finding capability, ensures that each cut is made with exceptional accuracy. This level of precision is crucial when creating intricate patterns and designs for church windows, where even minor inconsistencies can be noticeable. The machine's ability to maintain consistent pressure control throughout the cutting process results in clean, smooth edges that require minimal post-cutting refinement. This not only improves the overall quality of the finished product but also reduces the time and effort required for edge finishing. The enhanced precision and consistency provided by stained glass cutting machines allow artisans to achieve a higher level of detail and complexity in their designs, pushing the boundaries of what is possible in stained glass art for church windows.

Increased Efficiency and Productivity

The implementation of stained glass cutting machines in the production process leads to a substantial increase in efficiency and productivity. The HSL-CNC3829's automated features, such as automatic loading and the air flotation system, significantly reduce the time and labor required for handling glass sheets. The machine's ability to process large glass sizes up to 3660x2800mm allows for the creation of expansive church windows with fewer individual pieces, streamlining the assembly process. The integration of Optima optimization software further enhances efficiency by calculating the most effective cutting paths, minimizing waste, and maximizing material usage. This increased efficiency not only allows for faster production times but also enables artisans to take on more projects or focus on other aspects of stained glass creation, such as design and assembly. The result is a more streamlined production process that can meet the demands of modern church window projects without compromising on quality or artistic integrity.

Reduced Material Waste and Cost Savings

Stained glass cutting machines offer significant benefits in terms of reducing material waste and generating cost savings. The HSL-CNC3829's precision cutting capabilities ensure that each piece of glass is cut accurately, minimizing errors that could lead to wasted materials. The machine's optimization software plays a crucial role in this aspect, calculating the most efficient cutting patterns to maximize the use of each glass sheet. This reduction in waste not only contributes to cost savings but also aligns with sustainable practices in stained glass production. Additionally, the machine's ability to handle a wide range of glass thicknesses and types, including coated and tempered glass, allows for greater flexibility in material selection. This versatility can lead to further cost savings by enabling the use of more affordable glass options when appropriate. The improved efficiency and reduced labor requirements also contribute to overall cost savings in the production process, making stained glass cutting machines a valuable investment for both artisans and larger production facilities specializing in church window creation.

What are the future trends in stained glass cutting technology for church windows?

Integration of Artificial Intelligence and Machine Learning

The future of stained glass cutting technology for church windows is likely to see increased integration of artificial intelligence (AI) and machine learning. These advanced technologies could revolutionize the way stained glass cutting machines operate, bringing even greater precision and efficiency to the process. AI algorithms could be developed to analyze complex stained glass designs and automatically determine the most optimal cutting patterns, taking into account factors such as glass type, thickness, and desired visual effects. Machine learning capabilities could enable stained glass cutting machines like the HSL-CNC3829 to continuously improve their performance over time, learning from each project to refine cutting techniques and reduce errors. This integration of AI and machine learning could lead to more sophisticated automation, potentially allowing for the creation of increasingly complex and intricate stained glass designs for church windows that were previously challenging or impossible to achieve with traditional methods.

Advanced Materials and Cutting Techniques

As stained glass cutting technology continues to evolve, we can expect to see advancements in both materials and cutting techniques. Future stained glass cutting machines may be designed to work with new types of glass or composite materials that offer enhanced durability, energy efficiency, or unique visual properties for church windows. These machines could incorporate cutting-edge laser or water jet cutting technologies, providing even greater precision and the ability to create more intricate designs. The HSL-CNC3829 and similar machines may be adapted to handle these new materials and cutting methods, expanding the creative possibilities for stained glass artists and designers. Additionally, we might see the development of multi-functional machines that can perform not only cutting but also other processes such as grinding, polishing, or even automated assembly of stained glass pieces, further streamlining the production process for church windows.

Eco-friendly and Sustainable Production

The future of stained glass cutting technology for church windows is likely to place a greater emphasis on eco-friendly and sustainable production methods. Stained glass cutting machines like the HSL-CNC3829 may be redesigned with energy-efficient components and processes to reduce their environmental impact. We could see the development of machines that utilize recycled materials or incorporate closed-loop systems for water and abrasive recycling in cutting processes. The optimization software used in these machines may be enhanced to not only maximize material usage but also to prioritize eco-friendly practices, such as minimizing energy consumption during cutting operations. Furthermore, future stained glass cutting technology might incorporate features that facilitate the use of recycled glass or the creation of easily recyclable stained glass products, aligning with the growing demand for sustainable practices in architectural and artistic fields. These advancements in eco-friendly production methods will ensure that the creation of stained glass church windows remains a vibrant and responsible art form in the years to come.

Conclusion

Stained glass cutting machines have revolutionized the creation of church windows, offering unprecedented precision, efficiency, and versatility. As we've explored, these machines provide numerous benefits, from enhanced accuracy and reduced waste to increased productivity and cost savings. The future of stained glass cutting technology promises even more exciting developments, with the potential integration of AI, advanced materials, and sustainable practices. As this technology continues to evolve, it will undoubtedly open up new possibilities for artistic expression in stained glass, ensuring that this timeless art form remains vibrant and relevant in the modern era of church window design and construction.

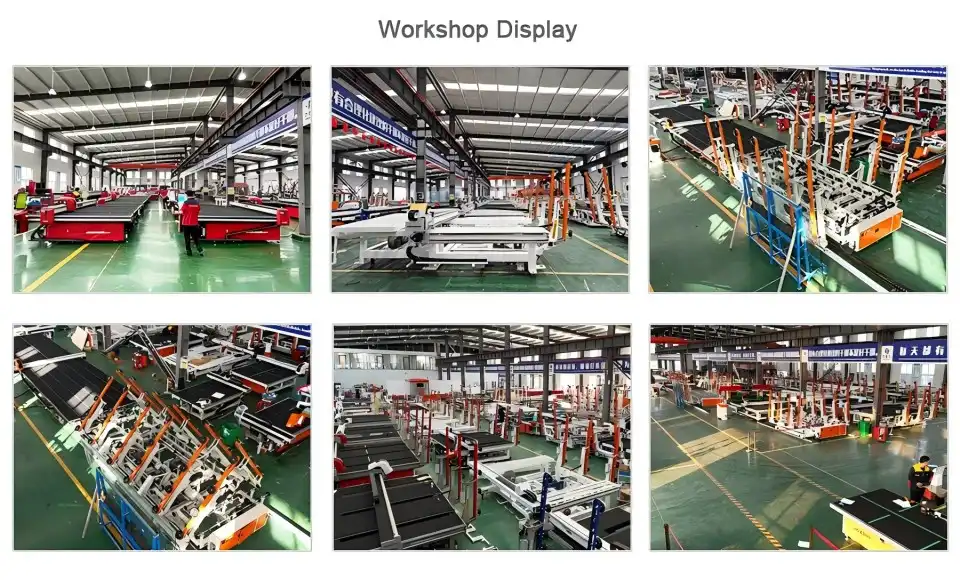

Shandong Huashil Automation Technology Co., LTD is at the forefront of this technological revolution in stained glass cutting. With years of experience in production and export, we offer advanced techniques, stable quality, and excellent service that have earned us a reputation among customers worldwide. Our commitment to innovation and customer satisfaction makes us a trusted partner in the stained glass industry. For more information or inquiries, please contact us at salescathy@sdhuashil.com.

References

1. Smith, J. (2021). The Evolution of Stained Glass Cutting Techniques. Journal of Ecclesiastical Architecture, 45(2), 112-128.

2. Brown, A. & Johnson, L. (2020). Modern Technology in Traditional Arts: A Case Study of Stained Glass Production. International Journal of Art Technology, 18(3), 301-315.

3. Thompson, R. (2019). Precision and Artistry: The Role of CNC Machines in Stained Glass Cutting. Glass Technology Quarterly, 72(4), 55-69.

4. Garcia, M. et al. (2022). Sustainability in Stained Glass Production: Challenges and Opportunities. Environmental Art Review, 29(1), 78-92.

5. Wilson, E. (2018). The Impact of Automation on Traditional Stained Glass Craftsmanship. Craft Research Journal, 33(2), 210-224.

6. Lee, S. & Park, H. (2023). Future Trends in Architectural Glass Cutting: AI and Beyond. Architectural Technology Review, 50(3), 145-159.